Painting the concrete floor: how to do it right?

Concrete floor is quite reliable and durable. Rarely it is painted to improve the appearance: more often it is done to protect the surface. The reason for this is the mechanical and climatic effects. It is important to choose the right paint for painting concrete and comply with the painting technology.

Features and specifications

The top layer of the concrete floor is particularly exposed to the environment. With time, pure concrete begins to peel, crumble, and create a lot of dust. The decorative properties of the surface suffer greatly, and with it your health is also undermined. Staining concrete improves floor resistance to moisture and stress, prevents the destruction of the upper layer.

Paint needs to be selected especially, the number of requirements includes:

- resistance to mechanical stress;

- durability of operation;

- resistance to temperature extremes, moisture and climatic conditions;

- good tenacity with porous concrete surface;

- decorative qualities.

The paint improves the key qualities of the concrete floor. It can be designed for outdoor and indoor use. The difference lies in resistance to various adverse factors. All dyes are made in accordance with established standards. GOST lists the substances that form a protective coating.

Types of paint

Initially, professionals isolated only suspensions on epoxy resins for painting concrete surfaces. It was believed that these tools are better than others. Today, there are many more options on the construction market. Today, manufacturers offer different formulations with their own characteristics and disadvantages. We denote several of the best varieties.

Acrylic

The paints are based on acrylic resins, organic, inorganic pigments. Acrylates and polyacrylates with various additional components form a protective film. Complex ester components provide quick drying and resistance to high humidity. Experts recommend using acrylic paint in garages, basements, on balconies. The composition is well suited for coloring a small room. The variety is resistant to non-aggressive chemistry and short-term exposure to moisture.

The rich color palette is presented in matte and glossy versions. Acrylic paint solvent is water. Put it in 2 layers, it dries 48 hours. It is applied on a small surface with a roller or with a brush; special sprayers are used for large rooms. The composition is environmentally friendly.

Acrylic silicone

Wear-resistant enamel contains acrylic copolymers and resins based on silicone. Two-component material combines the advantages of acrylic and silicone varieties. The composition helps to prevent the development of harmful microorganisms. Acrylic resins have high tenacity and adhere well to concrete.

Silicone resins contain silicon and provide durability to the paint. Enamel is electrostatic, prevents dust accumulation. The only drawback of acrylic silicone enamel is the poor color palette.

Wear-resistant enamel is applied in 2 or more layers. Between the application of each subsequent layer, you must wait at least 3 hours.

Epoxy

This paint is a two-component. A feature of the material is the need to mix before applying the two components to complete homogeneity of the structure. Despite the small number of colors in the palette, the coating is quite resistant to mechanical stress and is distinguished by a long service life. The paint is usually used in industrial facilities and in open areas.

Epoxy enamel is resistant to moisture. The composition does not deteriorate from exposure to aggressive chemicals. Good tenacity with concrete and invariance of decorative properties over time makes the paint attractive to the consumer. Apply a composition of at least 2 layers with an interval of 12 hours.

Alkyd urethane

This paint is more often used for interior decoration. Enamel has a glossy surface that is not erased and not scratched during operation. Paint hardens in just a couple of hours. Manufacturers indicate an impressive lifetime - up to 15 years.

Vinyl

This paint will last you about 7 years.It is enough to apply the composition in one layer and wait for complete drying within 2 hours. The expense of funds is quite small, so the coating will cost a small amount. The material is particularly environmentally friendly and is used in residential areas.

Rubber

Paint has unique properties. Dries the surface in just a few minutes. Manufacturers guarantee that coverage will delight you for at least 10 years. It is possible to work with rubber materials in heat and cold. This paint easily transfers temperature from -50 to +60 degrees Celsius.

After drying, a polymer film is formed. The strength of the layer allows the surface to withstand systematic mechanical effects of varying intensity. Rubber paint will protect concrete from cracks and breaks. Adding to the composition of the pigments allows you to create a wide color palette.

Rubber compound does not pose a health hazard.. The main components are water and acrylate dispersion. It is the last element that creates a protective film that prevents color fading during use. The painted surface is able to repel dust and moisture, concrete has access to oxygen.

Polyurethane

Before using this paint, you need to mix the two components to complete homogeneity. Wearproof material is suitable for carrying out finishing works indoors and in the open air. Dries the paint for a long time (within 2 weeks). The coating is odorless, so during the drying period will not cause unnecessary trouble.

At the first stage of drying out the moisture comes out of the mixture, after it comes the stage of solidification. In the second half of drying, polyurethane paint acquires a high resistance to mechanical stress. Self-leveling floor is used as a finishing coating on concrete screeds. Paint is used in residential and industrial areas. The floor of this material has proven itself in auto repair shops, garages and technical rooms. Popularity due to high resistance to mechanical, chemical and climatic influences.

Which one to choose?

Painting the floor is a matter of responsibility. When choosing a paint material should take into account such factors:

- type of premises (residential, technical);

- temperature range at which paint can be applied;

- the nature of the impact on the floor (for example, chemical, climatic, shock);

- intensity of various effects (constant or periodic, low or high).

Key recommendations for choosing paint:

- In an apartment or a residential building, water based formulations are recommended. Acrylic paint is considered a good option.

- Acrylic or epoxy compounds are used in utility rooms. The exact choice depends on the intensity of the load.

- Commercial premises are characterized by intense loads. Stop your choice on epoxy paint, which should be applied in 2 layers.

- In the bath, bathroom and rooms with high humidity, use epoxy or polyurethane compounds. Apply paint in 2 coats.

- It is better to paint the floor with alkyd or epoxy paint. They are ideal for dust removal, do not slip, do not spoil from chemical influences of varying intensity.

- Acrylic silicone enamel can be used on the landing. It will protect the floor from dust, the entrance will look more well-groomed. You can also use alkyd-urethane enamels, they have a rather long service life.

Means for finishing works on concrete must be chosen very carefully.

Remember that you can improve the decorative properties of the floor with the help of glitter (spangles) or flock. The main landmarks in the selection should be resistance to external influences and life.

Expense calculation

The following factors affect paint consumption:

- view;

- hiding power;

- Colour.

The standard indicator for concrete is 210-250 g of paint per 1 square meter. Approximately this is the paint consumption when covering the floor with one layer. The average rate can not be the same for all. As a rule, manufacturers indicate on the package how much of the composition is needed to cover 1 square meter. m. floor.

The hiding power of the paint is indicated on the packaging. Keep in mind that manufacturer indicates the indicator in ideal conditions. In reality, the paint will leave more.

Of great importance is the quality of the preparation of concrete for painting. Do the procedure as accurately and accurately as possible, it will save paint.

Training

The process of preparing the concrete surface should be carried out with great care. The quality of further staining depends on it. After laying the concrete should take at least 3 months, the temperature of the room at this time should be no higher than 20 degrees.If you do not have that much time, wait at least 30 days. Before applying the paint moisture content of concrete should not exceed 5%.

You can find out the moisture level of a concrete floor using a special device or a plastic film. Place it on a small area of concrete and secure the edges with adhesive tape. Wait 24 hours, remove the film and evaluate the condensate. Its very presence suggests that the floor is not yet ready for painting. For forced drying, you can use a heater.

If concrete has been used for a long time, and you decided to paint it, then you need to evaluate the general condition of the coating. Check the floor for chips, cracks and grease stains. Mechanical damage process a special repair solution, remove the fat with a solvent.

All dried dust must be removed from dried concrete. For better grip, the concrete floor is sandblasted.

Technology work

Repair is made in four stages. It is important to correctly follow all recommendations. Strictly following the instructions guarantees quality coverage and helps to avoid unnecessary expenses. You can paint the concrete like this:

Floor preparation

The removal of dust and grease has already been done, but the preparation does not end there. Often the old concrete floor requires sanding. Flatness - the key to success. Impregnate the floor to repel dust. So in the future, the dust will not interfere with the repair work.

Priming work

It is recommended to prime the concrete before painting. Choose a product according to the paint you choose. For proper preparation and application of primer, read the instructions. Foam roller will help evenly primed the entire floor. Many experts add quartz sand to the primer in the calculation of 0.1 of the total mass, after treatment with such a mixture the floor does not slip.

Soil is applied to the concrete in 1-2 layers. As a basic tool, you can use a roller, brush or spray. During the work humidity in the room should be no more than 85%, and the temperature in the range from +5 to +40.

Primer is preferable to choose deep penetration.

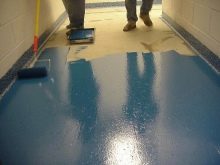

Coloring

The choice of paint depends solely on your preferences. Tools can be: spray, rollers, brushes. The expense during the work with a spray helps to save your time and paint.However, the use of hand tools can not be avoided, for example, a brush should be used when processing corners and hard-to-reach areas.

For dyeing with acrylic paint or enamels considered it is preferable to use a wide roller with a small pile. Such a tool makes it possible to apply a uniform layer in a fairly short time. For more comfort, a long handle is added to the roller. Hard to reach areas are brushed.

Prepare the coloring composition according to the manufacturer's instructions. Put smears on concrete in different directions. Spread the paint evenly over the base.

You should not apply too thick a layer, better make a few thin ones. Each next layer is applied after complete drying of the previous one.

Drying

The final and responsible stage of work. Paint should be allowed to dry. Follow the instructions to complete the process. It contains data for a specific type and type of coverage. Standard recommendations:

- temperature range should be from +18 to +20 degrees;

- moisture permissible up to 70%.

The drying time varies by the type of coloring composition. The time can vary from 1 hour to 2 weeks.It is important to consider the initial conditions.

Paint on fresh concrete will dry longer, it may take about 7 days to show resistance to mechanical and climatic influences.

Useful tips from professionals

Painting of a concrete floor assumes the maximum composure and accuracy. Properly stained process improves the properties of concrete. Professionals give beginners such recommendations:

- Before painting the concrete floor should be thoroughly cleaned. After washing it is important to allow the concrete to dry or dry it forcibly. Preliminary work affects the final result.

- Add quartz sand to the primer for the concrete floor. This mixture will prevent slipping after drying. Special compositions (toppings) are important in the preparation of concrete. They are able to improve durability and rid the surface of dust.

- After treatment with a primer, you can easily check the readiness of the floor for painting. To do this, touch it with your palm. If the floor does not stick, then you can proceed to further work.

- Make sure that the temperature of the concrete during painting was at least +5 degrees, and the air temperature was at least +10 degrees.

- Provided that the temperature and humidity conditions are observed, it is possible to walk on the floor within 24 hours after painting. After 3 days, it is already possible to expose the coating to mechanical stress (for example, to put furniture). Full hardening occurs in about a week.

Learn more about how to paint the concrete floor, you will learn from the following video.