Plastering bucket: varieties and subtleties of choice

Surely every master in the process of finishing work faced with the need to use an auxiliary device. One of these assistants can rightly be called a plastering bucket. What is it, what are its varieties, why is it needed and how to choose: let's understand.

Special features

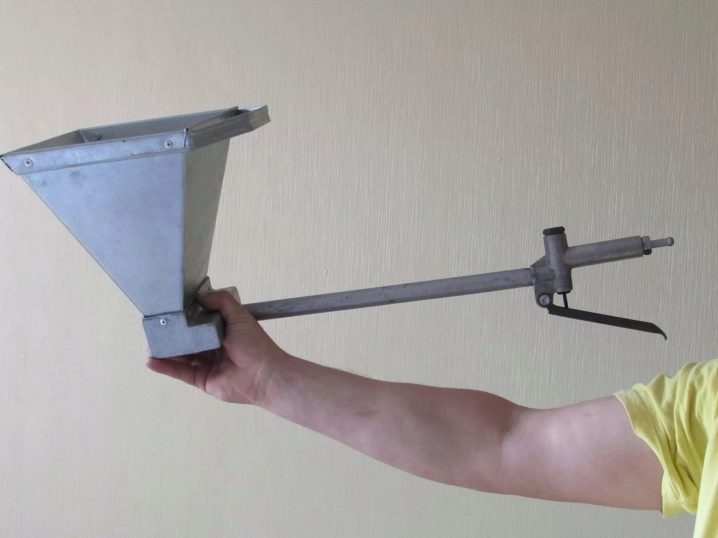

Plastering bucket is nothing but a device to facilitate labor and reduce the time of application of plaster material. Outwardly, it is a bucket with a handle or a kind of pneumogun with a bucket. However, some varieties of this construction tool imply a more complex structure.

The length of the handle depends on the type of plastering device. The modern unit is far from the Shaulsky bucket, which was more like a classic bucket with a wooden handle. Today, construction tools are known as hoppers, pneumatic buckets with compressors, pneumatics for applying plaster.

The tool fully corresponds to its name. Translated from English, it means "jumping", which explains the principle of the bucket. The bunker or plaster shovel has an exit nozzle through which the solution is applied to the treated surfaces. The manner of feeding is similar to the jumps of the mixture from the device to the base. Due to the increased pressure, the material is reliably imprinted on the surface, enhancing adhesion. Some modifications can be equipped with a rotating head.

For 1 time it can accommodate a large portion of the plaster composition. In this case, the bucket is completely free from the mass in a few seconds. This allows you to significantly simplify the decoration of the grounds, allowing you to meet in a matter of hours. It is a real find, allowing you to finish large areas quickly and evenly. On average, an hour of work with it will take up to 50-60 cubes of finishing solution.

The design is convenient for work. You do not have to understand its subtleties: everything is extremely simple. The bucket has a comfortable grip, so there is no need to adapt to the unit. Work is carried out in a short time by spraying the composition used on the prepared surface.

If necessary, a layer of plaster mix trim the rule or a wide trowel.

Advantages and disadvantages

The plaster bucket has a lot of advantages. Note them:

- Its use saves the used solution up to 30-40% (depending on the type of plaster material).

- The bucket is designed to work with different types of bases. However, it can be used not only for its intended purpose.

- Models vary in size. If desired, you can choose an option for finishing small areas.

- The tool can be rented if you plan a one-time work.

- Plaster bucket is designed for interior decoration inside and outside. It is often used to design the facades of buildings.

- The device is characterized by spray accuracy. In the process of finishing an even and uniform layer of plaster or other material is formed.

- The bucket is easy to clean. If it is cleaned in a timely manner, it will last a long time and will remain rust resistant.

- The tool copes with finishing hard-to-reach places. You do not have to suffer to put the mixture in difficult areas.

- When buying you can also offer a compressor and accessories.

- The range of these devices is extensive.The modern market for such products is ready to offer any modifications to the buyer, taking into account his needs and budget.

The design is sometimes so simple that to make it with your own hands under the power of each head of the family.

This unit has disadvantages:

- If you do not clean it immediately after completing the finish, the nozzle clogs up. This is the main cause of device failure.

- There is no need to buy a powerful unit with high functionality if the amount of work is minimal.

- Not every type of material used is worth buying. Some raw materials are deformed by the weight of the material in the bucket.

- Plastering bucket is not a tool for leveling plaster or starter layers. Starting coverings differ in coarse-grained fraction. This can damage the device, as the diameter of the nozzle is small.

- The device can not be called universal. For each type of material used, different outlet diameters are provided.

- Each type of product is designed to handle specific planes, as evidenced by the angle of inclination to the treated base.

Kinds

All models offered to the attention of the buyer, are divided into 2 categories: wall and ceiling. The name implies the scope of their application.

One device can not be replaced by another due to the location of the angle of inclination. For wall varieties, it is always 45 degrees. For finishing the ceiling such a product is not suitable: when tilting the bucket, the solution will flow out. For this reason, manufacturers produce ceiling products, in which the angle of inclination with respect to the plane to be processed is 90 degrees. Depending on the type of manufacturing plaster buckets are homemade and industrial.

Factory options are more powerful, but they cannot be considered universal. This disadvantage compensates for the different number of nozzles, which can be from 1 to several pieces.

The disadvantage of improvised devices is the fact that, with all the desire, they cannot be used to finish the ceiling. In this case, you will have to redo them, modifying to the desired type of work, which is not always possible. In addition, such devices are not designed for concrete.

Scope of use

Based on the purpose of the selected device,plastering bucket can be used for:

- splash paint;

- applying adhesive composition;

- basement distributions of liquid wallpaper;

- putting silk plaster.

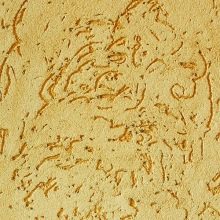

One of the advantages of such devices is compatibility with the use of textured plaster. They not only do not spoil the structural mixture, but also allow you to quickly and efficiently apply textured finishing material (for example, with the effect of “bark beetle”, “fur coat”, Venetian plaster).

If the size of the nozzle allows, plaster pnevmokovsh can be used in the work on the surface finishing paints multicolor and mosaic type. Use of the tool when drawing on the basis of a cotton covering, structures with glass and foam structure is allowed.

In addition to the standard use of gypsum and cement based compounds, plaster bucket is used in working with such mixtures:

- gunning;

- lime;

- clay;

- corkboard;

- glass fiber concrete;

- hydro insulator

All types of ready mixes can also be used in the finishing of surfaces with a plaster shovel. Reducing the time of applying the composition to the base allows you to perform an textured pattern with the highest quality and quickly.In this case, the pressure of the textured roller, special trowel, or scrap materials will be identical, rather than perform the decor gradually, section by section.

In a larger prepared area, wavy, arched, or chaotic lines are easier to perform.

How to choose?

The acquisition of the right tool is subject to a number of rules. Let's designate the main ones that professionals in the field of construction and repair rely on.

- A good pneumocomper is not cheap. In order not to fall for the trick of an unscrupulous seller, ask him for a quality certificate and relevant documentation. Branded products always have them.

- Take pnevmokovsh in hand. The handle should be comfortable. Inspect the spade for visual defects. There should be no scratches, chips, mechanical damage.

- For finishing work there is no need to buy a product with a large bunker. The weight of the diluted composition will affect the gravity of the device. This can cause discomfort at work.

- Buy at a trusted store. So you can be confident in the quality and durability of the purchased tool. Be sure to ask for the warranty card.

- Pay attention to the power of the air compressor. The level of adhesion of the applied solution directly depends on it.

- Some devices have a cover. This is their advantage and reduces the amount of spray from the material used in the process of spraying the composition.

- Pay attention to the size of the outlet. The larger it is, the greater should be the distance between the nozzle and the surface being trimmed.

Manufacturers

To get acquainted with the plastering bucket, you can look at the products of several popular brands.

- "Plasterer's Dream" - Pneumococci with good performance.

- "Hopper Bucket" - mechanized devices for finishing various bases with a 2 year warranty.

- Titan - industrial units with high power.

- "Condor" - wall and ceiling hopper models, consuming a 25 kg bag in a few minutes.

The products of each manufacturer are characterized by good quality and performance indicators. Sometimes pnevmokovsh is included in the equipment of the same name for carrying out finishing works on largesquares.

Reviews

Plaster pnevmokovsh is a good auxiliary tool during the finishing works. This sure many buyers who managed to test this device, it allows you to perform a higher-quality finish planes than with manual work. It is more convenient to work with it, especially when finishing the upper overlap.

The comments indicate that the plaster bucket actually reduces the consumption of raw materials used. However, in fact, this figure is less than 40%.

In addition, users notice: using a mixture with a very thick consistency of the composition takes more, as well as when working with textured plaster. In general, positive reviews are much more. Opinions are unanimous in that This device is a useful acquisition, whether it is homemade or factory machine.

To learn how to make a plastering hopper with your own hands, see below.