What is wax used for laminate?

Many buyers, considering the range of flooring, opt for a laminate, which is due to a large number of advantages, one of which is a special technique of applying a protective surface. Often on the shelves found laminate, wax-treated, so that moisture and light mechanical effects are not afraid of coating. Let's try to understand the features of such processing, for what and how it is done.

What is it used for?

Standard laminate surface treatment is often completely inadequate, since the rare coating will be resistant to furniture rearrangements, damage to pets' claws and heels, therefore defects appear on it during use of the product. It is in this situation that solid or liquid wax comes to the rescue.Due to the possibility of restoring the appearance of the floor, as in the case of parquet, the time of its operation can increase many times, which will save a good amount on a complete change of floor covering.

In the repair used different types of drugs:

- The pencils.

- Pastes.

- Sealants.

- Fluids.

Regardless of the form of release, each of the products contains wax, and all of them are used for the same purpose.

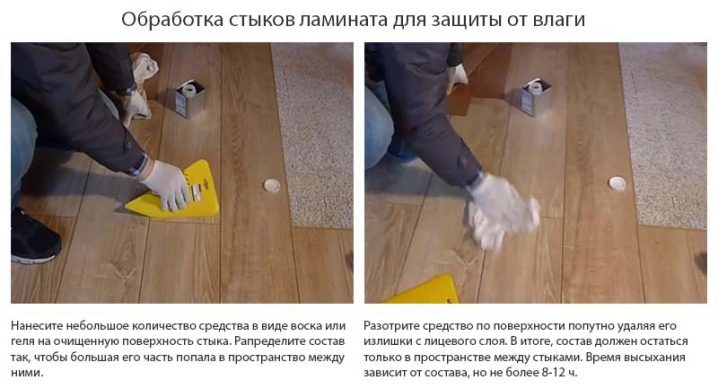

At the enterprises during the manufacture of the coating, only the front part of the laminate is treated with wax, but the joints are not subjected to such processing. In the future, after installing the floor at the junction of the panels, small gaps remain, which with use will only expand. During wet cleaning the water flows into these gaps, the result of this is the swelling of the panels and the appearance of squeaks.

Using wax to treat joints between panels can extend the life of the floor several times.

It is not recommended to polish the laminate with wax, due to the fact that the protective coating of the product has already been made on the basis of this component. If you apply the mentioned component to the laminated elements, you can see the stains and stains, while the protection of the product applied at the factory can deteriorate.It is more expedient to use specialized solutions that contain wax in their composition.

How to use wax at the joints and in the castle connections?

Laminate should be attributed to the flooring, characterized by high strength, but we should not forget that as a result of active regular use of its original characteristics are significantly lost. The “Achilles heel” of these products are compounds made according to the type of lock, based on this axiom, it can be concluded that the protection of the coating should be dealt with at the pre-assembly stage - It is necessary to wax the unprotected surfaces.

It is also possible to use gel for the joints. Of course, there is even a wax-impregnated product on the market, but the high cost of this solution is much higher than the proposed option. In addition, in order to avoid moisture under the coating after installation, it is necessary to lubricate the seams at the joints of the panels.

Forms of release protection range from liquid to pasty. Choose a tool should be based on the conditions and tools for the work, as well as on the purpose of its application.In cases where the release form is liquid, it is better to use a brush, in order to evenly distribute the protection over the entire area of the interlocking joint, the excess material falling onto the front of the product must be removed with a cloth. After all the installation work, the measures taken will contribute to the prevention of the ingress of fluid into the inter-lock gaps.

When purchasing a paste-like product, they should be used. immediately before installation. The contents of the paste are squeezed onto the lock requiring treatment, and then the laminate is assembled.

Excess material protruding from the seams is left untouched until it is completely dry, then, without applying excessive effort, they are removed with a rubber spatula. After the procedure described, the surface should be polished.

Frequent situations when wax is used for grouting joints. Such actions are practiced when it is necessary to achieve a tightness of the coating, for complete waterproofing of interlock connections, as well as the back surface of the laminate. To avoid damage to the face. It is recommended to protect the part of the panel adjacent to the joint with masking tape. After that, it is necessary to apply the substance to the seam and remove excess. After the product is dry it is necessary to remove the adhesive tape and polish the surface thoroughly.

Wax Pencil Application

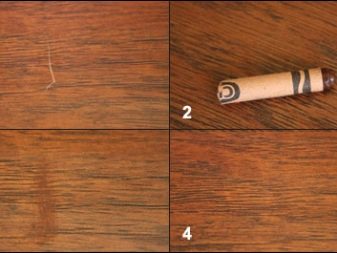

Wax stick will help to remove aesthetic defects resulting from prolonged use or exposure to damaging factors, which include chips, scratches and other oversized violations of the integrity of the laminate. In the case when the unspent materials remain after repair, the damaged fragment can be completely replaced, but if the panels are not from the same batch, then even the same manufacturer cannot guarantee a full match between the shades. For these situations, it is recommended to use a pencil for laminate.

Due to the fact that the front of the panel is covered with a texture image of natural wood, you need to select the desired shade. Depending on the area of the defect, you may need from one to several colors. When restoring coverage, you can use the following procedure:

- Clean the defect from small dust and dirt particles. Check the cut flatness of the side walls of the defect.

- Apply hard wax on the scratch, when using several shades, the product is applied in accordance with the texture of the coating.

- After application, it is necessary to polish the repaired place with a dry cloth.

The described manipulations help to eliminate small-sized damages of small depth.

Elimination of major damage

Mastics and wax sealants help eliminate defects that cannot be handled with a simple pencil. As well as in the previous case, the main condition is the correct choice of hue, because if you do not guess the color - all efforts will be in vain, because a different shade will be strongly striking, against the background of the overall composition of the floor:

- The drug with wax is injected into the defect.

- Then the cleaved area is placed on it and excess material is removed.

- After hardening, the surface must be polished.

Often sold a tool that is called superhard wax - before you use, it must be melted and applied to damaged areas.Then, after complete solidification of the solution, the surface must be polished.

Also, at the moment of choosing one or another material for repair, one should not forget about covering the panels, since the glossy stain on the matte floor will look completely non-aesthetic, as in the opposite case.

Removing wax stains

Of course, the use of wax can not be called narrowly focused, respectively, we can not exclude the possibility of wax drops on the floor. In the case of linoleum, it will not be difficult to remove such drops, however, if a laminate is used at home recommend following a few tips:

- Removing unsuccessful frost drops is easy - use a soft cloth or napkin.

- In the case of frozen wax, a plastic knife should be used to remove it from the coating. After this, the place where the drop was localized should be wiped and treated with a specialized solution.

- You can heat a drop with a hair dryer, and then follow the instructions of the first paragraph.

- It is possible to heat the wax locally, with the help of a hot, ironed napkin. Part of the substance will remain on the paper, the remaining part can be disposed of with the help of rags.

There are also a number of methods that must be avoided. so that the flooring can be used for many years:

- In no case do not use acetone - when in contact with wax, this solution promotes the formation of stains.

- Avoid cleaning products containing abrasives - small abrasive particles will leave small scratches and roughness.

- Scrapers and sponges made of metal break the protective layer of the panels, which contributes to the violation of their waterproofing.

As you can see, laminate can be called one of the most convenient coatings, however, its service life may differ significantly depending on the operating conditions, so this will last for more than ten years for thrifty residents.

Damage prevention

Finally I would like to give some tips on preventing the occurrence of deformations and damage:

- Do not walk on the cover in heels.

- Use soft linings for the legs of the overall furniture, not only if you plan to move it, but also in the case of a static position.The legs of the chairs and tables are recommended to be equipped with rubber or fabric linings.

- At the entrance to the room lay a rug that will prevent the separation of sand and dust particles.

- Conducting regular cleaning is a guarantee of the impossibility of accumulation of sand and dust, which adversely affect the coating during heavy traffic.

- It is recommended to remove spilled liquid immediately.

By following these simple rules, even minor repairs can be avoided and for a long time to enjoy high-quality and durable flooring.

How to protect the joints of laminate from moisture, see the following video.