M500 cement: features and specifications

The modern building materials market offers customers a huge selection of different types of cement products. All types of cements have universal properties and technical characteristics.

The first place in the cement material sales rating is occupied by products of the M500 brand. Cement M500 - a unique building material used for the manufacture of high strength structures. Reasonable price and high speed of hardening makes the material indispensable for emergency and repair and construction works.

Special features

M500 cement is a sought-after and indispensable building material used for the manufacture of high-quality and high-strength dry mixes. Constructions of this material withstand a load of 500 kg per 1 cm².Resistance to low temperatures and rapid curing gives the opportunity to work in the winter.

Professional builders note the undeniable advantages of Portland cement (hereinafter referred to as HRC):

- lack of corrosion and interaction with water;

- resistance to aggressive chemicals;

- low percentage of shrinkage;

- high resistance to mechanical stress and damage;

- elasticity;

- convenient packaging;

- short set time.

Among the disadvantages is the fact that during long-term storage of cement, its strength indicators are significantly reduced, it loses its qualities and properties.

To preserve the unique features and properties of the material, manufacturers advise not to add foreign components and other brands of cement products to the cement.

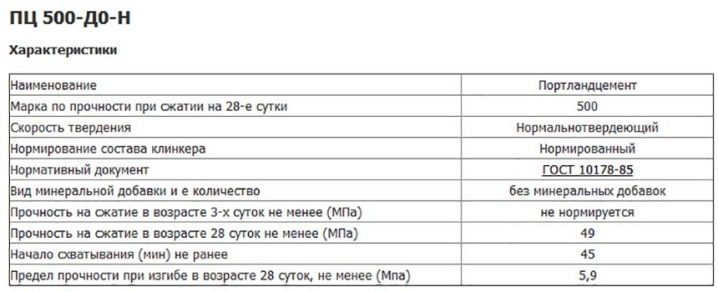

Composition and characteristics

Cement M500 - finely ground mineral powder of gray color is produced according to GOST 10178-85. Calcium silicate, which is part of the product, gives it high strength, reliability and resistance to temperature changes, prevents the appearance of cracks and bulk chips.The main components of the building material are gypsum stone, limestone, clay, mixture, modifying additives (hydrophobic, plasticizing).

Manufacturers of building materials indicate on the packaging information on the composition, description and specifications of products. Cement M500 has the following characteristic parameters:

- compressive strength 50 MPa;

- resistance to low temperatures F70;

- bending strength 7 MPa;

- full setting occurs after 5 hours;

- shelf life with intact packaging 12 months;

- density of 3300 kg per 1 m³;

- 1 class of radioactivity;

- low expansion rate;

- bulk density of 1000 kg per 1 cubic meter;

- the size and specific gravity of the particle fraction of the components and the fineness of grinding is 95%.

Which is better?

On the shelves of hardware stores you can find several types of cement mixtures with different markings. The letter M indicates cement strength, and the numbers indicate the weight of the compressive load. Marking M200 indicates that the design will withstand a load of 200 kg per 1 cm³ without damage, marking M300 indicates that the product has a compressive strength of 300 kg per 1 cm³ and so on.

Buying building mixtures, it is necessary to study the technical characteristics of each type of cement.

- M100 - has a low level of strength (10 MPa), is used to perform masonry work, plastering, sealing seams.

- M200 - used for the production of masonry mortars, paving of paving slabs, for the manufacture of weak concrete mortars, for sealing cracks. Gaining strength with high humidity in the room. Grasping occurs after 120 minutes, strength - up to 22 MPa.

- M300 - demanded material with reasonable price. It is used for the production of concrete mixes, floor screeds, for wall cladding and grouting. The setting time is 80 minutes, strength - 30 MPa.

- M400 - it is used for installation of all types of the base, for production of columns, for a batch of construction solutions. The beginning of the setting occurs in 2 hours, strength - 40 MPa.

- M500 - demanded type of building material with a strength of 50 MPa. It is applied on objects with high requirements and increased loads.

- M600 - used for the construction of military facilities, has a strength of 60 MPa, setting occurs after 45 minutes.

- M700 - it is applied on objects of the state value, has the high price and durability of 70 MPa.

Manufacturers of cement mixtures note that the higher the grade of material, the higher the strength of the resulting concrete. To obtain a low grade solution, you must take a small amount of binder. Knowing the proportions and the design of cement mortars, it is possible to significantly reduce the estimated cost of the work.

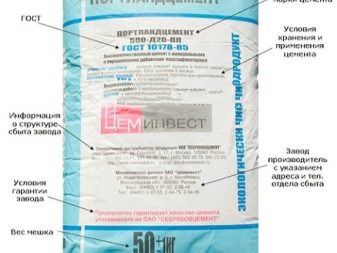

For self-buying cement mixes, professional builders advise you to follow some rules:

- choose products of famous brands;

- carefully look at the weight of the packaged goods;

- check the date of production and service life;

- study the technical characteristics indicated by the manufacturer on the package.

Proportions and packing

Portland cement has several types, differing in technical characteristics, price and proportions of the components included in the composition:

- D0 - pure mixture without impurities and additional components, has high resistance to low temperatures, moisture and mechanical loads, is used for large-scale construction of industrial facilities;

- D20 - mixture with the addition of modifying additives,the volume of additional components does not exceed 20 percent, has increased corrosion resistance, is used for minor repairs, has a high price.

When buying cement in hardware stores, it is necessary to pay attention to the additional marking on the packaging:

- H - the use of clinker in the normalized amount;

- B - has a high setting speed, it is used to eliminate hydraulic accident;

- Submarine - with the addition of plasticizers that increase resistance to low temperatures;

- VRTS - a mixture resistant to moisture, is used to eliminate cracks and cracks;

- Gf - at operation there is no absorption of water;

- BC - white mixture for decorative works;

- SS - high resistance of the solution to the action of aggressive elements;

- ShPC - has a large number of additional elements.

For high-quality construction work it is necessary to choose the type of cement that will meet the objectives.

Cement M500 brand is produced in the form of dry construction powder. Before starting work, the material must be diluted with water in the proportions indicated on the package.On the shelves of hardware stores one can find goods packaged in 25 kg and 50 kg packaging bags. To implement large-scale construction of industrial and civil facilities, construction organizations purchase cement in bulk quantities of several tons.

The interval of the price range depends on the quantity of purchased goods.

Application

Producers of cement mortar brand "Eurocement" classify the mixture depending on the application:

- quick hardening - used for accelerated construction;

- sulfate-resistant SSPTS - used for the installation of massive foundations of moorings and ports;

- with surfactants - special mixtures with high plasticity and low water permeability;

- waterproof - expanding cement for waterproofing mines and water systems;

- plugging - for waterproofing groundwater from industrial wells;

- decorative - used for decoration of facades of buildings, has a wide color gamut.

High-quality cement has a wide scope:

- pavement repair;

- construction of apartment buildings;

- production of reinforced concrete monolithic structures;

- construction of hydraulic structures;

- the accelerated installation of a timbering for the base;

- production of high strength structures;

- construction of airfield runways;

- emergency construction work;

- manufacture of fences and paving slabs according to European standards;

- production of building mixtures for masonry work and plastering surfaces;

- creation of decorative elements for landscape decoration.

Applying the cement mortar, the beginning masters make a number of serious mistakes and technological violations:

- the use of low-quality coarse sand;

- heterogeneous mix of cement and sand;

- violation of the proportions of the components;

- adding large amounts of water;

- ignoring the rules and technologies of drying.

Manufacturers

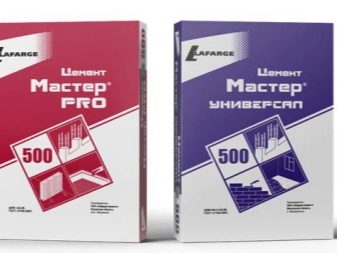

The annual increase in demand for cement grade M 500 leads to the constant emergence of new producers of building material. Leaders in the production of high quality building mixes brand M500 is French company Lafarge and Swiss Holcim. The combination of two large manufacturers into one LafargeHolcim trading brand has led to an increase in production capacity and the supply of products to more than 100 countries of the world.

The use of innovative production technologies and high-quality raw materials leads to a constant increase in the technical characteristics and properties of products. Special attention is paid to the production of sulphate-resistant types of cement for work in climatically difficult regions. Reasonable prices and high quality products of this brand allowed her to take first place in the sales of building mixes. To increase the production of cement mixes LafargeHolcim working on opening new branches in different countries of the world.

The brand LafargeHolcim has developed a new type of cement ExtraCem for strategic facilities, which has a high curing rate and resistance to frost.

Products of this brand have a number of differences and advantages:

- unique compatibility with various chemical components;

- long period of operation;

- high level of strength;

- mobility;

- resistance to low temperatures and high humidity.

Russian manufacturers of building mixtures are the main competitors for European companies. Products company "Eurocement" enjoys a well-deserved demand from buyers, and low prices and high quality make it indispensable in carrying out construction work of any complexity and in different climatic regions.

On the shelves of hardware stores you can find Mexican products. Cemex companies. The cement of this brand has a low price; it is produced on high-class equipment in accordance with European standards.

The unique technical characteristics, strength and durability of the building material allowed him to occupy a leading position in the sales of cement products. Reasonable price of the material significantly reduces the estimated cost of the object, and a high pouring rate reduces the time of construction and physical costs.

Choose the necessary type of material will help detailed instructions and specifications of the goods specified by the manufacturer on the packaging and professional consultants of building stores.Only the use of high-quality material from well-known manufacturers will allow the construction and operation of the planned facilities.

How to choose cement, see the next video.