Dry M-300: Pros and Cons

Universal sand concrete mixes are very popular because of their wide scope and high technical characteristics. One of the common varieties of dry mixes of this group is M-300. It is suitable for screeding and leveling the floor, cladding, masonry, used in construction and repair work.

Special features

Dry mix M-300 is a ready-mixed masonry mix, the components of which are selected in the right proportions. Before use, the composition is diluted with water in the amount specified by the manufacturer, and kneaded mechanically until a homogeneous mass.

The mixture is a sand concrete, because it is based on purified fine-grained concrete and portland cement. The dimensions of the first one do not exceed 3 mm, the used Portland cement has a brand strength of M-400 or M-500).To ensure certain characteristics (frost resistance, moisture resistance, and so on) plasticizers are introduced.

In the compositions, operated in conditions of negative temperatures, various reinforcing fibers may be present. To improve adhesion, a special kind of clay, coarse sand, granite chips are sometimes applied.

The result is a product characterized by increased strength, high adhesion and frost resistance.

Unlike usual concrete solutions, sand concrete M-300 is distinguished by its simplicity of preparation, plasticity (suitable for laying with a thin layer, which is necessary for certain types of masonry), high strength, economical consumption. Mixture M300 is a masonry, that is, it is used for fixing bricks or stone masonry. In addition, it can be used as a concrete mix for casting.

The composition is characterized by non-shrinkage, which allows it to be used as a floor screed. And due to the increased strength and durability of the mixture is used even in the organization of high-strength floors. The thixotropy of the composition allows it to be used also for leveling floors, as well as for embedding cracks in concrete surfaces.

The material is suitable for both private housing, and for the construction of industrial and administrative objects, as well as the installation of basements, garages. It is used when pouring the foundation, including in the places of adhesion of concrete and reinforcing sections. The mixture is also used for the device tracks on private suburban areas. According to its properties, the material resembles fine-grained concrete, therefore it is used both outside and indoors.

Release form - dry mix, delivered in multi-layered Kraft bags weighing 40 kg.

Specifications

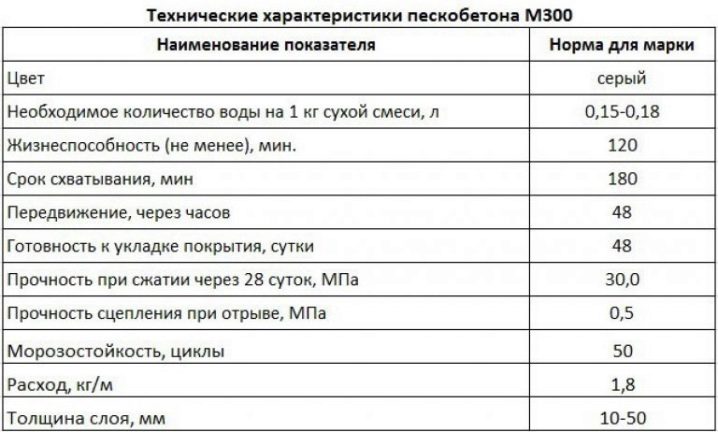

Peskobeton M-300 is a universal compound that is suitable for a wide range of construction works. In the first place - this is due to its high strength. Compressive strength is 300 kg / cm2. This means that 1 cm2 can withstand weight up to 300 kg.

The repair mixture has an average specific density, which indicates such a sand content, which eliminates the risk of voids being formed during pouring.

Frost composition is not less than 50 cycles, that is, it withstands up to 50 cycles of freezing / defrosting.

Due to a fairly moderate consumption (for 1 m2 with a layer thickness of 10 mm, 17-30 kg of the mixture is consumed), the M-300 becomes the best option for the screed, the organization of which is cheaper than using specialized compositions.

Important technical properties include high speed of hardening, as well as moisture resistance (the layer does not let water through). This allows you to use the composition in emergency situations - when you need to quickly and without prior preparation to eliminate cracks, cracks, loss of stability.

The seizure of the compound takes place already after 12 hours (after this time it is already possible to walk on the floor of sand concrete), the final solidification is on average 5 days later (after that the construction process can be continued).

At the same time, peskobeton M-300 demonstrates viability up to 120 minutes.that allows you to work at an optimal pace (without too much haste), even in the absence of building skills. The composition has a self-leveling ability, in other words, self-leveling sand concrete mix does not take much time and effort to level the surface.

Due to the plasticity of the composition can be applied as a thin (10 mm), and a thicker (up to 200 mm) layer, which also contributes to the expansion of its scope.For example, laying requires a thin layer of the mixture, while a thicker layer may be required to fill or level the floor.

In addition to these characteristics, it should be noted tixotropy (non-shrinkage), high adhesion (4 kg / cm2), the ability to work at temperatures below 5C. The ability to resist corrosion makes the composition suitable for casting reinforced concrete foundations and similar structures.

Manufacturers

Peskobeton M-300 is in great consumer demand, so it is not surprising that it is in the lineup of almost every manufacturer. You should not buy nameless compositions, as well as products of unknown manufacturers.

Preference should be given to reputable brands that have won the trust of suppliers and customers. So, for floor screed (including in a private residential facility), users recommend a mixture of M-300 from the brand "Etalon". Due to the fine fraction of the granules of the composition, it is possible to maintain the strength and uniform distribution of the layer of the solution, even with a large thickness. This makes the composition optimal for floor screed, leveling, including with significant differences in height.

"Reference" it mixes well, the sand does not settle to the bottom of the tank, it is easy to achieve a uniform composition. The demand for the composition is also due to its versatility - in addition to pouring the floor, it is also used for plastering surfaces, and also as a masonry mortar.

The composition of the mixtures "Etalon" coarse sand and cement, so they are intended for use on horizontal surfaces, experiencing moderate loads. The temperature range of operation is -40 ... + 65C.

Another composition suitable for floor screed - a mixture of M-300, produced at the Russian plant "Stone Flower". At the heart of - sand and cement, plasticizers. Treats the structures having the increased speed of drying. It demonstrates improved values of water resistance, frost resistance, weather resistance.

Another producer worthy of attention - company "Mountain Crystal". At the heart of the mixtures "MBR" of this brand is quartz sand, which leads to improved adhesion. In addition, the mixture includes portland cement and plasticizers. The main purpose is the repair and restoration work of concrete and reinforced concrete structures, pouring gaps and joints, process perforations.

Has similar properties Dauer compositioncharacterized by the same economical consumption (18-20 kg m2).

As a rule, all manufacturers manufacture their products in craft bags of 25, 30 and 40 kg. The packaging of some manufacturers may differ slightly, for example, Dauer mixtures are produced in bags not in 40, but 50 kg each.

Tips and tricks

When mixing the masonry mortar, you should strictly follow the manufacturer's instructions. As a rule, no more than 7 liters of water is required per 40 kg bag of composition. Experts recommend using only cold water. Dry components are poured into a liquid, after which the whole mixture is kneaded with a mixer. If there is none, you can use a regular drill, supplying it with a mixing nozzle.

The optimal temperature for work is + 5 ... + 50C. When the temperature drops below + 5C, sand concrete does not lose its properties, however, its adhesion time increases.

You should not try to mix the composition manually, because it will not be possible and may cause a desire to add more water than normal. This is fraught with a decrease in the adhesion of sand concrete.

The composition, brought to a uniform consistency, should be left “to rest” for 5-10 minutes, after which it should be mixed again.

Do not cook too much of the mixture. Basically, the M-300 has a vitality of 1.5-2 hours, after which it becomes unusable. You need to mix as much solution as you have time to spend during this time.

Before applying the composition should take care of the preparation of working grounds - they must be clean, free of grease, dry. Porous and highly absorbent surfaces are pre-primed. In the presence of collapsing surfaces they must first be reinforced.

Be sure to align the level and installation of beacons, which will be filled. When filling the floor with sand concrete, it is simply poured over the surface, leveling the rule. At the time of solidification (during the first 3 days), the evaporation of moisture from the solution should be prevented, for which purpose the bottled bases are covered with a tarpaulin.

Further you watch the comparative review of two popular producers of the dry mix M-300.