How much cement is needed for 1 cube of concrete?

The basis of concrete is cement, because it binds all the constituent parts of concrete into one whole mixture. And also cement influences durability, frost resistance and moisture resistance of the stiffened concrete. If it is not added enough for a particular brand, then the frozen element will not be as durable. It is worth noting that cement is the most expensive ingredient of the concrete solution.

Special features

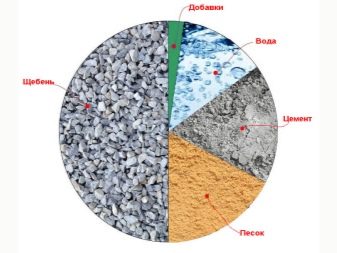

In order to calculate the right amount of cement, you must first understand the components of the material. The concrete mix includes crushed stone, sand, cement and water. But in order to mix the quality mixture, you need to strictly adhere to the rules. If the normalization of the components is not observed, then the mixture made will not correspond to the required brand.

In order to make the correct calculation, you need to know: the brand that is needed, the period of hardening and which mobility of the filled product is needed. The proportions of the components are determined, starting from a sufficient volume to fill a particular product.

When concrete is kneaded, the cement in it is a component unit, and the remaining materials are components of the mixture volume.

In order to mix high-quality material, the following rules for calculating the amount of materials must be observed when performing such work:

- cement should be added strictly according to the required proportion, otherwise the concrete will be fixed or, conversely, too mobile;

- when mixing concrete, it is necessary to take into account the brand of the cement itself, since it must be 2 times larger than the brand of concrete, for example, cement 400 or 450 must be used for the brand of concrete 200;

- in order to find out the desired brand of concrete and its quantity, you must first take into account its place of use;

- experts recommend that one part of cement grade 400 add two parts of sand and four parts of rubble;

- so that the quality of the prepared mixture was high, it is allowed to deviate from the norm, but not more than 1 kg;

- masters recommend purchasing cement in bags of 50 or 25 kg, because it will be much easier to calculate the amount of cement per concrete. If the concrete mix is made at home for their needs, then the calculation of the constituent material is best done using buckets.

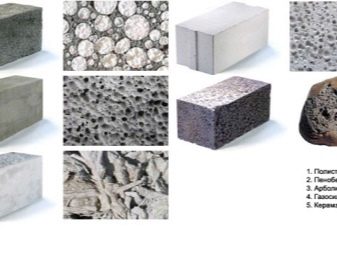

Kinds

As mentioned above, the composition of concrete includes gravel, cement, sand and water. Do not forget that for the preparation of high-quality concrete, if it is brand 200, then cement must be added brand 400.

Concrete is different brands, each of them is used for certain works.

The grades of concrete and their scope of application are as follows:

- Concrete grade 100 can be used for work related to the foundation, as well as serve as a cushion for the curb;

- the brand of concrete 200 is used to fill the foundation, screed, manufacture of concrete stairs or garden paths;

- Grade 300 is used to fill monolithic structures such as walls, floor slabs and stairways;

- brand 350 solution is used for the manufacture of concrete products, and even for the design of landing strips on the ground;

- Brand 400 is often used for casting pillars for bridges, columns, and similar structures with high quality requirements;

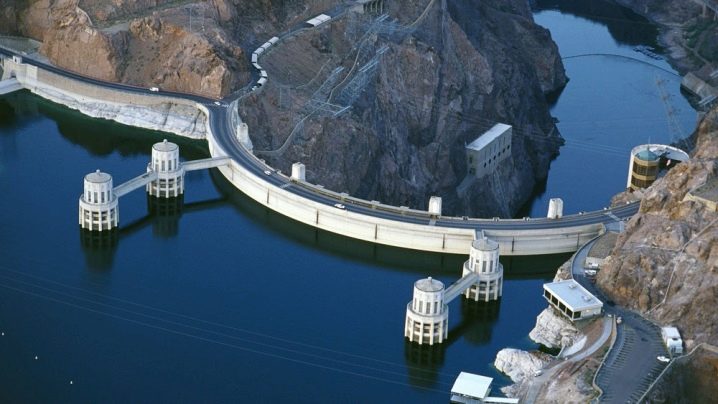

- The highest grade of concrete mix is M500, which is used to fill the bridge, to manufacture concrete products, as well as to fill floors in the metro and to design the dam.

In order to obtain the necessary type of concrete solution, it is necessary to adhere to the proportionality of all components during the manufacture. As for the amount of water in the concrete, in order for the concrete to set properly, it is necessary to divide the weight of the cement by 2. Thus, the required amount of water is obtained, which will be enough to create concrete.

Consumption

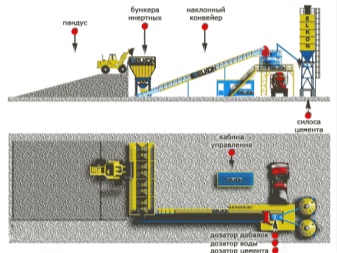

The quality and uniformity of the composition of the mixture will depend not only on what proportions are chosen and the degree of preparation of the components, but also on the sequence in which the ingredients for the solution will be combined. If we consider private construction, here we use two methods of manufacture - manual and mechanized (using a concrete mixer).

It is worth paying attention if the first version is used, then the filler and the binder component should be mixed only in a dry form and only after that can water be added.

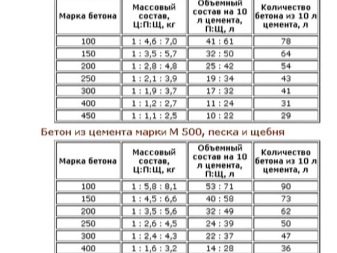

It is necessary to try to prepare all the components at once and strictly according to the required volumes. The amount of cement per cube of concrete can be viewed in the directory.

For the main grades of concrete, the consumption of cement grade 500 is as follows:

- for concrete grade 100, which is used for preparatory work for the main casting, it is necessary for one cubic meter of 166 kilograms of cement;

- if M200 is produced, which has a wide range of use, including for filling the foundation, then 241 kilograms of cement are needed per 1 cubic meter;

- in the manufacture of brand 300, which also has a wide scope of application, but has higher qualities, it is necessary to add 319 kg of cement;

- To mix 400 concrete, which quickly sets in and is often used for casting hydraulic structures, you need to add 417 kg of cement.

In order to get the appropriate grade, which will have a long period of operation, it is necessary to adhere fully to the proportion in the manufacture - 1 part of cement, 2 parts of sand and 4 parts of crushed stone. In this way, high-quality, ductile and durable concrete is produced.If you deviate from the norm and reduce the amount of cement, then a bunch of all other components will not be so resistant to external influences, which may entail a temporary service life of the filled product.

To calculate how many bags you need to work and what ratio of gravel, gravel and sand concrete is required for laying, you will need a table. It presents an approximate calculation of how many dropouts go, how much goes the total mass, and what the result will be. Such calculations are very important, especially for claydite-concrete blocks.

In principle, cement consumption per 1 m³ depends on the brand that they want to end up with. And the brand itself depends on the area of use, for what purpose concrete will be used. For household needs and structures of not more than one floor, the mark 200 is used. It is also used to fill the foundation, the site and the tracks. Another such concrete is used to construct a concrete staircase and as a cushion for curbs. Concrete M300 is mainly used for casting monolithic structures, for example, walls and floor slabs.

Concrete requires water. Concrete plants have exact proportions of water for each brand, as specialists know with which indicator moisture should be used sand.But for the manufacture of such a mixture on construction sites or at home, the factory proportions are irrelevant, since the workers do not know how much moisture contains sand and rubble.

In this case, water is added as the solution is stirred. Experienced experts recommend adding an incomplete bucket of water to one cement bucket, and if that is not enough, then add a little while using the mixture.

But do not forget that for the preparation of the mixture, you must use water that is clean and does not have salt mixtures.

Tips and tricks

Every person who plans or is engaged in construction should know that cement cannot be stored for a long time. According to experts, cement after a month of manufacture loses about 10% of its qualities, if, of course, it is not used. For this reason, when you buy cement, you must pay particular attention to the date of its manufacture.

If you buy cement brand 400 and not use it immediately, then by the time of preparation it may lose some of its qualities, so it will already be used as cement brand 350, and this already affects the proportion.According to the recommendations of experienced builders, it is necessary to knead the concrete in small volumes. If the solution is made by yourself, then you should stick to certain proportions. Basically, one part of cement, 3 parts of sand and 5 parts of crushed stone are used for kneading, that is, a ratio of 1: 3: 5 is obtained.

Following the advice, high-quality concrete, which will have few pores, is made with the addition of crushed stone of different fractions, and sand must have a grain size from 1.1 to 3.5 mm.

For the manufacture of high-quality concrete on the recommendation of experts it is necessary to use such components that meet the following requirements:

- the constituent materials of the solution must be clean and free from impurities of the chemical and organic type;

- as for the main ingredient in the solution, which is cement, it should be brand 400 and above, for example, to make a mixture of brand 350, you must add cement brand 500;

- no less important constituents of concrete is crushed stone. To obtain high-quality concrete, it is necessary to use crushed stone with a strength of 800 to 1000 kgf per 1 square centimeter, since brand 400 can be made from such crushed stone;

- for the preparation of concrete mixture can be used as a career, and river sand, but this ingredient must be washed from clay and dust impurities. The sand should be coarse or fine-grained, but not mixed.

If the mixture is produced at home, then the production process should take place without different chemical additives, since they can adversely affect the strength level of the filled product.

Another important thing to remember is that sand must be used for concrete, which does not contain in its composition of clay substances, which also adversely affect the quality of the solution. The main requirement for water that is added to the solution is cleanliness. For such purposes, experts do not recommend the use of river water, which contains algae and similar substances.

In conclusion, it is worth noting that for any construction work with concrete it can not only be independently kneaded, but also ordered in the finished form from the factory. Such concrete, of course, costs a decent amount, but its quality will be higher than self-made. Of course, if you need a small amount of concrete for household needs, for example,something to add to secure or reliability, pour the area under the gazebo, then ordering the finished mixture is irrelevant, since the cost of such delivery becomes much more expensive. For such cases, experts advise to knead the concrete on their own.

To learn how to correctly calculate the concrete, see the following video.