Sand-gravel mix: pros and cons

Sand-gravel mix is a versatile material for the construction of civil, industrial and defense facilities. The mixture ranks first in the ranking of sales of building materials among this group of products. The wide range of use and popularity of building material makes it possible to annually increase the production of inorganic natural minerals. Concrete composition, one of the components of which is CBC, has a high level of strength and a long period of use.

Special features

Sand-gravel mix belongs to the group of non-metallic rocks mined on the shores and bottom of water sources in open-cast mines. The percentage proportions of sedimentary elements of gravel and sand component depend on the location of the rock production site.

There are two types of minerals on the building materials market.

- Natural - used for the installation of children's playgrounds, sidewalks and roads. Advantages - the presence of several different types of composition, reasonable price. Feature - the absence of mechanical and chemical processing.

- Enriched - used for construction work. Advantages - the presence of mineral components that improve the technical parameters and quality of the material. Feature - undergoes technological processing with the enrichment of auxiliary chemical compounds.

There are three types of natural PGS:

- mountain or gully - consists of particles of different diameter with sharp edges, contains a high percentage of the presence of mountain elements, is not used for the manufacture of concrete solutions;

- lake or river - has a homogeneous composition with a high content of polluted natural impurities, consists of smooth particles;

- sea - has a universal composition with round elements, used for the manufacture of concrete mixtures.

Technological washing of mined rocks makes it possible to remove all impurities and contaminating elements as much as possible.

Experts divide the CBC into different types based on the following characteristics:

- percentage combination of sand particles and sedimentary mountain elements;

- diameter of sedimentary gravel;

- indicators of resistance to mechanical damage;

- the presence of additional components;

- resistance to low temperature conditions.

Experts identify several major advantages of the CBC:

- environmental Safety;

- universality;

- a high percentage of strength indicators;

- resistance to sudden temperature changes and the negative impact of the environment;

- long period of operation and lack of shelf life;

- preservation of universal qualities and parameters during long-term storage;

- the ability to increase the strength and durability of the concrete solution;

- affordable price;

- wide scope of use.

In order to preserve all the qualities and properties of natural fossil storage spaces and storage rooms, they must be protected from moisture and equipped with modern ventilation systems.

Specifications

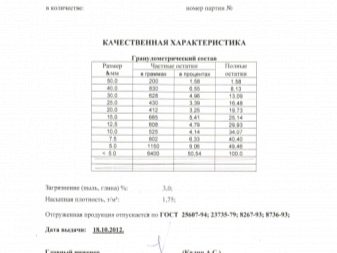

Each type of PGS has individual qualities and general technical properties. Technical properties and quality standards of enriched sand and gravel minerals are prescribed in GOST 23735-79, the properties of gravel are specified in GOST 8267-93, the parameters of sand components are described in GOST 8736-93.

Standard diameters of gravel in natural rocks from 1 cm to 65 mm. For individual orders, the particle diameter reaches 145 mm. The minimum particle size of the sand component is at least 0.15 mm, and sedimentary rubble is 0.5 cm.

Enriched rock types have different technical characteristics, depending on the proportions of sedimentary gravel rocks, and there are several types:

- group 1 - up to 20 percent;

- group 2 - up to 35 percent;

- group 3 - less than 50 percent;

- group 4 - not less than 60 percent;

- Group 5 - no higher than 74 percent.

An important element of the building fossil is sand. Durability and resistance to mechanical damage to concrete structures depend on the degree of its cleaning and humidity. The sand extracted at the bottom of water sources does not contain particles of silt, clay and other polluting elements and is of high quality. The addition of high-quality sand to the enriched solution improves the properties and parameters of the OPO. Sand moisture is one of the main parameters that affects the amount of water added when mixing the solution. The higher the moisture content of the material, the less liquid will be needed for the mortar.

Sedimentary gravel rocks in natural minerals have different levels of strength and are divided into the following groups:

- M 400 - low percentage of hardness;

- M 600 - the average degree of reliability;

- M 800 - sufficient level of strength;

- M 1000 - the maximum indicator of reliability with a low content of weak components.

The amount of impurities in a natural mineral cannot be higher than 6 percent, and in an enriched one — no more than 2 percent.

The construction of a building material that meets all standards and quality standards is capable of withstanding over 450 freezing and thawing cycles and does not exceed 10 percent loss from the original mass.

The specific gravity of 1 m3 of the mixture must be at least 1,600 kg.

The averaged value of the compaction module of the composition is at the level of 1.2 and is determined by the volume of gravel and the method of compacting the rock.

The Aeff indicator is the total specific efficiency ratio for enriched ASG, which determines the rate of radiation content.

Sand-gravel mixes are divided into three classes of radiation safety:

- Class 1 - not more than 370 Bq per 1 kg;

- Class 2 - no more than 740 Bq per 1 kg;

- 3 class - up to 1500 Bq per 1 kg.

Such a division into safety classes allows builders to use the material as efficiently and effectively as possible.

In enriched sand and gravel, it is possible to replace the components of sand and gravel with gravel rubble. Gravel rubble is processed gravel.This bulk building material has a rough surface and pointed corners; it is produced by crushing raw materials. Crushed stone increases strength and is used for the manufacture of asphalt.

Crushed stone mixtures (PSP) are of several types, depending on the particle size:

- C 12 - no more than 10 mm;

- C 2 - up to 2 cm;

- C 4 and 5 - up to 80 mm;

- C 6 - less than 40 mm.

Crushed stone compositions have similar parameters and properties with materials from gravel. The most durable and resistant types of Pschs - C 4 and C 5.

Application

PGS is used for the construction of facilities for various purposes. The use of minerals depends on their technical parameters and properties. To accurately determine the purpose of the mixture, it is necessary to know the density and percentage of all components of the composition. A mixture with a high content of gravel has a high percentage of strength.

Application areas:

- road;

- civil;

- industrial;

- defense

Natural sand-gravel mixtures are low cost and are used very rarely for the construction of buildings and structures due to the low strength of the objects obtained.

Natural CBC has a high proportion of sand and is used to perform various construction works:

- installation of the lower layer of the roadway;

- arrangement of sidewalks in a garden and a personal plot;

- installation of drainage systems;

- arrangement of communication channels.

For these types of work strength indicators are not the main ones and are in second place. The main task - the unique properties of sand to absorb and remove moisture from the surface of the object.

The 5th group of sand and gravel with a high content of gravel particles is most popular and in demand. The design, made of this group of PGS, is characterized by high strength, minimal shrinkage and no deformation at any level of mechanical load.

A mixture with a gravel content of not more than 30 percent is used to perform certain types of work:

- repair and construction of roads for different purposes;

- production of concrete with low strength (to increase strength, a small percentage of rubble is added to the solution).

The scope depends on the class of radiation safety. Materials related to class 1, are used for the construction of small buildings and repairs. Mixes of the 2nd class of safety are applied to construction works on the device of roads, sidewalks and installation of buildings and premises.PGS 3 class have a high level of strength and are used for industrial and defense construction.

Tips and tricks

Buying sand-gravel bulk building material, It is necessary to demand quality certificates from the seller and carefully study the following parameters and properties:

- the diameter of all elements of the composition;

- proportions of all components;

- the quantitative level of clay, silt and other polluting elements;

- density indicators;

- properties of sand elements and sediment rubble.

For high-quality performance of work it is necessary to acquire inorganic rocks that meet all quality standards. Construction companies engaged in the extraction and sale of the CBC, must have documents for each batch of material with the following data:

- name of the organization and its legal location;

- registration information;

- lot series and volume of building material;

- type of ASG;

- composition and properties of PGS;

- proportions of all components;

- maximum diameter of gravel;

- percentage of clay elements;

- fractional type;

- type of resistance to low temperatures;

- quality standard number.

For self-production of concrete solution with the addition of sedimentary minerals experienced builders advise to prepare a set of inventory and building components:

- cement mix of the planned type and in the required amount;

- ASG;

- water;

- construction packaging;

- shovel (mixer).

To obtain a high-quality concrete solution, you must comply with the percentage of all components.

Concrete with enriched PGS has the following proportions:

- mountain mix - 8 parts;

- cement - 1 part.

The volume of water depends on the moisture percentage of all components. The size of the gravel should not exceed 8 mm.

Before starting the production of a mortar with the use of the CBC, it is necessary to take into account the final type of concrete mix, the cement mix brand used, the amount of sand and gravel.

Sand-gravel mixtures are demanded construction materials with low cost. By purchasing this building material, you must carefully examine all the accompanying documents and certificates of quality. Only high-quality material will allow you to create strong and durable objects that meet all European standards.The wide scope and versatility of the material make manufacturers increase the production volumes of this building material.

However, it must be remembered that the uncontrolled mining of rocks can lead to environmental disaster and disrupt the natural harmony of the environment. Rational use of natural resources will provide an opportunity for many years to extract the necessary materials.

On the enriched sand and gravel mixture, see the following video.