Quicklime: pros and cons

Some materials used today in different fields have been known for a long time, and their properties, as a rule, were determined completely by chance. These materials include lime. By this word, derived from the Greek "asbestos", which means "inextinguishable", they mean burnt lime, which has been successfully used today in many industries.

Special features

Quicklime is a product of burning of rocks, mined in special mines. A special kiln is used as a tool, and the materials used to obtain the final product are limestone, dolomite, chalk and other rocks of calcium-magnesium type, which are subjected to sizing and crushing before firing, if the particles exceed the allowable dimensions.

The design of the kilns used for firing the rock can be different, but the end goal is always the same - to obtain a material suitable for further use.

The shaft type of the furnace, where gas is used as fuel, is one of the most popular designs. The reason for their popularity is very simple: the cost of processing the material is low, and the final product is of very good quality.

Furnaces in which coal is used as a fuel, and the firing process is based on a pouring principle, gradually fading. Although this method of material processing is more economically and productively profitable, it occurs less and less because of emissions to the surrounding atmosphere.

Due to the high cost of the firing process, furnaces with a rotating construction are even less common, allowing to obtain the final product of the highest quality. Furnaces with a remote furnace ensure cleanliness and a minimum percentage of impurities in the final calcination product. This type of furnaces, in which solid fuel is used to warm up and maintain the temperature, has a small capacity compared with similar structures, therefore they are not widely used.

The type of ring and floor furnaces was developed a long time ago. Compared to more modern structures, they have lower productivity and consume more fuel during processing, so they are gradually removed from production, replacing more advanced types of furnaces.

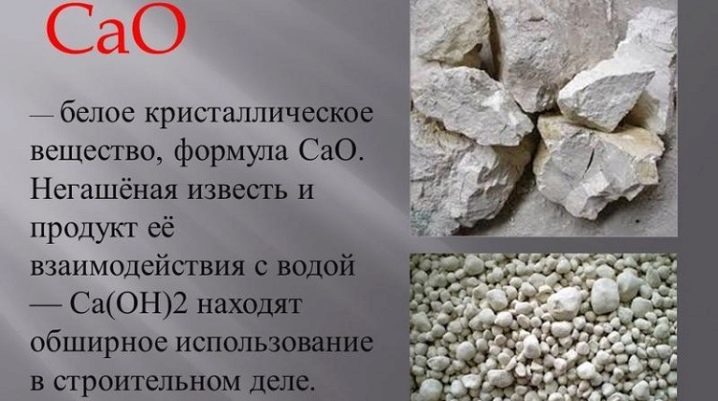

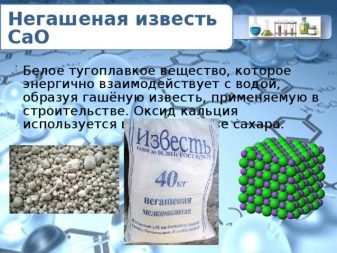

The substance obtained as a result of roasting has a white shade and a crystalline structure with a small fraction of impurities. As a rule, their value does not exceed 6-8% in the total mass. The common chemical formula of quicklime is CaO, or calcium oxide.

The composition of the substance may include other compounds, most often it is magnesium oxide - MgO.

Specifications

Any materials mined in nature and processed in an industrial way have a certain standard, and quicklime is no exception. For quicklime, belonging to the second class of hazard used in construction, there is a quality standard - GOST №9179-77, in which the physical and chemical indicators of this material are clearly stated.

According to the written requirements, the lime particles after grinding should have a certain size. To determine the degree of grinding take a sample and sift through sieves with different cells. The amount of sieved lime is expressed as a percentage.When passing through a sieve with cells No. 02, 98.5% of the substance of the total sample mass is sieved, and for a sieve with smaller cells No. 008 85% of the substance is allowed to pass.

According to technical requirements, additives are permissible in lime. This composition is divided into two varieties: the first and second. Pure lime is characterized by three varieties: first, second and third.

To determine the grade of lime used indicators: active CO + MgO, active Mg, CO2 level and non-extinguished grains. Their number is indicated in percentages, the numerical index of which depends on the variety, the presence or absence of additives in the samples, and also on the breed. If for some indicators the sample of lime corresponds to different grades, then the indicator is taken as a basis with a value corresponding to the lowest grade.

For chemical analysis, as well as the determination of the physicomechanical properties of the samples, they are based on GOST-22688.

Advantages and disadvantages

Like any other material, lime has its advantages and disadvantages. As a rule, it is compared with hydrated lime. The main advantage of the material is a wide range of applications and a relatively low cost of the final product.When working with this material, regardless of the industry, there is no waste, which is very profitable from an economic point of view.

The material perfectly absorbs moisture, which makes it possible to successfully use it as an additional element in the preparation of mortars and concrete mixtures to increase their density and strength. The selection of material in the process of hydration of a large amount of thermal energy allows the solutions, which include quicklime, to harden evenly, and, as a result, to have improved indicators of the strength of the resulting surface.

The only disadvantage of this material is its high toxicity.

What is different from slaked?

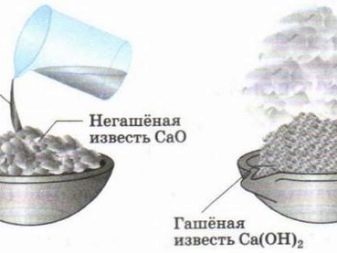

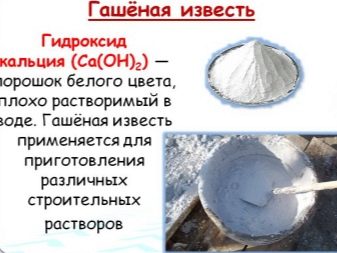

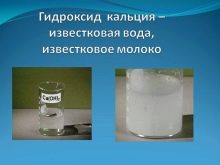

Slaked lime is a modified quicklime product; it is obtained by adding water to the original composition. As a result of a chemical reaction occurring as CaO + H? O → Ca (OH)?, A significant amount of thermal energy is released into the surrounding space, and calcium oxide is converted into calcium hydroxide.

Two types of lime differ in other parameters, namely, the percentage content of indicatorsindicated in GOST №9179-77 and the number of varieties.Slaked (hydrated) lime is characterized by 2 varieties.

The values of the active CO + MgO index differ in two types of lime. For slaked lime without additives, depending on the grade, their quantitative content varies between 70-90% (for calcium composition) and 65-85% (for magnesia and dolomite), and in slaked lime they are only 60-67%. In the compositions with additives, active CO + MgO in the calcium, magnesia and dolomite mixture of quicklime are in the range of 50-65%, and in hydrate this indicator is lower by only 40-50%.

Such an indicator as active MgO in hydrated lime is completely absent. In quicken this indicator varies depending on the origin of the material. It is only 5% in calcium lime, 20% in magnesia lime, and 40% in dolomitic lime.

The level of CO in quicklime without additives is within 3–7% (for the calcium mixture) and 5–11% (for magnesia and dolomitic); in the hydrate composition, the index does not exceed 3-5%. In compositions with additives level of CO? slightly reduced. For calcium lime it is within 4-6%, for the other two types of quicklime - 6-9%. In the hydrate composition of the level of CO? - from 2 to 4%.

The indicator of non-extinguished grains is relevant only for quicklime. For the first grade of calcium lime, 7% of the substance not participating in the reaction is allowed, 11% for the second and 14%, and in some cases 20% for the third grade. For magnesia and dolomite composition, this indicator is slightly higher. In the first grade, 10% is permissible, in the second - 15%, and in the third - 20%.

Kinds

Quicklime is classified according to many indicators, allowing to divide it into different subspecies. According to the degree of grinding particles lumpy and ground lime. For a lumpy look, lumps of various shapes, fractions and sizes are characteristic. In addition to calcium oxides, which are the main component, and magnesium oxide, to a lesser extent present in the composition, other additives may be in the mixture.

Depending on the degree of burning of the lump material, there is distinguished medium burnt, soft burnt and strongly burnt lime. The degree of firing of the material affects subsequently the time taken for the quenching process. In the firing process, the composition is enriched with aluminates, silicates and magnesium or calcium ferrites.

The degree of burning is influenced by the residence time of the product in the furnace, the type of fuel and the temperature.In the firing method, where coke is used as a fuel and the temperature in the furnace is maintained at about 2000 ° C, carbide (CaC?) Is used, which is subsequently used in different areas. Lumpy lime, regardless of how and to what degree it is calcined, is a semi-product and therefore subject to further processing: grinding or slaking.

The composition of the ground mixture is not much different from the lumpy. The difference lies only in the size of the lime particles. The grinding process is used for more convenient operation of calcium oxide. Shredded granulated or ground quicklime reacts faster with other components than a lumpy look.

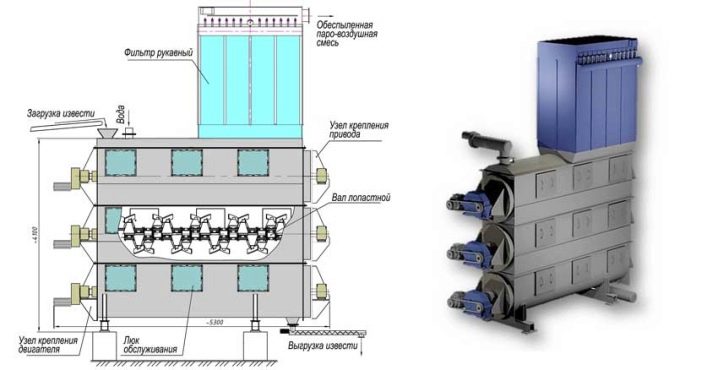

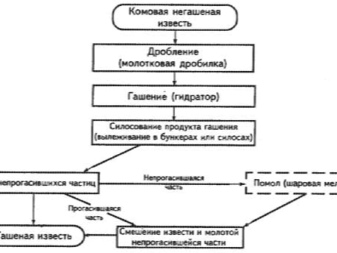

According to the degree of grinding particles distinguish crushed and powdered lime. Crushers and mills can be used for grinding depending on the required particle sizes. When choosing mills and grinding schemes, they are guided by the degree of calcination of lime, and also take into account the presence of solid inclusions and flaws in the calcination process (underburning or burnout). Particles of the material, calcined in a strong or moderate degree, are crushed by means of impact and abrasion in special tanks of ball mills.

A lumpy mixture is used to produce different types of hydrated lime. The quenching process (inorganic chemistry) takes place very rapidly, the water boils up during the reaction, so the lumpy mixture is called the boil. Different percentages of water give different compositions. There are three types of hydrated lime: limestone milk, limestone dough and hydrated fluff.

Limestone milk is a suspension, where a fraction of the particles are dissolved, and the other is in a suspended state. To obtain such a consistency of water is required with an excess of, as a rule, 8-10 times more mass of the product.

It takes less water to get the lime dough, but its amount is still several times larger than the mass of lime prepared for quenching. As a rule, in order to obtain the desired pasty consistency, water is added to the product, which exceeds the basic substance by 3-4 times.

A powder mixture or a hydrated fluff is obtained in a similar way, but the amount of water added is less than for a pasty or liquid composition. Depending on the percentage content of alumoferrites and silicates, fine powder or fuzz is divided into air and hydraulic types of lime.

The time taken for the quenching reaction makes it possible to classify quicklime into fast-extinguishing, middle-extinguishing and slow-extinguishing lime. By the quick-sight form are compositions, the conversion of which takes no more than 8 minutes. If the quenching reaction occurs longer, but the conversion does not last longer than 25 minutes, then such a composition is attributed to the average form. If the quenching reaction takes more than 25 minutes, then this composition is of the slow-extinguishing type.

Special types of calcium quicklime include chlorine and sodium mixture. Chlorine composition is obtained by adding chlorine to the hydrated lime. Soda lime is the product of the interaction of soda ash and calcium hydroxide.

Scope of application

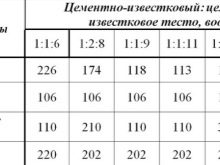

Quicklime can be used in various fields of human activity. It is most widely spread in construction and everyday life. The material is used as an additional component for the preparation of cement mortars. Its astringent properties give the necessary plasticity of the mixture, as well as shorten the curing time.Lime is used as an additional component in the production of silicate bricks.

Solutions based on lime are used for whitewashing different surfaces in the premises. This method of processing ceiling and wall surfaces is relevant to this day, as lime refers to materials that are very affordable, and the decorative effect created by it is no worse than from expensive paints and varnishes.

In agriculture and horticulture, lime is also an important component. It is used to lower the acidity and enrich the soil with calcium. The quicklime compound introduced into the soil promotes nitrogen retention in the soil, activating the work of beneficial microorganisms and stimulating the growth of the root system of plants.

Quicklime also has a negative effect on crop pests. For preventive measures aimed at combating insects, lime is used as a solution with which plants are sprayed or treated at the bottom of tree trunks. For animals, lime is a source of calcium,therefore, it is often given as a top dressing.

In everyday life and medical institutions bleach is used as an excellent disinfectant. The solution from it kills most of the known pathogenic microorganisms, inhibiting the growth and further development. Quicklime helps in the neutralization of domestic gases and wastewater.

In the food industry, lime is known as emulsifier E-529. Its presence allows to improve the mixing process for components whose structure does not allow them to connect correctly.

How to breed?

Quicklime is packed in bags by manufacturers. As a rule, a bag of 2-5 kg is enough for processing plants and whitewashing fruit trees. In order to dilute the lime properly, it is necessary to prepare the container and follow the procedure.

Before cultivating lime, it is necessary to select a container that is suitable in size and material. The volume of the container is selected on the basis of the expected volume, and the material of the dishes can be any, it is allowed to use even metal dishes, as long as it is free of chips and rust.

Lime is poured into the prepared container and water is added. In order for the quenching process to affect the entire mass, the solution must be stirred, especially in the first 30 minutes. As a device, you can use any stick at hand, with which you can later also check the readiness of the composition. A bright white mark on the surface of the stick, which is formed when it is lowered into the solution, confirms its readiness for use.

In order to get the fluff, 1 liter per 1 kg (1: 1) is enough, and in order to get the lime dough, add 0.5 liters of water to the same mass of lime. When breeding must take into account the type of composition. For the slow-extinguishing lime, the prepared volume of water is poured in parts. Water should be added to the quick-extinguishing and lime-extinguishing lime before the evaporation stops, so that the mixture does not burn out.

For processing tree trunks in 1 kg of lime, add 4 liters of water (4: 1), and allow the mixture to infuse for two days. For spraying plants, the composition is prepared two hours before use, and copper sulfate is poured into the solution.

For the preparation of the solution used in the future for whitewashing ceiling or wall surfaces, it is necessary to observe a proportion of 2: 1 - for 1 kg of dry matter you need at least 2 liters.The amount of additionally added water depends on the required consistency of the solution. To use the prepared solution for its intended purpose insist for at least two days and filter before direct application.

Often, after preparation of the solution, there are pieces of outstanding lime that do not need to be thrown away. They can be used, you only need to re-fill them with water and wait for the time required for extinguishing. The resulting mixture is used for its intended purpose.

Tips and tricks

In horticulture, the use of lime as a top dressing for plants is justified only in the autumn or spring period. So lime is better mixed with the soil, having had time to plant the plants to saturate it with the necessary substances. Do not apply lime to the soil along with the compost to avoid an unnecessary reaction between chemical compounds of substances.

Quicklime is still a toxic product, so before proceeding to the dilution of the mixture, you should familiarize yourself with the recommendations indicated on the packaging by the manufacturer.

Handling lime should be done in a well-ventilated area or in open space.

As a means of protection, a respirator is used, which protects the respiratory system from particles, and special glasses that protect the eyes from burns.

It is not always possible to avoid unpleasant consequences when working with lime., and signs of poisoning with a small amount of lime may not appear so brightly. If, after working with lime, symptoms such as swelling and redness of the oral cavity, aching pain in the stomach and esophagus, thirst, and even more nausea and asthma attacks, should be reported immediately to the nearest medical institution or call an ambulance.

Rinse the affected area with plenty of water before the doctors arrive. Especially pay attention to the eyes, because it is there that accumulates the greatest amount of this chemical compound. After washing with water, mucous membranes are irrigated with 0.9% NaCl solution, after which 5% ointment of chloramphenicol is used for the eyes.

If you take all precautions when working with lime and correctly prepare the mixture for use, an excellent result in construction, gardening and other areas is guaranteed, because lime is a universal and inexpensive material used by mankind for several millennia.

How to extinguish the lime, see the next video.