Cement consumption per 1 m2 of brick laying

Among the huge and diverse range of building materials, brick is one of the leading places. Brick buildings are valued for durability, environmental friendliness and durability, architects love it for the opportunity to create unique projects. However, the quality of the future building depends not only on the material, but also on the cement mixture, which is placed between the bricks.

The preparatory stage before construction is not complete without counting the amount of raw materials needed.

After all, the correct calculation of cement will help to build a high-quality housing, which will serve the owners for many years, as well as save money.

If, after completion of construction, the cement mortar remains in excess, there will be a need to look for a place to store, and after all, over time, the raw materials may become unusable. In the opposite case, when you purchased an insufficient amount of cement, you will have to be interrupted in the process of work and urgently acquire additional raw materials.

In this article, you will learn what you need to know to correctly calculate the cement consumption per square meter of masonry.

What influences consumption?

If during the construction of buildings the consumption of concrete is calculated in cubes, then in working with facing bricks the calculation is carried out in square meters.

Even at the preparatory stage of construction it is necessary to evaluate the characteristics that indirectly affect the consumption of cement in the process of work:

- terrain relief;

- soil properties;

- climatic conditions.

From these important details, in fact, it will depend on how the brick will be laid, what material will be used and what composition of cement mortar is needed for laying.

Professional builders before installation take into account the following factors:

- It is necessary to consider the type of masonry and the thickness of the walls You can put in a half brick - in this case, about 50 standard bricks will be left for 1 m². The one-and-a-half masonry variant has a consumption of up to 150 bricks per 1 m².

- An important role is played by the brand of cement. For example, in the construction of residential buildings it is recommended to use the brand M100, M300 or M500.

- A larger amount of cement is spent on hollow bricks than on full-bodied ones, because of the voids in the product, which should be completely filled with mortar during operation, excluding airing of the wall.Also the expense will depend on the water-absorbing properties of the material.

Great attention is also paid to the composition of cement mortars and the process of preparing the mixture.

Varieties of solutions:

- cement-sand - the standard type of mortar mixed on cement, sand and water;

- mixed - it is a combination of cement and sand, diluted with lime milk;

- plasticizer blend - polymeric additives, to improve ductility.

What tools are needed?

For high-quality kneading and laying cement mix will be required:

- Construction mixer for the preparation of cement mix or concrete mixer. Recently, a new model for working with cement - a mixer drill, equipped with needle bearings.

- Net capacity.

Cooking technology

Cement can be of any brand, and, accordingly, of different strength. For the construction of brick buildings are usually used brand M200 or M300, for the construction of the foundation - M500. Sand is needed in order for the mortar to acquire an astringent consistency; without it, the cement will turn into a mixture without adhesive qualities. Water is needed for the reaction of sand and lime,which is contained in cement powder.

Depending on the method of laying and the size of the bricks, the mixture will be used differently.

Typically, the proportions of cement and sand have a standard formula: one part of cement accounts for 3 to 6 parts of sand. But the most common classic version is 1: 4.

The volume of water is about half the volume of cement.

For greater plasticity of the masonry composition, you can add special additives, for example, conventional detergent, plasticizers or mineral additives.

Cement mortar, which holds the bricks together, loses its plasticity very quickly, so not only skill is needed, but also the ability to calculate in advance the speed of their own work so as not to spoil the resulting cement mortar, which eventually begins to dry and crack. With the help of special additives, it is possible to obtain quickly hardening or, on the contrary, slowly thickening solutions, hydrophobic, colored or white cement mixture.

Mortar kneading is a crucial stage on which the strength of the future construction and the reliability of the masonry depend.

You can prepare the cement mixture with your own hands or with the help of special equipment.The use of a concrete mixer is a more convenient, fast and high-quality option, especially for the preparation of large volumes of the composition. It is important to achieve complete homogeneity, eliminate the formation of lumps.

Pour into a concrete mixer 1/2 volume of water, add a little detergent for better plasticity, and then pour sand and cement.

It is necessary to mix the mixture each time after a new filling of components within 3-5 minutes. It is most convenient to adjust the density of the mixture at the very end of the mix.

It doesn't matter what order you put in the ingredients for the mix. The most important thing is that the prepared cement solution for work does not bubble and does not have lumps and seals.

To obtain one cubic meter of cement mixture will need 1 m³ of sand and 0.25 m³ of cement.

It should be remembered that the masonry solution hardens very quickly, so it is not recommended to do its preparation for future use.

When mixing by hand, it is important to adhere to the necessary ratio, so that the mixture is homogeneous. At the same time, sand and cement are mixed in a separate container and only in a dry form. After the mixture acquires a uniform gray color, water is poured into it in small portions using a funnel. The resulting mixture is thoroughly mixed to a uniform consistency.

Please note that it is better to use clean water and no impurities.. Detergent choose to your taste, but it should have excellent solubility in water and not settle at the bottom. Together him you can add any plasticizerwhich today are presented in a wide range in any hardware store.

The sand must also be cleaned, without clay and other impurities, sifted through a sieve. If you decide to use colored cement for decorative solutions, remember that dyes significantly reduce the quality and hardness of the mixture.

How much will it take?

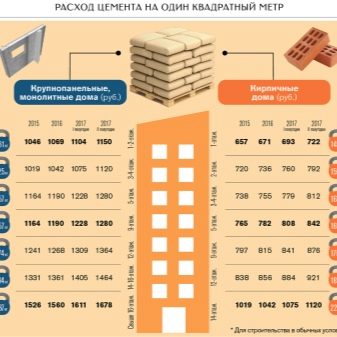

When facing with brick, developers are interested in the required mix consumption per 1m². All the norms are laid down in the SNiP, but in reality it turns out that the real numbers are always greater.

The greater the thickness of the walls, the greater the volume of cement mortar needed. For example, in the construction of walls whose thickness is equal to a quarter of a brick, then 5 kilograms are needed for 1 m² of masonry when using cement of the M100 brand.

The volume of cement will drop to 4 kilograms if you mix the mixture on cement grade M75.

The consumption of cement powder will significantly decrease with the addition of other components, such as limestone, marble or clay.

For example, per 1,000 bricks will need 0.9 cubic meters of cement mortar. After that, it is not difficult to calculate the consumption per square meter of the wall of the building under construction. For convenience, the calculation can be ordered from professional builders or use online calculators.

For information on how to calculate the amount of cement, see the video below.