How to choose a plate for a warm floor?

Modern housing should be not only beautiful, but also warm. To do this, in many apartments install a system of centralized heating, but it often does not justify itself. Therefore, in the rooms it is necessary to additionally place heaters that dry the air and consume a lot of electricity.

The installation of the “warm” floor is considered a way out of this situation; it is not only a good source of heat, but also allows you to effectively save energy costs.

Heat-conducting plates that are part of the heating structure, increase the insulating functions of the floor and provide uniform heat dissipation.

Features and benefits

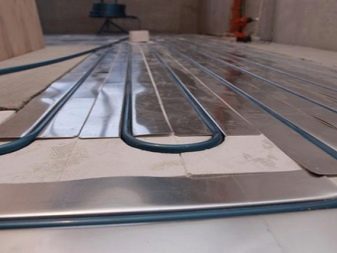

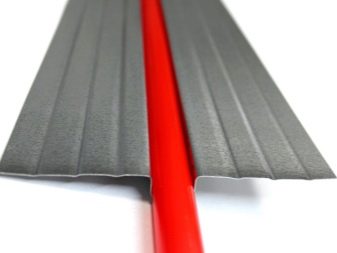

Thermoplates are considered the main element of the system, which is used for laying the "warm" floor.They are metal profiles and are suitable solely for substrates leveled using the dry method. Distinguish aluminum and steel heat-removing plates, outwardly they have a simple look, are available in different sizes and configurations. Depending on the type of production, this element may have a different structure, but its main indicators are:

- Omeogoobraznaya groove. This is a heat distribution niche that runs along the entire length of the profile; it serves as a place for laying all thermal floor carriers.

- Ribs. They are additional parts of the structure running parallel to the groove and are responsible for the strength and reliability of the plate.

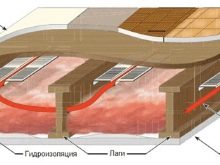

Heat is distributed through the system as follows: a pipeline is placed in the channel, it transmits the required temperature to the profile surface, and that, in turn, provides the finishing floor with heat. It is worth noting that this process does not require concrete pouring or cement screed.

To increase the efficiency of heat transfer, an additional heat-reflecting film is used during installation.

It is worth noting that a similar distribution The design has many positive characteristics:

- Fast heating and high heat conductivity. The heat-reflecting function of the material from which the plates are made allows to obtain the desired microclimate indoors in a short period of time.

- Simplicity in calculations and ease of installation. The minimum distance between the profiles is 12.5 cm, therefore, knowing their exact weight, you can quickly calculate the material consumption. To install and fix the pipes, you do not need to use a reinforcing mesh, they are laid directly on the heat plates.

- Preservation of floor height. Distribution profiles are well suited for rooms with low ceilings. If, for example, a concrete screed “takes” an average of 9-11 cm of flooring, then using metal plates this indicator will decrease by almost 3 times.

- Low weight. Thermal profiles on an area of 1 m2 weigh about 10 kg. Therefore, they can be laid in the premises of any type.

- Efficiency. Unlike a conventional heating system, the floor with distribution plates not only warms up faster, but also allows significant energy savings.On average, its consumption is reduced by 20%. In addition, for the installation of the finishing coating does not require additional costs for finishing and other equipment. The decorative layer is applied directly on top of the structure.

Material

Heat plates are made of steel and aluminum, with the latter being used more often. The metal surface is subjected to careful treatment with solutions against corrosion. In addition, light-repellent layers can also be applied to the substrate, which increase the effect of heat transfer.

As for steel products, they are not resistant to rust, so they are covered with special powder mixtures. Also, steel alloys have a natural structure, which is not characterized by prolonged operation, but such profiles are not subjected to mechanical deformations. Therefore, they are recommended for all types of flooring.

Where can I use?

The heating system on the basis of plates is well suited for heating in homes where the floors are covered with uneven bars. Due to the unique structure of the profiles, such an installation is an alternative solution for arranging old buildings in which it was impossible to install “warm” floors earlier.In addition, the new coating will in no way affect the height of the premises, which is not the case for a concrete screed.

As a rule, the plates “take” 30 mm of height, and if they are laid directly on the beams, then its loss will be zero. The heat exchanger of the plates is placed between the "rough" base and the leveling sheets, the pipes are inserted into special grooves, then the finishing floor is mounted.

Heat distribution profiles are also ideal for new buildings in which the heat supply system is carried out at the primary stage and does not need reconstruction or repair.

They are suitable for all types of coverage, they are quickly installed and last for a long time. Therefore, such designs have received positive feedback and are very popular in modern construction.

What to look for when choosing?

To date, the construction market is represented by a chic selection of heat distribution sheets, they all differ in the type of production, as well as the material from which the frame is made. To purchase a quality plate, you must carefully study its performance characteristics and pay attention to the following product indicators:

- Heat capacity. Many trademarks represent different types of thermal profiles, while advertising their high thermal permeability and reflectivity. In fact, this is not true, since, regardless of the conditions of use of the heating system, the sheets will constantly heat up, so the rate of heat supply slows down.

- Efficiency. This indicator does not depend on whether the plates are made of steel or aluminum. As a rule, in order to improve efficiency, it is necessary to additionally use special heat-insulating materials, which when installing the structure are laid out in a small layer on metal fittings.

- Corrosion protection. Many believe that if heat sheets are constantly heated, they are not in danger of metal corrosion, so the products do not need special coating. This opinion is erroneous, since even with the slightest ingress of moisture through the top layer of the floor at high temperatures, favorable conditions for the formation of rust are created.

In this regard, when purchasing products, it is necessary to check the presence of a corrosion-resistant coating on them; if it is not there, you will have to purchase moisture-proof materials separately.

- Availability of quality certificates. In order for the distribution system to serve for a long time and reliably after completion of the installation, the manufacturer must ensure that it complies with all operational characteristics.

It is also worth noting that the choice of plates depends on the room in which the installation of a “warm” floor is planned. Each room has its own microclimate and humidity, so profiles of different models, differing in protective qualities, accumulative capacity and heat capacity, can be used. For example, for bathrooms and kitchens, where constant temperature changes and high humidity are observed, a product with a good anti-corrosion coating is suitable, and if the floor is laid on concrete, aluminum or copper plates will be needed to increase heat transfer.

An important indicator for the purchase will be the height of the room where the floor is carpeted. For high rooms it is necessary to use aluminum frames, they transfer heat energy faster, and the flow of warm air is evenly distributed around the entire perimeter of the room.

Summing up, we can say that the plates play a huge role in the distribution system and provide a room with good heating.But in order for the construction to work efficiently, it is also necessary to select high-quality pipelines for these elements. Only the transfer of energy depends on the heatplate. Therefore, you should worry about the presence of an insulating substrate. Before the start of installation work, it is necessary to carry out the correct calculations of the material and prepare the installation diagrams.

How to bend an aluminum plate for a warm floor, see the next video.