Infrared warm floor: the pros and cons

Currently, there are many thoughtful and high-tech heating systems that can be chosen for any conditions. Such a useful and practical designs include infrared floor heating, which is now very popular. Let's get acquainted with the features, advantages and disadvantages of this modern heating system.

What it is?

Before proceeding to a detailed introduction to the infrared heat-insulated floor, it should be indicated what it is.

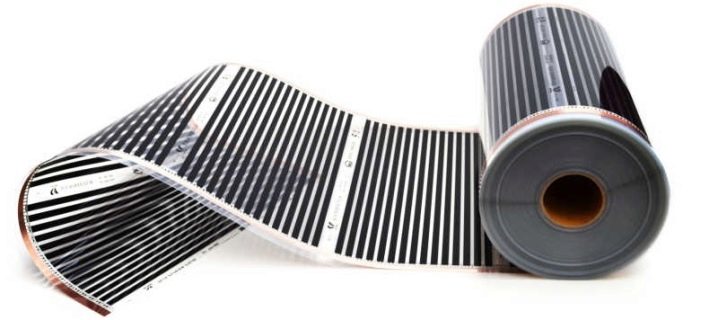

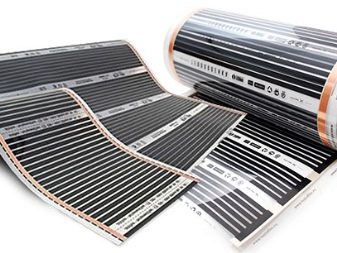

It contains a special thermal film and a polyethylene thermal film with strips of carbon paste. The last parts are interconnected by special copper bars.If the heating sheet is in the on state, then from it comes infrared radiation (wavelength of 5-20 microns).

Infrared heating coating is different from classic heaters and standard radiators in that the air around it does not overheat and does not become dry.

This characteristic is a pleasant surprise for people who have sensitive skin, as in conditions of dried air, it can crack, peel and blush.

Principle of operation

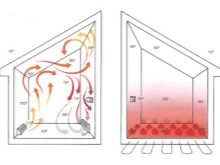

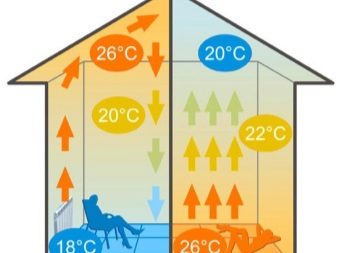

Modern high-tech heating systems can heat a room without “eating” living space, so they can be safely used even in small rooms. The high-quality infrared floor functions according to the principle of secondary convection, which means that the original becomes the heating of the human body and the objects around it and only then the air in the room.

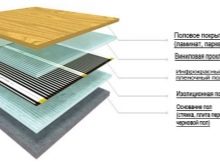

As described above, the infrared floor consists of a special film with heating strips, securely fixed in it. Heating of the strips occurs due to the supply of electricity through the conductors of copper and silver. Special carbon fiber paste is always applied to the top of the film, which is the direct recipient of the required heat energy.

Infrared radiation through the conductors of carbon fiber warms up objects located in the room, as well as air.

There is a standard set of parameters that are required to be written in the technical documentation of the heating system. Among the general characteristics of infrared floor heating can be identified:

- The melting point of a thermal film is 130 degrees.

- Power consumption per 1 square. m is 45-46 W / h.

- The length of the heating wave of the infrared floor, as a rule, is from 5 to 20 microns.

- Width of a thermofilm does not exceed 50 cm.

- The share of direct infrared radiation is about 95% in the total spectrum.

- The longest is the thermal film 8 m.

- Power infrared floor heating - 220V / 50 Hz.

Features: pros and cons

Modern infrared floor is quite popular thermal system, the relevance of which is due to the following positive qualities:

- With the help of such heating structures can be heated local zones.In such canvases there are heaters in an arbitrary position, which only insulate surfaces located in a recreation area or in passageways. Thanks to this characteristic, the owners have the opportunity to rationally spend materials in the process of installing a heated floor.

- A high-quality infrared floor differs from standard and simpler thermal systems in that it heats only the coatings and objects around it, but does not heat at all and does not make the air in the room dry.

- Today in the shops you can find infrared warm floors, the price of which is often different from the cable and water options. Carbon samples are cheaper, even if assembled into a complete kit, consisting of a thermostat, sensor, substrate, wiring and infrared film.

- The cost of installing such warm floors is also more affordable, since all the tools and necessary materials have a democratic price.

- Modern infrared floors are absolutely not afraid of low temperatures and frost. That is why many owners safely leave them unattended for a long time in the winter, which does not affect their functionality during the launch.This feature allows you to install similar designs in country houses and country houses.

- Also, infrared thermal systems are characterized by low inertia. Thanks to this feature, you can achieve the most comfortable temperature immediately after turning on the heaters.

- Due to the high efficiency of carbon heaters and the possibility of heating by radiation, the consumption of electricity consumed is significantly reduced.

- Infrared heated floors can be safely installed not only in modern private houses, but also in apartments of high-rise buildings. In such cases, do not have to worry about the fact that your neighbors will be flooded (as is the case with water systems).

- Such constructions are mounted rather quickly and easily. Even if you need to remove, and then re-install the direct floor heating, then all the work can be done in a couple of days. Other heating systems cannot boast of such quality. For them, as a rule, 2-3 weeks of waiting are necessary (necessary for complete fixing of the concrete screed).

- Many consumers prefer infrared systems due to the fact that they can be installed with their own hands. To do this, it is not necessary to have special skills and knowledge at the professional level. In addition, there is no need for specialized and complex tools in such works.

- Carbon parts in these heating systems emit energy that is completely identical to the energy of the Sun, which indicates its safety and simplicity, so this floor is not harmful.

- Infrared constructions can boast of the fact that they heat the room evenly along the whole height. At the same time, the optimum level of comfort is achieved precisely in the lower part of the space.

- In the case of infrared floors, it becomes possible to quickly and fairly easily remove heaters. If required, the entire system can be easily dismantled and moved to a new location. With cable and water variants, this work will be complicated by the dismantling of the concrete screed, which, as a rule, leads to serious damage to the heating system.

Despite such an impressive list of positive qualities and excellent technical characteristics,infrared warm floor has its drawbacks, which should be aware of every buyer who plans to buy them. The disadvantages of such structures include:

- Carbon heaters operate on 220V mains. In these cases, the current strength is a dangerous factor. Despite the presence of grounding and the presence of an automatic shutdown system, there is still a risk of electric shock.

- Despite the fact that infrared floors are one of the most effective and practical, they are much inferior to water structures in terms of efficiency. This gap becomes even more impressive if the contour of the last heating web is operated with natural gas.

- Infrared warm floors are completely dependent on the availability of electricity in the home. Of course, reliable and high-quality operation of such systems in the event of a power outage is excluded.

- Many owners attribute to the category of deficiencies that stationary furniture such as tables, cabinets or sofas cannot be located at the location of the infrared thermal system. Of course, at the very beginning of the installation work, it is necessary to take into account this fact in order to correctly furnish the room and not to harm the heating structure.

- If you plan to install infrared floor heating under soft flooring, then you will have to additionally stock up with an intermediate lining that is resistant to mechanical damage. Most often for this purpose sheets of plywood, laminated chipboard or OSB are used.

Types and characteristics

Today, there are two types of floors with infrared radiation - rod and film. Each of them differs in its method of installation and application features.

Rod

Rod cloths are mats consisting of silver-graphite rods, which are hidden in a special protective film of copper. These elements are interconnected using stranded wires. This design is valid. from electricity.

The current in the system heats the rods themselves, and the carbonaceous material located in them, which begins to radiate heat in the infrared spectrum. It rises up the room and warms it.

It is worth noting that in most cases such a floor is self-regulating. This means that it can independently increase or decrease the temperature regime and the amount of radiated heat at each particular site.

Film

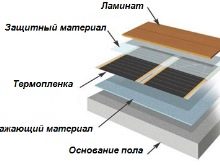

Film infrared floors are more simple and undemanding in terms of installation. The main conductor of heat in them is also carbon. However, it is placed in this case not in the rods, and in the interior of a special polymer film in the form of strips.

In such systems, the heating elements are very tightly and securely laminated, because of which they are not afraid of dampness and moisture, as well as mechanical damage in the form of dents, punctures and creases, despite the small thickness of the film coating, which is 0.4 cm. steps from 1 to 1.5 cm. This is necessary so that the surface in the room warms up evenly and efficiently.

Installed similar structures without laying concrete screed. Otherwise, such works are called "dry installation." Currently, manufacturers have appeared on the market, making special films that are completely covered with carbon material from above.

Simply put, these elements are not present in them in the form of small strips, but on the scale of the canvas.

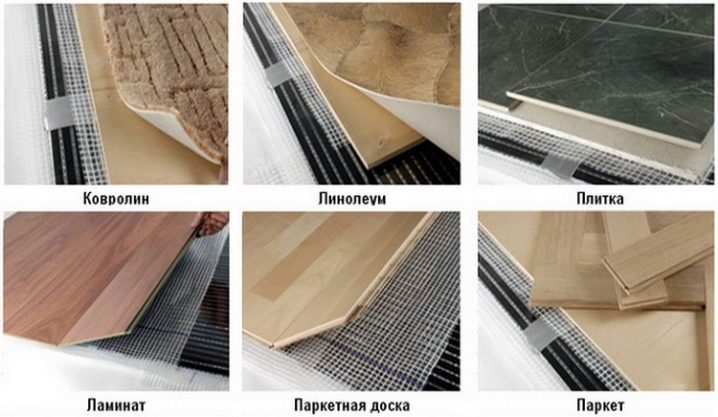

What flooring is suitable for?

Many owners of private houses and city apartments are wondering what kind of flooring can use modern infrared thermal systems.First of all, it should be noted that they are not recommended to be applied in cases when in the room there is a bimetallic floor.

As for the permissible coatings, they can be attributed to wood (in the form of parquet or laminate), linoleum and special cork sheets, which today enjoy an enviable popularity.

The main condition in the installation of the infrared floor is the addition of its thermostat. With it, it will be possible to maintain the optimum temperature evenly over the entire area (within 27 degrees). Why is this value so important? If you pay attention to the physical properties of wood flooring, it becomes clear that the change of its structure occurs at a temperature of 28 degrees. It means that when the floor is heated above 27 degrees, serious deformation of the finishing material may occur.

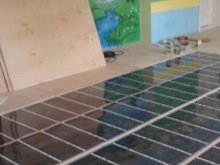

The situation is different with laying ceramic tiles and ceramic granite slabs over the infrared floor. The necessary glue and tiles can be safely boldly laid directly on a warm film. Thus, you need to do if you use a coating resembling the type of "single crystal", characterized by perforation.However, in such cases it is better to reinforce the resulting structure with a reinforcing mesh.

In such cases, it is necessary to adhere to one important condition - the layer of tile glue and the tiles themselves must exceed 2 cm. This is necessary in order to create a sufficiently rigid layer that will protect the film of the infrared floor from various damages.

In addition, a similar measure of thickness will guarantee a good heat distribution over the entire surface of the floor covering.

The situation is more difficult with soft finishing materials. So, fleecy carpet, linoleum, carpet and other similar coatings should be supplemented with rigid heat-reflecting bases. For this most often used sheets of chipboard, OSB, GVL (the most successful option).

Such panels are laid on a polyethylene film spread on top or a material similar to the substrate under the laminate. This additional coating will protect the warm floor film from various damages due to constant friction.

Of course, it is necessary to try not to harm the tires, which remain visible even through the film, and break the minimum number of carbon strips.After the substrate is properly and reliably installed, it is possible to lay the finish coat.

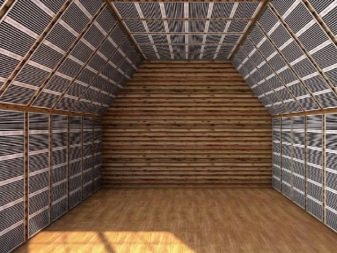

Infrared warm floor, a distinctive feature of which is democratic energy consumption, often used on the balcony. Moreover, they often cover not only the floors in such rooms, but also the walls. If you plan to split a beautiful winter garden on the balcony or equip a recreation area and a corner for reading books, then this solution is very successful and practical.

It is also worth noting that the use of an infrared floor is absolutely safe for the health of households, regardless of the composition of the flooring, be it soft carpet or a classic laminate of any class.

Tips for choosing

Before buying a high-tech infrared floor, you need to familiarize yourself with all its pros and cons. If you still decide to purchase such a heating system for your home, then you should learn about a few of the most important and significant criteria for choosing such products. First of all, you should look for models of high quality in an assortment of warm floors. The following recommendations will help you in this matter:

- Pay attention to the material from which the film is made. It may have a matte or plain transparent surface.

- View the status of the print. Experts recommend paying attention to the uniformity of carbon printing.

- Also important is the width of the film. You can check it, based on the length of the roll.

- Inspect the surface. It should be perfectly smooth and even (without damage, protrusions or irregularities).

- There should be no garbage under the film (even if it has tiny dimensions).

- On a high-quality film should not remain.

- Pay attention to the variety of copper. Pure copper has the highest conductivity. It is usually used in premium class coatings.

- The thickness of copper is also important, since the probability of overheating of the floor directly depends on it.

- Experts recommend choosing thinner copper.

- In such heat systems there is a special silver tire. Between copper and carbon must be at least 1 ohm of resistance.

- Choose only the safest designs, which prevent sparks from being used.

- Pay attention to the stickiness of the film. It should not stratify in any way.

An important role in the functioning of the warm infrared floor plays heat distribution part - thermostat. Such devices today are produced both mechanically and electronically. The last versions are more popular and widespread, as they have good functionality. There are even such instances that easily support the work on a given program.

Electronic thermostats are more appropriate in the matter of energy savings, since the floor can connect with them only in the morning or in the evening when you return home from work. Many people set up a program in which the carbon floor is turned off for the night, if at this time of day an additional heater in the room is not needed.

To choose such elements is no less responsible than the very heated film. The main thing you should pay attention to is the compliance of the power indicators of the regulator itself with the power of the heated floor.

Installation

Many people opt for well-thought-out and efficient infrared heating structures, because for their installation it is not necessary to call a team of specialists.With the installation of such systems, you can easily cope on their own.

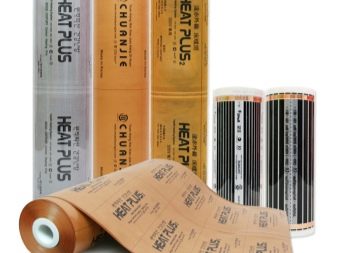

First you need to determine the scope of delivery. It hardly differs from different manufacturers, but nevertheless, experts recommend to apply only to popular and eminent brands that are popular with modern consumers. The best is a kit, which includes the following necessary elements:

- Installation Instructions.

- Roll Thermofilm.

- Electrical cable kit.

- Bituminous isolation in a set.

- Thermostat

In addition, for this work it is necessary to stock up the following devices:

- Heat reflecting material (for example, an isolon 3 mm thick can be used).

- Polyethylene protective film.

- Scotch.

- Knife.

- Passatizhi.

- Screwdriver.

- Scissors.

As a rule, all the listed tools and tools are not included in one standard set, so you will have to purchase different items separately.

Preparatory work

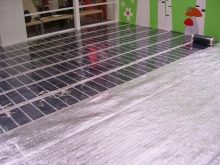

To begin with, it is necessary to make the correct measurement and calculation of the space for the installation of the infrared floor thermofilm. During this stage, it is necessary to take into account that the film is never placed under the pieces of furniture in the room, in order not to overuse it itself and not to warm up the wasted furniture.

After that, you need to choose a specific place for mounting the thermostat on the wall in the room. He must be in a zone of full visibility. Nothing should interfere with its use.

Then you can put izolon. It is worth noting that the insulation must be spread throughout the room, and not just in the zone where the warm floor will be located. Izolon can be fixed with a construction stapler or double-sided tape. The joints that remain between the isolon strips are recommended to be closed with adhesive tape strips in order to qualitatively but imperceptibly fix them.

Thermal Film Laying

First, the thermal film must be rolled out in such a way that the copper strip “looks” down. It should be cut into individual straight pieces of the required size in specially provided for this part.

Connection

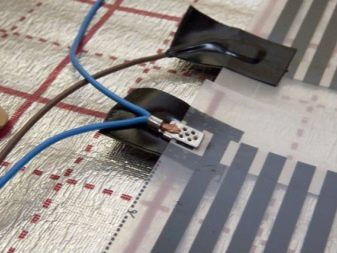

In areas where we cut the film, you need to isolate the middle bus with bitumen insulation, which, as a rule, comes with a warm floor. Be sure to ensure that the insulation completely covers the silver contacts of the system, which interconnect the copper bus and carbon heaters.

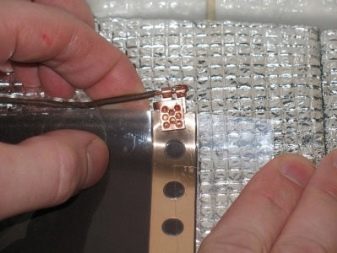

Where future wire connections are assumed, special contact clamps should be installed, which are also often bundled with the main system. One side of such parts should be in the inner part of the thermal film. The second side always stays outside and heads for the floor.

After proper installation, the clamp must be securely fixed using pliers.

After that, you need to secure each other a strip of film with ordinary tape. This is necessary in order to avoid “movement” of the structure during further installation work. Now you need to connect the wire to a special contact clip, which we installed a little earlier. It should also be crimped with pliers.

Then it is necessary to isolate all sections of the wire connection using the same bituminous material. For each connection is to allocate two segments. It is necessary to carefully monitor that so that silver light contacts are in complete and high-quality insulation.

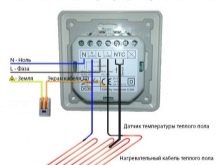

Installing the thermostat

A special sensor temperature controller, as a rule, comes in a set with the main thermostat.First you need to install it. To do this, install the part in the lower part of the thermal film (directly onto the black heating strip), and then fix it with bitumen insulation. Isolation is necessary to make a cut. It is necessary in order to avoid the appearance of various irregularities and bumps.

You also need to make appropriate cuts in the junction of contacts. After that, you can safely attach the thermostat to the surface of the wall and connect all the necessary contacts. In such cases, it is recommended to rely on the scheme available in the instructions for the infrared floor.

Take care that the temperature controller is connected using a special circuit breaker.

Laying protective coating

The final step in the installation of an infrared floor is the laying of the main protective coating. To do this, expand the film over the entire surface of the system. It is also permissible to use a substrate for laminate. It perfectly protects a thermofilm from various mechanical damages. Next you need to make the laying of the protective coating: laminate, carpet, parquet, tile or special carpet paths.

Manufacturers

Currently on the market there are a large number of famous brands that produce high-quality and durable infrared floors that perfectly protect from the cold in any home. Let's get acquainted with the most popular manufacturers, whose products are in great demand among buyers:

- Caleo. Quality products from Caleo are very popular due to the simple installation, which does not take much time and effort. Many consumers stop the choice on these warm floors, as their energy consumption is reduced by 20%, which makes structures more popular than, for example, cable options.

- Heat Plus. This famous Korean brand installs high-quality and reliable floors with a heating system. The main advantage of the products of the popular company from Korea is that the heating of the room occurs without the use of additional pipes or heating boilers. Currently, Heat Plus products are premium-class.

- "Heatlux". The leading position in the rating of Russian manufacturers of warm infrared floors is taken by the company “Thermolux”. Its products are notable for high reliability, durability and trouble-free many years of operation.

Branded goods of this manufacturer are produced on the Russian market since 1994, and already in 2010, “Thermolux” was recognized as the most recognizable brand of warm floors in Russia.

Reviews

Currently, many people use warm infrared floors, as they are relatively inexpensive, they are installed quite simply, and they cope with their main task perfectly well.

Many owners of such carbon floors leave positive reviews of the following characteristics and parameters:

- Heating quality. People really liked the thermal characteristics of the infrared floor. With its help, many owners heat even large and spacious rooms, as well as walls on the balcony, which speaks of their high quality and versatility. In addition, many users note the fact that such structures heat up rather quickly.

- Easy installation. For installation of warm infrared floors do not need to make a concrete screed. Most of the buyers because of this, chose such systems, because they are installed quite easily and quickly, and they can be easily transferred to a new place.

- Environmental friendliness. Consumers could not fail to note that infrared heating systems are environmentally friendly and completely safe for health. Even with their daily work, people do not feel unwell. The household does not hurt and does not feel dizzy, as is often the case with many types of heating. This fact especially pleases families with small children.

- Cost Often, buyers say that the decisive factor that influenced their choice was the low cost of IR systems. Of course, everything depends on the manufacturer of the floor and its pricing policy, but, fortunately, today there are many designs on the market at a very affordable price.

- Efficiency. The infrared floor consumes a relatively small number of kilowatts, as noticed by many owners of such systems. They are classified as economical, as they consume a small amount of electricity.

However, buyers leave high-tech carbon-based heating systems not only positive reviews. Many of them are faced with unpleasant problems, which will be discussed below:

- Insecurity.On the Internet, you can find rare reviews that these thermal structures are unsafe. There were cases when the infrared floor almost burned out when it was laid under linoleum, and before that it emitted very unpleasant characteristic odors.

- Short life Some buyers say not the longest service life of such heating systems. There are cases when they served no more than 2 years from the date of installation, which, of course, is very small.

- Cost If you want to buy a really high-quality and durable construction, then you should contact the manufacturer of the premium class. Unfortunately, the products of this category are quite expensive, which upsets many buyers who want to save on the purchase of a warm floor.

- Long heating. Owners of many warm infrared floors have noticed that it often takes a long time to heat the system, which affects energy consumption. This is especially true of cheap designs.

Successful examples and options

Infrared heat-insulated floors can be installed safely both in a private house and in an apartment. This is especially pleased with the owners of living space with a balcony or loggia.With the help of such a heating system, you can completely warm the room, making it more residential and more functional (if, of course, there is a warm glazing in it).

So, in such conditions compact workrooms or cozy sitting areas with small sofas, coffee tables and even bookshelves / shelves look great.

In a cozy private house (cottage, country mansion, or just a country house) such a heating system will be very helpful. Over it you can safely lay the flooring of any type, whether it is natural wood board or luxurious glossy tiles.

Infrared warm floors are often laid in areas such as garages or workshops. This is a very pragmatic and practical solution, since you can stay in these spaces for a long time without freezing. Moreover, for such situations it is recommended to use special designs with self-regulating system, which will allow to use them only at the right moments, significantly saving electricity.

Do not forget that the furniture should not stand on the heating elements of the infrared floor.To avoid unnecessary incidents, it is worthwhile to think over every square meter in advance and exactly where you will place all the objects in the interior. For example, if we are talking about a living room, then a soft corner and a small table in it can be positioned in the center, and the rest of the space can be placed under a heated floor.

Similar layout should be followed in the bedroom. For example, for a bed and a dresser with a dressing table, take a free corner, and fill the remaining space with an infrared heating system.

See how to install infrared film underfloor heating in the next video.