How to choose a substrate for laminate flooring?

Laminate has long ceased to be considered a sign of luxury, and today it is available to almost every buyer. However, the price of this flooring is still relatively high, and therefore, when choosing this material, it is necessary to take into account all the subtleties of installation and operation, so that in the future you do not have to regret the wasted money.

The purpose of the substrate

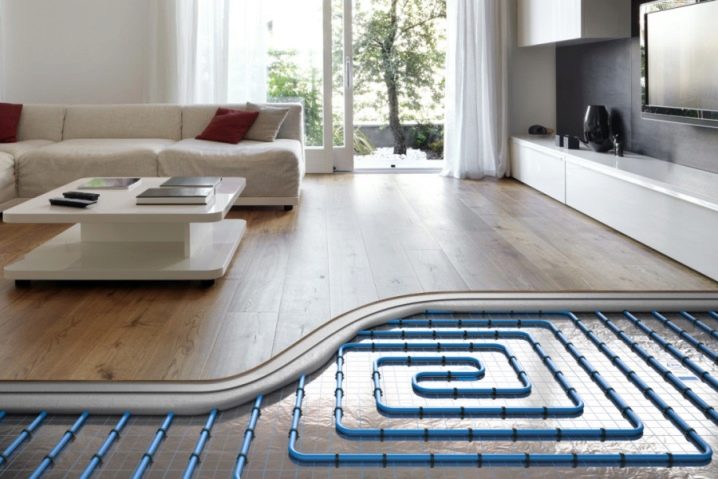

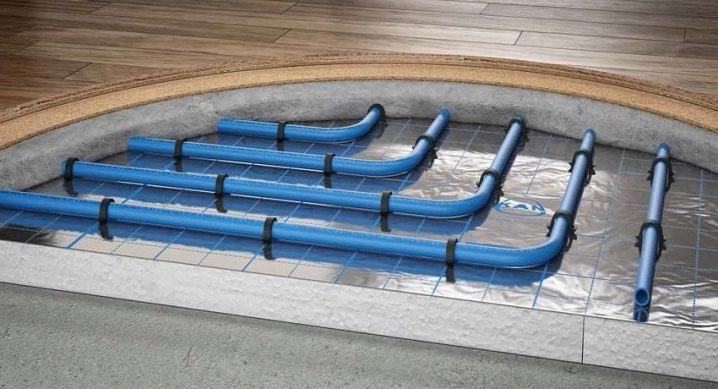

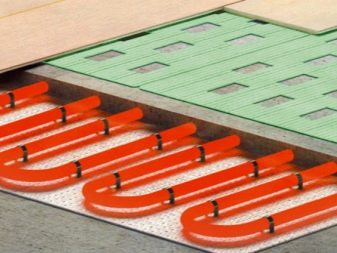

Of particular importance are the features of the combination of laminate with a warm water floor. A few years ago, builders did not recommend laying laminate flooring with underfloor heating. To date, manufacturers have developed a wide range of materials, allowing to take into account any requests of the consumer. Properly chosen substrate for laminate able to compensate for the shortcomings of this neighborhood and extend the life of the flooring.

The substrate on the warm water floor should perform various tasks:

- Waterproofing. At its core, laminate is a pressed wood fiber coated with a layer of plastic and resin. No matter how carefully the owners would not protect their floors from contact with water, they cannot control the moisture that seeps through the porous concrete floors. Prolonged exposure to water vapor will cause bloating and deformation of the panels. In addition, the substrate, laid between the laminate and the heating elements, should save a beautiful floor in case of a possible accident.

- Leveling the floor. Properly chosen substrate for laminate will eliminate surface drops. A flat base is a guarantee of high-quality installation and long service life of locks (system of coupling of panels according to the thorn-groove principle).

- Thermal conductivity. Any additional layer mounted above the heating elements will inevitably reduce their effectiveness. Therefore, the substrate under the laminate should not be too thick and dense, if we are talking about heated floors.

- Soundproofing. Wood, as well as concrete floors, have a resonating effect, and therefore, reinforce every step, creak, slight noise.Some laminate classes have built-in soundproofing layers, but this markedly increases the price of the floor and is not always suitable for heated floors. Due to its plasticity, the substrate fills small roughness and eliminates excess noise.

- Environmental friendliness. When heated too much, the laminate can release harmful chemicals into the air, such as phenol. Properly chosen substrate evenly distributes heat and does not allow the plastic, which is part of the panels, to overheat.

- Alkali resistance. It is known that many detergents for the floor are composed of aggressive components. The substrate material must withstand accidental ingress of household chemical mixtures.

Among other things, a good substrate for laminate "do not favor" rodents and insects. They will not want to make nests and eat next to such material (do not forget that the laminate, which consists of natural wood fibers, can attract many kinds of bugs, it is not resistant to mouse teeth).

Thus, the seemingly insignificant detail is in fact of great importance for the organization of an optimal microclimate and comfort in the house.

Types of underlays for underfloor heating

To an inexperienced eye, it may seem that the thicker the substrate layer, the better. Some, without consulting a specialist, even assemble several layers of material, seeking to increase the insulating properties of the substrate. But in fact, such enthusiasm can lead to disastrous results and additional costs.

Too thick and dense layer will prevent the heating of the room (do not forget that the laminate itself has poor thermal conductivity), and all the benefits of a warm water floor will be lost.

It should be borne in mind that such a coating as laminate is not designed for significant deformations. The panel is not able to sag under the weight of furniture or a person.

If the elements of the floor covering will support an excessively thick and loose base, then under pressure and loads on the floor it will be rubbed off. This will lead to cracks and deformations of the panels, breakage of locks and deformation of the seams. The floor will quickly lose its presentable appearance and will creak.

Experts agree that the optimum thickness of the substrate under the laminate in combination with a warm water floor should vary from 2 to 5 mm. On a flat base is sufficient the thinnest layer.In case of small irregularities, it is better to choose a substrate 3-4 millimeters thick, but the overall height of the intermediate layer and laminate should not exceed one centimeter.

PE foam

This material has a second, shorter name - izolon. Polyethylene foam has several advantages:

- it has high moisture resistance;

- perfectly compensates for uneven ground;

- many grades have a foil layer that enhances the thermal insulation properties of the substrate;

- insensitive to household chemicals;

- does not provoke the reproduction of mold, fungus, insects;

- it is easily mounted with the help of ordinary office tape and is practically waste-free during installation.

However, the foam is not too strong and is easily torn. It is not recommended to use isolon in rooms with low humidity: when the heating is running, it is able to accumulate static electricity. But its price is low and affordable for every consumer.

Cork backing

Pressed cork substrate is available in several versions: with rubber, with bitumen, crumbs of cork oak. In stores you can find both rolls and ready-cut sheets of this type of substrate for laminate.

The advantages of cork:

- has a low thermal conductivity, which is considered one of the most heat-saving materials;

- considerable elasticity allows the cork to recover its shape even after considerable loads; This property prevents locks from breakage and prolongs the life of the laminate;

- Being a material of natural origin, the cork is nevertheless not susceptible to rotting and prevents the growth of mold.

Of the minuses of the cork substrate for a warm water floor, it is appropriate to note the high hygroscopicity: the cork is not afraid of moisture, but easily misses it. The density of cork coating has a restriction on use: it cannot be laid on an uneven floor.

Considering the high ecological properties of the cork substrate, it is often advised to be used for children's rooms and bedrooms.

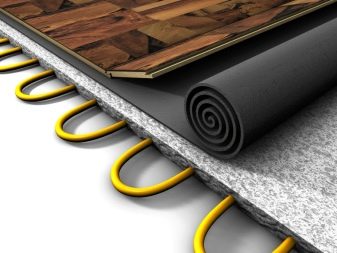

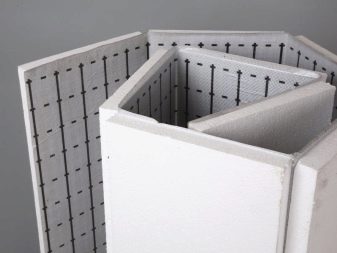

Styrofoam

This is a material with a cellular structure, not losing its properties in the range from -180 to +180 degrees.

It has excellent insulating properties and an affordable price. It protects well against moisture due to foil or propylene coating and is excellent for a bathroom, kitchen or any room with a water floor heating system.

Penpolystyrene does not require special installation skills, even a novice will cope with its installation: sheets are produced with ready-made markup. This type of substrate is not subject to deformation and has a long service life.

However, the stiffness and lack of cushioning action allows styrofoam to be laid only on a well-leveled surface.

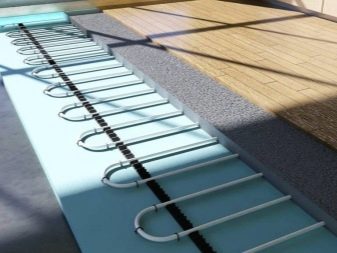

Perforated backing

Perforated - that is, having small holes - the substrate was developed specifically for the systems "warm floor". They are usually made of polystyrene foam, produced in the form of sheets and canvases.

Noting the high efficiency and wear resistance of the perforated substrate, experts recommend using it when combining a laminate with a warm water floor.

Foil Mineral Wool

This type of substrate under the laminate (and under any other coating) is extremely undesirable when installing water heated floor. The reason is that in the event of a leak, mineral wool is saturated with moisture, will lose all its properties and will hopelessly ruin the laminate.

In addition to its "rabies" when heated, mineral wool releases harmful substances into the air. Therefore, this type of substrate not recommended for residential use.

In conclusion, I would like to remind you that when choosing materials for arranging the substrate for the final coating, preference should be given to those materials on the packaging which indicate that the product is compatible with floor heating systems.

And, of course, do not neglect the advice of specialists and consultants of building stores.

About what are the substrate and insulation for floor heating, see the following video.