Cement-sand plaster: properties and scope of application

Alignment of the walls is an important procedure that must be carried out for a successful repair. To ensure that this process is carried out most conveniently and efficiently, users choose cement-sand plaster. Despite the fact that this composition has already become a classic tool for leveling surfaces, it is necessary to know in advance all the nuances of using this mixture and its characteristics.

It is especially important to familiarize yourself with this information to users who do not have much experience in carrying out repairs.

What it is?

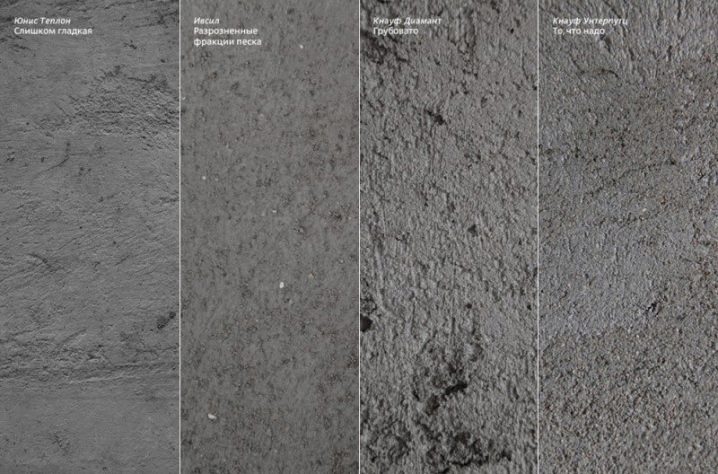

Cement-sand plaster, as the name implies, is a two-component mixture. The first component is sand, the size and purity of which greatly affect the leveling results. The grains of sand should not be too small; the presence in the plaster mixture of impurities in the form of clay and other elements, leading to cracking of the composition after its drying, is also unacceptable.

The sand component is of several types:

- river: sand grains have a size of 0.05 cm;

- career: sometimes fractions reach 2 mm;

- sand for brickwork: granule size - 2.5 mm;

- sand for work with reinforced concrete structures: the grain size reaches 5 mm.

The cement component may have different strengths. Some formulations are used for exterior applications, and some are used only for interior applications. You can also highlight a special type of cement in the composition of the plaster mix - cement with mineral filler. This mixture has a lighter structure and has a lower thermal conductivity.

Another component in the composition of the cement-sand mortar is water, due to which the bond between the sand and cement molecules is carried out.

In the process of repair often plasticizing elements are often added to the compositionwhich improve the adhesion of the plaster to the surface.

Like any building material, cement-sand plaster has its own technical characteristics:

- Thermal conductivity. Compared with other compounds, cement-sand plaster mixture has a high thermal conductivity.Usually this indicator is equal to 0.9 W (m * K).

- Drying period. This indicator is largely determined by such factors as the thickness of the applied layer and the temperature at which the surface is flattened. The most versatile is the two-centimeter layer applied at a temperature of 15 to 20 degrees Celsius. In this case, the coating is completely dry in 12-14 hours. If you make a thicker layer, then, respectively, increases the drying time of the solution. Sometimes it can reach days.

- Density - a very important indicator. It is the density coefficient that determines the strength of the composition. Plastering solutions are considered quite heavy. The density of the cement-sand mixture in the frozen state can be from 1600 to 1800 kg / m³.

- To prevent condensation on the walls, it is necessary to choose a leveling compound with good vapor permeability. For cement mortar with sand, the optimal value is 0.09 mg / mchPa.

Accounting for all characteristics helps to thoroughly calculate the required amount of materials and to foresee the influence of the conditions in which the process of leveling the surface will be carried out with plaster.

Features and benefits

Technical signs explain a number of features inherent in cement-sand plaster:

- It is recommended to use such plaster mix only in a certain temperature range: from 5 to 30 degrees Celsius. Going beyond these limits will result in poor-quality alignment and crackling of the material. If the plastering process is carried out at sub-zero temperatures, you can purchase special additives that make the mixture resistant to frost.

- To strengthen the cement-sand layer, it is necessary to use fiberglass.

- Among products for plastering with the addition of sand there are options with different strengths. The strength index directly depends on the grade that determines the binding component. Remember that strength becomes final after four weeks from the date of application.

- It is important to know that after the preparation of cement-sand plaster mortar, the time of its use is limited: this solution can withstand no more than half an hour. In this regard, it is recommended to dilute it in small portions.

- It is important to clearly follow the instructions when diluting the composition, since deviations can significantly affect the functionality of the leveling coating.

The main advantages of the material include the following qualities:

- resistance to stress;

- wear resistance;

- good adhesion with the treated surface;

- resistance to weathering;

- elasticity;

- ease of manufacture.

But, like any building material, cement-sand plaster is not without flaws:

- To the composition acquired the necessary in specific conditions of quality, it is necessary to buy additional additives.

- When the repair is done thorough, the purchase of cement-sand leveling mixture can be quite expensive, especially if you prefer the most famous companies.

- A large layer of similar plaster on the walls creates an additional load on the foundation.

- The need to quickly use the solution explains the additional consumption of material. For reasons of various circumstances, it is not always possible to apply the coating in half an hour, therefore, the surplus has time to become unusable. Because of this nuance for repair, the plaster is bought with a reserve for such cases. When the solution dries, you can dilute it with water, but you will need to apply such a mixture even faster,as the re-solidification process is accelerated.

- For many users, the negative quality is the drying time of the mixture.

Knowing all the advantages and disadvantages of the material, the process of leveling the surface can be carried out most productively.

Kinds

The introduction of new technologies in the creation of building and finishing materials allows us to subdivide the cement-sand plaster into several types:

- Simple compositiondesigned for interior walls. The walls are covered with mortar in two stages: spray and primer. Most often, the composition is used to seal irregularities and cracks in the walls, sometimes it is used for hygienic surface treatment. When applying simple plaster there is no need to put construction beacons on the walls.

- Improved composition Suitable for both indoor and outdoor use. In addition to spray and soil, as in the previous version, the stage of covering is involved in working with this mixture.

- High quality composition It is a universal blend used for leveling the surfaces of external facades and walls indoors with unevenness of almost any complexity.Such a mixture is applied in several layers, the minimum number of which is 5. For a successful result, more work stages need to be carried out: several layers of soil should be applied, and after applying the covering, it is recommended to iron it using cement.

Depending on the complexity and quality of the composition, the time it takes to level the walls also changes. But remember that the result always justifies the hours spent.

Spheres of use

Cement-sand plaster mix is used in many areas related to repair and decoration.

The most popular are the following:

- with the help of similar compositions facade finishing is carried out;

- cement-sand mortar is used to seal up potholes, irregularities and other errors of various surfaces;

- the mixture is popular for decoration of rooms in which there is no heating or there is an increased level of humidity;

- due to the presence of sand and cement in the composition, this type of plaster is suitable for leveling large defects;

- Sometimes a similar solution is used in the preparation of walls for laying tiles.

Consumption

Before you perform plastering work, you should calculate the consumption of cement-sand composition. This is important in order not to be mistaken in the amount of material required. To do this, take into account the fixed flow rates.

When laying a layer with a thickness of 1 centimeter per 1m², it will be necessary to use 17 kg of cement-sand plaster. If you mix the composition yourself, you need to calculate the right amount of sand, water and cement to cover one square meter.

If you take cement and sand in proportions of 1 to 4, given that for one kilogram of dry mix you need from 0.15 to 0.17 l of water, then you need the following amount of materials:

- 11.7 kg of sand;

- 2.4 liters of water;

- 2.9 kg of cement.

In the case of buying ready-made mixture, be sure to see the recommended proportions on the package. Often, manufacturers indicate consumption for layers of different thickness, which greatly facilitates repair work.

Universal cement-plaster mixture is usually sold in bags weighing 25 - 30 kg, which must also be taken into account when calculating the total amount of material required.

Manufacturers

It is important to decide in advance with the manufacturer of plaster. On the construction market are products of many companies.

Consider the unconditional leaders who have successfully established themselves among consumers.

- Cement sand Knauf mix differs in long service life and resistance to various influences. Most often, the products of this brand are used for finishing the external facades. But the company took care of various users and created a rich assortment of plaster mixes for any type of work.

- Ceresit products It stands out for its resistance to mechanical stress and excellent vapor permeability. This mixture perfectly tolerates temperature extremes. In addition to the main purpose - leveling, the plaster of this company is also used to create a decorative coating. But in terms of price, this mixture is one of the most expensive.

- Brand Vetonit ideal for those plastering walls at low temperatures.

- Among domestic manufacturers in demand products brand "miners". The company produces various versions of formulations created for both manual and machine-type application. Dry mix includes the components improving its main functions, for example, it can be an easy filler or special additives of high quality.

- For those users who need increased strength of the plaster coating, suitable Volma products. Its feature is in the presence of reinforcing fibers.

If you take into account all the nuances of the use and purchase of cement-sand plaster, it will help you to effectively carry out repair work and prepare the surface of the walls for further finishing.

For how to plaster the walls, see the following video.