Mechanized plaster for walls: the pros and cons

Mechanized plaster for the walls appeared not so long ago, however, this type of repair work took a strong position, having proved itself from the best side. Before you start plastering, you need to familiarize yourself with how the work is done and whether it is rational to carry out such a delicate matter rationally.

What it is?

There is no such thing as mechanized plaster when it comes to dry mixtures for plastering. However, plaster mortars are universal, suitable for both manual and machine methods.

If we talk about mechanized plaster as a method of work, then a person tries to simplify his life as much as possible, and the construction industry is no exception.Machines in many areas have completely supplanted manual labor, and it is no wonder the desire to at least somehow make the hard work of plastering walls or ceilings easier. So the idea was born to build a mechanism that can perform the most unpleasant and time-consuming aspects of plastering work.

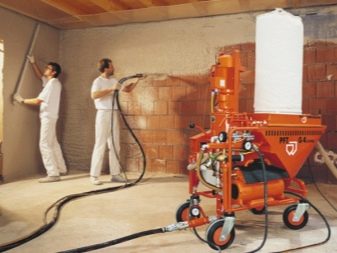

Mechanized plaster is the same process for plastering walls, but using special machines., allowing you to do all the work much faster and easier. Thus, the application of plaster by machine method takes 5-6 times less time than manual, while the quality of work is a level higher.

Plastering with the help of special equipment requires not only the availability of this equipment itself, but also special knowledge and skills. For a person unprepared for this, it is better not to undertake, since the probability that everything will work out the first time is extremely small.

Ideally, a team of professionals should be engaged in automated plastering, since it is impossible to cope with a plastering machine alone.

Special features

In total, two types of plaster compositions are used for application by the automatic method:

- on the basis of gypsum;

- cement-sand mixture.

Depending on the type of composition varies and a set of features, pros and cons. So, gypsum plaster is more in demand in the modern market. Many are attracted by its aesthetic side - a pleasant white color after drying.

However, the advantage of the composition is not limited to external properties alone:

- Since gypsum acts as the main element in such plasters, they can be safely attributed to environmentally friendly materials, since gypsum has a completely natural origin.

- Gypsum plaster layer weighs very little, which greatly relieves the load on the surface.

- After drying, the plaster mix does not shrink, is not deformed. This logically leads to the fact that cracks do not appear on the walls: the surface remains smooth and neat.

- Another important factor is the high porosity of the material. So, when wet, water evaporates quickly from the surface, and wetting itself does not lead to the development of mold fungi.

- Both the heat and sound insulating qualities of the plaster plaster layer are important.It hides the sounds passing through the wall from the adjacent rooms, thereby increasing the overall noise insulation background of an apartment or house.

- Gypsum helps regulate the indoor climate by absorbing moisture from the air.

- Gypsum plaster treatment is indicated in cases where the risk of fire has to be reduced, since the material is not so easily ignited.

The disadvantages can be attributed to the high cost of materials compared with sand-cement mortars, but it is worth considering that the consumption of gypsum plaster is less. And also to use the gypsum option in conditions of high humidity is not the best idea: the plaster can peel off.

As for cement-based plaster compositions, they also have their pros and cons. First you need to focus on the positive aspects:

- As for strength, the cement option is the best choice. It is reliable, allowing less frequent repairs with the reconstruction of the plaster layer.

- Cement-based plaster adheres well to the surface. No need to specially prepare the base for plaster, to take any special measures.She will still stick to him well and become whole.

- Cement solutions tolerate high humidity, so they can be used to decorate rooms such as a bathroom, for example. But also thanks to this property they can be applied outside the house.

- Finally, compared to gypsum, cement mixtures are not so expensive because of the cheapness of the materials that make up their composition.

The disadvantages of cement-sand plasters are many:

- they can not be applied to each material. They are not "friends" with plastic and wood, painted surfaces are also a bad option.

- since the material weighs quite a lot, they first verify whether the wall will sustain the mass of such a plastering layer. For this you need to perform special calculations.

- after applying the plaster, it is imperative to perform works on spatula and leveling the surface.

- To the shortcomings applies a long drying period of the solution, which is about a month.

In general, mixtures for mechanized application of any of the types have no particular differences. Fraction can be any. The car is pre-set up for a particular solution or mixture.

The specifics of the method

Like every type of construction work, mechanical plaster of the walls has its pros and cons. Starting to consider specific features is best with the advantages of the method:

- Automatic application of plaster differs from manual overlay in how much material the material will have. Thus, about 13 kg is applied mechanically per 1 m2, and 16 kg is applied manually. If we consider that you need to impose at least three layers, the difference will be significant.

- All processes are greatly simplified. Now you do not need to engage in mixing the solution, constantly prepare new portions. Human labor is almost replaced by machine labor.

- Due to the fact that the mixing is performed in a constant mode, and even water is supplied automatically, the solution is homogeneous. This ensures that it will not crack and warp over time.

- Applying plaster using the machine is much faster. Thanks to it plaster dries evenly. There is no “Dalmatian” effect: it has dried up here, it has grabbed, but here it is still quite damp. Because of this, there are no joints, and the layer of plaster turns monolithic.

- In some works that are usually carried out after plastering, there is no need. These include, for example, putty.

Since the walls and so are ideally smooth, they do not need to putty.

In addition to the above, there is a hardware method and several disadvantages:

- Affects the high cost of equipment. For independent use its acquisition is irrational, as well as rent. At the cost of hiring a team of workers working on this technology, will cost the same amount.

- To work with the machine you need two people, as well as another one who will level the wall.

If you still decide to do the mechanical plastering yourself, you still can not cope.

Types of jobs

Mechanized plaster is used everywhere. There is no one sphere to which this technology would be limited. The only limitation is temperature. Do not carry out work outside in winter. The surface should not be colder than 20 degrees. And this requirement is due rather to the specificity of the solutions used, and not by the hardware method itself.

The mechanical method of plastering is successfully used for both exterior and interior work. The only thing worth remembering is which of the mixes and where to use.If during the internal work both compositions are permissible, then only cement will be suitable for facing, since it only has the necessary set of characteristic qualities. It is worth examining each of the areas in more detail in order to better understand the specifics of the work of mechanized plaster in certain conditions.

Internal work

As mentioned above, both types of plaster are suitable for interior work. It is logical that the best solution is a gypsum-based solution, due to its positive properties, as well as the fact that it is easier to work with it. Fewer coats will be required.

Both a plus and a minus at the same time consist in the fact that gypsum dries very quickly, so working with it requires speed. It will be necessary to wash the equipment immediately after applying the layer, otherwise it will be practically impossible to wipe the plaster plaster from the machine.

Before applying the plaster mixture in a mechanized way, all the same preparation as for the manual one is required. Walls will need to be primed or moistened with water. Only after that you can proceed directly to the splashing of the plaster composition.

When working with cement-sand plaster, it may be necessary to first apply the mounting grid to keep the plaster layer. Especially it concerns the bases with almost zero adhesion, for example, monolithic concrete.

Facing

Work on the street should be done only at above zero temperature. This is due not only to the fact that the surface should be prepared, but also comfort. Anyway, mechanical plastering is hard physical labor, and workers applying and leveling should feel comfortable.

Only cement plaster is suitable for cladding. Working with it requires preliminary debugging of the machine. It is important to note that there are fragments of a large fraction, so all settings should be set according to the data specified by the manufacturer on the package. This is especially true of decorative options, for example, bark beetle plaster.

In addition to what works which of the compositions is used, it is important to know in which forms they are sold. Both ready and dry plasters are available.

With the help of special equipment, it is possible to work with both.

Dry Mixing

The beauty of the mechanized method lies in the fact that it allows you to completely abandon manual labor in relation to the dilution and application of the mixture. Before you start working with a dry mixture, it is important to ensure machine access to running water and the electrical network. For its power is enough voltage of 220 watts.

Works are performed as follows: A dry mixture is added to a specially provided container, then the machine independently mixes the solution in accordance with the specified parameters. Thus, the plaster is kneaded constantly, and the solution is uniform, airy, of the same consistency.

This method of work is recognized as more preferable, since it is cheaper, but the quality of the solution is no worse than with the purchase of the finished one.

Walls treated in this way have a flat surface suitable for painting or wallpaper even without further processing.

Processing ready solutions

Unlike the previous method, in this case, the work is performed using a liquid solution. Here it will be necessary to take care only about the connection to the mains.Water supply is not needed here. The solution will constantly knead, so it does not grab ahead of time.

Both methods are suitable for work not only with walls, but also with floors. For example, using a mechanized method, you can make a semi-dry or wet floor screed, as well as plaster ceilings. Specificity of the solution supply allows it.

Preparation of the walls will have to be done manually:

- make staking;

- install beacons.

Plaster mechanically allows only to apply the composition, but not to align the walls.

In general, much less time will be spent on leveling the walls, since the most time-consuming process — application — is automated.

Necessary equipment and tools

For plastering mechanically, you will need not only plaster mixture, but also special tools and equipment. The simplest thing you can do is to contact specialists who have special machines available for sprinkling plaster. They will carry out all the work quickly and practically without garbage. What is remarkable, usually this option is cheaper.

If you or your friends have any tools for applying plaster mechanically, and they are ready to lend them to you for free, it will be easier for you to do all the work yourself. However, it should be borne in mind that this will require some knowledge of the selected tool: an understanding of the specifics of his work, his device, as well as the difficulties that may be associated with plastering when using the unit.

Plastering machines and stations

If you have someone to borrow a plastering machine, you can consider yourself lucky. Renting such a device will cost a lot of money, and it may take some time to adapt to a new method of application, and not all the work can be done correctly. However, plastering using this method is most preferable, because the plaster station provides an even monolithic layer, and the walls are almost flawless.

Machines are of two types - screw and pneumatic. In the first case, the supply solution is fully automated. The finished mixture passes through a pipe under high pressure and is fed into the sprayer.In the second case, the work is done with the ready solution, which is supplied to the sprayer under pressure. The machine itself cannot knead the solution.

Pneumolopata-hopper

Pnevmolopata-hopper - the easiest of the available tools and the cheapest. In fact, the plastering itself is not carried out here - the material is simply pounced on the surface with the help of this unit, and all further work must be done manually. However, pnevmolopaty have positive features: for example, the ability to work with materials of different fractions and different hardness.

Working with the device does not require special knowledge. The handle-conductor is connected to the compressor, after which the solution is collected in the ladle. Directing it to the wall, you just need to spray. Labor productivity is approximately 60 square meters. m per hour of work.

There are pnevmolopaty-hoppers for both walls and ceiling. The difference lies in the shape of the buckets used.

Pneumatic pistol

A pneumatic pistol is probably the most inconvenient of all mechanical plastering devices. It is a unit, indeed, like a gun, on top of which is attached a large container for the solution.This is the reason for the difficulties in the work: it is very difficult to hold such weight constantly on outstretched hands.

As in the previous case, a compressor hose is attached to the pistol grip, which helps to deliver the solution under high pressure. The use of a pistol air pistol is possible only when processing walls. There is no such mechanism for ceilings.

In addition to the above, there are even less common and not found their fans tools for mechanized plastering. These include a plastering robot, for example.

Famous manufacturers and reviews

Many companies are engaged in the production of plaster mixtures and ready-to-apply solutions. Sadly, not all of them produce quality products. Both gypsum and cement-sand plasters are represented in a wide variety, but only a few firms, especially in the Russian Federation, have gained the reputation of trustworthy manufacturers.

Specialized plasters designed exclusively for machines, notherefore, it makes sense to consider the best quality plaster in general.Below is a list of companies that produce both gypsum and cement-sand mixtures. Some of them still indicate on the packaging that the product is suitable for machine use, but in fact it is universal. The only possible difference may be in the addition of various additives and plasticizers, which accelerate the setting and drying time.

This means that without due experience in the shortest possible time it is almost impossible to apply such plaster correctly.

"Miners"

The company "Miners" has focused on the production and sale of dry mixtures for mechanized application. The company believes that one of the most important properties of mechanized plaster is not to spoil the device. So, the solution should be well washed out, not clogged in the key parts of the equipment.

As for diversity, not only gypsum and cement plasters are offered here, but also specialized cement-sand mixtures.developed taking into account specifics of front works. Additives are added to the compositions, which do not allow the plasters to “grasp” for 30 minutes, and also make them more plastic.

In addition to wall samples, the company "Miners" produces options for floors, which are also intended for mechanized use. There are compositions that can be applied in different layers: 30-80 mm for screed, 5-30 mm for alignment and 5-80 mm - a combined version.

"Founds"

Unlike the previous company, Osonit did not take the liberty to declare its plaster mixtures as specialized, focused only on machine work. Only universal dry plasters are produced, suitable for both manual and machine labor.

The "trick" of this manufacturer is that it offers a separate plaster mixture for each layer. So, there is a plaster for spray - pre-seal all the cracks and dents on the base, thin-layer version and facade. Plaster samples are available in various colors. There are both gray and white. Among other things, the emphasis is on eliminating the shortcomings of plastering materials. In particular, a lightweight cement variant is proposed.

All products for mechanized work are suitable for different reasons, some do not require subsequent filing.

Volma

Volma was one of the first companies in Russia to start producing plasters and other materials suitable for machine spraying. To date, the range of the company is quite impressive. There are plasters that are suitable for applying on the string, there is for applying on the beacons, and there are some that are perfect for working in the same way.

Like the others, the company offers both cement and plaster dry plaster mixes with a longer setting time. Here it can be up to 60 minutes versus 30 minutes from other manufacturers. It is important to note that the plaster materials of this manufacturer are suitable for application by machine and on the surface of walls and ceilings. There are plasters of various fractional sizes, but the maximum particle size usually does not exceed 1.25 mm.

The company declares that the full cycle of work with its materials is not more than 2 days.

Knauf

This German company was one of the founders of the machine application of various building mixtures as such. She didn’t stop at the production of plasters, offering machine filling to the attention of consumers.The MP and IL rulers are positioned as intended for use exclusively by machines, and the company recommends choosing their own devices - PFT.

Plaster mixes differ from each other in the degree of adhesion to the basesHowever, the manufacturer guarantees good adhesion even with an unprepared surface. You can plaster different surfaces: brick, concrete, gas and concrete blocks, wood and wooden plates. Information about what plaster for what is intended is available on the packaging.

Having touched upon the topic of manufacturers, about which the best reviews were given, it is impossible not to mention the plastering machines themselves. The best equipment comes from Germany, but there is also a good Russian company.

Knauf (Germany)

The company supplies equipment under the trade name PFT. Plastering machines have small dimensions, but this does not affect their power. In particular, the power of the equipment is also different, feeding the constantly kneaded solution under high pressure. This allows plaster to be applied in hard-to-reach places, for example, those slightly higher than human height.

Machines have a structure that completely eliminates the formation of dust.therefore, all works will be performed with minimal losses and with the minimum required cleaning in the future. The supply can be carried out at a distance of up to 150 m. The units are usually controlled by two: the operator who monitors the machine’s condition and puts a dry mixture, and the one who directly applies the plaster on the walls.

Machines on wheels, which facilitates their movement around the room when processing large areas.

Putzmeister (Germany)

This manufacturer does not represent ordinary plastering machines, but entire stations of small size. Each of them can be configured to work with compositions of different fractions up to 3 mm. To date, two models are presented: Putzmeister MP 25 and Putzmeister MP 15.

Putzmeister MP 25 - a model known for a long time. It can often be found in teams that professionally deal with plaster spraying in a mechanized way. To work with such a station will require special training, as the management of it is not easy. Suitable for work both outdoors and indoors.

Putzmeister MP 15 - A new car, which appeared not so long ago.It differs from its predecessor in size and power. Thus, this option is somewhat more compact and, moreover, it can work with large-fractioned plasters (up to 3 mm). Managing the device is easier than Putzmeister MP 25.

The price still “bites”, so you should not buy such equipment for private use.

M-Tec (Germany)

The advantage of the machines from this manufacturer is their intuitive control. There will not have to acquire any special knowledge or skills in order to handle the equipment. The only thing that needs to be done is to adjust to applying plaster with a spray under great pressure.

At all, M-Tec equipment is positioned as suitable for start-up companies., whose employees do not yet own all the techniques of machine plaster. The functionality of the samples can be called limited, but all the necessary operations can be performed. Compared with the rest of the samples, prices are rather low - about 400,000 rubles for a plaster station. Again, the team and the self-purchase of plaster materials will cost much less.

Finally, the last of the most good judging by the reviews of samples - the car from Russia.

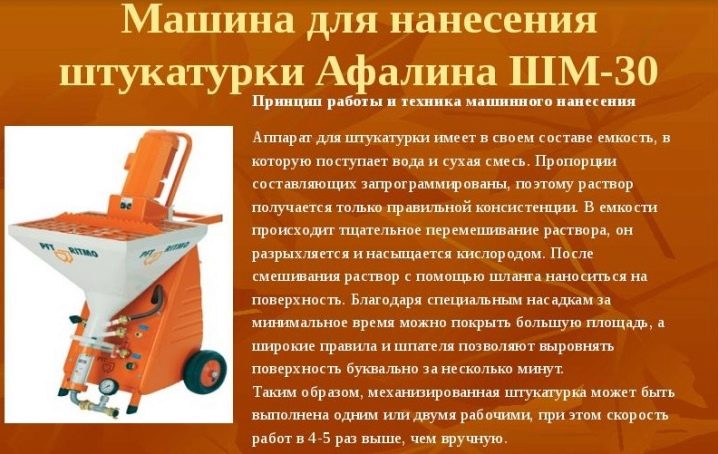

Afalina (Russia)

Station "Afalina" are universal. They are designed not only for plastering walls, but also for pouring floors, as well as the treatment of ceilings. Functionality and power are on the same level as foreign analogues, but there is one important difference - size. So, Afalina cars are much larger. This causes some difficulties when working with it: it needs more people to maintain it.

Due to the fact that the machine is more labor-intensive in service and work, and at the price it is not much inferior to foreign models, hiring a brigade working on such equipment is usually more expensive than paying for the services of a company with foreign stations in stock. Therefore, this sample is not very popular, and you can meet it quite rarely.

But the quality of mechanized plaster, made with the help of this unit, does not suffer.

Ways and technology of drawing

When working with a special plastering machine, you need to follow a certain sequence of actions.

- To start the walls need to be cleaned. Experts advise using a special metal brush.

- Next, the base must be wet.This is done with a primer or plain water.

- Then proceed to the preparation of the equipment: connect it in accordance with the instructions, set up under the existing plaster composition.

- Now you can go directly to the application itself. The classic way is to apply the composition from top to bottom in strips, when each new strip is applied so as to half cover the previous one.

- If possible, a bottom up method can be used. The overlapping bands should be the same.

- After setting the mortar, it is necessary to smooth it out with a construction mesh grater.

- When the solution is completely dry (the freezing time is indicated on the package), you can proceed to the subsequent finishing: for example, putty the walls or paint.

Tips

Experts give some advice on the choice and use of mechanical plaster.

- Pay attention to the uniformity of the composition. It should not be lumps.

- In no case do not buy plaster in order to perform mechanized application, if it is designed exclusively for manual work.

- All work must be carried out at a temperature of from +5 to +30 degrees, otherwise the mixture will change its technical characteristics.

You can visually get acquainted with the process of mechanized plaster in the video below.