Types of insulation for the floor in a wooden house

So the walls and roof of the wooden house were erected, windows and doors were inserted. It is time to move on to the interior decorating. And they usually begin with the device floors. This is one of the most important and crucial stages of work, because the general microclimate in the rooms of the wooden building and the level of heating costs will depend on how correctly and efficiently the floor cake is made. In this case, close attention should be paid to the choice of insulation for floors, because up to 20% of the heat in the house is lost through the flooring.

How to choose a heater?

The most important thing that determines the choice of insulation for finishing the bottom floor is the type of foundation and, accordingly, the floor construction:

- If the foundation is tape, then the floor can be laid directly on the ground or on the ceiling, arranged on the beams.

- A low grillage foundation implies the same options for flooring as in the case of a tape type of foundation.

- With a high basement base, the floor is arranged according to the ceilings laid along the beams.

- If there is a floating slab (this is often done when building wooden houses on wet soils), then the floor can be arranged on logs or on the screed.

So, it becomes clear that there are three options for flooring in a wooden house, on which the choice of material for their insulation directly depends. This device floors on the ground, on the slab and on the wooden floors with logs.

Therefore, when choosing insulation, it is necessary to take into account the mutual influence of materials used in the construction of the floor cake.

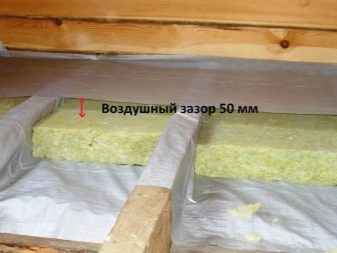

Hardwood floors

Since the overlappings of a wooden house are also made of wood, when applying vapor-proof insulation, all moisture that is inside the floor structure will be absorbed into the wood and, due to the tight contact with the insulation, cannot go outside. The result of this will be the appearance in a year and a half of the fungus, insects and the spread of rotting processes.

Insulants with the property of hygroscopicity give a completely different result. (sawdust, ecowool, cork granules, mineral wool, expanded clay) and due to this, absorbing moisture as well as wood, but at the same time giving it away.

Therefore, with this type of floor device, it is categorically impossible to use different insulators based on polystyrene foam and foam plastic.

Wood and similar materials are incompatible.

Floors on the ground and slab

In this kind of genital constructions, the insulation is covered with a tie on top.

Loose and wadded materials will not be able to provide the required level of strength, although they are now releasing mineral wool with a sufficiently large density.

In addition, these types of thermal insulation are hygroscopic and there is a possibility of their getting wet. And, wet, they can not give away moisture through the screed.

Therefore, for this type of floors are most suitable foam polystyrene insulation - dense and not absorbing moisture.

In addition, when choosing insulation for floors in a wooden house should proceed from the following factors:

- maximum weight of the floor construction;

- required thickness;

- humidity-temperature conditions inside the house, the presence of temperature changes;

- design loads on the floor structure and its operating conditions.

Separately, you should stay on the thickness of the insulating layer.

This indicator determines how warm it will be in a wooden house. It is calculated individually and depends on the climatic conditions in which the house is built, and the thermal conductivity of the insulation itself. To determine the thickness of the insulation, it is necessary to multiply the thermal conductivity coefficient specified in the technical description for a specific heater by the thermal resistance of the structure (determined by SNiP “Thermal protection of buildings”). This formula helps to calculate exactly what the insulation layer should be in the floor construction in order to ensure optimal temperature conditions in the house.

When choosing insulation for the floor, you should also pay attention to:

- material convenience in installation;

- environmental friendliness;

- efficiency, that is, the preservation of its characteristics throughout the entire service life;

- fire safety;

- density and reliability;

- price

What to insulate?

Warm floors in wooden houses can be different materials.Today, the building materials market is replete with a wide variety of thermal insulation from the simplest to the most modern types.

Materials for insulation

Sawdust

The easiest and cheapest insulation. It is easy to apply - just sprinkle on a rough foundation of the floor. This material is environmentally friendly and safe. But he has a serious drawback - a high degree of fire hazard. And also when using sawdust as a heater, they will have to be laid in a layer as much as 0.3 m. Sawdust, moreover, like any wood product, can rot, rodents can build up in them. Therefore, just sawdust is most often used for warming the floor of unused attic space.

However, sawdust in recent times increasingly act as a raw material in the production of other more modern and efficient thermal insulation.

Ecowool

Thermal insulation material made from cellulose with the addition of flame retardants and antiseptic compounds. This product has good thermal insulation, vapor permeability. It is environmentally friendly, non-flammable, resistant to rodents and fungi. But ecowool absorbs moisture.This is its main drawback.

Expanded clay

Material with high strength and thermal insulation characteristics. Expanded clay is suitable for flooring on an even basis. To ensure optimal thermal insulation performance of expanded clay, you need to lay a layer of at least 15 cm. The convenience of this material also lies in the fact that you can lay all the necessary communications in it. Expanded clay is quite hygroscopic, so before using it on the ground you should definitely perform waterproofing measures.

The main advantage of bulk thermal insulation for the floor is their wastelessness and the ability to fill all kinds of (even the most difficult to reach) voids.

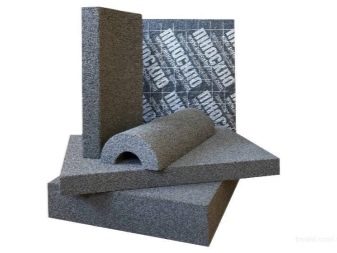

Expanded polystyrene, foam, polyethylene

These materials are vapor proof insulation, which can be used when building a pie on a flat base. For floors with overlappings with a device for logging (in wooden houses on piles, poles, strip and grillage foundations) such material is not suitable due to the laws of building heat engineering.

The thickness of the insulation layer will be 5-10 cm for polystyrene foam and 5-13 cm for foam plastic.

These types of thermal insulation materials have the following characteristics:

- low thermal conductivity;

- strength;

- resistance to rodents and rotting;

- resistance to temperature extremes.

Polystyrene insulation in our country are presented under the names "Penoplex", "Technopleks", "Knauf".

Insulation based on polyethylene foam is also used for floor insulation. One of the varieties of such insulation is rolled foil material penofol, which has high performance and thermal insulation properties. Penofol is a polyethylene foam, covered on one or both sides with a layer of foil.

High rates of thermal insulation of this material are provided by preserving heat in air bubbles, sealed in polyethylene balls. The foil acts as a barrier that retains heat in the winter and reflects the sun's heat in the summer, thereby maintaining the optimal thermal conditions in the room.

Penofol is also a waterproofing material.

It is light, non-hygroscopic, safe for health and has a long service life (up to 25 years).

Fibrolite

Not very common type of insulation, which is made from a mixture of liquid glass, cement powder and wood wool. This material retains heat well and has high sound insulation characteristics. Due to its hygroscopicity, such insulation is not suitable for laying floors along the ground, but it is ideal for floors by beams. To insulate the floor of the first floor, it is covered with a layer of 15 cm, the second - 10 cm.

Foam glass

Foam glass is produced by foaming of quartz sand. It is a strong slab or granular material with high vapor barrier and noise insulation characteristics, which is able to withstand the weight of a truck.

Fiberboard slabs are used to insulate floors on a flat base, granules for filling between lags on rough floors. The thickness of the insulation layer is 18 cm for the first floor and 15 cm for the second floor.

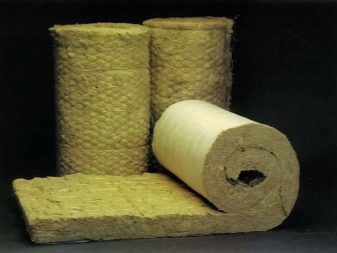

Mineral wool

This type of insulation is by far the most popular. Mineral wool insulation is made from slag fiber, fiberglass or basalt.

The most budgetary mineral wool insulation is glass wool, which is made from glass, sand, borax, dolomite, limestone and soda.

The raw material for slag is blast furnace slag, which is a waste in the production of pig iron. Because of its excessive hygroscopicity, slag wool has hardly been used in recent times.

Stone wool is made from basalt rocks such as gabbro, basalt. Diabase with the addition of carbonate rocks (limestone and dolomite).

The main advantages of such insulation:

- they conduct heat poorly and, therefore, retain it well;

- vapor permeability. Insulation provides good air exchange, the floor design is “breathable”, which allows you to maintain the optimum temperature and humidity conditions in a wooden house. The probability of condensation in the insulation is small;

- high density;

- high noise insulation characteristics;

- they are resistant to high temperatures and fire, smoke does not emit when in contact with fire;

- water resistant Stone wool and glass wool do not absorb moisture, so you should not be afraid of the occurrence of dampness inside the field construction;

- long service life - up to 50 years. This type of insulation is not subject to rotting and damage by rodents.

The disadvantages of mineral wool insulation are ambiguous. At present, many large manufacturers have practically reduced them to zero, while the rest are successfully working to minimize them.

Among the shortcomings, it is noted that when working with mineral wool, especially glass wool, a lot of dust occurs, since the insulation consists of brittle fibers, which, when damaged, form very thin and sharp fragments. Getting on the skin when installing the insulation, they lead to an itch. Danger of penetration of these fibers in the respiratory system. Therefore, such a heater can be laid only with the use of personal protective equipment, such as a respirator, overalls, glasses, gloves.

When wet, mineral wool loses its high thermal performance. Therefore, such heaters are specially treated with hydrophobes. In order to reduce the likelihood of wetting of mineral wool, it is recommended that when installing it, the waterproofing should be laid from the side of the room, and the vapor barrier from the side of the street.

Until now, builders argue that mineral wool releases phenol-formaldehyde resins into the air. But the latest research data point to a completely small amount of them, which cannot have a detrimental effect on human health.

Mineral wool can be produced in the form of rolls or plates. Mineral wool material in rolls has a lower density than heat insulation in slabs. It is used more often as an addition to slab material or where a low level of thermal insulation is required.

The main brands of mineral wool - "Izover", "Rokvol", "Knauf", "Ursa", "TechnoNikol", "Ecover", "Izovol", "Parok" and others.

Professional Tips

Professionals can not give a definite answer to the question about the insulation of floors for a wooden house - which choice is the best.

For each case, you need to choose your own version of insulation (the best in all indicators).

It is necessary to proceed from the fact that the base is insulated - concrete, soil or wood.

The best option for smooth bases without the use of wooden structures would be foam plastic, polystyrene foam insulation, expanded clay or mineral wool with increased strength.

Mineral wool insulators are more suitable for wooden beams, especially basalt-based thermal insulation.Today it is the most progressive material with a minimum number of flaws.

Professional master finishers claim that the best insulation is insulation that:

- corresponds to the type of the base of the floor;

- easy to install;

- has the most advantages over other thermal insulation;

- has minor flaws that can be easily compensated.

Manufacturers Rating

The most popular companies producing insulation materials for the floor are:

- Rockwool The company has existed since 1909. Its products are in demand around the world. The company specializes in basalt insulation, which have high technical characteristics and affordable price. In Russia, the company has production in the Moscow, Leningrad and Chelyabinsk regions.

- Saint-Gobain. Exists on the market for over 350 years. According to the Forbs rating, the company is among the hundred largest industrial companies in the world. In the field of thermal insulation, the company specializes in the production of glass wool and stone wool under the brands “Izover”, “Izotek” and “Izorok”.

- Knauf. An international group of companies with almost 90 years of history, whose products are recognized worldwide.In Russia, the company is represented by a wide network of a plant for the production of building materials. Thermal insulation is represented by the brands "TeploKNAUF" and Knauf Insulation. These are natural mineral wool insulation made by innovative technology, have high thermal performance.

The list of popular manufacturers of heat insulators in Russia also includes the following companies: TechnoNIKOL (extruded polystyrene foam and stone mineral wool), URSA Eurasia (extruded polystyrene foam, glass wool), PAROC (stone wool), Penoplex (extruded polystyrene foam), PAROC (stone wool), Penoplex (extruded polystyrene foam), PAROC (stone wool), Penoplex (extrusion polystyrene foam), PAROC (stone wool), Penoplex (extrusion polystyrene foam), PAROC (stone wool), Penoplex (extrusion polystyrene foam), (wool), PAROC (stone wool), Penoplex (extrusion foam polystyrene), and "(Basalt mineral wool), Information Technology Plant" LIT "(Penofol reflective insulation) and others.

More information about insulation for the floor you will learn from the following video.