How to calculate the consumption of gypsum plaster per 1 m2 wall?

The stage of plaster during construction is not only inevitable, but basic and important if you want to give the room a decent look. One of the most commonly used mixtures is gypsum plaster. How to correctly calculate the consumption of gypsum mix per 1 m2 of the wall in order not to overpay for the material purchased with excess material, we will analyze in detail below.

What is plaster for?

When applying plaster material, the wall surface is leveled, small and not very small gaps are filled, the walls are protected from subsequent exposure to moisture. In some cases, the plaster performs a decorative function, as in a loft-style design, or prepares a wall surface for paint application. In each case, the question of the norm and calculation of plaster material per square meter of surface is acute.

Methods for calculating the flow rate of the mixture

Due to the relevance of this issue, a lot of gypsum, cement and many other plaster mixes have appeared on the vast Internet space. All calculations are carried out fairly quickly online. As a rule, you need to enter the name of the manufacturer, the area of the treated surface and the layer thickness (most often entered in mm). For example, if you take the plastering of the “Prospectors” plaster and add “a layer of the applied mixture” to the column - 10 mm, the calculator will give us the figure of 9.5 kg of the dry mixture.

Calculation of plaster can be done yourself. First of all, it begins with the fact that the thickness of the applied mixture is precisely determined. At a thickness of 2 cm or any other small thickness of the applied layer, a well-cleaned and level surface will be required. You can check this with the help of special beacons.

Then on the wall there are several points on which the deviation will be recorded. Each value of the deviation at these points is summed with the others and is divided by the number of all measurements. Next, apply the formula for calculating the consumption of material. She looks like this: mixture consumption (on the label) x estimated application layer (in cm) x surface dimensions (in square meters).

To clarify, give an example. Imagine that a 15 square meter treatment is required with a layer of plaster 6 cm thick.

- The arithmetic average of the applied layer should be 36 mm. The calculation of this number is carried out from the values where the thinnest layer is 1.5 cm, and the thickest one is 6 cm.

- Next, we look at the label, which indicates the so-called specific or average mixture consumption per 1 square meter of 1 cm. For example, for a mixture of “Volma” it is 8.5 kg.

- Then the mixture consumption per 1 square meter will be 8.5 kg x 3.6 cm = 30.6 kg.

- Since we need to calculate the volume per 15 square meters, then 30.6 kg x 15 = 459 kg.

- If you buy the mixture in bags of 30 kg, then 459: 30 = 15.3 pieces. In this case, it is better to buy 16 bags of 30 kg.

Gypsum plaster and its features

Gypsum mixtures are often preferable to cement, they better adhere to the surface of the walls and can create a flat surface, which is not always possible to achieve with cement composition. It is the gypsum ones that are used for final finishing, since after drying the surface is ready for applying paint or other decorating elements. One of the advantages of the gypsum composition is that it perfectly maintains normal humidity and microclimate. At high humidity, it absorbs moisture, and when the air is too dry, on the contrary, it gives up.

It must be said that few people plaster the plaster mix on their own, most often this is done by repair masters or specially hired brigades, because the application and leveling process requires experience. Without skill and skills will not be able to make a completely flat surface. In such conditions, an accurate calculation of material consumption becomes more popular and prevents possible financial misunderstandings.

In addition to accurate calculations, there are more generalizing parameters, but no less important, which should be guided by when purchasing a mixture.

- Manufacturing firm. It is best to opt for the products of a famous brand. But if you need to process large surfaces, then you need to look at the label material consumption per 1 square meter. In such cases, the smaller it is, the better. On the other hand, if you are targeting the ideal surface for years to come, then Western brands will suit you more.

- Work area In addition to the obviously greater expense for a larger area, in this case the financial issue remains important.

If you are limited in finances, then you can purchase products with average consumer estimates, but with less consumption per square meter.

- Surface to be treated. No one doubts that a varying amount of mixture and elapsed time will be spent on the plaster of the brickwork and the cement block. Most of the thickness of the applied mixture should be at the wooden surface, a little less at the brick and may be very small at the concrete.

- Curvature. According to the norms, the curvature of the walls can be no more than 1 mm vertically and less than 3 mm horizontally. From this we conclude that when applying the mixture and its subsequent drying, the curvature of the walls should remain within this framework. Simply put, the more irregular the wall, the more material is required for its processing and alignment. The more sloping walls, cracks, mounds, the more mixture is required.

When processing especially uneven surfaces, the proper fixing of the walls will help to calculate the proper thickness.

Wall fixing

This stage is used to level the walls, without which the application of gypsum plaster does not make sense. Before starting to fix the walls, it is necessary to carry out preparatory work before plastering.

- Completely remove previous coatings: paint, wallpaper, decorative panels.

- Remove excess mortar between the seams of the masonry if primary repairs are made to the surfaces of the new walls.

- Grinding. It is better to abandon the machine procedure and do it manually. It is necessary to try as much as possible to align the bumps and slopes.

- Check the surface for crumbling parts and try to remove them.

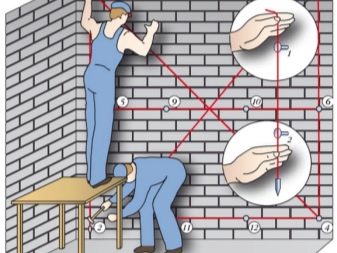

Now the stage itself of the walling is being made. The whole wall is divided into several squares, two horizontal lines are drawn. At the junctions of these lines are placed beacons with a level that will indicate the required thickness.

Next, you need to measure the height of each beacon, sum up all the values and calculate the arithmetic average. This was discussed in more detail in the previous paragraph. As a result of all these marks and calculations, we get the height of the required application layer, which is marked on each beacon. In this process of hanging walls can be considered complete.

It is necessary to bear in mind that the calculations of one wall will only suit her. For the four walls of one room, you will need to carry out the step of hanging 4 times for each of the walls.

Features of the use of plasters of various companies

Different manufacturers have different material consumption per square meter, which is indicated on the label of each product. In general, this difference is small, but when processing large surfaces it becomes more significant. In the domestic market there are several popular manufacturers, below is the consumption of each mixture per unit area:

- low consumption per square meter of Perfekta products, 8 kg at a thickness of 1 cm;

- for Volma plaster consumption will be 8.5 kg;

- Agat products declare that their consumption will be 8-9 kg per square meter;

- Unis mixes will require a little more per square meter. meter - from 8.5 kg to 9 kg;

- Ivsil, a domestic plaster manufacturer, claims to need 9-11 kg per unit area;

- consumption of Western brand Rotband will be 10 kg at a layer of application of 1 cm;

- another Russian manufacturer Bergauf, whose products will require consumption of 11 to 13 kg with a layer thickness of 1 cm per 1 square meter.

Separately, it is worth noting the production of "Bark-beetle", which is a structural mixture, its consumption is only 3 kg per square meter. But it is used only if you want to achieve a special design.

Here are examples of the consumption of gypsum plaster per 1 square meter with an application thickness of 1 cm.

Important nuances

When mixing the plaster mix, one should remember that the drying time is very short, about 20 minutes, during which time it is necessary to have time to apply it. That is why a small bucket is used for kneading such compositions, which is not completely filled with the composition.

For decorative mixtures, the setting period is even shorter.

When buying a material, you should always focus on a larger quantity, since the consumption will be more than what has been calculated. The mixture remains on the application tools, in the container, may become unusable during the application, due to which it will have to be kneaded again. Usually, it is best to additionally purchase another 5-10% of the calculated volume. Consumption will increase if there are many cracks in the wall.

Putting plaster plaster is not easy, so it is recommended if you make calculations of expenses yourself, then hire a professional repair team to work.

On the Knauf Rotband plaster and the features of its consumption, see the next video.