Ceramic tile drills: selection criteria

The final stage of repair - finishing work. An important role in decorating the room is played by the competent selection of material, taking into account its properties and features. A high level of interior decoration with hanging furniture and equipment, its reliable fixation is a guarantee of coziness and comfort in your home.

The most suitable building material for lining the pool and dining area - ceramic tile. Tiled covering is a reliable and waterproof material. But on a durable and fragile tile at the same time, chips and cracks may appear if the holes are made with a conventional concrete drill and not with a special tool.

Experience and the advice of professionals, the observance of simple rules will help to avoid errors in the repair and deformation of expensive coating.

Surface features

Ceramic tile is the most popular material for finishing the premises and facing the building, its small size makes it possible to perform work in the most difficult, textured and inaccessible places.The modern building materials market offers a huge selection of tiles. Before making a final decision on the choice of tile it is necessary to know for what purposes and under what conditions it will be used, its properties and surface features.

Tile - red and white clay, treated at high temperatures. Due to the different composition of clay and firing temperature, ceramics can be divided into types:

- on external signs - glazed, with a non-uniform surface, without processing, porous;

- according to the degree of heat treatment - with double and single roasting;

- in size - wall and floor.

It is necessary to take into account the important characteristics:

- strength - affects the life;

- wear resistance - the ability to maintain decorative qualities, relevant for flooring and paving;

- elasticity - the ability to bend under deformation and withstand significant loads;

- porosity - the ability to absorb moisture, which leads to a decrease in slip in the pools and bathrooms.

When choosing a material for cladding, you should pay attention to the indisputable advantages of tile:

- a variety of colors, textures and forms with a margin of safety and density;

- chemical inert properties of the material;

- environmental safety composition.

The above features of the surface dictate the conditions of work, in which the smallest probability of tile destruction:

- at the stage of drilling to eliminate the pressure on the ceramic plane;

- reduction of rotational speeds of the drill and vibrating electric drill (it is advisable not to use electric mechanisms);

- reducing the temperature and wetting the metal surface of the tool will reduce overheating of the drill, which will contribute to the qualitative implementation of the tasks;

- drilling from the back of the tile, on smooth and hard glaze, is often impossible.

Types of drills

Before you start choosing a drill, you need to choose the best working tool, meeting all requirements:

- control of the speed of rotation of the drill;

- pressure control on the surface.

Depending on the hardness of the tile, several options of tools are used:

- perforator - shock electric machine for solid materials;

- hand drill - a simple mechanism for drilling small holes;

- electric drill - a professional tool operating at low revs from the 220-volt network, using an easy feed;

- screwdriver - divided into battery and running from the network, used only at low speeds of not more than 900 revolutions per minute.

The most popular tool is a screwdriver, in the second place is an electric drill with a speed controller.

The choice of mechanisms for work depends on some factors:

- bore size;

- scope of work;

- drilling before or after laying ceramics.

To perform work on the improvement of the premises, it is necessary to choose a special professional drill for ceramics and plexiglass with high strength. The principle of operation of such drills is completely different from the tools for metal and wood, it is based on friction through abrasives. The use of another tool will lead to the deterioration of building material, irrational financial costs and increase the lining time interval.

Drills can be classified into specific groups:

- tile coating drills - drill holes in the clay surface ranging in size from 10 mm to 70 mm;

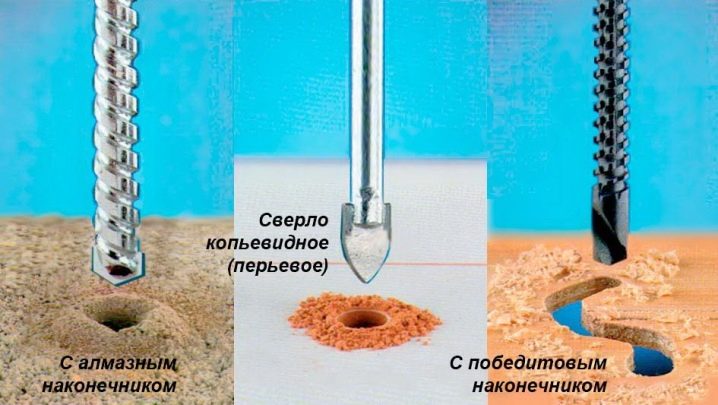

- feather (feather) drill - the appearance of the tip, similar to a pen, makes it possible not to use punching, the size of the groove can reach up to 3 centimeters;

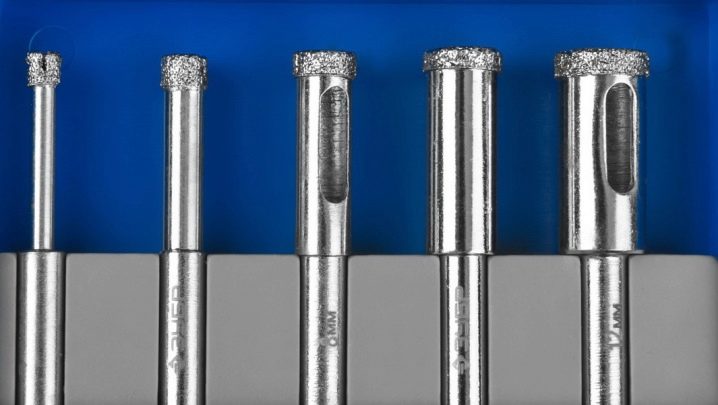

- diamond-coated crowns - recommended by trim specialists, have a high price and ideal performance, can make up to a depth of 15 cm;

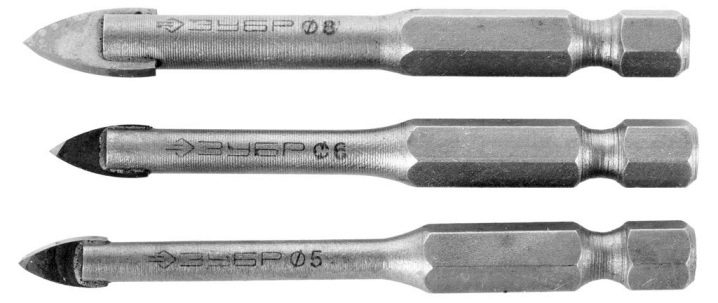

- drills with a head of hard alloys (gear cutters) - a tool with one sharpened stripe and a pointed sharpening angle, drills up to 15 mm of the surface, has the ability to sharpen, suitable for smooth ceramics;

- Pobedite-shaped spear drills - the low price and limited period of use allows drilling no more than 5 openings for dowels, the drilling process is carried out exclusively at low speeds with a recess diameter of less than 1.5 cm;

- spear-shaped drills with diamond film - drills for reusable use;

- a ballerina is a special purpose drill; it consists of a centering drill and a parallel cutter on the bracket; drilling under the socket is performed by special taps on sharp metal parts.

For a one-time use, you can choose an inexpensive, pointy drill sharpened on a diamond wheel. Doing the work carefully and attentively, using measures for the stable cooling of the tool, the master has the opportunity to make several necessary holes.

Professional builders are advised to purchase a set of drills for tiles, ceramics and glass with dimensions of 3 mm, 6 mm, 8 mm, 10 mm.

When selecting a drill, it is necessary to take into account certain characteristics:

- type of shank - cylindrical (most common) and with six faces (the most durable);

- diameter - determines the circumference of the recess;

- length - affects the size of the hole.

Principles of drilling

Getting started with the tile, it is necessary to carefully study its characteristics and properties. Drilling should be carried out as accurately and carefully as possible without disturbing the integrity of the coating, strictly following the drilling principles:

- keep the drill at a 90 degree angle to the surface;

- add momentum only when it reached the concrete;

- constantly cool the work surface;

- prevent overheating of ceramics and tools;

- choose the optimal pressure force on the tool;

- turn off the reverse mode, perform smooth turns according to the movement of the clock hand;

- place the hole in the center of the seam (there is no protective layer at the edge and near the edge of the tile).

Making the opening under the dowels for fixing the toilet, you must comply with some requirements:

- drill the lining only with a drill with a feather for the tile, and concrete with a percussion instrument;

- the size of the recess in the tile must be larger than in concrete in order to preserve the integrity of the tile;

- fasten fastener very carefully.

Making a circular hole

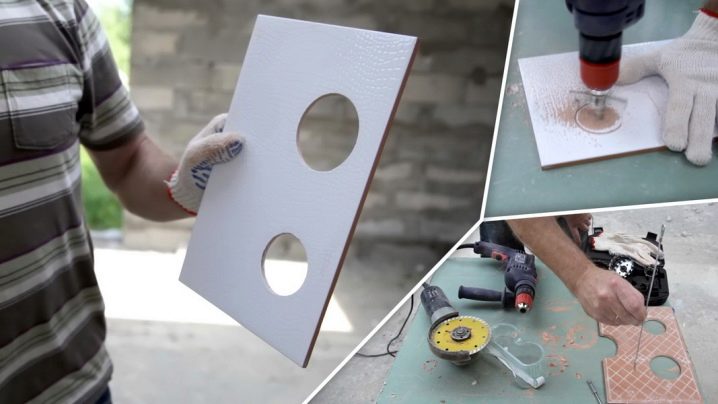

At the stage of tile installation or after its installation, it is necessary to make circular holes of large diameters in order to install fittings for electrical appliances and switches in the planned places. There are several options for performing the task:

- grind a hole with a grinder - mark out a contour loose on the surface, use a diamond disk for dry cutting to smoothly cut from a convenient edge, holding the tile;

- cut with a jigsaw - on the front side draw a line, slowly cut the necessary figure with the cutting thread of the tool;

- make a cut using glass cutter and tongs along the marked contour of the future hole, cut the slot using a glass cutter (taking care not to crush the tile), sand the edges with forceps with fine grit;

- use special purpose tools - drills with a cylindrical working part or a ballerina drill.

The design of the ballerina is similar to compasses. The drill is fixed in the center of the cut-out circle, the cutting tool from carbide plates makes a circular recess (size from 3 cm to 9 cm).

To obtain a high-quality and large opening with a large diameter it is necessary to use crowns with a diamond film or coated with tungsten carbide. The high price of the instrument will pay off with high quality indicators. Following the instructions is an important step in the drilling process:

- unacceptable speeding above 500 rpm;

- compulsory lowering of the temperature of the metal surface with water;

- pasting the place of drilling with masking tape;

- stationary equipment for drilling is a pledge of effective performance of the assigned tasks if there is no centering drill in the kit with the crown.

Useful tips

The readiness of the tile for drilling without the possible occurrence of cracks is determined by lightly tapping the surface. Deaf and dense sound - a sign of the fearless start of work. Proper drill selection is an important step in the finishing process. The drill size must exactly match the size of the planned opening. For the installation of dowels suitable drill for tile, with a diamond film or pobeditovye. Indentations of large sizes are performed by crowns or ballerinas.

The biggest problem when facing tiles is the glazed layer, which has high strength. Mark the place of drilling and fastening the drill, it is possible to carry out the following ways:

- by punching - the deepening of the conical shape is performed by the fastener, by scratching a small dot on the surface;

- sticking - fixing on the surface of the film tape with adhesive coating;

- marker tag - drawing on the place of drilling a rough mark with a special felt-tip pen.

Having installed the selected drill bit in the tool, be sure to turn off the hammer mode and switch to the drilling position.It is necessary to begin work on small turns, having arranged a drill perpendicular to a surface. This will help keep the drill at the right point. After deepening the tip in ceramics, you can increase the speed. High speed will reduce the time spent and speed up the process, but will lead to overheating of the surface. Cooling with water will not only reduce the temperature, but also bring down ceramic dust.

The work of the drill cutting element with a diamond segment sputtering is performed at high speed. Rigid fixation of the tool will help avoid displacement and destruction of the lining. The use of liquid will reduce the degree of temperature and the probability of damage to the tool. Diamond film cutter allows you to drill dry ceramics at low speed. Goggles - a prerequisite when working as a ballerina.

Having set the required diameter, start drilling at low speed, holding the tile. Hold the drill in the same position, work accurately and with care.

To work on smooth glaze and to reduce slip, you must follow simple recommendations:

- make indentations in the center of the future hole with the pointed side of the file;

- stick masking tape;

- markup with a stationery knife for correction;

- turn off the hammer mode at the drill.

When working with a laid tile, the specialists derived a simple sequence of actions:

- soak ceramics in water for at least 40 minutes;

- place the tile on a flat and smooth wooden or concrete base;

- marking the place of drilling, fix the tile with masking tape;

- to work on the same rules as on the wall.

To facilitate drilling and improve the quality of work will help the secrets of professional masters:

- Drilling a hole near the edge will cause the tile to split;

- at low revolutions of drilling, special drills can be replaced with drills for a metal surface;

- wooden chopik will help reduce the size of the recess;

- an installed spatula at the drilling site will help reduce cleaning time and reduce pollution;

- to get a hole of a certain length, you need to mark the desired distance with a marker on the drill, which will allow you to stop work at a certain moment;

- work only with a sharp drill, use a machine and an emery wheel for sharpening, a diamond wheel and a coolant for a victorious drill;

- it is forbidden to change the movement of rotation of the drill head;

- personal protective equipment for eyes, face and hands - the safety and the ability to avoid splinters on the skin;

- trial work is carried out on unnecessary remnants of the tile;

- the formed chips are cleaned with sandpaper and hidden under decorative rings.

Novice builders need to carefully study the experience of professionals, this will avoid mistakes and frustration in the repair.

To learn how to drill ceramic tiles, see the following video.