Vetonit finishing putty: types and application

The trade brand "Weber" is one of the manufacturers of high-quality building mixtures. The high quality of their Vetonit brand products is guaranteed by full certification of the production process. In addition to other building materials, the company produces a finishing putty, designed to complete the alignment of the walls, eliminate small cracks and give the surface an aesthetic appearance.

Description and General Features

A choice of various options for finishing putty: plaster, cement, polymer, each of which is designed for specific purposes and operating conditions.

The characteristic features of Vetonit products include the following features:

- Putty made from natural ingredients.

- The structure easily lays down and is well drawn out on a surface.

- The powder nature of the mixture provides a smooth and level surface.

- It is easy to sand.

- Improves the soundproofing qualities of the finished surface.

- It has a small expense.

- The form of release is:

- dry mix;

- ready to paste.

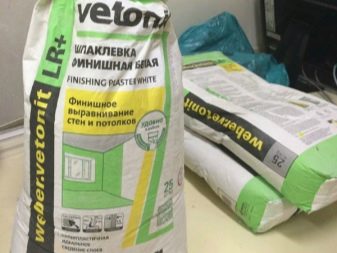

- It is realized in strong three-layer bags weighing 5 and 25 kg.

Kinds

Vetonit supplies the building materials market with the following finishing putty options:

- "B" - cement plaster with high moisture resistance.

- "BX" is suitable for facade work, having powerful waterproofing qualities.

- "JS" and "LR" - putty for finishing and superfinishing finishes with high strength and excellent appearance.

- "T", "KR" - types intended for rooms with low humidity.

- “LR Fayn”, “LR +” are used for places with low and normal humidity levels.

- "VH" and "KR" - lime plaster putty.

Vetonit LR +

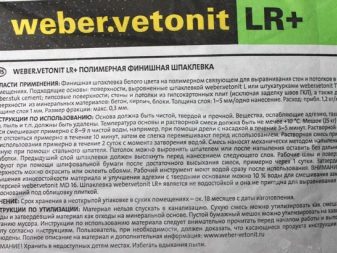

Finishing putty from white limestone of high quality, fine ground marble and polymer additives. It is used for clean, pre-leveled surfaces, before applying the coating should be degreased and cleaned from small debris.

The main features include:

- particle size up to 3 millimeters;

- the thickness of the applied layer is from 1 to 5 millimeters, a thicker layer is recommended to be used on small surfaces and thin with an increase in the treated web;

- the rate of complete drying at a temperature of 20 ° C is 24 hours;

- should be used in rooms with low humidity levels, otherwise the color will become yellow;

- putty consumption with a layer thickness of 1 mm - 1.2 kg / sq. m;

- the shelf life of the mixed solution is a day in an open container, 48 hours in a closed one;

- It is sold in bags weighing 5.25 kg;

- dry mixture can be stored for 1.5 years.

"Vetonit JS"

Putty mixture on polymer glue with finely ground marble, used for finishing and superfinishing putty for painting and sticking wallpaper.

Other features include:

- intended for:

- putty plasterboard and grouting;

- drawing on the surface which is earlier painted by any kind of paint.

- drying speed ranges from 3 to 24 hours;

- very durable structure reinforced with reinforcing microfibers;

- powerful adhesion;

- complete absence of cracks;

- magnificent appearance, ideally smooth and equal surface.

Vetonit LR

Polymer filler mix, specific differences are:

- use for wall and ceiling work;

- excellent compatibility with plastered and concrete surfaces;

- it is put with one layer;

- does not apply at high humidity;

- Sold in bags of 25 kg.

"Vetonit VH"

To the characteristic qualities of this facade finishing putty Such features include:

- The composition is used on concrete and brick surfaces.

- It can not be applied to the surface treated with lime and water-based.

- It is better to prepare the solution using a drill with a nozzle for mixing.

- It should stand for about 3 hours after preparation.

- Apply the mixture in two layers no thicker than 3 millimeters, each next is applied after the previous one dries.

- There is a high level of waterproofing.

"Vetonit KR"

Organic hard putty for the finishing stage is used in rooms with low humidity.

Other features include:

- used for walls and ceilings;

- great for drywall work before painting or wallpapering;

- average consumption at a layer of 1 mm - 1.2 / sq.m;

- not applicable for:

- floor decoration;

- on a tiled surface;

- eliminate seams and crevices.

Methods for applying putty

To achieve the desired result in the process of finishing work, you must follow the established procedure.

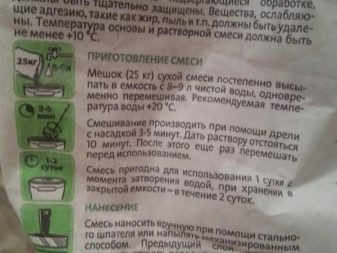

For proper mixing of the solution, do the following:

- The components of the putty solution are prepared from an approximate calculation - 1.2 kg / m2 with a layer thickness of 1 mm. On a bag weighing 25 kg consumes about 8 liters of water.

- The contents of the bag is laid out in water, the solution is stirred for about 10 minutes using an electric drill with a nozzle, manually the consistency will be worse. The mixture is settled on average for 20 minutes and then whipped again. The average time of availability of the mixed solution is about one day.

- For application apply narrow (30 cm) and wide (70 cm) spatulas.

- Putty mixture is applied in one or two layers. In the case of two-layer processing, the second layer is applied only to the completely dried first.

- For priming it is best to apply acrylic solution.

Putty walls

The procedure includes the following steps:

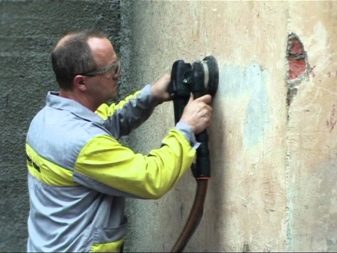

- Training. Before applying the putty work surface is cleaned from debris and old finishes.If there are minor defects on the surface, they must be removed with a starting putty or plaster and then sanded to approximately the same level. Next, the surface is degreased.

- Padding. In order for the mortar to stick to the wall, it must be treated with a primer.

- Application The solution is drawn smoothly from side to side. The thickness of the applied layer is determined by the specific type of putty, each subsequent layer is applied after the previous one dries. After hardening of the first layer, the surface can be ground and then cleaned of construction dust. The coating is re-primed, the final layer is further stretched.

- Finalized When the finish layer dries, the surface is polished, cleaned and primed, after which the wall is ready for further finishing work: wallpapering, painting.

Ceiling putty

The process has a specific algorithm:

- Training. The ceiling is cleaned from dirt and dust, the remnants of the previous finish are removed, the surface is ground and degreased.

- Padding. Like the wall, the ceiling is primed with a roller.

- Application Putty in small portions superimposed on a large spatula and pulled along the ceiling plane. In the end the surface is polished.

Subtleties of application

Surface. Before applying any finishing putty to the Vetonit, the working surface must be pre-leveled. Any defects must be smeared or ground, the finishing solution is not designed to eliminate them. All excess dirt, dust, old finishes, mold must be cleaned. After that, you need to carry out degreasing and primer.

For each brand of putty, it is necessary to carefully study the instructions, despite the external similarity, the thickness of the applied layer, the hardening time, the water temperature, the setting time and other properties of them are different. Please note that diluted putty in a closed container is stored twice as long.

Vetonit putty is designed for manual application., although it is possible to apply it with a spray. After hardening of the applied layer (24 hours), pay attention to those places where there were previously joints and seams. Irregularities are often formed in these areas. After finishing the filling work, it is better to immediately rinse the tools with water,after the solution hardens, it will be much more difficult.

When working, it is better to use protective equipment: glasses, a mask or a respirator. Although Vetonit spackling mixes, produced in Russia, are made from natural raw materials and do not have a toxic effect, the dust generated during work can mechanically damage health, for example, if it gets into your eyes or lungs. For the brands “KR” and “LR” it is better to use water at a temperature of about +10 C. If necessary, to obtain a particularly strong surface, use a special mesh.

To get a perfectly flat surface, for example, when the finishing putty layer should become the front part of the wall, use beacons. This will allow the mixture to be stretched more evenly and will reduce the amount of work on further leveling.

This putty mixture has only positive feedback. and is suitable even for complex reasons. If you decide to repair or other construction, then feel free to choose it.

In the next video, the professional shares the secrets and tips for applying and choosing putty.