Features siding with imitation logs

Modern manufacturers of veneering materials offer a wide selection of their products. Finishing the exterior walls of the room with siding will not only provide an opportunity to aesthetically decorate the living space, but also protect it from the negative environmental effects, increase thermal insulation and sound insulation, help to create and maintain a favorable microclimate in the building. Installation of this finishing material can be done independently without the involvement of professional builders.

Reasonable price, unique technical characteristics and properties, ease of installation made the material popular and in demand.

Special features

Siding with imitation logs is a modern method of aesthetic design of the exterior walls of buildings for various purposes.

It has the following advantages:

- environmental Safety;

- affordable price;

- durability;

- resistance to sudden changes in temperature and the negative impact of the environment;

- high aesthetic performance;

- ease of care;

- refractoriness;

- ease of installation;

- resistance to the appearance of corrosion and damage from insects;

- creating a comfortable indoor microclimate;

- high level of strength;

- resistance to ultraviolet radiation;

- high level of imitation wood without joints;

- heat insulation;

- the possibility of repair and replacement of damaged parts of the structure;

- soundproofing.

If we talk about the disadvantages of such products, then it is worth noting the complexity of installation on an uneven surface of a curved shape.

Buyers can purchase two types of siding: with one and two waves. The size of siding panels depends on the manufacturer, and the width - on the number of waves. The most popular are products with a length of at least 3 m and a thickness of 15 mm.

When purchasing this facing material, experts advise to pay attention to such features as:

- for regions with a high temperature fit siding with a high level of resistance to fire;

- metal panels with a uniform finish suitable for brick houses;

- the surface of acrylic and vinyl panels should not be cracked.

Kinds

On the shelves of hardware stores you can find several types of this facing material.

Metal

Metal siding under the log is an industrial type of facing material used for finishing warehouses, industrial and defense infrastructure facilities.

Metal siding panels have the following layers:

- metal base;

- primer;

- topcoat.

The advantages of metal panels with imitation logs include the following:

- wide temperature range of application;

- high level of fireproof indicators;

- simplicity of installation with the help of locking floors;

- durability;

- resistance to mechanical damage;

- wide color range;

- individual production of panels of the required size;

- environmental Safety.

If we consider the shortcomings, it is worth highlighting the following:

- big weight of a design;

- special strengthening and strengthening the foundation of the building.

Vinyl

Vinyl (plastic) front wood siding takes the first place in the sales rating of this group of products. The starting material is polyvinyl chloride. Adding auxiliary components, stabilizers and modifiers can improve the natural property of the finishing material and improve its quality.

The advantages of plastic siding are as follows:

- long period of operation;

- high aesthetic performance;

- resistance of expensive material to fade;

- wide color range;

- lack of corrosion and rotting;

- water tightness;

- resistance to ultraviolet radiation;

- no burning process in case of fire;

- small weight;

- ease of installation;

- affordable price.

The disadvantages include the low resistance of cheap types of products to burnout.

Acrylic siding under the log is a popular and modern type of cladding material made from vinyl. Acrylic panels are of high quality and maximum similarity with the structure of the tree.

This species has the following advantages:

- high strength;

- resistance to solar radiation;

- color fastness;

- the possibility of use in sunny areas;

- period of operation over 40 years;

- resistance to mold, fungi and corrosion;

- high aesthetic performance;

- high quality imitation of wood structure;

- wide color range.

The disadvantages of acrylic siding should include a high price range.

Fiber cement siding under the log is an innovative development of producers of this group of products, consisting of sand, cement and reinforcing fiber.

If we consider the advantages of this type, it is worth noting the following:

- high strength;

- refractoriness;

- operation period over 50 years;

- environmental Safety;

- resistance to sunlight and fading;

- wide temperature range of application.

Fiber cement siding has the following disadvantages:

- installation complexity;

- big weight;

- small color assortment.

To perform high-quality cladding work, it is necessary to use material that complies with the norms and quality standards of well-known commercial manufacturers.

Comparison with iron and natural materials

Experienced builders have noted a significant decline in consumer demand for classic facing materials made of natural wood and iron. Modern designers give preference to new materials, made with the account of modern technologies and developments.

Siding made of natural wood is used only for the implementation of individual and exclusive projects and has the following advantages:

- high level of thermal conductivity;

- environmental Safety.

It is necessary to pay attention to the disadvantages of this facing material, namely:

- combustibility;

- constant treatment with antifungal, water-repellent chemicals;

- high price;

- mandatory coating with a special varnish.

Iron siding panels have become less in demand when facing residential premises due to the large weight of the structure.

Before starting work on the installation of panels, it is necessary to strengthen the foundation of the dwelling with the involvement of professional builders.

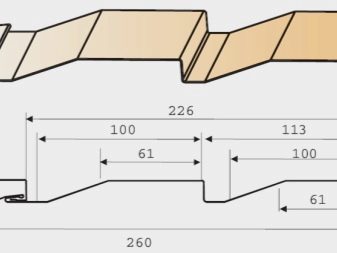

Dimensions

Modern manufacturers of siding cladding produce panels with a length of 250 to 650 cm and a width of 10 to 30 cm. The thickness of the panels under the tree does not exceed 10 mm.These dimensions make the finishing material easy to install and versatile to use, and the wide range of colors allows designers to realize the most daring wishes of the customers. In the building stores you can buy a wide range of siding under the tree - from dark wenge to golden oak, but the most popular are shades of oak, cherry and sandalwood.

Design

Professional builders distinguish such design types of wood siding as:

- Herringbone - This is a foreign design solution for facing the outer walls of buildings, which has low popularity among Russian customers;

- Under the log - it is used for decoration of summer houses, having a high percentage of similarity with a log round log house;

- Under the ship's board - this is a classic type of cladding of buildings, which has the appearance of light wooden wood, is widely used in domestic design projects.

The main requirement for the design decoration of the house facing is the harmonious combination of a new finishing material with the general style not only of the house, but of the entire household plot.On the shelves of hardware stores you can find two types of wood siding: vertical and horizontal. Horizontal panels are used for projects made in the classic design solution. Young and modern designers have increasingly begun to use vertical siding panels in their projects, which make objects interesting and unique.

The combination of different types of panels in the lining of residential premises will favorably emphasize the individuality of the owners of the house.

Installation

Before starting installation of siding panels, it is necessary to purchase additional parts of the structure, namely:

- launch pad with mount;

- finishing panel for fixing on horizontal cuts;

- interior and exterior decorative corners;

- vertical docking panel;

- trim parts for window frames and doorways;

- spotlights for eaves and ceiling.

The sizes of additional elements and accessories depend on the type of panels, their dimensions and installation. For a high-quality building lining, it is necessary to purchase panels, accessories and auxiliary elements from the same manufacturer and one brand.For self-installation of siding with imitation of logs, it is necessary to carefully study the installation technology and its rules. Famous manufacturers of this group of products indicate on the packaging complete instructions for all types of work. Experienced builders advise novice masters to carefully study the information and use it in their work.

The preparatory stage is the treatment of the working surface. The working base must be carefully treated with antiseptic solutions, remove debris and remnants of old material, securely fasten all the elements. To increase the rigidity of the cladding structure and mount the panels on the same level, you need to create a reliable frame.

The design of the frame is of two types.

- Wooden. For such a frame, a high-quality and even bar is used, treated with antiseptic solutions and protective compounds. The fastening elements of the frame is carried out according to the dimensions specified in the drawing. The distance between the parts should not be less than 50 cm, and in regions with difficult climatic conditions - more than 35 cm. The drilled bar is attached to the base with self-tapping screws.To obtain an even base apply the substrate of the desired size.

- Metal carcass made of iron profile. Fastening is carried out with the help of brackets and hangers, installed in accordance with the dimensions. Fixing racks carried out using the construction level. To obtain a strong, reliable and durable construction, it is necessary to mount all the parts on the same level.

Insulation in a wooden frame is placed in empty cells, and in the metal structure, the insulating material is attached to the brackets.

Covering and fastening facing panels is a simple process that does not require special skills. With proper and accurate installation of construction and additional elements of the work on siding will not take a long period of time.

It is necessary to perform the following stages of installation:

- determination of the lower level of attachment using a tensioned cord;

- installation of the starting profile with special screws, which are installed in the center of the special holes;

- installation of external and internal angle profiles in planned locations;

- fastening facing profiles overlap; the distance between the screws should not be more than 20 mm;

- framing window and door openings with additional elements;

- installation of a finishing profile before fastening the last panel;

- trim panels last row.

Manufacturers

On the shelves of building stores you can find siding with imitation of logs from different manufacturers. Choosing the right facing material, you should carefully review the reviews of companies engaged in the production of this product, and consult with the sales department of construction departments. The most popular is siding with imitation of logs from the domestic company Alta Profile.

The products of this company have the following undeniable advantages:

- high quality products;

- affordable prices;

- strict adherence to norms and quality standards;

- environmental safety panels;

- modern design;

- durability of products.

In second place in popularity is the Russian company Fineber. The demand for the products of this brand is constantly increasing and allows the company to occupy a leading position in the sales rating of this group of products.

Experts identify the following advantages of Fineber products:

- resistance to climatic conditions of different regions;

- durability with full preservation of all properties and qualities;

- ease of installation;

- affordable price range;

- small weight of panels.

Domestic manufacturers of siding with imitation logs not only produce high-quality products that are popular with designers and builders, but also constantly expanding the range of products using new materials and modern production technologies.

Beautiful examples

In order to live in a beautiful house, it is not necessary to begin the construction of a new building. Enough to carefully examine the market of modern lining products and choose for themselves the necessary finishing material. Modern production technologies make it possible to produce high-quality finishing siding panels that meet European standards and standards, and experienced designers will help you choose the right facing material of the desired type and color range.

The house, trimmed with siding, will decorate the backyard.

The metal lining of the village house will not only decorate the living space, but also create a favorable microclimate inside the building.The combination of light and dark colors will increase the size of the dwelling and will favorably emphasize its shape.

Acrylic siding of rich gray color will give comfort and nobility to any room, and the brown roof and white windows will give you individuality and uniqueness.

A small country house, sheathed and decorated with white siding panels, will be the highlight of the backyard and help to hide from the summer heat and autumn rains.

Wooden siding on the walls of the dwelling will give the owners the opportunity to create an atmosphere of warmth and comfort in their home at any time of the year, and large white windows will fill the rooms with light and sunlight.

Overview of a beautiful house with imitation logs - in the next video.