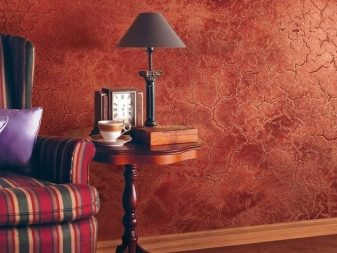

Finishing plaster: types and features of application

Painting walls and applying other coatings on them requires special preparation (leveling, elimination of defects). Often for this purpose used plaster composition. But finishing plaster deserves special consideration, it is she who completes the preparation for the final finish. In addition, sometimes such compositions can act as a final coating. In any case, the key features of the use of finishing plasters need to know, at least for confident control of the work of specialists.

Special features

Preparation of plastered surfaces for sticking various plates and wallpaper was initially the most time-consuming and very important step. But experience shows that, with due diligence, it is entirely possible to do all the work properly, without even turning to professionals. Finishing is a type of surface that allows you to:

- paint the walls;

- cover them with whitewash;

- use liquid wallpaper.

If you immediately start finishing on the ground and the bulk of the plaster, its shrinkage and a significant amount of grains will not allow to achieve a good result. This is not surprising; with the same success it would be possible to try to glue wallpaper to sandpaper with an average grain. The curvature and unevenness of the walls will always be found.

The final plaster creates an almost perfectly even background, especially when using paint rollers with a long nap.

other methods

In finishing plastering, it should be noted, there are alternatives. This application of multiple layers of primer on the least successful part of the coating. Also, cut manually protruding spots with sandpaper. This method helps if the adjustment was not made when leveling the main plaster layer. The problem is that even with careful execution of each operation, there may still be uneven shrinkage or lifting, there may be a deviation from the geometry. Therefore, the final plaster finish is required.

Composition

If it is possible to devote many hours (days) to the processing of walls, and there was an intention to try your creative talents, you can try to choose the finishing plaster mixture by yourself. It is selected by varying the proportions:

- sand from quartz rocks (well screened out and necessarily the smallest fraction);

- astringent Portland cement M400;

- PVA glue (it should be quite a bit).

But it is necessary to take into account that such combinations allow to get only smooth and as smooth surfaces as possible, mainly protruding lining for a more perfect finish. If the task is to achieve the original appearance, special fillers are used.

The effect of opalescence and marble drawing are formed due to the introduction of ground glass, calcite dust, and various pigments. When there is already a company that you can trust, you should buy finished or superfinishing compositions from it, as well as the necessary amount of primer on acrylic base. Such a step will surely be more reliable than spontaneous experiments. Even experienced home craftsmen can not achieve the same success as the trained technologists.

Composition

Finishing material can be applied on the dried and partially hardened mass of the main plaster. But before that, verification with the help of the rule is necessary. Yes, such a tool has been used in painting and finishing crafts for a very long time - and yet it is more reliable, more practical than everything that engineers created later. There is no need to use a marker to mark the areas causing these or other questions - there is enough of any pencil.

The largest hills are carefully removed not too sharp tools or sandpaper with an average grain; after such a manipulation, additional verification is required.

The edges of the deepest depressions and the most curved fragments of the wall are marked, then applied over the composition based on acrylic. A gross mistake is cutting a large part of the main plaster with spatula blades or steel rulers. Such advice is given by non-professional masters who follow the path of least resistance. The only result of such efforts is the ugly look of cracked material.

Work with certain types of mixtures

Finishing plaster for painting or for wallpaper is smeared on the walls with an even thin layer (0.2–0.5 cm), then it is additionally ironed with a trowel. If not smooth material is used, but “bark beetle”, they initially work with insignificant area (approximately 1 sq. M, with visual accuracy), on which the desired relief is achieved. The first tool in this case is the trowel. For the final shaping, it is advisable to take a grating construction of plastic. All such manipulations are done with their own hands easily and confidently, you just need to know the process and not be afraid.

If the task is to simulate the appearance of a fabric, natural stone, or some other material, there is nothing to think about completing the work in one go. It necessarily breaks into two complementary operations.

First, the mixture covers the wall, and using the tools creates a relief. After that, the coating is dried naturally without amplification with hair dryers and other devices for exactly 24 hours. Then they take up the second layer, which necessarily has a different color from the first.

When working with Venetian plaster can be from 2 to 4 working methods, this is determined by the exact type of the mixture and the target effects.First, the mass is distributed on the walls, and this should be done with short strokes, smoothly. As soon as 120 minutes have passed, you should stretch the composition and form its relief. Next, they work with the second layer, which is also pulled out to achieve a translucent base. When the required number of manipulations are done, the wall should dry for 24 hours.

A standard bag of "miners" with a neat application lasts for 20 m²; with regard to the weakness of the coating - the most important of them is associated with low viability after preparation. As a result, you will have to either do a little work, or form a large brigade. Finishing CU is a polymer mixture, a typical tare weight ranges from 3 to 20 kg, so it is easy to choose the optimal portion for solving a specific task.

As in the previous case, everything that has been prepared will have to either be immediately applied or thrown into a landfill. Cover 1 square. m. surface can be 500–2500 g of the mixture, the exact value is determined by the thickness of the layers.

It does not matter whether it is decided to replace the factory composition with homemade or not - the principles of operation remain unchanged.

Be sure to need spatulas of all sizes (for fine and coarse work), as well as a special spatula for handling angles.Mixing composition is a drill with a special nozzle, and check the geometry of the coating - building levels. It is impossible to do without unnecessary rags in the household (they erase the mixture that fell on the places that are not subject to finishing) and sandpaper (to correct errors). Important: if the walls are slightly moistened with water using the same rags before work, the adhesion will increase and the dustiness will be reduced.

When working with walls where drywall, concrete blocks are used, or with a brick foundation, applying the mixture from the bottom up is the most practical solution. It is recommended to keep the tool at a sharp angle to the wall plane and not tear it off. This approach ensures a smooth surface.

When the wall is completely dry, it is overwritten and form a texture. This work with factory or artisanal finish plaster can be considered finished.

In the video below, see the process of applying finishing plaster.