Lime: what is it and what is it used for?

Lime is one of the materials that is often used in construction, as well as in a number of other areas. In this article we will talk about this material, describe its properties, types, give a definition, and also explain where it is used, how to breed it, and how to apply it in each case.

What it is?

Lime is a binder material, which is obtained as a result of burning, as well as the subsequent transformation of limestone, chalk, as well as other magnesian-calcareous rocks. If we talk about the properties of pure, genuine lime, then it is a colorless product that is extremely difficult to dissolve in water.This word usually means quicklime and the product of its interaction with a liquid.

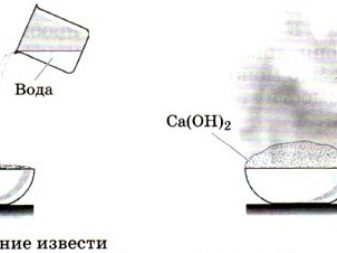

It should be noted that this material may be in several forms. - hammer, powder, and also in the form of the test. Speaking about the formula of this material, it looks like CaO. Lime is the result of burning rocks, when calcium oxide is the main component of the chemical plan. It interacts quite well with moisture. As a result of the hydration process, we get slaked lime.

Special features

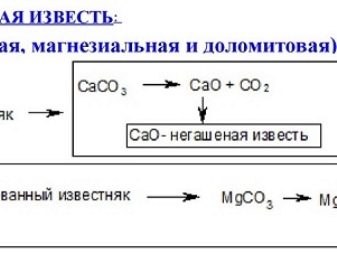

Quicklime is a white substance that has a crystalline structure. The proportion of impurities of various types - dolomite, limestone, as well as other magnesium-calcium minerals cannot exceed 6-8%. It is made in accordance with GOST under number 9179-77, which is called “Building Lime. Technical conditions. Such lime is created from carbonate type rocks using various additives that are mineral in nature: electrothermophosphoric or domain type slags or quartz sand. According to the requirements of GOST, lime must be crushed so that the residue after passing through a sieve with the numbers 02 and 008 is no more than 1.5 and 15%, respectively.

Quicklime type lime belongs to the danger group of the second group. If we talk about clean lime air type, then it can be both the first and second, as well as the third type. If we talk about lime with impurities, then this is only the first and second grades. And if we are talking about hydrated lime, then this is also only the first and second grade.

Kinds

Lime obtains hydraulic characteristics due to the presence of silicates. From how many of them there are, it can be divided into hydraulic or air. The first category has the ability to improve the hardening processes and the strength of solutions in both air and water environment. If you look at the content of clinker materials, lime can be highly hydraulic or weakly hydraulic.

Note that the air lime is intended to ensure the hardening of the applied solutions in construction, as well as that they retain their strength when the moisture level is at a normal level.

If we talk about the types of lime, it should be noted that it is divided into different categories depending on the criteria that we take as a basis for classification.

If you look at the types of lime by type of processing, then it may be:

- Lumpy.It is also called the kettle.

- Fuzzy. This is, in essence, slaked lime, which is obtained after the lumps have been extinguished by the liquid.

- Milk of lime type in the form of a white suspension.

- Limy dough. This is the result of the slaking of lumpy raw materials

- Ground powder. It is obtained usually due to the grinding of burnt lumps.

If we talk about the content of the oxide level, then lime happens:

- based on dolomites;

- magnesia;

- based on calcium.

In the case of calcium, the amount of its content can range from 70 to 95 percent. In magnesian content of magnesium oxide is usually from 5 to 20%, and in dolomitic - from 20 to 40%.

If we take the rate of quenching, then lime is divided into:

- Quenching quickly. As a rule, the indicator is no more than eight minutes.

- The average rate of extinction. This is a time period of not more than 25 minutes.

- Long extinguishing. Such lime is extinguished over 25 minutes.

If we take as a basis the criteria of technical parameters for burning various rocks, we get lumps of lime with varying degrees of strength:

- mildly burned;

- hard burned, that is burned out;

- medium degree of deification, that is, burned.

In addition, it is also separated by chemical composition. We are talking about the ratio of calcium alumoferrites, as well as silicates.

It happens:

- Hydraulic. This option makes it possible to harden solutions that are used both in water and simply in open areas.

- Aerial. This option allows various solutions and mixtures of building destination to harden in cases where there is normal humidity. It should be noted that the composition of air lime is such that the percentage of the above-mentioned substances is 5-15%, and in rare cases there may be 20 percent. There is also weakly hydraulic lime, which has from 25 to 40% of the content of so-called clinker materials. If we talk about the strongly hydraulic type, then it is characterized by the fact that these alumoferrites and silicates from 40 to 90% are contained here.

What are they doing?

For lime will be the determining factors of the brand and type, which determine the main segment of its application.

If we are talking about lime for construction, then this type, as a rule, consists of rocks that contain a very high percentage of calcium, as well as magnesium.This type is used as a plasticizer for various kinds of binding solutions, as well as for concrete mixtures. This brand is usually sold in the form of lumps and fluff or lime dough.

Usually for the production of this type are required:

- rocks carbonate plan;

- various mineral-based additives, which include active mineral additives, as well as quartz-based sands and electrothermophosphorus slags or granules domain-based.

If we need a hydraulic mixture, then it is released from limestone, which contains up to 20% clay impurity. Do it with roasting. It should be noted that this type is usually made for the production of low-grade concrete. Simply, its plasticity is extremely low, and its strength is very high. This type of lime is usually used to create structures that will be used in conditions of high or high humidity.

The lumpy type is usually used as a kind of semi-finished material in order to create various solutions and powders. This type is usually stored in closed warehouses, so that it does not have a destructive effect of moisture.

During periods of rain in spring and autumn, quicklime or slaked lime is sometimes added to the soil. By the way, the latter releases alkali when in contact with water. Due to precipitation, limestone dissolves better.

There is also the so-called natra variety. It is a combination of hydrated lime and caustic soda. Usually used in the creation of pressure chambers, gas masks, as well as various diving equipment.

There is also a chloric variety. It consists of calcium hydroxide, as well as free chlorine. She has excellent whitening characteristics and is a powerful antiseptic.

Shelf life

Different categories of lime have different shelf life. For example, if you take quicklime, it should be stored for about two weeks in a room that will be exclusively unheated, dry and closed. If there is an opportunity to store it in a production environment, then it is better to do it in special containers in which there is a supply system.

If such a product is stored in a sealed package, then its shelf life is unlimited. It must be said here that the storage of this type of lime should completely exclude the ingress of any liquid on it, otherwise it may cause very strong heating of the substance.

After the dehydration has been carried out, the lime must be kept in a specially created pit about a crescent in case it is used for masonry or to create some solutions. If it will be used for plastering, then it should be stored for about a month.

After the solution is usually poured 20-centimeter layer of fine sand. If the temperature is below zero in order to exclude the possibility of frost penetration, a 70-centimeter layer of earth can be poured onto the sand. Also, a pit of lime should be fenced off and noted so that everyone around would be aware of its presence and animals could not enter it. As a rule, in the consistency of the test, such lime is stored for quite a long time. And the more time passes, the better it becomes.

Bleaching powder is usually stored exclusively in airtight packs in an area that is completely protected from moisture and ultraviolet rays. The package must be labeled, which indicates that the substance has a caustic character. It is packed in bags of polypropylene or polyethylene, as well as in drums of steel with inserts of polyethylene.In the market it will be packages weighing 0.5, 1.2 and 1.5 kilograms. The pack may be sealed, or it may be tied with a ring made of metal or with a twine of chlorine-resistant type.

If we talk about the severity of human exposure, substances such as lime are in the group of moderately hazardous products of the third group, and the released chlorine is in the second group.

The breakdown of lime on a chlorine base leads to the release of oxygen and chlorine. But this is possible only under the influence of natural factors. It is the strongest oxidizer, and chlorine dust can cause irritation of the mucous membrane.

When working with such a substance, the respiratory system and eyes should be protected with special means. - respirator or filter type gas mask. Packages with this type can be stored in warehouses with a high-quality ventilation system that is unheated and protects lime from ultraviolet rays. Floors must be made of brick, concrete or asphalt. In a room with such substances can not be stored gas cylinders, flammable, as well as various explosives. Shelf life in warehouses can be either a year or three years.

By the way, storage facilities should be equipped with fire extinguishing devices: acid-based fire extinguishers, cranes with fire hoses, boxes filled with sand, and so on.

Scope of application

For a long time, lime was used to obtain lime cement. Despite the fact that it perfectly freezes in air, it absorbs a large amount of moisture, which causes fungus on the walls. For this reason, it is no longer used as such. Such lime will also be a component of various materials for plastering, making dyes, bricks based on silicates, cinder concrete, and so on.

It is also actively used in horticulture, as well as agriculture. For example, bleaching powder is an excellent material for treating trees and plants from various rodents and pests, fertilizing soils with acidic properties, and also whitewashing. Ground limestone, which has the same properties as chalk, is used as raw material in the creation of animal feed, as well as feeding for poultry.

The use of quicklime allows the neutralization of wastewater as well as flue gases. In addition, with its help they paint various types of surfaces - walls, technical rooms.

Lime is often used in the food industry. For example, it is in a number of products as an emulsifier with the designation E-529. In addition, it needs any area where it is necessary to mix substances that cannot be mixed due to their nature - for example, water and oil.

Lime has gained popularity for the following reasons:

- low cost;

- excellent disinfection properties;

- resistance to moisture;

- the absence of some unpleasant smell;

- universality;

- good compatibility with dyes;

- resistance to ultraviolet radiation.

But she has a couple of drawbacks:

- very caustic in work, which requires caution;

- Bubbles, streaks and streaks may appear if the solution was prepared incorrectly.

How to breed?

This process is rather dirty and time consuming. Before carrying out the work, it is necessary to cover the floors and furniture with a film and wear protective clothing. If you decide to whitewash the room, the flow rate will vary from the method of its application, as well as the surface area that is being processed.If the whitewash is applied using a brush, its consumption will increase significantly.

In addition, it all depends on what kind of lime you choose. For example, dry quicklime is poured in a ratio of one to one. Pouring three liters of water to one part of the lime, you can get a lime-type dough. And after that lime can be diluted with liquid.

From one kilogram of quick lime it is easy to get 10 liters of whitewash, ready to use. In some cases, for the cultivation of lime, you can use gypsum and sand, but only to improve its properties.

Consumption

It will depend on exactly where the mixture will be used. To whiten a room, you need 0.5 liters of finished whitewashing per square meter. If we are talking about pushonok, then from a two-kilogram pack you can get six liters of whitewash, which will be enough to whiten about 12 square meters of surface. However, if you have to work with masonry, then you will need a larger number.

If we talk about the finished lime test, then its ratio will be such that three liters of liquid are required per kilogram of dough.

If we are talking about quicklime, then it must first be extinguished, and only then diluted with water. In the case of one kilogram of quicklime, you can get about ten liters of whitewash, ready to use.

Application technology

Whiten the room with a spray gun, spray or brush. A roller is never used for whitewashing, because if the whitewash is rolled out with a roller, but already the second layer, the first layer simply will not stand the load and move away from the surface. Usually a special brush is used for whitewashing. Before use, it should be soaked in warm water for several hours.

Brick walls can be machined with a simple brush that has natural bristles. By the way, if you do everything with a brush, then there will be bands. In order to remove them, a second whitewash layer should be applied in the direction of light flow.

It will be best to whitewash using a spray gun. She will go to bed smoothly, and the consumption of lime will be significantly less.

If we talk about the work algorithm itself, then first it is necessary to cover all windows, doors and furniture with a film.You can greatly facilitate the work when you need to carry out cleaning of rooms. After that, the surface should be prepared for the process, namely, to remove the old layer, remove stains, and also whitewash, which is already peeling. Also, it would not be superfluous to seal the cracks.

Now should dilute whitewash. If the process is carried out using a spray gun or spray gun, the mixture should be first filtered. Before adding the next portion of lime to the device, you should mix the solution.

Before working with the equipment, it is necessary to familiarize yourself with the rules that the technological instruction contains. Before applying whitewash, you should slightly wet the surface using a spray. Now whitewash needs to be poured into the spray gun and pumped air inside. Now adjust the spray nozzle, so that whitewashing sprayed as evenly as possible. If spraying does not occur, it is too thick.

Then there must be added a liquid and prevent it. The sprayer should be at a distance of 15-20 centimeters from the surface. The process should occur exclusively with the help of circular movements.After a couple of hours on the first layer, which has not yet dried out, a second whitewash layer should be applied.

Tips and tricks

If you keep lime in bags, it is best to do it in a dry place where the sun's rays do not fall. When buying this substance, make sure that it is stored in suitable conditions, the description of which must be on the package. In addition, lime whitewashing is quite cheap and would be an excellent solution for a limited budget. Another important point - lime whitewashing will be an excellent solution for wet rooms, as it has excellent moisture-resistant properties.

Before you apply a new whitewash, you must first wash the old whitewash from the ceiling. In any other case, a new whitewash will simply fall off along with the old one.

It should also be very careful to dissolve the lime in water. Given the differences between different species with each other, the amount of water that is necessary will be different. Lime-boil, sodium or carbonate will require different amounts of water for proper dilution.

To give whitewash a pleasant shade, you can add color to it.Usually in this case, 20 g of blue is added to the whitewash container. To carry out various kinds of finishing work at home made of wood or brick, it will be best to pick up an overcast day or evening time. The reason is simple. The characteristic of lime is that it does not like too dry and hot weather, as well as exposure to direct sunlight.

The technological procedure for applying whitewash should be as much as possible followed. Any deviation from the process will cause the result to disappoint you.

Lime is an excellent material that is used in many areas. For example, white lime traditionally decorates trees from spring, protecting them from pests, is an excellent solution for whitewashing walls and generally has a lot of advantages that distinguish this fairly affordable material from others.

How to extinguish the lime, see the next video.