Waterproof laminate from Germany

One of the most popular flooring is laminate, which due to its low cost and excellent quality characteristics has become a leader in sales. Manufacturers offer many of its models that are durable, coloring, texture, resistance to external factors. Special demand is water-resistant laminate, produced in German factories. In Germany, a commission to control the quality of construction and finishing materials.

Export products are subject to special verification, since the Germans value their image.

Special features

Germany manufactures high quality waterproof laminate with excellent technical characteristics. It is characterized by the following:

- Almost absolute immunity to moisture.

- The big term of operation that is caused by high resistance to attrition and the raised loadings, including to blows.

- Resistant to chemicals, fading and UV light.This is achieved by treating the outer layer with special compounds and melamine resin.

- Possibility of installation on "warm floors", because the material is not deformed when temperature drops.

- Laminate floor does not burn, does not emit harmful substances during smoldering.

- German flooring is easy to install and, if necessary, dismantled.

- Ease of care.

The laminated moisture resistant floor of German production has several advantages:

- Exceptional product quality.

- Using the latest technology and modern equipment in the production, which reduces the likelihood of marriage, increase the service life.

- Manufacturers have achieved the full identity of the panels of a particular model from different batches.

- High quality and environmental safety of the raw materials used is guaranteed, so it is used for children and medical institutions.

- A wide range and versatility allow it to operate in various fields.

Since the waterproof laminated coating often covers the floors in rooms with high humidity, the outer layer is usually made with a rough texture so that it is not slippery.

What is different from the usual?

Experts draw attention to the difference between the concepts of "waterproof" and "waterproof." In the first case, the panels are made of wood fibers and resin. They are pressed under high pressure and heat treated. The second option eliminates the use of components from wood. The main feature of the German flooring is in the raw materials that are used for its manufacture.

Unlike the usual moisture-resistant laminate, the structure of which contains components from wood, the waterproof version completely eliminates the filling of wood, which is what provides hygroscopicity.

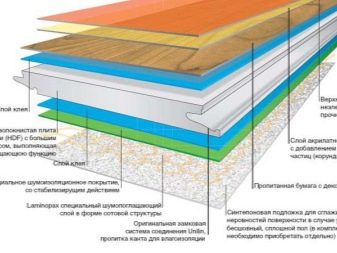

Manufacturers themselves approve the structure of the lamellae, but traditionally the following elements are provided:

- outer layer of polyurethane that performs the main protective functions. This material has a high degree of resistance to various external factors. In addition, it is environmentally friendly. Manufacturers sometimes add alumina to the outer layer, which provides additional strength.

- The base layer is usually made of PVC.It is not susceptible to the effects of liquids, the proliferation of bacteria and insects.

The main advantages of German waterproof laminate are:

- due to the presence of PVC in the composition, the panels are characterized by a high degree of wear resistance and durability. Laminate withstands the maximum possible load of the order of 100 kg per 1 square meter, without deforming.

- Absolute hygroscopicity. Even when the room is flooded, the coating will not swell or crack.

- Elasticity and flexibility. Ability to withstand heavy bending loads without cracks.

- High level of noise absorption, lack of echoing and squeaking.

- Resistance to temperature changes.

Compared to traditional materials, certain negative aspects can be distinguished:

- due to artificial origin material is difficult to dispose of;

- for durability you have to pay: high cost is one more minus.

Testing moisture resistant and waterproof laminate, see the following video.

Is it possible to put in the bathroom?

Premises that are characterized by an aggressive wet environment, such as a bathroom, showers, swimming pools, are subject to swelling of floor coverings.As a consequence, the formation of mold and the appearance of rot with an unpleasant smell. To eliminate such consequences it is necessary to competently approach the choice of material.

First of all, you will have to figure out what is the difference between a waterproof laminate and a waterproof one. which has increased resistance to water:

- The moisture-resistant coating is based on the HDF plate, which is treated with water-repellent impregnation and antibacterial agents. Its composition contains melamine resins, which increase resistance to moisture. A floor covering of this type withstands contact with water for two to three hours.

Manufacturers of high-quality laminate is subjected to additional processing with wax and silicone locks at the joints of cloths.

- Waterproof laminate using fibreboard has a similar production and processing with the exception of the lining of the polymer water-repellent layer. The panels are able to withstand exposure to water for 5-6 hours.

- Plastic laminate does not swell in water, is hygroscopic and aqua-resistant. Since the basis of moisture-resistant laminate coating is not wood, but PVC, it is recommended to lay it in the bathroom. The design of the laminated panels is multilayered.The bearing layer is made of polyvinyl chloride, which has channels that play the role of ventilation and heat insulation at the same time. The outer sheeting is made of polyurethane, which makes the floor waterproof.

German-made laminated panels for the bathroom are better than tiles, because they are warm and pleasant to the touch. In this regard, it is not required to install a “warm floor” system, as is the case with tiles. German manufacturers offer other interesting solutions waterproof laminate in the form of tiles, stylized stone, or with a picture. The material from which the panels are made is flexible, which allows it to be laid without leveling the floor. It does not require additional insulation substrates.

The level of water resistance allows you to lay such laminate on the floors not only in the bathroom, but also in the bath, while it is guaranteed to serve for many years. When buying a waterproof German coating should take into account its only drawback - high cost.

Materials

German laminate is a great option regardless of the material used to produce it. This is due to the high quality of raw materials, its environmental friendliness and multi-stage quality control:

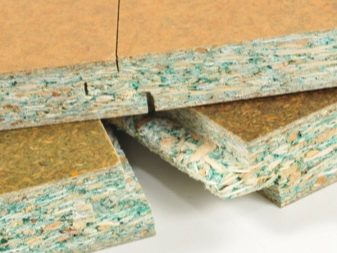

- Tongue and groove chipboard - Moisture-resistant version of the floor covering, made of compressed wood chips and thermosetting resin. The method of pressing high temperature. To increase the moisture resistance of the Germans introduced into the composition of special polymers, which allows the use of lamellae in wet areas. The material is resistant to biological effects, prevents the appearance of mold and rot.

- Vinyl laminate - an innovative product that is extremely waterproof, is not afraid of temperature changes, is not damaged when heavy objects fall on it.

In addition, the material is compatible with the system "warm floor".

- German plastic laminate It has a lot of competitive advantages. PVC is the basis and provides rigidity of the structure, prolonging its service life, because it is hygroscopic and durable. The middle core layer is made of fiberglass and quartz sand for heat resistance. Reinforced fiberglass is sometimes placed between these two layers. This “sandwich” provides the basic characteristics inherent in the product: strength, “soundlessness”,wear resistance. The outer layer is made of polyurethane to protect against abrasion. Under it is a decorative layer that mimics different textures.

- Quartzvinyl It contains fine crushed porcelain stoneware. German companies use nanotechnology in the production process, using the properties of silver, so the material has antibacterial characteristics. The effect is achieved due to the interaction of silver ions with fine fibers of the fabric. This provides almost 100% sterilization, destruction of odors.

The material of the laminated floor can be divided into groups according to the type of surface of the outer layer into glossy and matte. The first option is different from the second acrylic content. This layer gives the laminate a varnished look. Designers use this effect in small dark rooms in order to visually increase the area and let in more light. In large rooms, acrylic floor will add solemnity and brilliance. The disadvantages of vinyl material noted by experts are as follows:

- high price;

- loss of color when in contact with rubber, and therefore rubber mats and soles are contraindicated;

- with prolonged exposure to direct sunlight fading of the material occurs;

- poor quality panels can emit toxic substances during ignition;

- due to the low coating thickness, the floor may be cold.

Classification

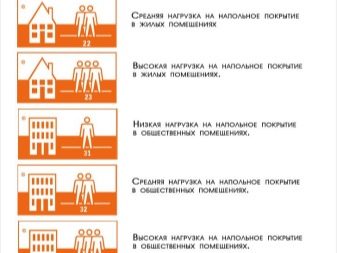

For the first time, panels are classified by the rate of wear of steel in European countries where they are tested for strength, abrasion, moisture and noise insulation. As a result, modern laminated flooring is divided into two large groups by scope: commercial and domestic.

The first digit in the class name indicates the scope of use.

The larger it is, the higher the quality characteristics of the product:

- 3 - commercial laminate;

- 2 - panels for household use.

German manufacturers recently refuse to produce a laminated coating with a minimum indicator of wear resistance, because it can last only 5 years, and it can not be given a guarantee. In this regard, 31 class is now considered to be everyday:

- Laminate 31 class - A good option for apartments where only a few people live.Its cost is the lowest in its group, but the life is relatively small. Experts advise when laying necessarily apply the substrate. It should be remembered that the laminated panels of this class are afraid of blows and are not suitable for the bathroom and kitchen. With careful handling, the floor can last from 10 to 12 years.

- Products 32 classes more durable, they are often used in office space. However, the panels of this group are optimal for use in the apartment. Since the patency is less than in the office, the service life will increase significantly. It should be noted that the floor of this class is quite hollow, so it is better to lay the substrate under it. It is not deformed when heavy objects fall, and therefore is perfect for a children's room or kitchen. Manufacturers from Germany to improve the protective characteristics of the laminate at the joints process locks wax. The presence of a textured outer layer makes the floor less slippery.

- Group with 33 class The most common among German moisture resistant coatings. Laminate is laid both in private houses and in offices. It shows itself perfectly when used for 20 years.Since the laminate initially has sound-proofing characteristics, additional insulation materials will not be needed during installation. Often the panels are treated with antistatic agents, thanks to which the coating can be laid in computer labs and laboratories with sensitive instruments. This class of products is characterized by a wide range of textures and color shades.

- 34 class It has a greater coefficient of maximum permissible loads than 33. The high level of moisture resistance allows laying such laminate in rooms with high humidity. However, its cost is high, which reduces demand. As a rule, products are used in gyms, on dance floors, in office corridors.

Experts jokingly call this flooring "unkillable."

- Laminate 35 classes It is highly durable, which allows manufacturers to guarantee a service life of 20 years.

- Material 36 classes widely used for flooring shopping centers in Europe.

- 42 and 43 - premium classes, such products are made only by special order. Today, they are made by only a few German companies.Laminate is positioned as waterproof, shockproof and resistant to mechanical stress. Sometimes it is called "vinyl" because it is based on PVC plates. Products can be used for bathrooms and showers, on open terraces and saunas. Manufacturers provide a warranty of up to 25 years.

Dimensions

As a rule, the thicker the board is, the stronger it is, however, as the thickness increases, so does the price of the laminate. Experts advise choosing a model corresponding to the conditions of operation of the premises so as not to overpay:

- Laminated coatings of the household class are the thinnest. German brands refused to manufacture it due to low competitive ability.

- For laminated panels of 31 classes, a thickness of 6-8 mm is typical.

- Lamels of 32 and 33 classes are characterized by a thickness of 8 to 10 mm, but when it is increased to 12 mm, the laminate becomes more practical.

- The thickness of the products of class 34 remains at the same level as the previous ones.

- The thickness of all subsequent groups in the classification can vary from 12 to 14 mm.

Experts advise when installing the system "warm floor" to use German laminate with wear resistance not lower than 32 classes.

About what are the dimensions of the laminate, see the next video.

Design

Vinyl waterproof laminate from Germany is presented on the market by several models. The artistic version makes it possible to get an imitation of stone, marble, natural wood, tile, what allows to combine the laminated floor with various finishing materials easily:

- For the design of baths and bathrooms, German designers have developed a laminate in the form of tiles, which gives a complete feeling of the tiled floor surface. The main advantage that distinguishes laminated panels from tiles is heat protection. There are several varieties of such coverage:

- waterproof for use in the bathroom, the joints of which are treated with a special compound to increase protection;

- 33 grade coating is used in office space and is resistant to household chemicals such as bleach;

- 34 class laminate is used, as a rule, in public lounges, restaurants, shopping areas.

- Imitation wood of valuable species.

The decorative layer allows you to adapt the flooring to any type of interior while maintaining all other characteristics.

- The laminate under a stone differs in effective appearance. With almost complete resemblance to natural stone material is much easier, easy to clean and easy to install. In addition, laminated panels are warmer and more pleasant to the touch. The choice of "stone" floor should be approached with caution, because it is not always appropriate. It is necessary to consider color, lighting and even the type of stone. For example, the marble version is a great solution for a large kitchen, bright entrance hall or office.

For small and dark rooms it is better to use light shades and a small pattern. In such cases, German firms offer limestone or marble chips.

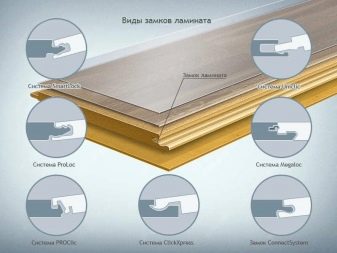

Classification by type of attachment:

- the lock type of installation is similar to the traditional one and consists in coupling the panels with the help of special locks. Among the German goods, this species prevails;

- self adhesive Recently, self-adhesive laminated panels have appeared on the European market. They are characterized by a special type of mounting during installation, allowing you to fully protect the joining seams from moisture. The design of the laminate is different, but due to its popularity in the bathrooms,Deals with a pattern under the tile most in demand;

- the glue option is the most inexpensive, but certain skills are required for its installation. One of the factories in Germany, producing products on the basis of glue, is the firm Wineo.

Germany is the leader of the laminate market, so do not mention the rich range of products, among which you can choose the flooring for any design taste:

- Provence. The interiors in the light style of the French countryside suggest pastel shades. In this case, it would be appropriate to lay the floor with a laminate imitating natural wood of light colors or decorative stone.

- Scandinavia. In cold countries, the rooms are made comfortable, cozy and warm. Therefore, such interiors are characterized by light, almost white tones, and floor coverings are stylized as whitewashed wood.

- Kitchens and bathrooms in the Mediterranean version are often made in the form of tiles.

- In the Greek style used cover, stylized limestone or marble.

- Italian interiors are characterized by solemnity, solid classics, which combines decorative stone and oak flooring.

- Art Deco style has a black and white gamma and expensive semi-antique decor.

For floor decoration, you can use a laminate that imitates metal, ceramic tile or textiles. Natural wood dark shades are also welcome.

- Modernist approach allows you to make new notes in the interior. For example, you can make the floor glossy so that it looks almost transparent, or use flooring to decorate walls. Modern allows you to use all the variety of colors, expressed in bright patterns and wall elements.

- Classic solutions will never go out of style. Classic style requires simplicity in the interior, lightness and convenience, so the usual waterproof laminated panels will always be in demand.

- English primness is embodied in the high quality of products of famous German manufacturers, while the laminate looks expensive and presentable.

How to choose?

Professionals caution that if you choose a laminate that is not suitable for a room, then even a high-quality German version will not last long. It is necessary to take into account a lot of room features: humidity, lighting, temperature, mechanical effects, so the choice of a laminated floor should be approached very responsibly.For example, for the bedroom, study or children's room, you can safely use the panel 31 class.

Since the patency in these rooms is low, the service life of products will be long. However, if two or more children live in the children's room, the coverage of this class will no longer work. Now the load has increased significantly, which means that in order not to change the gender often, it is better to cover it with laminate with a higher grade.

German manufacturers recommend 32 laminated panels for living rooms, hallways or kitchens. The floor in the most crowded areas of the apartment needs quality protection. Professionals are advised to lay the substrate under it to eliminate boom and increase noise insulation. For a private house is better to opt for several versions of the laminate. The upper floors, as a rule, are intended for living rooms, which are suitable for covering 33 strength classes, whereas for the first floors and the hall a floor covering of 34 groups would be an excellent solution.

Experts urge not to be afraid to choose a German laminate for decorating country houses. It is sufficiently resistant to any external factors.An important requirement for this will be moisture and wear resistance. However, you have to choose between cost and quality. Many owners of country houses consider it unreasonable to lay a laminated coating where they spend the least amount of time during the year.

The fact is that a high-quality waterproof product is much better than wooden, it retains its characteristics in the absence of heating in the winter months, with high humidity in spring and autumn.

Covered balconies and balconies due to temperature changes better lay laminate 34 class. In the case of terraces and other open spaces, you should pay attention to waterproof materials. If pets live in the living room with the owners, then floors should be covered with moisture resistant panels from Germany with a high degree of resistance to mechanical stress (33 or 34 class), as pets can scratch.

For a bathroom, experts advise purchasing a waterproof material with a grade of 34 and above, despite its price. Quality laminate will last a long time, even if water floods the floor. In this case it is better not to skimp.German waterproof laminated panels can be used for installation on "warm floor", because material is not deformed at temperature drops.

High-quality waterproof models from Germany are quite expensive. In this regard, the choice should be approached seriously, so as not to be disappointed in the future. The basic criteria that are worth paying attention to first are the following:

- product labeling. The product packaging must contain a special badge or logo that indicates the water resistance of the material. As a rule, this is a picture in the form of a tap with a drop or an umbrella. Letters are allowed, for example, Aqua, Aqua Protest or Aqua Resist.

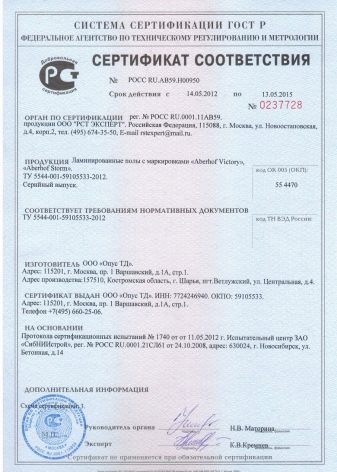

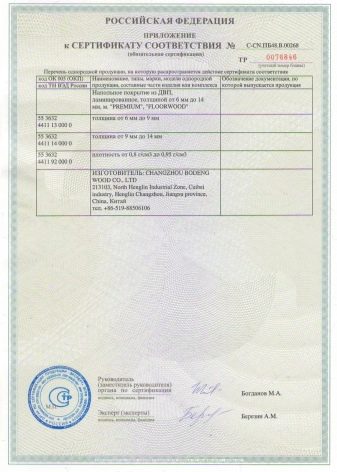

- The name of the manufacturer and the document confirming the fact of production in Germany, Sweden or Austria.

- A package of documents with translation into Russian. Products of branded suppliers must be accompanied by certificates confirming compliance with Russian standards and regulations.

- Wear resistance class.

- Density and swelling ratio. The latter is indicated as a percentage and characterizes the degree of expansion of the material during a long stay in the water.The smaller it is, the higher the moisture resistance.

For 31 and 32 classes, the coefficient should not exceed 18%, for 34 - 8%.

- The quality of the castle joints and their water-repellent treatment.

When choosing, experts also recommend paying attention to the following material properties:

- water resistance of both the panels themselves and the interstitial space;

- susceptibility to deformation at temperature drops;

- preservation of the original size under the influence of external factors;

- wear resistance;

- susceptibility to household chemicals and various reagents;

- impact resistance;

- thermal conductivity;

- insulating properties;

- Compatibility with “warm floor”, if necessary.

Most of the reputable German laminate companies in the market ensure that products meet international quality standards and are environmentally friendly. Therefore, you should choose the flooring of famous brands with a good reputation, because they are trustworthy and give a good guarantee for the products. In addition, it is worthwhile to give ways to determine fake

- Request a certificate of conformity issued in the Russian Federation.

- Read the accompanying documents from the manufacturer.

- Check that the description of the laminate on the packaging, specifications and components were written in Russian.

In addition to these criteria, law-abiding and responsible German suppliers voluntarily certify every product in the country of implementation. Therefore, as a rule, the goods have three additional documents:

- fire certificate;

- sanitary certificate;

- voluntary certificate that complies with accepted state standards and technical regulations.

If such a package of documents is missing, then you can consider the product a fake.

Manufacturers Rating

In addition to Germany, waterproof laminate is produced by manufacturers from Belgium, France, China and Russia, but the German laminated floor is the leader in the coatings market. The following brands are best known:

- Aberhof;

- Classen;

- Ecoflooring;

- Egger;

- Hessen Floor;

- Floorwood;

- Krono Original;

- Kronotex;

- Maxwood;

- Proteco;

- Vega;

- Westerhof;

- Zigart and others.

Unfortunately, not all are available to the domestic consumer.

It is known that for the first time the technology of laminating panels was used in 1979 by the Pergo company from Sweden. It is the global leader in the flooring market. The plants are located in different countries, they use the full production cycle.

The range is represented by laminated, vinyl and parquet products.

The advantages include the following:

- Antimicrobial barrier formed by silver ions in the outer layer.

- Antistatic.

- The high density of the panel and the lock connection ensures moisture resistance.

- TitanX's patented protection technology.

- Warranty period of operation up to 25 years.

- Certified environmentally friendly raw materials.

- Variety of design ideas, textures and color shades.

Customer reviews clearly indicate the best Austrian-German brand that produces moisture-resistant laminate - Kronotex, part of the largest concern Krono Swiss Group. In particular, the most in demand waterproof laminate class 33, which is based on the HDF plate. The following collections have gained wide popularity:

- Dinamic. Moisture resistant coating with imitation wood texture of oak, beech, chestnut, wenge, cypress. Guaranteed service life is up to 15 years.

- Mammut has a five-layer configuration. Clic-2-Clic type end lock joints are paraffin-treated, which increases the tightness of the entire coating.

- Exguisit positioned as a laminate with the most exquisite decors. The collection is popular with designers, as the accuracy of the simulated surfaces is under special control.Due to the high level of thermodynamics is used as a warm floor.

Factory Witite produces a wide range of coatings of different thickness and class, which are not afraid of moisture and are resistant to mechanical damage. High quality products are achieved through the use of innovative technologies and multi-step verification. The range includes a variety of collections. both classic options and modern design innovations:

- Witex Piazza presents glossy and authentic variations imitating the texture of valuable species of exotic trees, for example, Indian rosewood or African afzelia. The panels have 33 wear resistance classes and have a high degree of moisture resistance, which makes it possible to lay them in wet rooms with varying air temperatures.

- Witex Arioza offers laminated material 12 mm thick. The high cost is justified by a long service life and practicality in use.

- Witex Casa V4 - waterproof laminate, an analogue of ceramic tiles.

The collection offers models styled as concrete, limestone and travertine.

Moisture-resistant laminate Classen is produced in the territory of Germany.Like any German product, it is of high quality. In the product range there are economy collections at affordable prices. Recently, the models of this company are produced in the Russian Federation in the city of Gagarin. The main advantage of Classen laminate is an antibacterial coating that allows the use of plates in children's and medical institutions. In addition, there are other undeniable advantages:

- thermal stability and impact resistance;

- low susceptibility to UV rays;

- wide scope of application;

- antistatic and hygienic.

The brand Ecoflooring belongs to Germany, but the production is carried out in China. In this regard, the products are more affordable. The size range of lamellas presented in the assortment is small, but you can choose from a variety of decorative solutions suitable.