Topping for a concrete floor: pros and cons

Concrete floor - the most common coating that is used everywhere. But concrete, no matter how durable it is, quickly comes into disrepair in conditions of intensive use, from contact with water and chemical solutions. Topping of the coating and making it invulnerable to aggressive external factors will allow topping for the concrete floor.

What is it and why is it needed?

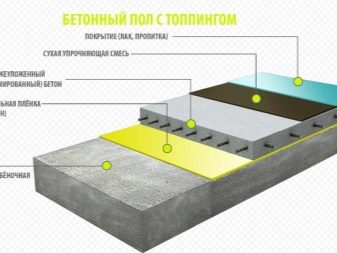

Topping is a special mixture that has reinforcing properties. It may be liquid or dry. It is applied to the finished concrete base. The topping penetrates deep into the concrete and solidifies in such a state. Thus, the pores are securely sealed.

The mixture contains many different components., among which there are plasticizers, fixers, dyes, high-quality concrete. Ceramics, quartz, corundum, metal chips or microfiber may also be added.The compositions of different mixtures may vary significantly.

The topping is applied with a top coat on the finished concrete, thus creating reliable protection for the surface. Concrete itself is rough and porous, prone to absorbing water and other liquid substances. Over time, the unprotected surface flakes off and cracks. Concrete coating is poorly cleanable. All these negative moments are negated by the application of topping.

Species

The topping market is surprisingly fast and actively developing. In a short time, many varieties of this material have appeared, so there is something to choose from for a modern buyer.

By structure, topping is divided into two broad categories:

- The dry mix can be presented in the form of a powder or a crumb. It spreads over the surface (dry or wet), compacted and polished.

- Liquid material resembles a bulk, liquid mixture. This material is poured over the surface, leveled and left to dry completely. This is followed by grinding and grouting.

The first species is more common in Russia. This is due to high performance and durability.According to these characteristics, liquid topping is inferior to dry material. Dry topping, in turn, is also divided into varieties. The basis of this separation is the composition of topping.

The most common are the following positions:

- Quartz filler in the form of powder or crumb is best suited for objects with an average load level, for example, private garages.

- Corundum filler is selected for objects in which the floor is under severe stress. The cost of such material is affordable, and the effect of its use is high and long-lasting.

- Top ping with the addition of metal is expensive, but very effective. Serious loads are not afraid of such a coating, it will withstand all types of impacts.

Application Methods

For the application of topping can be used various technologies:

- DTW - this name is created from two words: dry and wet. The essence of this method is to apply a dry mix on wet concrete. For work on a large area, special carts are used, which evenly and quickly cover the surface with dry topping. Cement hardens together with topping, which allows to achieve high adhesion.The coating is very reliable, stable and durable. After the concrete has dried, the impregnated mixture is rubbed, again, using a special trowel.

- WTW - here implies the use of liquid topping, which is applied to wet concrete. This method began to be used recently, it is complex and expensive, so it is not yet widespread. But the strength of the coating is obtained maximum, and the coloring is uniform and beautiful. Even metal spikes are not capable of damaging surfaces with such treatment.

- WTD based on the use of a solution of dry hardening mixture, which can be laid on a dry or wet screed. Completes the process of concrete processing grouting stage.

- Bulk topping implies hardening of concrete by weight (throughout the thickness). Even at the stage of pouring the floor, a special modifier is added to the cement mortar, which improves the performance characteristics of the coating. This technology requires the use of cement with a grade not lower than 350, which is not always beneficial.

Dry material

The application of such topping is carried out on a fresh fill.

The technology is as follows:

- Flooded surface rubbed with a grinding machine. Thus, it will turn out to level a floor even before a concrete hardening.

- With the help of a trolley the mixture is distributed, you need to move from the windows towards the exit. The mixture will absorb moisture, which is still in the concrete and crystallize.

- The polishing process again follows, during which the floor is thoroughly leveled, and the fixer fills the concrete as much as possible.

- Residues of the mixture are distributed over the surface and left for some time to soak.

- The surface is again rubbed and left for a couple of days. After this time, the floor is rubbed with paddle knives until the surface is mirrored.

- The application of the kuring allows to obtain a thin film. This is done to preserve moisture inside the surface, the floor is obtained, as if conserved.

- Completes the processing technology cutting deformation joints, which will eliminate the possibility of concrete cracks. Seams are treated with sealant.

For more on the technology of applying topping see the following video.

Such coverage will be ready for full operation only after 28 days. That is how much time it takes for the top layer to gain maximum strength.

Liquid material

In this case, it does not matter when the concrete was poured: just recently, recently or long ago. The effect will be equally good anyway.

The main thing is adherence to technology, which consists of the following steps:

- In the working room the temperature should be kept within +5 - +35 degrees. The surface should be well cleaned from dust. If there are cracks, chips and holes, it is necessary to fill in the repair solution on such problem areas. Fresh screed requires grinding.

- For the application of the solution is used spray or roller. The first device is preferred, with it consumption will be economical, and the application is uniform.

- The thickness of the solution should be up to 3 mm. In some places, the topping can be absorbed faster; reapplication is required here.

- The surface is left for a day. During this time, the solution will be absorbed, compacted, become durable and smooth. Excess material is washed off with water.

This completes the work, the surface can be put into operation.This method takes a little time and does not require the use of complex devices. But the cost is more, and the strength is lower compared to the dry material.

Advantages and disadvantages

Covering a concrete surface with a topping is definitely necessary.

If there are doubts about this, then it is worth exploring the list of advantages characteristic of this material:

- Wear resistance of the surface increases several times.

- Dustiness, which is typical for concrete, is significantly reduced.

- The impact of moisture does not have a disastrous effect on concrete, which expands the possibilities for using the coating.

- The service life without the need for repair and restoration work is increased several times.

- The availability of topping and the possibility of using low-grade concrete saves money and reduces costs.

- The aesthetic side of the question is certainly an important advantage. When creating a protective layer for concrete, the issue of further decorative finishing is immediately resolved. Toppings are available in a large color palette, but it is better not to experiment strongly and stick to a natural, restrained gamut.

- Heat resistance becomes more substantial.

- Significant ease of cleaning the coating with topping.

The list is impressive and you already want to make the floor stronger, but do not hurry. There are also drawbacks, there are very few of them, but it’s still worth exploring the cons.

The list of negative points is as follows:

- When using dry material, seams will form on the surface. To avoid this will not work, even experienced professionals can not guarantee the absence of seams.

- In front of some chemicals, the coating becomes vulnerable. In general, resistance to chemicals is reduced.

- Repair of the coating becomes impossible. We'll have to remove the old concrete and lay a new one. There is a certain convention here, because the floor will become unusable at least in 15 years. All this time, it will retain its original appearance and will not lose its operational characteristics, therefore, the issue of repairs will soon become urgent.

The list of deficiencies fades before the positive moments. Plus more and they are more significant.