Laminate thickness: how to choose?

Today, the modern construction market and the shops provide in abundance laminate of various types and with different characteristics. The thickness among them is one of the most important. Despite the common misconception, it does not affect the resistance to wear of the laminated coating. Only the top protective layer is responsible for this. According to statistics, panels with the greatest thickness are distinguished by a high level of stability in the process of use, and their fastening between them becomes more reliable.

What happens?

The first thing you need to learn in the selection process - in most cases, the standard thickness depends on the class of laminate. The release of laminated floors are engaged in many global manufacturers and lesser-known companies.

Mainly customers It is proposed to consider options with a thickness of 6 to 12 mm (although these parameters are not threshold).But there are unique instances, for example, a waterproof vinyl coating with a thickness of 4 to 5 millimeters.

There is also a thicker laminate, whose thickness is 14 millimeters. When choosing which coating is best suited, it is also important to consider the operating conditions. It is necessary to pay attention not only to the characteristics, but also to the classes:

- Class 31 with a thickness of 6 to 8 millimeters is the thinnest type of laminated coating. It can be used for decorative purposes at home;

- Class 32 with an average thickness of up to 10 millimeters is more suitable for commercial use. Due to the greater thickness of the coating can withstand a more serious load;

- Class 33 is designed for a commercial platform. Its thickness varies from 9 to 12 millimeters, but may exceed this figure, if there is a need. Such a laminated coating is ideal for large rooms. It is stable in both length and width, and there will be no problems with dynamic loads during operation;

- Class 34 has not received such distribution among users, but in addition to its main characteristics, it also has waterproof properties. It is used only in the commercial field.For an apartment or a private house, this option is not suitable.

If we talk about the castle connection of the laminated floor, then it can be found several types:

- click;

- lock.

To distinguish them easily due to the characteristics of the connection. For example, in the first case, the external spike resembles a hook and connects the panels using a hook and a slot coupling. Once they are connected, the panel can be lowered. When everything went well, you can hear a characteristic click.

Dismantling is also quite simple: to lock off, simply lift the panel. Both assembly and disassembly take a minimum of time, do not require too much effort and special knowledge. Therefore, this type of castle is very popular.

The second type of castle connection was developed a bit earlier. This is a common drive-in model with a tongue and groove connection. The spike is made of dense wooden base. In the preparation of the groove make special notches. It is through them that the entire structure preserves its integrity.

But this castle has a small minus: over time, under the influence of constant loads, the comb can be erased. As a result, cracks may appear in the laminated coating. Another disadvantage is the relative complexity of installation, as in the process you need to make sure not to spoil the plate.

The lock type, unlike the first, is simply inserted horizontally.. No angle or special pressure is required for tight contact. The only caveat - during the installation process you will need to ensure that the seams on the panels everywhere turn out to be smooth. Floors with such a lock joint are often installed in the bathroom or in the kitchen. The seams at the joints later are additionally treated with a sealant.

PVC coating

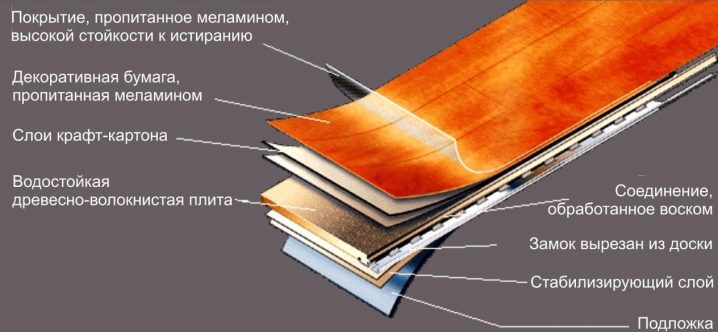

The structure of a conventional laminate floor is very simple:

- The lower layer is responsible for stabilization, it is made of special paper, and in addition, serves as a reliable protection against moisture penetration, provides protection against noise and increases the overall density indicator;

- Next comes the main sheet, which has increased rigidity and thickness. It is made from the most dense chipboard and it is from him, as a rule, the answer to the question depends on whether the layer is thick enough or not;

- After this comes the texture and the upper protective layers, on which the life of the material depends. The texture imitates any design, from natural stones to industrial concrete.

The difference of such coatings is that the surface is additionally protected by another layer (most often it is polyurethane). Drawing on the panel does not fade much longer even under prolonged exposure to ultraviolet rays during operation. The dimensions of the panels at the same time geometrically accurate, so the client does not need to worry about crevices or scratches.

The connection of the layers is provided through the use of several methods of manufacture:

- Press under pressure;

- Normal pressing.

The latter is very often used during the manufacture of laminate for residential buildings and apartments. Layers are laid in the required sequence and pressed together in one stage. This not only simplifies the workflow, but also saves time.

Pressing using high pressure is more complicated and expensive. In this case, production involves several steps:

- Decorative and protective layers are interconnected under the influence ofpressure and high temperatures;

- After that, everything is pressed with the base for the coating and the lower protective layer.

Phased production provides higher performance. The panels are more resistant and durable, they are usually used for industrial production.

What does it affect?

The number of indicators depends on the thickness of the laminated coating:

- Resistance to dynamic and static load. This is very important in the process of choosing panels in the room where the placement of heavy furniture or equipment is planned;

- Strength. Although the wear parameter does not depend on it, the thicker laminate will be more durable. Therefore, it is well suited for commercial real estate;

- Insulation. The thicker the material, the higher its thermal conductivity. If you plan to install a heated floor, it is better to choose a coating with a minimum thickness.

You should also pay attention to these characteristics when you need to choose the floor for an office or public space. Usually the rooms in this case are quite spacious, so maximum stability plays a very important role.

In addition, features such as insulation and the creation of a flat floor. For example, if we consider panels with a thickness of 6 millimeters, then they are considered thin. And laying on its basis is best only a cosmetic or decorative coating.

If the thickness of the coating is 7-8 millimeters, then such a floor can successfully carry home loads, fully justify the price and withstand the service life. The apartment will change dramatically if you use the original design solutions that are provided today to the attention of customers in the construction market. The price will remain at the maximum available level.

Substrate

The substrate is used in the process of laying laminate. If you plan to put heavy furniture in the room and periodically make a rearrangement, it will be most convenient to perform it on a flat surface.

It is for these purposes and need lining. With it, you can not only achieve a perfectly flat surface, but also protect the floor itself from damage.

But it is also worth noting that you can only choose the lining based on what type of board is used in the room. Having considered the options provided below, The client will be able to choose for himself the panel on the characteristics and properties:

- A board of 4 millimeters should be made of cork bark. You can use both panels and rolls or sheets. They also have some additional advantages - the material retains heat, provides good noise insulation, does not sag, does not burn and eliminates the appearance of mold or fungi;

- A laminate coating of 5 millimeters is suitable if the client needs an optimal value. In addition to the performance characteristics of a high level, this material is quite durable. Throughout the entire period of operation, neither scratches nor cracks will appear.

Making choices for home and office

When it comes to home repair, it is recommended most often 31 or 32 class. The technical characteristics of such a floor is ideal for home loads, especially if the client does not plan to move furniture too often in places.

Making a choice in favor of thin laminated panels, we must not forget that they are less durable than other models. Therefore, the replacement of thin panels may be required more often.If we are talking about residential premises where heavy equipment is to be installed, the class of laminate should be at least 33 meters. Its installation is usually done together with the lining, which helps to maintain all the performance of the floor, even after several years of operation.

Thickness is important for an office and commercial space. Therefore, most often used either 33 or 34 classes with the thickest panels. They cost a little more, but fully justify their cost, as they withstand even increased loads.

If you wish, you can install such a laminate in a residential area, the service life will be several decades longer.

As for the cost, the thickness, although it influences it, is far from decisive. It is best to buy flooring in specialized stores with full accompanying documentation. All measurements of the premises are also worth doing in advance, it will be much easier to calculate how much the panels will need to be purchased.

If you need a floor for a commercial enterprise, it is best to take a laminated coating of 33 or 34 class.These classes are very resistant to wear, have additional protection against water and can retain their primary appearance for the entire life cycle.

Due to their durability, these classes easily carry static and dynamic loads in the room. All these properties are saved not only the entire warranty period, but also after it. There are no cracks, streaks or other signs of use left on the floor.

In addition, for the original design decision, many choose the chamfer. This is a beveled edge on the panels that can imitate a wooden plank floor. Depth and shape depend on the selected modification. A double-sided chamfer is usually used on the sides, a quadrilateral around the perimeter of the room.

When choosing a laminate flooring, you need to consider the room itself. It is especially important to make the right choice when it comes to children's room. There are several requirements that must be met in the child’s room:

- Ecological purity and safety of the selected material;

- Strength;

- Good sound insulation;

- Water resistance;

- Ease of installation.

Laminate is ideal for all the above parameters.Its installation takes only a few hours, and if necessary, dismantling work can also be carried out easily. In addition, the laminated coating does not require special care during use.

The service life depends on the chosen class. Also at installation of a heat-insulated floor this covering is most often used. According to statistics, the panels serve much longer than their warranty period.

In the nursery, many manufacturers also provide specially designed coating. In addition to the fact that it fully meets all the requirements stated above, a wide variety of different colors and original design is presented to the attention of customers.

In addition, today a moisture resistant coating is available on the building materials market. It is made of special fiber plates, having an increased density. It is also worth noting that an additional bottom layer is installed for better sound insulation and a protective film in order to protect the decorative cover from tarnishing.

Another difference between the moisture-resistant coating and the usualthat the core of the hardboard is subjected to additional processing right during installation.

The lock connection also receives additional protection against moisture. It is impregnated with wax, which repels moisture. As a result, such a floor will not need to be replaced for several decades, and the problem of wear of the laminate from the effects of water completely disappears.

Examples and options

Popular laminated coating from Belgium. But if you take the Russian laminate of a similar class, the quality will be just as good, and the price in this case will be much more affordable.

The main thing before buying is to choose a coverage class. From this will depend on the characteristics, durability and durability. Next, pay attention to the size. You can immediately lay wide panels up to one and a half meters. This will allow the client to save time.

It is more difficult to install narrow panels and this will require much more effort. Beforehand it is important not to forget to make measurements of the room.

For the home fit a simple and reliable click click lock system. Since the panels are easy to install and remove, moving the floor to another room or when moving will take a minimum of time and effort.After that, choose the desired color and texture panels. In the process of choosing a client is limited only by their own imagination and budget.

On how to choose the right laminate, see below.