Choosing a laminate in the apartment and country house

Laminate flooring has become one of the most used flooring materials in the world. When we choose it for the decoration of the walls, the floor and even the ceilings of our apartment or country house, we rarely think about the history of its origin. And it is very interesting at least in that it proves once again a simple truth: everything ingenious is simple.

What it is?

To understand what a laminate is and why it is so in demand in the modern market, you need to know the history of its origin, which is made up of interesting facts of discovery, creation and improvement of this material.

There is a legend that the predecessor of laminate - a laminated parquet flooring model was accidentally subjected to unforeseen use, when an employee of the Swedish company Pergo put a hot kettle on its film surface. He did not cause any damage to the film.Next, the new surface was tested for mechanical strength, trying to damage by various means at hand - a knife, a hammer. The results pleasantly surprised the company's management, and she began to develop new material for the floor.

It happened in 1977, since then the market for flooring and finishing materials has changed dramatically due to the fact that it was firmly occupied by the laminate, on the development of which several companies worked. The one we know produced the Hornitex Werke Beeskow brand in 1987.

And that same Swedish company Pergo invented the first version of the laminated floor by squeezing the product under pressure. Faus, Alloc and Unilin (now Quick Step) were also working on developing improved versions of laminate flooring.

The main milestones of its production:

- He invented himself and his first technology from the Pergo Swedish specialists in 1977 - squeezing high-pressure fibreboard under high pressure - HPL. Although the same coatings for kitchen worktops were invented even earlier - sometime in the fifties, and already on their basis - the first laminate, after a famous story with a teapot on laminated parquet.

- Engineers of the German company Hornitex in 1987 finalized the Swedish model of laminated board, almost the way it has come down to us.At the same time, in Pergo, not wanting to lag behind the Germans, they replaced fiberboard with chipboard, improving the water repellent properties of the material and its density. Chipboard of higher density than fiberboard chipboard, perfectly absorbs resin and glue. Competition is the engine of progress.

- In 1989, the technology of direct pressing (or pressure) - DPL (Direct Pressure Laminate) appeared, now it is the most demanded, 90 percent of the entire laminate is made in this way.

- The 90s are characterized by the emergence of all sorts of decor options, the first stone pattern appears.

- 1996 - the year of the breakthrough invention of the castle laying system, which became the best for laying a laminated floor, invented at the moment, and since then it has only been improved.

- In 2000, invented soundproofing.

- 2001 entered the history of laminate due to the appearance of wood textures and imitation of tiles in the decor.

- The year 2006 changed the usual form of panels - square and elongated boards appeared.

- Since 2008, there is a new design in different styles.

It remains to mention the newest methods of production of this material - this is DPR - direct printing, CPL - method of continuous pressure, HPL - high pressure and DPL - direct pressure, which has become a classic method. As a basis take chipboard, MDF and HDF.Melamine-formaldehyde resins protect the decorative layer.

Such a number of technologies is explained by the high demand for this material, whose decorative and practical qualities have become the key to its widespread use in rooms of various types - from residential spaces to any objects with intensive traffic.

Interesting fact: laminated flooring came to the United States in 1994, and it has been used in Europe since 1984. Since then, the whole world has been actively developing its production and its application. Let us proceed directly to the definition of what a laminate is, what its properties are, consider what it consists of and find out what it is like.

Laminate can be called laminated flooring, which replaces the expensive solid wood floor and repeats the shape and decor of ceramic tiles, natural stone. It consists of a base - a high density of thin fibreboard or chipboard. Different layers of paper are stacked on them in stages, and the resins impregnate them. Next, the layers are one of the following methods are glued together, pressed under strong pressure with the participation of high temperature.

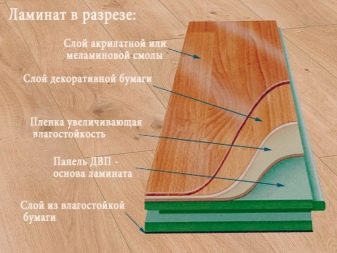

Layers of which the laminated material consists:

- Overlay (topmost layer) - a film of acrylic or melamine resin, which protects the drawing from abrasion, loss of color, and the board itself from wear. The strength class and, accordingly, the scope of the floor covering are determined by the quality of the overlay. The matte or glossy appearance of the panel depends on the additives applied to the top layer.

- The layer of paper that follows the overlay is responsible for the décor of the panel - it can be any color, texture and relief, from wood to tile, from the original bright color board to a complex artistic pattern.

- Layer of hardboard or particleboard. His task is to ensure the rigidity of the product. The durability of the panel depends on the thickness of this layer (8-12 mm). The thicker it is, the more reliable the panel.

- The last layer consists of a base paper that is impregnated with resin or plastic. The purpose of this layer is to protect the slab from moisture and help preserve its shape during temperature changes.

- Additionally, in the top layer, the manufacturer can add corundum, which increases the strength of the panel, and an antistatic agent to repel dust.

As you can see, there is nothing difficult in the composition of the laminate, this figure shows it in section:

There are classes of wear resistance and durability of the laminated floor. 21, 22, 23 classes are discontinued in Russia, but they can be imported from other countries if necessary. 31, 32, 33, 34 - belong to classes with high indicators of strength and reliability of floor coverings.

The higher the class, the better the material in all respects, the thickness of the plate also testifies to this.

The quality indicators of the laminate are:

- Resistance to abrasion and fading of the surface (depends on the overlay, its composition and additives);

- The strength of the base, the willingness to keep a given shape (ensures the composition of the base, chipboard - keeps its shape well and is not very permeable, HDF - has the highest density);

- Sound absorption level;

- Moisture and water resistance (determined by the class and depends on the type of lock, the quality of its impregnation, the composition of the base and the stabilizing bottom layer);

- The refractory properties are equally high in all grades due to the composition of the overlay — melamine-based resins;

- The type of lock connections - Click or Lock - also refers to the quality of the floor covering;

- Safety - the level of formaldehyde in the composition or class of emission.It must be indicated on the packaging. Its labeling E1 indicates a normal, safe content in the material (toxic substances in the air - a maximum of 0.12 mg / 1 m3), and the European quality system is of particular confidence. Laminate with such marking can be safely chosen even in the nursery. E0 marking indicates the almost complete absence of formaldehyde in the composition of the panels, but such a floor is included in the highest price category.

Ask the seller whether the laminate flooring plant he recommends belongs to the European Laminated Floor Association (EPLF). This can guarantee the safety of its products and their compliance with the stated quality standards.

- 21, 22 and 23 - the panels of these classes are intended for home use. They were made with glue and castle type of fastening, but their thickness was small (6-7 mm) and the quality of the overlay was low, which led to a short, and therefore unprofitable, time to use such a floor. Now, when this material was used not only for its intended purpose, but also as a finishing material - for walls and ceilings, along with the floor covering, the master repairmen expressed regret that we did not have these classes for sale (they were light in weight).They could be glued to the walls and ceiling (they are not walked on), then the coating of these classes would serve for a long time, without being subjected to mechanical stress and water resistance testing. Perhaps demand will give birth to supply again.

- 31 class it is intended for public places with low passability, as in an office of the head, for example. Service life for them is 3 years. In an apartment or a house, it is suitable for a bedroom, a study, where it will last about 12 years.

- 32 class it is intended for public places with average passability, in such places the term of operation - 5 years. In a residential area with a normal level of humidity (bathroom and kitchen excluded) will be a quality floor covering up to 15 years.

- 33 class fits into rooms with high traffic, there he will serve 6-12 years, in an apartment - up to 20 years.

- 34 class implies a maximum load and throughput, as in the gym, where it will last 10-15 years, for housing the indicator will be 25-30 years.

Currently classes have the following features:

- 32 grades 7-12 mm thick, embossed surface, a variety of colors, good sound insulation properties, high mechanical and heat resistance.

- Class 33 has a thickness of 8-12 mm, the locks are reinforced and prevent the ingress of moisture, are qualitatively impregnated, the decor imitates any surface. The laminate of this class has high strength and moisture resistance. It can be used in the bathroom.

- The coating class 34 is the most durable, has more protective layers. Supplied with sound absorbing substrate. Patency for this class is 1000 people / day.

There is also a so-called vinyl (flexible) laminate on the market - PVC tile, its composition does not have anything to do with a laminate based on fiberboard or particleboard. If we compare them, then the main criterion for comparison will be their composition: at the base of the laminate is wood, and at the PVC tile it is polyvinyl chloride. These are two different categories of flooring - both with a multi-layer, but completely different composition. Of course, if we proceed from the fact that laminate is a coating of film type, then PVC tile is a laminate. They are united, but they do not at the same time resemble (because they are two different compositions and two different materials at the base) the castle anchorage system, the need for leveling the floor and the decorative layer.

Types of Mounts

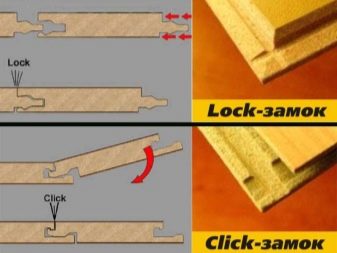

More recently, an adhesive type of fastening was commonbut it was pushed out by more progressive and more advanced types of joints - castle joints, thanks to which the entire coverage can now be disassembled without damage, and reassembled differently or in a new place, which was impossible with the adhesive joints. The outdated method made it impossible for the owner to replace one panel or a small section without destroying the entire structure. The glue has crumbled with time and gaps were formed, the type of coating deteriorated, its operational properties were disturbed.

For high-quality styling, convenient locking systems are now being used, which make it, if not a pleasure, then at least more rapid, compared to the adhesive method in the recent past.

Click Lock Systems (“Double locks”, or snap-type) and Lock (like thorn-groove, or tongue-and-groove) - two fundamentally different types of connections. The first system - Click - is considered the best, so large stores sell 85% of the laminated floor with this type of lock. But the priority of this system, in the opinion of specialists in laying, is greatly exaggerated. Click-system collapsible type, it provides a secure fit.

Have a lock system It has its advantages: the floor covering with it is cheaper while maintaining the same level of quality of grip of the slats and their installation. The next advantage of the Lock system in comparison with the Click-system is that over time it will stretch a little and will make it easier to re-assemble if necessary. Click-grip will remain rigid with the condition of the plate density of at least 750 kg / m3, and the density of the chipboard, which can be used in panels with a Click-lock, is lower. In addition to this factor, there is another, speaking not in favor of expensive Click-connection - plastic inserts in the improved systems of 33-34 laminate classes interfere, and if reassembly of the floor is necessary, they have to be removed at the very next assembly, resorting to gel sealing.

Professionals point out that in order to assemble the floor with high quality, the height difference cannot be greater than 2 mm with any type of lock. Do not believe those who promise that the Click-system will cope with a drop of 4 mm, the surface should still be perfectly aligned.

On the basis of these locks created improved mounting options:

- System Loc-Tec - Witex company (high load on the floor with such a lock, long floor life);

- T-lock - Tarkett company (convenient angle for fast and comfortable installation);

- Uniclic - Quick-Step corporation (for a complex perimeter, locks on four edges and the minimum angle of inclination simplify the work process as much as possible, you can both click and tamp bar);

- PressXpress - Balterio company (plastic tongue was added to the click system with aluminum compounds. The entire PressXpress system makes joints extremely durable and applies to 3G, 4G or 5G locks);

- Aluminum Locking System - Berry Alloc company (4G and 5G-S locking system, an amazing model that combines the excellent qualities of the two main types of Click and Lock locks - the groove-comb is made of metal, there is an aluminum profile and a stiffener on both sides, the system is light by weight, but very durable, the manufacturer claims that a three-fold assembly of the coating is possible).

We can say the following about modern types of laminate anchorages: each of the systems is good in its own way, but how smoothly, without squeaks and gaps the floor will be laid, depends largely not on the type of lock, but on the professionalism of the handlers, their exact following instructions to laying and from compliance of the board to the characteristics.

Modern innovations and design

Laminate, used as a finishing material for walls and ceilings, for several years now ceased to be a wonder.Consumers liked this versatile material so much that they are already finishing them with everything that they have enough imagination and courage: you won't surprise anyone with a laminate floor, but finishing with laminate flooring in the balcony and walls in our bedroom and bathroom is only gaining momentum in our country.

Laminate is combined with different surfaces and interior details - stone, brick, plastic. Here you can see its interesting combination with stone, antique furniture, wood and modern artistic creation.

It is selected according to the appropriate style of the room - classical, Provence, vintage, art deco, under furniture - old, extravagant, eco-friendly or modern. The texture, shades, designs and decor of this material are so diverse that you can pick them up for everything you need, even accessories. Arrange a decent background for an old clock - a worn board patinated on the wall, and vice versa, modern panel design set off antique items. Country will suit a country house, it has a lot of natural wood. The effect of aged boards will emphasize the modest elegance of Provence.

Finishing the loggia laminate is very relevant, especially if the owner spends a lot of time there, arranging there a study or a personal corner to relax.It is not necessary for this to resort to expensive natural materials like solid wood or stone (wood will require additional measures for fire safety). These and other natural materials have long imitated laminate perfectly, and its properties eliminate their disadvantages.

additional characteristics

When choosing a laminated floor, it is worth considering its additional characteristics, such as noise absorbing properties, thermal conductivity (the lower, the better the coating will conduct heat), moisture-proof qualities, the possibility of laying on the “warm floor”, antistatic, material allergenicity. All this is marked on the packaging by manufacturers. It is also necessary to know the weight of the purchased floor, which is especially important for houses with old floors.

- System Sound Absorb System will tell you that we have a “quiet floor”, - 50% of the noise dissipation from the sound of steps.

- System Antistatic saves from accumulation, attracting dust, this option becomes possible due to the presence of graphite in the overlay. But antistatic agents for laminate surface treatment will be a less expensive way out.

- Aqua stop protect from moisture, but not from leakage, if the water on the floor is more than 3-4 hours.

If you have a cold floor in the house and you plan to install its heating system, make sure that the laminate you are going to purchase can be installed on this system (there are different systems - “warm water floor”, “infrared floor”, electric).

The shape and size of the panels, the class of laminate (thickness and level of durability) affect its weight. The figure for 1 m2 of coating manufacturer indicates on the package. So you can calculate how many packages you need, based on the area of the room for which the material is purchased, and how much, therefore, they will weigh.

If you need to cover 20 square meters of laminated floor, and one of its packaging weighs 15 kg and 2 m2 in it, then you need only 10 packages and your floor will weigh 150 kg. Of course, you need to take 10-15 percent for the culling margin, because then you may not find this particular laminate or spend time and energy on the search, which are already missing due to repairs. After the final calculations, you will accurately determine the weight of your flooring.

So you calculate the weight of the selected material and the load on your floor.And in this example we will figure out how to calculate the number of packages you need for a particular manufacturer for the area prepared for the floor (let's take for the same bill the same 20 m2). To do this, we give the size of the boards and their quantity in the packaging of two well-known companies: Bode from the Lamini collection and BerryAlloc from the Grandioso collection. The length and width of the board in cm of the first company is 80.8 * 13.0, the number of boards in the package is 15 pcs. The same for the second company - 203.3 * 20.9 cm, boards in the package - 5 pcs.

Simple arithmetic: 80.8 * 13.0 cm = 1050.4 cm2 / 10000 cm2 (to get S of one board in m2) = 0.10504 m2 * 15 (number of boards in a package) = 1.5756 m2 - S laminate in one pack. Finally, our 20 m2 / 1.5756 = 12.69 packs and * 1.15% allowance (15% of the stock for culling) = 13.84 packs we need to cover 20 meters. That is, we will need 14 packages of the Bode company from the Lamini collection.

Now let's do the same with the size and number of boards of the second firm - BerryAlloc of the Grandioso collection:

203,3*20,9 = 4248,97 / 10000 = 0,424897*5 = 2,124485.

20 m2 / 2,124485 = 9.414 * 1.15% = 10.82, that is, in this case we will need 11 packs.

These additional properties of the laminate do not affect its durability, in contrast to the density of the base panel and the quality of the overlay, but provide a high level of comfort of its use.

Dimensions

The dimensions of this flooring can be common and non-standard.The parameters are determined by the manufacturer.

An example of common slat sizes:

- At a minimum thickness of 6 mm, length - 30 cm, width - 9 cm;

- The most common with a thickness of 8 mm length - 126–138 cm, width - 18.5–19.5 cm;

- At a maximum thickness of 12 mm, length - 184.5 cm, width - 33 cm.

The weight and dimensions of the packaging depend on the size of the laminated panel. Thick laminate to collect more convenient, so choose a thickness of 8 mm. The board has 32 classes, 8 mm thick, has low thermal conductivity, the floor will be warmer with it. There are long two-meter boards, they should not be laid by themselves, only professionals can cope with it. Short narrow boards can be laid in a small room, and to place a large area it is better to choose wide and long.

The width of the slat creates the desired decorative effect. Planks from 18 to 20 cm wide convey the texture of wood more naturally, and in order to paint a tile, you will need a board 33 cm wide.

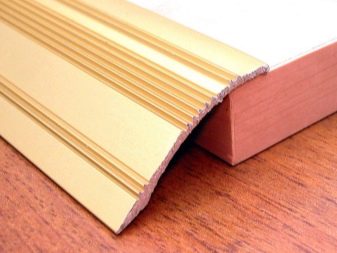

Accessories

These products provide protection and care for the flooring. It is difficult to lay the laminate in a continuous fabric throughout the house. It is easier to mount it in each room separately, connecting all the parts of the laid covering with sills, which are a kind of component for the floor covering.

Tasks performed by the threshold:

- Protects joints of laminated panels from moisture and debris;

- Can hide the irregularities of their installation;

- Binds two different types of material (tile and carpet, for example), hiding their joints;

- Aesthetically completes the installation so that the decorative transition is smooth, consistent;

- It draws up the inner corner of the steps of laminate - risers and the outer corner of the step;

- It combines multi-level surfaces of the coating and flat arched surfaces from different materials (tile, laminate).

It is possible to fix the sills in an external and hidden way. The first method is easier to install and more reliable in operation. The second one is more complicated, but the floor with such a threshold looks more harmonious, since the color and decor chosen to match the coating correspond to the aesthetic parameters of your laminate, and the appearance of the screw can disturb them.

Classic powders, which are designed for the steps of a laminated coating, its inner and outer corners, have a large load, so they must be made, at least, of aluminum - light and durable metal, convenient to install. Brass and steel thresholds are rarely found, they are straightforward and designed for maximum load.Features of brass - resistance to reagents, but not to mechanical damage to the surface with metal objects (heels).

A small height difference (up to 1 cm) implies the use of Kanta thresholds. This is a strip of aluminum, covered with the desired decor with a layer of rubber. The rubber layer compensates for this small height difference.

The joints of the laminate, mounted in different rooms, closes a different type of nut - lining the plane. For a surface of the same level with different joined arcuate materials, a curvilinear threshold is designed; it is made of cork or plastic. Its installation is very complicated, it is better to entrust it to a specialist. When the decorative top layer of the nut is worn, this layer can be replaced, and the nut will remain in place.

Wood and plastic - fragile materials for the nut, it is better to avoid them.

Aluminum thresholds are painted in several ways:

- Anodize (galvanic bath), receiving the color of precious metals - gold, silver, bronze;

- Paint powder enamel - get a variety of metallic shades;

- Decorate wood and stone with a textural effect - cherry and cork,marble and granite — an incomplete list of surface decors obtained;

- Laminated - film surface is the color of maple, alder, oak and beech.

There is another type of components for flooring - it is sealants and wax grout.

Lack of proper care and improper operation of a quality floor can lead to its loss of aesthetic and practical properties. These special care products will help bring back former greatness.

The joints of the laminate must be tightly closed, the straps are tightly coupled, but sometimes they diverge for various reasons: poor installation, careless floor operation. In this case, a joint putty agent - sealant - will come to the rescue. Of course, if the installation is done according to the rules, you are unlikely to need it soon, but if the seams have already gone apart, they need urgent repair.

Sealants are used at the stage of laying, put on the ends of the boards. They can be bundled with coating or purchased separately. Sealants protect the panel locks and the panels themselves from moisture, prevent dust and debris from entering the joints and seams.

Silicone sealants have a number of properties for which they are appreciated by the consumer:

- Effectively protect against moisture;

- There are different colors (there are transparent), so that you can choose the color of the coating;

- Have a large temperature range of use;

- Have strength and elasticity;

- For a long time they retain their physical and chemical qualities.

Sealant will extend the life of your floor, but it is not used as a laminate care product. To do this, there is a wax that will help eliminate mechanical defects.

Wax grout can restore the coating and its small areas, it is possible to seal up the loose seams. A wax grinder solves similar problems with a sealant (but does not replace it, but only complements or compensates for its absence): creak of the boards, care for the coating, strength of the lock, protection from moisture and increased durability.

Types and color

Types of laminated flooring are of great interest from the point of view of their choice in terms of quality and aesthetic parameters. Previously, the laminate was of two types - adhesive and locking, but as already mentioned, there is only one left now - the best of them, with locking fastening.

Laminate is divided by thickness. Board thickness of 8-12 mm is more expensive, but it is a profitable investment: it is stronger, more convenient to install, locks stronger and more reliable. This will last longer.

By the presence of additives in the overlay, the laminate floor is distinguished by the type of surface - it can be smooth, smooth with gloss, matte and texture. The laminate with a facet stands alone.

Smooth has a smooth surface. Smooth with gloss is very slippery, although manufacturers promise that it can be used in rooms with high humidity if anti-slip components are added to it (there is information on the package). In addition, it quickly gets dirty, difficult to clean. But if you decorate a wall for them, all these troubles will pass by you.

Laminate with a chamfer is an improved version of the coating, which has beveled edges or has a rounding at the edge. Such a coating in the living room will look very presentable. The chamfer has a practical function (besides improving the external properties of the floor): it can disguise the places on which water has got and managed to damage the panels, if these were minor damages.

Waterproof laminate with a facet is generally indispensable. The most important practical qualities are added to its unconditional external advantages. Moisture will not destroy it, only long hours of contact with water (5-6 hours) is destructive, it looks luxurious and natural.

Laminate flooring has become so often used flooring that he headed the list, leaving behind expensive materials - parquet, natural stone, solid wood floor. And this is absolutely deserved - its quality characteristics and all sorts of décor, combined with affordable prices for most consumers, have made it the sales leader for floor coverings. It began to be used as a finishing material for walls and ceilings in apartments and houses, in commercial premises and public places (cinemas, television studios). This is not just a “piece of bread”, but a “black caviar sandwich” for designers, whose boundless imagination creates new interiors with the participation of this material.

Its coating imitates not only wood - cherry, alder, beech, rosewood, birch, walnut, ash, maple, pine, chestnut, larch, bamboo, oak, teak. It can be under a stone (marble), tile, metal (for high-tech style, in particular). The number of colors is impossible to count - from simple light and dark brown, beige and smoky, - natural, to color - blue, red, green, yellow, multi-colored. The name of the colors is not to be remembered - white pear, wenge, dark and bleached oak, Milanese nut, wild cherry, white coconut - just a few for example.

In the living room and in the kitchen, in the nursery and in the bathroom, in the bedroom and study - everywhere you can use this type of flooring and finishing material. You can decorate and solve practical issues with it. To do this, he has everything - from the necessary qualities to a variety of colors, patterns, patterns, textures, colors.

Useful stuff

Such useful items as mats are provided for a laminated floor: rugs in the hallway at the very threshold, large or small, even classic carpets are suitable for slippery glossy surfaces. Nobody will forbid us to lay our favorite carpet on the most luxurious floor, no fashion for the absence of this interior detail.

But if this choice is a matter of taste, then the presence of a small carpet for parquet and laminate at the entrance to the bedroom, its presence in the hallway, living room is practically important. He will play the role of a safety element on a slippery glossy finish or protect any kind of coating from mechanical damage by heels, if, of course, their hostess prefers to leave her shoes at the entrance.

Protect coating and rubber wheels at tables or computer chair.For scratches there is such a convenient thing as a repair pencil. Gasoline, alcohol and acetone will help to remove stains.

Famous manufacturers

Laminate Balterio - one of the best, it is bought in Russia and Europe. The latest technologies patented by this manufacturer increase the wear-resistant qualities of the coating, increase its service life. There are models with non-slip coating and high moisture resistance. About such trifles as a large range, resistance to the formation of stains and heat resistance can not be remembered. To its merits you can add a lower price, the presence of the necessary accessories, a serious quality check.

Customer reviews for such a floor are positive (its excellent qualities cannot be worth a little), they can be dissatisfied with mostly the price.

Egger manufactures flooring, furniture and building materials. Exceptionally positive reviews on the laminate of this company show how important experience is in any business - Egger has been manufacturing its products for more than fifty years.

Swiss floor - brand from Switzerland, guaranteeing quality.

In a row with these companies need to put a few more:

- Haro;

- Kaindl;

- Kronotex;

- Pergo;

- Tarkett / Sinteros;

- Quick step;

- Kronospan;

- Ritter;

- Floorwood;

- Goodway.

Consumers around the world have their own quality rating, it varies in countries with different income levels of the population. The higher this level, the more difficult it is to please the buyer, which affects the competitiveness of enterprises, providing high quality products in these countries.

Reviews on Belarusian, Russian and Chinese manufacturers, in general, are positive. Consumers are marked by such shortcomings as an unreasonably high price, occasionally falling boards with inaccurate geometry and poor-quality locks in individual packages (quality control suffers). But the overwhelming majority are noted by the large selection of collections, decors and the consistency of the pricing policy of these manufacturers.

Chinese companies, oddly enough, are currently producing fairly high-quality products, the production of which is controlled by European brands.

How to choose: tips from a professional

Specialists gave us valuable tips on laying laminate, its types, the choice of class of laminate floor, tips on caring for it. The diagonal way of laying visually expands the room.Wall mounted Christmas tree, horizontal or vertical stripes of bright or muted color of the panels creates the desired effect depending on the task:

- emphasize the contrast of the laminate with the color of the walls;

- make bright laminate inserts;

- narrow the wall too wide and make the room more comfortable;

- widen narrow opening with horizontal installation.

If you need to save on installation work, you can do it yourself. To do this, you need to accurately calculate the amount of material, make the markup and strictly follow the instructions for laying. Markings on the packaging will tell us about all the main important characteristics of the floor covering.

Care of the laminate will not be difficult, you just need to follow the rules for its operation and take care of the coating with the help of suitable means: wipe it, do not fill it with water, resort to sealants and wax if necessary, remove spots immediately, so that you do not have to rub them off acetone, do not scratch with heavy furniture, when moving it use rubber or fabric substrates.

By following these simple rules, you can long admire the beautiful surface of your flooring.

The substrate under the laminate will increase its service life, protects against the loudness of the steps, thereby saving your nerves to you and your neighbors. Polyurethane varnish will also extend the life of this floor. Choosing the class and thickness of the laminated floor for an apartment, house, it is necessary to take into account its durability and durability. You cannot choose class 31 in the living room, where a large number of people constantly gather, children and animals frolic, and expect that it will serve as much as the wear-resistant 32nd or 33rd with special resistance to abrasion. Or put a laminate in the kitchen that does not have a moisture-resistant characteristic and hope that it will “carry it through” and it will not swell in a short time. Classes must fit the premises.

Owners of country houses need to know that in an unheated room, this coating will deteriorate. Do not choose it and the owners of cottages, standing without heating in winter. A warm balcony and loggia can be finished with laminate.

It is necessary to maintain optimum air temperature in a room with a laminated floor and a humidity level - this is useful not only for a person, but also for a floor covering. Normal temperature - from 16 to 30 degrees, and the humidity level - 50-80%.If your indicators do not reach, it is advisable to resort to humidifiers, air conditioners, not forgetting to clean the filters of the latter in time. But steam cleaners for laminate to use is strictly prohibited, since there is a possibility of its separation.

Laying specialists recommend: the laminate should be in the place of installation for at least two days to adapt to its temperature and humidity. It is necessary to take into account the level of complexity of care for laminate before his choice. Light, glossy and lacquered - the most difficult to care for, you can see everything from stains to washing stains. Weigh your strengths and capabilities before choosing such surfaces. If you chose varnished laminate (for artistic parquet, for example), take grade 33 with a high-quality protective varnish on the surface. Beautiful artistic laminate is better than natural parquet with affordable price, richness of colors and patterns, ease of installation.

Caring for the floor covering includes the use of special tools such as wax and sealants, but there is no need to constantly use them. It is necessary to resort to them only when minor repairs are required or seams disperse.The wax should be applied thinly several times, always letting the previous layer dry. And when the wax dries after the repair of the chip, it should be polished with a dry cloth.

If the care of complex surfaces (especially in the kitchen-dining area) is not for you, you can stop at the cork laminate (there will be dents because of the soft surface, but it is warm), modular marmoleum (marmoleum laminate) or HDF floorboard . Varnish, wax or oil cover a layer of natural veneer of these materials, waterproof and easy to maintain and restore.

Professionals advise a more expensive (than a board) square laminate in the form of a tile to demanding customers looking for complicated patterns, but remind of the difficulties of its repair.

Advantages and disadvantages

Indisputable advantages of laminate flooring will be the following qualities:

- A huge range of colors, decors and textures, unusual and classic - an alternative "under the board", bright and imitating natural materials;

- The possibility of laying special models on the "warm floor";

- Repeated assembly;

- Water resistance of some classes, the ability to use in bathrooms and kitchens;

- Durability, wear resistance, impact resistance and long service life of high-quality materials of famous European brands;

- Heat resistance;

- UV resistance;

- Big warranty period;

- The ability to quickly simple installation, which will cope even technically untrained person;

- The uniqueness of the material as a type of finish for all surfaces of the room in any place - from a private designer home to a public place.

The disadvantage includes only some properties:

- This is a tactilely cold material;

- Noisy without special substrate, which does not save;

- High demands on the surface on which it will be mounted - it must be perfectly aligned;

- Fear of the flood and increased humidity - not all classes even have moisture resistance, not to mention water resistance, but, on the other hand, the panels in the worst case scenario will swell up and can be replaced, but they will not get fungi or mold, like natural wood, because in their composition they have polymer impregnations that do not allow them to deteriorate;

- Laminate is short-lived, compared to natural wood.But so says a person who does not know what a solid wood floor is and does not understand how hard it is to preserve its geometry and laboriously restore it.

We finish on this beautiful note in honor of the laminate, wishing to anyone who wants to replace the floor covering, to have the opportunity to purchase a high-quality laminated floor.

For more tips on choosing the right laminate flooring, see the next video.