White cement: types and popular manufacturers

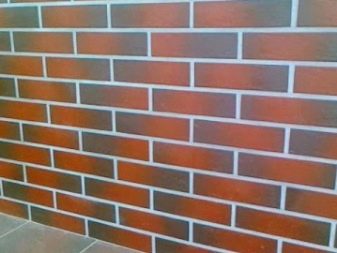

Today, white cement is often used in construction, which has excellent aesthetic properties and excellent technical characteristics. The white color of the material allows it to be used to create various architectural forms, including sculptures.

Special features

White cement is a material in demand due to the light shade, which is obtained by applying a special production technology and components used. It is made on the basis of low-iron clinker, and it also contains mineral supplements, gypsum, limestone, chloric salts, due to which the material acquires such an attractive color. The content of manganese and chromium is almost zero.

All components are amenable to firing, followed by quenching. This process ensures the strength and reliability of white cement.

This material is characterized by functionality, since it can be used not only in construction, but also used as one of the components of dry mixes for finishing works, as well as for creating self-leveling floors.

The technology of white cement production is carried out in special crusher mills, which are used for crushing clinker and other raw materials (porcelain, basalt, and silicon plates). The fineness of the white cement is higher than that of the gray analog, because it is 4,500 cm² / g, and for gray cement this figure is 3,500 cm² / g. The material is burned through the use of gaseous, liquid or other fuels that are not characterized by emissions of ash or soot.

After firing, the cement is cooled in an acid-free environment, with a sudden change in temperature from + 1200ºС to + 200ºС. Cooling can be done with water, then the firing temperature reaches + 1500ºС, and water - + 500ºС. To dry wet clinker, a tumble dryer is used, which has a temperature of + 300ºС.

So, there are two main ways of making white cement:

- Dry. This method is quite common, since many large companies prefer it because of the low humidity of the raw materials. In special shaft furnaces, the grinding, mixing and drying of all components is carried out. The clinker can be fired at a temperature of + 800ºС.

- Wet. Solid components can be ground in a special mill, while soft components are placed in a mash, and water is used. After grinding, the sludge is dried and amenable to further crushing, as in the dry method.

Today, two modifications of white cement — M400 and M500 — are tested in the construction market in accordance with GOST 310.1-76 and 310.4. -81.

Since this material is characterized by fineness of grinding, for sifting it is used mesh No. 008, while no more than 12% of the raw material goes into the sediment.

White cement has the following advantages:

- Durability, reliability and rapid hardening. After 16 hours, the solution hardens by more than 50%. This ability saves money.

- The material is protected from damage under the influence of chemical solutions and moisture due to dispersion.

- Environmental friendliness is achieved through the use of mineralogical components of natural origin.

- The stability and strength of the finished structures is due to the resistance to the formation of chips and cracks. This feature significantly reduces the cost of restoration or repair work.

- Attractive appearance.

- Color fastness, because the cement does not fade under sunlight.

- The versatility of the material lies in the ability to be combined with various decorative materials for decoration.

- Functionality - white cement is used as a decorative and building material, is part of the putty, grout, colored concrete and various dry glue mixtures, and is also widely used in the creation of bricks and floor slabs.

If we talk about the disadvantages of white cement, it is worth noting its high cost compared to the gray counterpart. Some users do not perceive white cement as it should be, but call it something average between clay and cement. Some buyers indicate that many white cement formulations contain a large amount of additives that do not match the composition on the package.

Today, white cement is used in almost all areas of construction work. In some cases, one cannot do without it. It is perfect for building facades.because it gives them not only reliability and durability, but also expressiveness, attractiveness and beauty.

Due to the excellent technical characteristics of this material does not change its original color. It can be safely used not only for external work, but also for internal use. He is not afraid of the effects of weather.

Kinds

Today, manufacturers offer several varieties of white cement to meet the needs in various fields and achieve their objectives as quickly and conveniently as possible.

Depending on the strength of the composition, the following grades of white cement are distinguished:

- M400 - differs in high frost resistance, low sulfate resistance. Deformation during shrinkage and the rate of hardening are average.

- M500 - attracts attention with good frost and weather resistance, medium sulfate resistance. Deformation during shrinkage is low, and the rate of hardening is medium.

- M600 - has high frost resistance, quickly hardens, practically does not shrink, and also is characterized by low sulfate resistance.

White cement has three varieties depending on the reflection coefficient, such as:

- Class I is the highest since its reflection coefficient is 80%;

- second grade - 75%;

- third grade - 68%.

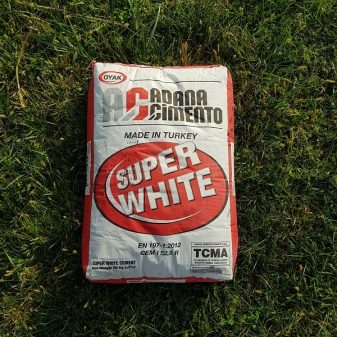

Each manufacturer indicates on packaging the degree of whiteness and grade of cement. These indicators are fundamental when choosing the appropriate option to implement the goals. They have an impact on the cost of production, as well as the appearance of products, the manufacture of which used white cement. A “Super White” cement produced in Turkey is on sale, which has a reflectivity of about 90% and M600 marking. The cost of one bag on average ranges from 700 to 800 rubles.

If we compare white cement with a gray analogue, then it is worth noting that the maximum grade of the second is M500. Decorative grade of snow-white material is labeled M700. It is made according to the latest innovative developments, its technical characteristics comply with European building codes.

It is worth noting that due to the fine grinding, this material is characterized by increased shrinkage.

Often, when creating a strong, reliable and beautiful floor using marble. Marble-mosaic variants, for the manufacture of which marble and cement are used, are in great demand. Decorative effect attracts the attention of many buyers, as manufacturers use not only white cement, but also color (red, green, yellow, beige, light blue and others).

Manufacturers

In the construction market you can find white cement from various manufacturers - Iranian, Egyptian, Danish and, of course, Turkish. The cheapest product is from Iran, but cheap does not mean quality. It is worth getting acquainted in more detail with well-known manufacturers who enjoy fame in many countries around the world.

Aalborg white

The Danish cement plant Aalborg White has gained popularity through the use of clean raw materials and improved production technologies. Brand products can be found in 80 countries of the world, because it attracts attention with excellent whiteness and increased strength. Today, the company's factories are located in Malaysia, China, Denmark and Egypt.But besides the advantages, the products have one major drawback - the high cost.

White cement M700 from Aalborg White has the following technical characteristics:

- whiteness is 85–90%;

- refers to the first grade;

- sold in paper bags of 25 kg;

- the price for one bag is 300 rubles;

- setting of the solution begins after 85 minutes, and ends after 2 hours;

- strength of 36–44 MPa is achieved on the second day, and 68–78 MPa - on the 28th day;

- expansion - up to 2 mm.

Cimsa

This company is a very well-known manufacturer of building materials not only in Turkey, but also in other countries. In addition to decorative white cement, it produces decorative plaster, a variety of putty and grouting.

White cement from the company Cimsa is ideal for creating arches, fountains, columns, balusters, statues. This material in the future does not require painting, because it is protected from burnout and is not afraid of various weather phenomena.

Turkey is home to white cement, and the company's products fully confirm this through the creation of a strong and sought-after product. High quality at an affordable price is the main advantage of Cimsa products.

White cement brand M600 from Cimsa has the following technical characteristics:

- degree of whiteness ranges from 92 to 97%;

- compressive strength after 3 days - 37.0 MPa, after 7 days - 49.1 MPa and after 28 days - 60.7 MPa;

- shrinkage is only 0.01%;

- the beginning of the setting occurs after 100 minutes, and the end - 130 minutes;

- density is 3060 kg / m³.

Adana

Another popular Turkish manufacturer is Adana. It ranks second in the market after Cimsa and is a well-known exporter of construction products, including white cement.

A prime example is the super-white cement CEM I 52.5R. It differs in the increased weatherability, inertness to pigments and can be used for various purposes thanks to durability and reliability.

Technical characteristics of white cement CEM I 52.5R are as follows:

- strength class - M600;

- light reflectance - 90.13%;

- setting of the mortar begins after 140 minutes, and ends - 190 minutes;

- compressive strength after 2 days - 38.3 MPa, after 28 days - 61 MPa.

Tips

Professionals recommend sticking with the following tips when using white cement:

- Various cement tools and molds should always be kept clean. It is necessary to clean them before work from rust, grease, dirt and dust, if any. This rule also applies to concrete mixers.

- To knead the solution, it is necessary to use only pure water.

- If the structure consists of steel reinforcement, then it is necessary to initially cover it with a layer of concrete 3 cm thick. This will prevent the possibility of the appearance of rust spots.

- As a filler should be used only the white version of the fine fraction.

- To make colored concrete at home, you should use cement and white sand, which will allow you to use less coloring pigments to create the desired shade.

- To create a high-quality cement mix, you must adhere to the correct proportions.

- For plastering, it is necessary to mix white cement and sand in a ratio of 1: 3, and then dilute it with water, the amount of which should correspond to the amount of cement.

- To give plasticity to the mixture, it is worth mixing the solution with lime, while about 1–0.7 parts of lime are used for 1 part of sand.

To learn how to prepare a solution of white cement, see the following video.