Fiberglass mesh: the pros and cons

For their comfort, people have come up with many amenities, one of the main is their own housing. Millions of square meters of tiles are laid every minute, hundreds and thousands of kilometers of pipelines are laid, electricity cables are laid, and so on. New technologies help us pave the way for success much faster and more confidently.

A look into the future

The main thing for a person is comfort in the house. The construction industry is not standing still, many new equipment, materials and technologies have already been invented to facilitate the work of specialists. One type of improvement and acceleration of the repair process is the invention of the plaster grid. This is an indispensable assistant in the quality of repair or construction of buildings of any complexity and volume.

Before the invention of this material, people had to make recessions that were frequent on the surface of the walls with an ax, so that the plaster had a better bond with the wall, the second method was to build an additional crate of small planks.

With the advent of the innovative mesh, the lifespan and attractive appearance of the restored surface has increased significantly.

The material is popular at the moment due to its properties. Under various conditions, even unfavorable ones, such as uneven walls, high humidity or temperature, an insufficiently cleaned surface, the mesh for plaster will do its job perfectly, the length of a presentable appearance will be preserved for a long time. It minimizes the negative result of the work done.

Kinds

There are many types of reinforcing mesh. When selecting materials should pay attention to the particular type of mesh, the size of its cells, the surface of attachment.

Main types:

- masonry net - used for brickwork, made of a polymeric substance;

- wagon - plastering and finishing works, created from polyurethane;

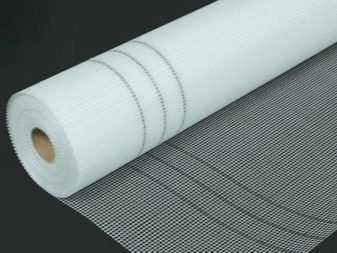

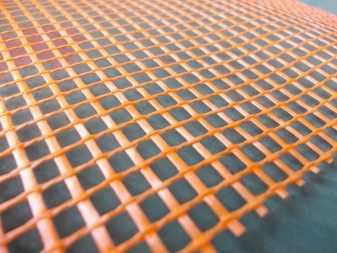

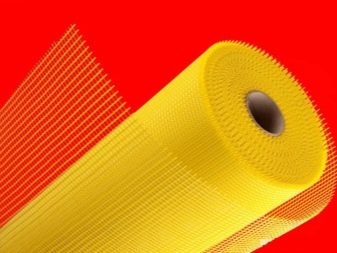

- fiberglass - made from specially treated fiberglass, has good strength and resistance to chemical and temperature effects, used for internal and external works;

- plurima (fiberglass) - the main component is polypropylene, it is inert by chemical characteristics, used for all types of finishing works;

- armaflex - the base is polypropylene, the mesh is reinforced with additional knots, as it is superimposed on a thick layer of plaster;

- sintoflex - analogue of Armaflex in composition, suitable for work in the circumference of the structure;

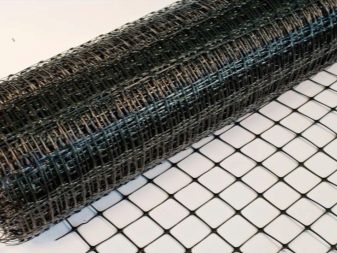

- steel mesh - the main material is steel rods soldered into a one-piece construction, the size range of cells is quite wide;

- metal - only for internal work due to the ease of corrosion;

- galvanized - made of galvanized rods, they are soldered together in knots, has the strength, durability and reliability.

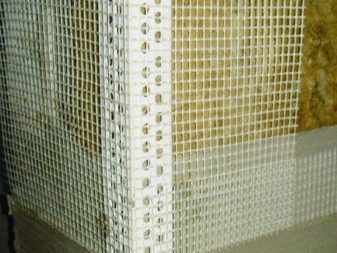

Each type is special, depending on the working conditions, it is necessary to make the right choice, which will be half of the successfully completed repairs. When choosing a material, you should use the laser or building level to identify the lowest point on the ceiling, to assess the situation and the thickness of the future layer of plaster. Depending on the measurement result, the option of reinforcing mesh is selected.

Scope of application

One of the most common types is fiberglass mesh, it is used for interior work in such cases:

- between partitions;

- when combining two different materials;

- in the area of large cracks;

- with an impressive thickness of the plaster layer;

- when creating a flat surface.

Fiberglass mesh is used to prevent the early destruction of the plaster layer, the occurrence of cracks. It gives confidence in the durability of the connection surface with plaster.

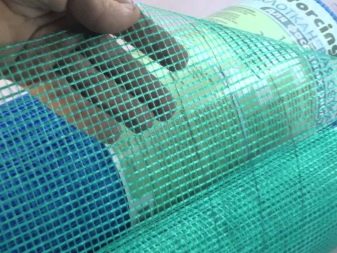

Fiberglass mesh - made from high-quality polymer fibers, which are impregnated with high-grade polyacrylic dispersion.

Types of fasteners when performing plastering

Due to its high quality and properties it has a wide range of use, due to this there are several varieties.

The painting fiberglass mesh is used for internal putty work:

- decoration of the ceiling, walls, destruction of cracks;

- smoothing the joints with the adjacent surface;

- putty plasterboard sheets;

- waterproofing works;

- processing door and window jambs.

For facade work is used for external improvements:

- strengthening the facade of the structure;

- restoration and repair of the building;

- improvement and restoration of surface properties;

- the creation of a waterproofing shell.

Universal reinforcing mesh has the ability to endure a strong stress of the plaster layer, does not allow the occurrence of cracks. Has found application in all types of spackling processes:

- waterproofing work;

- strengthening ceilings;

- insulation of facades.

Features of fiberglass mesh

Fiberglass material has a number of positive qualities.

The main advantages should be considered:

- mechanical strength of the product;

- flexibility and elasticity in use;

- lightweight material;

- reflection of corrosion and rotting;

- increased adhesion of the plaster layer to the surface;

- resistance to deformation and any changes;

- compliance with fire safety standards;

- reinforcement of waterproofing and heat-insulating systems;

- resistance to temperature fluctuations, environmental changes;

- ease of fixation (attached to the mortar and adhesion of the plastering layer occurs);

- high resistance to tearing and damage.

With all the positive aspects has also negative sides.

The disadvantages of fiberglass mesh are:

- Do not apply a layer of plaster over six or eight millimeters on top of the material;

- if used improperly, the perfect result will not be achieved;

- the occurrence of unpleasant sensations when interacting without protection.

Depending on the above, both positive and negative factors, it should be concluded that fiberglass mesh has excellent properties and will greatly facilitate the process of repair or construction.

Installation of plaster material

The first step is to prepare the desired surface for work. Regardless of whether the old house or just built, it is required to perform the same actions.

- It is necessary to remove the fungus, dirt, old finish, dust.

- Then the surface is required to be treated with soil. This procedure is mandatory, as it acts as a defense in the future.

- It is required to allow to dry completely, then preparatory work for the mesh material is carried out.

It is necessary to measure the height, cut the roll, attach to the wall and fix.

Fixation can be carried out in several ways: nails, screws, glue.

The material is applied overlap. Glue should be applied under it and on its surface, thereby filling the voids to avoid cracking.

The last stage is putty. It should be smooth movements from the middle to the edge to immerse the fiberglass. Preparing a mixture of sour cream consistency and applied to the surface, the thickness is necessarily more than one centimeter. After hardening, the second layer is applied more dense, you need to wait and align. After properly done work, the result will be incredible.

How to glue the plaster grid, see the following video.