Plaster Rotband: the pros and cons

Practically every home craftsman or beginner plasterer, not to mention the repair pro, is well acquainted with the universal plaster plaster Knauf Rotband, which for a long time remains one of the leaders in the construction market. Popular leveling agent can be described as a strong, highly reliable coating that does not fail, which is confirmed by many years of experience and customers of repairs of various categories.

The use of plaster Rotband allows you to perform high-quality and durable interior decoration of objects for various purposes - multifunctional residential complexes, apartments, private houses and offices.

Special features

The production policy of the German brand Knauf is based on the principles of a systematic, integrated approach, thanks to which products appear that can solve any tasks arising in the process of repair and finishing works.All Knauf products, which quality is recognized and appreciated by the global user community, are famous for this.

In the production of plaster mixes Rotband used the latest innovative developments, modern equipment and high-quality raw materials.

Traditionally, Knauf leveling compounds are made with a plaster binder base, the addition of modified polymer additives that increase the adhesive properties of the mixture, as well as reduce the intensity of the setting of the working solution and fillers in the form of chalk, limestone or quartz and expanded clay sand.

The new Knauf family is the main approach of the company, which has a number of advantages. The main plus is the perfect compatibility of building materials with each other. In addition, they can not only complement each other, but, if necessary, interchange with each other. Today, the new Rotband Knauf family is represented by four products such as:

- primer composition Knauf Rotband - primer under the plaster mix;

- Knauf Rotband universal gypsum plaster;

- thin-layer leveling compounds are Knauf Rotband Finish and Knauf Rotband Pasta Profi putties, which are used to finish surface preparation for decorative finishes.

Experienced builders recommend using products from one manufacturer during the repair, which completely eliminates the risk of conflict between finishing materials, which means that you do not have to look for alternative solutions, losing time and money.

Knauf specialists took care of solving this problem by creating a whole line of materials with which you can perform the whole cycle of work on the finishing finishing.

Advantages and disadvantages

Due to the use of gypsum, which is considered an ideal material for the production of plaster mixes, gypsum leveling coatings acquire a whole set of attractive characteristics, namely:

- ecological safety, as gypsum stone is a pure material of natural origin, excluding the content of impurities that harm human health;

- plasticity, due to which the compositions are easily applied and quickly distributed over the working surface. Therefore, not only professional builders can work with them, but also those who have just begun to comprehend the wisdom of decoration;

- provide a very smooth, pleasant to the touch surface that does not need to be additionally putty,and you can immediately paint, glue wallpaper or cover with decorative plaster;

- The ability to quickly absorb moisture and moisture. Rotband actively participates in the regulation of the humidity regime in the room and contributes to the formation of a favorable and comfortable microclimate;

- hygiene. The product itself has a porous structure and, accordingly, the ability to drain the excess moisture. This coating protects the walls and ceiling from mold fungus;

- excellent heat and sound insulation properties;

- high adhesive ability to bases from various materials;

- excellent decorative quality, which makes available textured finish wall and ceiling surfaces;

- eliminate the formation of cracks even when applying a thick layer;

- consumption rates are twice as low as traditional cement and sand based plaster mixtures;

- the ability to apply one layer of plaster maximum layer of 5 cm, excluding pre-wetting. If necessary, thicker layers can be applied in a couple of approaches;

- versatility in use - the mixtures are suitable for simultaneous plastering with puttying, making decor, repair work and restoration measures;

- have a high water retention capacity, so that the working solution eliminates delamination, cracking and dehydration when applied to porous substrates that actively absorb the liquid, as well as when working in high temperature conditions;

- fire resistance is similar to concrete;

- high drying speed. Compared with cement plaster, drying for a month, the composition with a plaster base will dry in a week;

- Unlike cement plaster mixtures, Rotband weighs much less, therefore, the load on the treated surfaces will be lower. Due to the light weight, it is easier and cheaper to transport it.

Despite the impressive list of advantages and the many years of popularity of plaster mixes Rotband, they have some drawbacks, although they are quite controversial, because they were revealed by users whose opinions are always subjective.

So, the minuses buyers consider several features.

- High price. Although this plaster belongs to building materials of the average price category, but according to the opponents of this brand there are many analogues of other brands that have similar performance characteristics, but their purchase is much cheaper.

- The probability of shrinkage of the coating. Knauf ensures that its product is resistant to cracking, regardless of the thickness of the applied layer. As practice shows, the material shrinks or becomes covered with cracks for three reasons: when the technology for preparing a mortar mix is violated, the working solution is incorrectly applied or a fake is caught.

Today, markets and even large construction markets are replete with low-quality imitations of the sought-after plaster, which contains gypsum, ground sand and added acrylic resin.

The secret of the composition

The company Knauf, which produces high-quality plaster mixes, still keeps secret information about the main components of their composition, and is not going to share with the public the details of the manufacturing technology of its leveling finishing coatings.

The law requires manufacturers of building materials only to confirm the sanitary safety of products and to provide evidence of the environmental friendliness of the components used, while manufacturing companies have the right to protect the intricacies of production by commercial secret, and to protect monopoly rights to common characteristics, to undergo a patenting procedure.Therefore, the secret of the composition of Rotband Knauf is known only.

All those interested in this issue have to be content with well-known information about the components of the plaster, presented:

- gypsum binder as a base;

- functional additives that help improve the setting of the mortar mixture and prevent shrinkage;

- plasticizers to increase the viscosity of the solution and accelerate the transition of the mortar mixture to a solid state;

- dust-like inert filler, the main component of which is silica, having a fine-crystalline structure.

In what proportions and which ingredients are contained in Rotband, Knauf has not yet announced.

How to distinguish a fake?

Due to the popularity of the plaster mix Rotband, an avalanche of counterfeit has come to the fore. The negative consequences of such a phenomenon are the probability of discrediting building materials with a subsequent decrease in demand for it. In order to dissociate itself from low-grade counterfeits, Knauf promptly took steps to protect the reputation of its product.

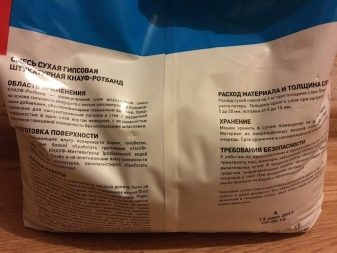

As the first level of protection, plaster began to be packed in original bags, for the manufacture of which there is corrugated paper, and they are made on the company's special order.The second level of protection was the use of per-second marking, that is, each bag contains information on the exact time of its manufacture, up to seconds, which eliminates the possibility of the existence of two packages having identical markings. Finally, the presence of a hologram that changes color in friction is the third level of protection for the originality of Rotband.

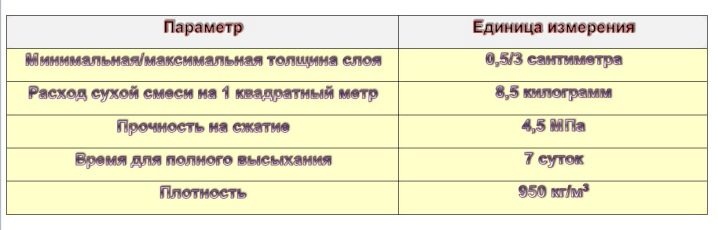

Specifications

All products for repair and finishing, produced under the trademark Knauf, are certified, their quality is confirmed by a certificate of conformity with the requirements of GOST. Product safety is confirmed by a fire certificate and a certificate of sanitary-epidemiological conclusion. Therefore, plaster mixes Rotband can absolutely safely finish any residential premises without fear for the health of residents.

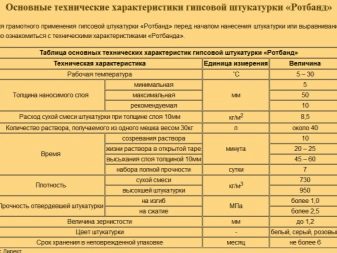

The main operational properties of the leveling coating are as follows:

- Description of the appearance - a powdery mixture of white, pinkish, gray, depending on what natural impurities the gypsum stone contains. This parameter does not affect the performance of the product;

- working temperature range is from +5 to + 30ºС;

- permissible values of the thickness of the leveling layer for the wall vary from 5 to 50 mm, for ceilings - from 5 to 15 mm. The recommended thickness is 10 mm;

- the consumption rate at a layer thickness of 1 cm is 8.5 kg / m²;

- the volume of the mortar mixture obtained from 30 kg of dry product is 38–40 l;

- maximum sizes of filler fractions - 1.2 mm;

- the period of maturation of the mortar mixture is from 5 to 10 minutes;

- the period of viability of the working solution in an open tank is from 20 to 25 minutes;

- the period of drying of the coating applied with a layer of 1 cm thick is from 45 minutes to 1 hour;

- full drying time - the mixture gains brand strength in 7 days;

- density of the frozen coating is about 950 kg / m³;

- compressive strength - at least 25.49 kgf / cm²;

- Flexural strength - at least 10.19 kgf / cm²;

- packaging - the mixture is packaged in paper bags of different volumes of 5, 10, 25, 30 kg or plastic bags weighing 5 kg;

- shelf life - the mixture is stored in a sealed bag for half a year.

The most important technical characteristics of the plaster mixture for the dresser are the period of viability of the mortar mixture and the time during which the finishing layer dries.Since in the case of Rotband, the time of "survivability" of the working solution is limited to 25 minutes, it is important to pre-calculate the volume of the mixture, which can be managed to produce within the designated time, while keeping in mind the pace of work.

When it is necessary to plaster walls, then it is not necessary to be puzzled by this question. When finishing a small section of a wall or ceiling with the accuracy of determining the desired volume of the solution, problems may arise, since it is rather difficult to do this.

In such situations, professional builders recommend in advance to find a place for laying unused mortar mixture.

Application area

The purpose of the Rotband gypsum plaster is a high-quality internal manual finish of vertical surfaces and ceilings with solid types of foundations: concrete, brick, plastered cement leveling coatings. Along with the listed materials, this product is allowed to plaster building structures made of polystyrene foam blocks and cement-bonded chipboard.

The manufacturer recommends processing Rotband smooth concrete wall or ceiling surfaces.. They are allowed to finish both dry and wet areas (kitchens, bathrooms), provided that the plastered surfaces do not directly contact with water.

To achieve an ideal surface quality for decorative coatings, after Rotband it is advisable to use Rotband Finish dry compound and or ready-made Rotband Pasta Profi.

Consumption

Consumption of gypsum plaster can vary, depending on several factors, such as:

- type and initial state of the working surface;

- the quality of the preparation of the base;

- thickness of the leveling layer.

As a starting point, it is best to take the leveling cover consumption value on the assumption that 8 kg of the mortar mixture goes to 1 square provided the application of a finishing layer 1.2 cm thick. That is, by simple calculations it can be established that a standard 30-kilogram Rotband bag enough to process 4 squares of walls or ceilings. To calculate the required number of packages of plaster mix, S of the plastered base is divided by 4.

How to make a mixture?

Before preparing the working solution, be sure to read the instructions on the back of the bag with Rotband. One 30-kilogram packing of the leveling compound requires about 18 liters of liquid.To knead the mortar mixture, a required volume of water is poured into a capacious tank and powder is poured in parts, mixing the contents with a construction mixer to obtain a homogeneous mass without lumpy inclusions.

To determine the desired consistency of the plasterer, it is advised to collect a small amount of mortar mix with a spatula or trowel, and then turn the tool over. When the solution "keeps" on the metal, it is suitable for work.

If necessary, the dry mixture is permissible to pour into the tank, you can also add water. After adding the components to the solution, they wait for 5–6 minutes, letting it mature, and then finally mix the plaster mass. It is worth keeping in mind that directly in the process of working with plaster, a portion of the addition to the mortar mixture of powder or water is absolutely unacceptable.

Terms of use

The quality of finishing in private or industrial construction largely depends on the observance of elementary rules, familiar to everyone who has ever made repairs with the use of leveling coatings.

Preparatory work

The use of plaster mix Rotband implies the mandatory high-quality preparation of working surfaces.Requirements to the basis - dry, cleared of an old finishing covering and pollution, and also dust-free. According to the instructions, it is necessary to get rid of all clearly pronounced protrusions on the walls or ceiling, and to protect metal parts, apply anti-corrosion compounds.

The recommended base t is at least + 5 ° C. Drafts, increased air humidity and direct access of the sun to the room during operation are highly undesirable.

When plastering of a porous base, characterized by the active absorption of moisture such as aerated concrete, gypsum-fiber sheets, ceramic or silicate bricks, is necessary, the working surface is treated with Knauf Tiefengrund brand primer with a roller or spray gun. Grounds with low water absorption (polystyrene foam blocks) must be pretreated with Knauf Betokontakt, and only then you can begin to plastering Rotband.

How to install beacons and corner profiles?

The technology of plastering Rotband wall surfaces on beacon profiles has a number of features.

- Installation of beacons. On a wall with a pitch of 0.3 m, vertical discontinuous strips are formed from individual sculptures of thick mortar mixture, which are then pressed into beacon profiles.Then they are aligned in one plane.

- When installing beacon profiles, it is recommended to place them at a distance from each other so that the rule in length exceeds it by 15–20 cm.

- Corner profiles are covered with moldings of the mortar mixture on the inner side with a step of 0.3 m.

When installing profiles in the corners, they are fixed first in the center, and then gradually pressed, moving towards the edges, and aligned in the same plane with the beacon profiles on the walls.

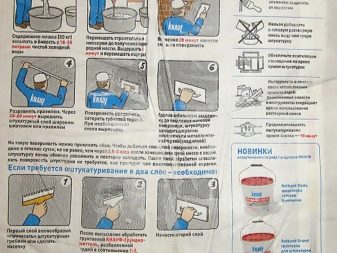

How to apply and level?

As already mentioned, it is important to have a mortar mix in a certain period of time - a maximum of 25 minutes from the moment of its preparation. The ceiling surface is covered with plaster using a falcon - a construction tool in the form of a square platform made of wood, metal or polyurethane, equipped with a handle. You can also plaster the walls of the Rotband with a construction falcon or by throwing the mortar with a trowel, after which you can level the sculptures using a rule so that you get a flat surface.

Creating a thick layer of plaster is done in two approaches. The first step is the formation of the first layer, which, after being applied to the working surface, is profiled with a plastering comb until the composition starts to set. By the second stage - the application of the next layer can begin only after a day.

Finishing building structures from TsSP (cement-bonded chipboard) or polystyrene foam blocks requires the use of a reinforcing mesh with a mesh size of 5x5 cm. It is fixed onto polyvinyl acetate emulsion or covered with a thin layer of plaster mixture, and then pressed into the mesh, smoothing with a spatula so that it does not start to bubble .

When the net is dry, it is sanded, dedusted, primed and plastered. The setting time of the applied mortar mixture is about an hour, after which it is smoothed with a metal spatula or lath, the bulges and flows are cut off, and the cavities and grooves are filled with plaster mixture. The slopes or corners eliminate the irregularities through a special plaster planer. A wall with such a layer can already be tiled.

How to rub and smooth the surface?

For painting, applying decorative plaster or pasting tapestries, preparation of the plastered surface requires a different approach. Apply the mortar mixture to withstand about 15 minutes, then moisten it with a wet rag, and then start rubbing, using a felt sponge or a very stiff sponge, to level the marks left by the rake.

After waiting another 15 minutes, the plaster layer will need to be smoothed with a wide trowel. When the walls are completely dry, you can proceed to the finish finishing with decorative coatings - wallpaper or paint.

Tips and tricks

Experts recommend sticking to several simple rules when working with Knauf Rotband plaster plaster.

- When it is planned to glue the tapestries of white color or light pastel colors, it is better to process the plastered walls before pasting with a white-colored finishing putty.

- In order to give the walls or the ceiling a spectacular gloss, the applied working solution after 3–3.5 hours is thoroughly moistened, and then smoothed down with a wide spatula or a trowel. The advantage of this procedure is that Rotband does not need to be putty, as the surface prepared in this way can be painted.

- This leveling finishing coating is allowed to be used as a starting putty due to its high strength properties and excellent adhesive ability. However, Rotband as a putty is compatible exclusively with finishing compositions with a plaster binder base.

- To obtain a structural surface are as follows. First, level the plaster using the rule, and then, without waiting for the layer to set, use the embossed roller. To create a structure on the plaster layer, you can also walk with a brush with stiff bristles or grout.

- Upon completion of the finishing works, in order for the plaster to dry faster, the room must be aired.

- Rotband plaster composition known for its high adhesive properties, perfectly adheres to everything it comes into contact with. Therefore, at the end of the work can not be postponed washing tool "for later." If you do not do it right away, then you will not be able to get rid of the impurities with the help of water, but you will have to remove them mechanically, wasting a lot of time and effort on scraping the adhered solution.

- Experienced plasterers always have a bucket of water ready to wash the mixer. Each time, after mixing the solution, the spiral nozzle, leaving it in the drill, is dipped in a bucket of water and washed with the drill on, which is very convenient.

- In construction at the stage of roughing works, masters often use technical water, and if there is no water supply at the facility, then they use well water or draw it from the nearest reservoir.

It is extremely important to dilute dry plaster mixtures with clean running water, since as a result of its stagnation a favorable environment is created for the reproduction of microorganisms that can provoke the development of a mold fungus on plastered surfaces.

Comparison with other brands

The line of dry gypsum plaster mixes Knauf, in addition to the Rotband under consideration, is represented by several other types of leveling coatings with polymer additives. It:

- Knauf eisberg - it is a white compound recommended for use as a light base for finishing coatings.

- Knauf goldbandwhich aligns rough walls well with obvious height differences and other serious construction defects.

- Knauf HP Start - this mixture creates a leveling starting layer, the thickness of which varies from 10 to 30 mm. This coating helps to remove construction flaws with a height difference of a maximum of 1.5 cm.

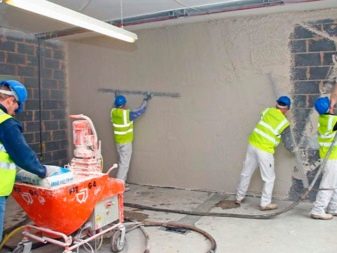

The main difference between Knauf plasters is in the method of application. Rotband, as well as the above three types of mixtures plaster by hand. But there are still three universal gypsum plasters - Knauf MN Start and high-adhesive compounds Knauf MP 75 and Knauf MP 75 Ultra,which are intended for mechanized plastering of surfaces with the help of mobile construction units - plaster stations, allowing to work continuously with dry mixtures.

Their main advantage is the high productivity of work, exceeding at least three times the application of plaster by hand.

Any of the leveling coatings, like Rotband, can be used to perform interior renovation and finishing works in rooms where the humidity level is normal. In addition, they are suitable for finishing wet rooms - bathrooms and kitchen spaces, if direct interaction of plastered surfaces with water is excluded.

However, in the case of the selection of gypsum plasters, the main criterion for the selection of a suitable mixture is the scale of the repair and finishing works. If you plan to make repairs in one room or a small apartment, then it is reasonable to purchase the mixture for plastering manually. It can be a Rotband or Goldband if the walls are too uneven, with which it does an excellent job. When in the plans of pasting the room with light wallpaper, it is definitely worth stopping the choice of white light on Knauf Eisberg, so as not to worry about the probability of formation of ugly gaps through the canvases of light tones.

If you have to finish large areas in a cottage, beauty salon or sales area, then definitely it is worth considering any of the leveling coatings for mechanized plastering, which, although not less time consuming than manual, but saves a lot of time when performing large volumes of work.

Exterior work and finishing of premises with high humidity conditions - basements, laundries, production workshops are carried out with Knauf cement plasters.

So, in the range of Knauf plasters, you can find a product for your own needs to solve problems of any complexity, regardless of the level and extent of the repair.

Reviews

The overwhelming majority of users positively respond to Rotband plaster. Professional finishers give high marks to the quality, plasticity, ease of applying and leveling the mixture, and home craftsmen pay tribute to the convenience of preparing a solution, noting that “everything is simple, clear and fast.”

Claims against a plaster leveling coating usually concern a high setting speed of the mortar mixture. As a rule, newcomers in repairs complain about this, since it is rather difficult for them to plaster at a high pace in order to work out a solution in the allotted time limit.

When analyzing reviews about Knauf products, there are always opinions of those who are not satisfied with their high cost in comparison with many other brands of dry building mixes. Plaster Rotband is no exception. Some believe that the price of it is unreasonably high.

This is a paradox, but at the same time, buyers are dissatisfied with the price policy of Knauf, they certainly praise the quality and performance characteristics of a dry plaster mix from a German manufacturer.

For how to level the walls with Rotband plaster, see the video below.