How to make cement milk and how to use it?

Perhaps everyone who has worked with the sand-cement mixture is familiar with the concept of cement milk. Quite often this watery mass becomes an undesirable consequence of the laying and tamping of a layer of cement. Cement milk must be removed from the surface of the screed. But in many cases, such a watery composition is prepared purposefully for use in various construction purposes.

What it is?

Sand cement mortar is mixed from three components: cement powder, sand and water. This composition, in the case of the correct ratio of all its parts, is a homogeneous mass. However, after the laying of the cement and its tamping, a watery film of a dull white or gray color often appears on the surface. This white matter is the so-called cement milk.In appearance, it resembles liquid glass, especially in the early stages of solidification.

This watery mass is formed as a result of the fact that during the tamping of the laid solution, its separation occurs. Often this process can occur if the cement mixture was prepared with the addition of an insufficient amount of water, and the finished solution turned out to be too dry. In this case, water and individual particles of cement are forced out of the inner layers to the surface, forming a liquid film. Another reason for the formation of a liquid surface layer can be a chemical reaction inside the sand-cement mass. It is associated with the influence of alkali metals.

If ash wastes were added to the concrete or cement mix, then almost always milk is formed on the surface.

Properties

In many cases, a liquid film on the surface of the screed is undesirable. It should be deleted. The fact is that the properties of cement milk differ from the properties of the dried sand cement mass. In particular, this solution has very low strength. Frozen cement milk has a glossy surface, which greatly reduces the adhesion of the concrete or cement base under it.Paint or other finishing layer will not be able to firmly hold at a similar defect in the surface of the screed. After a few years, a layer of paint may begin to fall off in uneven pieces, because the frozen water-cement film will not allow Kohl to adhere well to the sand-cement coating.

Water-cement mortar is used in various types of construction and finishing works due to the following properties:

- fast drying and hardening time;

- water resistance, which allows the use of cement milk as a waterproofing layer for various surfaces and materials;

- hardened layer of water-cement mixture has the properties of heat and sound insulation.

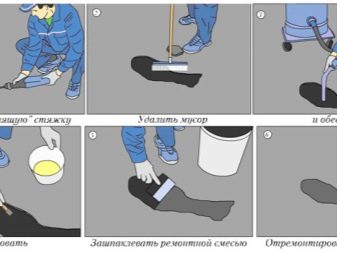

To remove uncured liquid layer on the surface of the screed, grouting is used. Hardened cement milk is removed by mechanical scraping or is treated with a reducing chemical composition, usually on an acid basis.

Application

However, cement milk is not a completely useless mass. In addition to its negative and undesirable functions, this composition can be used for a number of construction works.

Cement milk is specially prepared and used for the following purposes:

- implementation of small cracks in the concrete or cement layer, embed chipping;

- the composition serves as a spill for claydite particles in the thermal insulation layer of the screed;

- alignment of various surfaces;

- hardening of the plaster layer;

- fixing and protection of surfaces from the effects of precipitation;

- ironification of the bases;

- corrosion protection of metal surfaces and containers;

- pretreatment of concrete pump and mortar pumping hoses before the first start-up. The composition envelops the walls of the hoses and prevents the buildup of solutions on them, which reduces the likelihood of plugging and blockage.

Preparation of the mixture

Depending on the purpose and use of the water-cement mixture can be prepared in different ratios of components. There are three main types of compounds that differ in the proportion of the components in the mixture - portland cement and water: suspension (1: 2), batter (1.5: 1), suspension (1: 1).

It is recommended to sift cement before mixing. The presence of lumps or debris will not make the mixture homogeneous.For mixing the water-cement mortar, a drill with a special nozzle or a construction mixer is used.

The following solution preparation technology is used in case it is necessary to shed a claydite layer:

- the proportion required for this type of work is 1 part portland cement and 2 parts water. At first, the cement dissolves with a small amount of water to the thickness of sour cream;

- then, with constant vigorous stirring, the remaining water is added in small portions. The solution must be fluid;

- stirring continues until a completely homogeneous liquid mass is obtained.

If the composition will seal up the cracks in the concrete, it is preparing a thicker. The proportions of cement and water are 2: 1. To strengthen the concrete or cement screed in the composition of the cement milk should be about 30% of Portland cement. For laying under the foundation of the underlying layer, cement powder and water are mixed in equal proportions. In the case of using the composition for interior decoration, 3 parts of portland cement and 1 part of water are put into the solution.

Cost calculation

Mixture costs per m²,as well as the weight of one liter of the mixture will vary depending on the type of the composition itself and the type of work. Typically, the pouring of claydite requires the greatest consumption of water-cement solution.

An approximate calculation of the cost of the solution from the ratio of its constituent components is as follows:

- at a ratio of 1 part of cement to three parts of water, the rate in the estimate will be approximately 2,800–3,000 rubles per m³;

- if 1.5 or 2 parts of water is taken for 1 part of portland cement, then the cost of a cubic meter will increase to 3000–3500 rubles;

- for a solution with an equal ratio of composite components, the price will increase to 4,500 rubles per 1 m³ of the finished mixture;

- if for the preparation of the solution it is necessary to spend 2 parts of cement per 1 part of water, then the cost of the cube of the finished cement milk will exceed 5,000 rubles.

Tips

Follow the advice of experts to properly prepare and use cement milk.

- To prepare a cement-water solution is necessary in the quantities that are needed for the work. This composition has a high rate of solidification and will be unsuitable for use several hours after mixing.In addition, cement particles are intensively precipitated to the bottom, so re-bringing the mass to a homogeneous state is very difficult.

- In the implementation of the passage of expanded clay, you must add milk gradually in small portions. You can make the following fillings after the whole mass of the heat-insulating layer is well saturated with the composition. However, one should avoid flooding of expanded clay mass.

- As an additional component in the kneading of a water-cement slurry, a small amount of primer may be added to it. This will improve the setting properties of the composition and harden the hardened layer.

- During the preparation of the solution and work with it you need to remember about the precautions. The respiratory tract should be protected by a respirator, and the eyes - with special protective glasses. Avoid prolonged contact of the prepared solution with open areas of the body.

The fact that such a cement milk, see the following video.