Portland cement M500: properties and scope

Building mixtures for the construction of various structures and objects almost always contain cement. This important binder is divided into a number of brands, among which the leading position is occupied by the M500. Any builder (developer) should thoroughly deal with it even before the start of work.

Obtaining astringent reagent

Chemical analysis of the qualitative mixture shows that it includes:

lime;

gypsum rocks;

iron compounds with oxygen;

silicon dioxide.

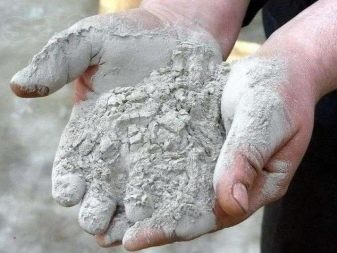

In order to obtain the well-known “gray soft powder”, the components used are mixed in a strictly defined proportion and ground. Each stage is strictly described by the state standard.

Portland cement can be used both by professionals and amateurs who need it to build their own houses. The strength and density of the masonry being created is quite decent by modern standards.

The material can be used when joining bricks, concrete blocks. and other construction blanks.

Using

Portland, complying with the standards of the Russian GOST, can be applied:

for the needs of road construction;

in the formation of runways at airports and at airports;

as a formwork for building foundations;

when creating beams and floors, under heavy load;

for receiving the inseparable bases in places with high standing underground waters.

This material is also useful for plastering on various surfaces. Separate masters can use it in the formation of sculptures and architectural columns, in obtaining finishing materials.

The advantage of the cement mortar category M500 is its strength and reliable cover from the destructive environmental factors. Equally important for consumers is the price of the binder, which does not prevent it from having excellent qualities. There are dry cements from various companies on the market, the properties of which are strictly the same due to proven technology.

Key benefits

The characteristics of the PC allow this material to carry a significant load. The figure in the description of the brand shows that 1 square. cm will be able to withstand the effects of pressure up to 500 kg. Calcium silicate gives the material high frost resistance and eliminates the occurrence of cracks even after prolonged use.

It is quite possible to pour concrete mix in winter., it will not affect the quality of the construction. Additional advantages of Portland cement are fast setting, elasticity of the coating and reliable work in a chemically aggressive environment.

It is not allowed to mix Portland cement with astringent mixtures of other categories, even higher ones; this may result in a poor quality product.

Cement of such a group divided into two main subspecies - D0 and D20. In the first type of material, no additional substances are used, and the resistance to humidity and cold allows the use of Portland cement in large-scale construction. But the second subtype is much better resistant to corrosion. Therefore, it is actively used when you need to repair broken concrete structures, walls.

Portland cement is represented in the assortment of suppliers by powder and ready mix. Powdered substance is bought by individual developers and those who repair private houses themselves. But here it makes sense to build large-sized objects only when receiving portions of the finished solution. This allows you to speed up the process of work. In addition, the fabrication of a significant amount of concrete minimizes the likelihood of errors and the effect of negative factors that are always present on the construction site.

Cement D20 doing, taking a clean clinker and adding a small amount of gypsum. Such a decision is justified by accelerated hardening. A mixture of the same name is required in the repair and the formation of a self-leveling floor. It is also used to make plaster on the facade. Although the price of Portland cement M500 is acceptable for most people, it can vary somewhat in certain regions. The final figure is best learned directly from the seller.

Recommendations for selection and use

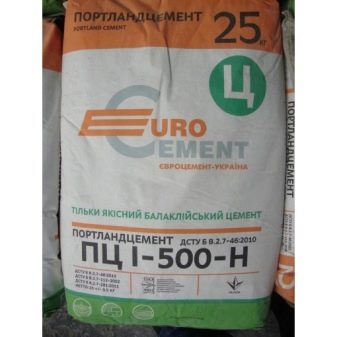

Experienced consumers always carefully study the labeling and related documentary materials.Thus, some manufacturers try to promote their products with reference to a low price, but at the same time the density of the cement is insufficient or it is simply shipped in a bag less than 50 kg. Reputable suppliers always indicate the GOST to which the building material corresponds, and write on the packaging a city (in no case a mobile) telephone.

Marking shows what are the main characteristics of the material:

H - clinker concentration is standardized;

Submarine - added plasticizers;

B - the solution will harden quickly;

Gf - the resulting layer of concrete will effectively repel water;

VRTS - 100% water tight;

SS - suitable for use in a chemically aggressive environment.

It is important to take into account the objective weaknesses of Portland cement. Like all members of this group of building materials, it should be stored in an ideally dry place, where condensation or saturated air vapor is excluded.

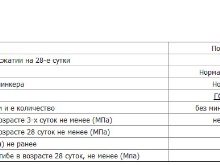

The solution grabs at least 45 minutes later, and working strength gains within 600 minutes. Bulk density can vary from 1100 to 1600 kg per 1 cu. m, but the actual density is standardized and is 3200 kg.In accordance with the latest standard, Portland cement may be labeled starting with the letters "CEM". It shows the category of the fortress, how quickly it sets. These parameters for the choice of a binder by non-specialists are quite enough.

It is not necessary to use the services of a professional laboratory to assess the quality of Portland cement. Home inspection begins with the preparation of a portion of the solution in mineral water. You should wear gloves and glasses in advance. The liquid, heated during the reaction, boils. The resulting dough rolls into a kind of pancake, the core of which is thicker than the edges. A good binder should become hard on average in 20 minutes, maximum 25-30.

Portland cement can be used to form retaining walls and precast concrete. He also behaves well as the basis for a strong concrete foundation.

The solution is easily poured into even the most difficult to reach areas due to its plasticity. From it you can get a hard flame resistant material. Portland cement is used even in the prevention of corrosion on river and sea vessels.

How to choose cement, see the video below.