Laying the substrate under the laminate: method description

Laminate - a multi-layer floor covering, which can be made of plywood or wood. It enjoys well-deserved popularity due to its low cost, durability and attractive appearance, very reminiscent of expensive parquet. In order for the laminate to last for a long time, you should take a responsible approach to the installation of this floorboard and be sure to use a special substrate.

Functions

Laminate, despite all the advantages, during the operation accumulates a number of significant drawbacks, including:

- deformation of the board due to physical impact or the natural unevenness of the floor;

- breakage of the lock fastening elements with each other;

- squeaking and other noises during operation;

- penetration of microorganisms (including mold) or insect pests into the board;

- condensation.

All these defects can very quickly destroy the laminate. To restore the floor in this case will have to perepilat flooring.

A special substrate is able to prevent such troubles and significantly extend the life of the floorboard.

However, even the most expensive laminate base does not eliminate the need to pre-level the floor, as the substrate hides only small imperfections.

The main functions of the substrate under the laminate are:

- Heat and noise insulation. The fact is that the porous structure of the material makes it possible to soften the sound of the steps, therefore the room in which the laminate is laid according to all the rules is very quiet. In addition, this floor will always be a comfortable temperature, so you can not use carpets and paths for additional comfort.

- Aligns the floor, allowing you to lay an inflexible laminate without causing unpleasant consequences during operation.

- Hydroprotection. The fact is that the inner surface of the laminate is not treated with water-repellent compositions, so the condensate can easily “destroy” the floor covering.

Thus, the installation of high-quality and suitable base for laminate will allow the most comfortable to operate this flooring and not be afraid of its premature damage.

Kinds

In order to properly choose the basis for laminate, you need to figure out which varieties of this building material exist, how they differ and in what conditions it is better to use one or another variant of the substrate. The basis under the laminate is:

- corkboard;

- coniferous;

- leafy;

- foil (penoprotein);

- film (polyethylene foam).

Cork lining under the laminate is made of crushed bark of the same tree. This is one of the most suitable materials for this purpose. It has the following properties:

- high sound insulation;

- resistant to mechanical stress;

- good thermal insulation;

- environmental Safety;

- hypoallergenic.

The only drawback of the material is its fear of moisture, so you should not use a cork backing in damp rooms, and in the rest it is necessary to additionally use a waterproofing layer. In addition, this material is expensive, which makes it not available for all categories of buyers.

Cork-bituminous coating is the most moisture-resistant variant, which is characterized by increased wear resistance and immunity to dampness.

Coniferous basis for laminate - modern development, characterized by the following advantages:

- environmental friendliness;

- perfectly evens the highly deformed floor;

- high noise and moisture protection properties;

- can be laid in damp areas.

Among the minuses can be noted the high brittleness of the material, which can deliver certain inconveniences during transportation and installation of the coating. Also, due to the natural composition, it can be an excellent bait for various parasites. In addition, you should know that coniferous substrate can cause allergic reactions.

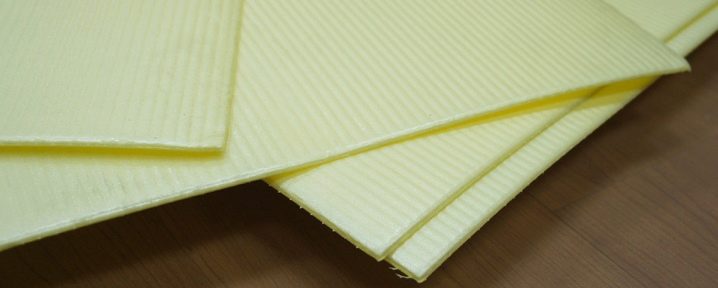

Sheet base under the laminate is often made from specially prepared polystyrene and fiberglass. Fiberglass is environmentally safe, has good technical characteristics.

Extruded polystyrene is one of the most cost-effective options, combining low cost and excellent quality. It has the following advantages.:

- resistant to high physical exertion;

- high hydro protection;

- resistant to mold and mildew;

- effectively absorbs vibrations that occur during walking.

However, the material has one major drawback. It is flammable, and when exposed to high temperatures begins to release toxic compounds that can cause poisoning in humans and animals.

The foil laminate substrate is made of polyethylene foam and is produced in convenient rolls. Recommended for installation in rooms with high humidity. The corrugated surface allows to achieve high levels of heat and sound insulation. This foundation is compatible with a warm floor system.

A substrate made of poetilene (film) is a budget option, but it has a short lifespan, quickly deforms, loses its elasticity and becomes unusable.

How to lay?

After a suitable substrate for laminate has been selected, and preparatory measures have been taken, the installation of the base can be started. Knowing the main points of the substrate flooring, you can do everything yourself and not turn to the help of professionals. As in any case, the technology of lining under the floor covering has its own characteristics:

- Mounting of the substrate is carried out perpendicular to the future direction of the laminate boards.This secret will help to avoid deformation of the lock that holds the boards together, which means the floor will not creak and crunch when used.

- Under the substrate must be put waterproofing layer. This does not apply to the foil base, it is simply placed on the floor by the side that is reinforced with foil. Lay waterproofing necessarily when using natural materials (cork, needles), this will prevent the formation of mold and mildew.

- Correct laying of different types of base under the laminate can be done according to the algorithm: roll materials are placed with a slight overlap on the walls, tiled ones - at the joint, in a checkerboard pattern.

- It is possible to glue sheets of the substrate material with the help of masking and ordinary adhesive tape, paying attention to the quality of the connection of parts. It is forbidden to fasten material with nails, clips and other metal objects that may damage the base of the laminate.

Following these recommendations, you can qualitatively put the laminate in any room without special skills.

Materials and tools

In order to mount the substrate, you will need the following materials and tools:

- the base under the floor covering;

- waterproofing film;

- painting or office tape;

- scissors;

- roulette;

- glue;

- stationery knife;

- gon;

- a vacuum cleaner.

It is recommended not to save not only on materials, but also on tools and fastening, since the quality of the work will largely depend on their convenience.

Surface preparation

Before laying the substrate under the laminate, the following steps should be carried out:

- leveling the floor;

- laying waterproofing.

Despite the use of a substrate for laminate flooring, the floor on which the flooring will be installed should be as flat as possible. This will ensure a high end result and a long service life.

Screed wet concrete and sand solutions - one of the most common ways to prepare the floor for laying laminate. Allows to smooth irregularities horizontally from one to eight centimeters. In order to be able to smoothly lay laminate flooring, beacons are installed and filled in before installing the tie. It is possible to mount the substrate after complete drying of the cement-sand mass.

The semi-dry method is to use special leveling compounds withthe addition of plasticizers. This material is well distributed over the floor surface, does not emit excess moisture. Even a very curved floor can be leveled with such a mixture, since there is no limit to the thickness of the screed, and the simplicity of working with this material will allow creating a perfectly smooth surface in a short time.

Leveling the floor with wood-shaving sheets or plywood is one of the fastest ways to prepare a surface for laying a floor covering.

Installation technology step by step

Proper laying of the substrate under the laminate - a guarantee of durability of the floor covering, therefore the work should be carried out in a strictly defined sequence:

- The surface for laying is thoroughly vacuumed from dust and small debris, as it can give creaking sounds and crunching during the subsequent operation of the laminate.

- The surface is primed with special solutions. Cover the floor with primer usually 2-3 times with an interval of several hours.

- Put waterproofing. This step should be performed only after the last layer of soil has dried completely. To fix the material can be using special compositions.It is necessary to glue the layers of waterproofing carefully, leaving no gaps.

- Laying the substrate under the laminate. The technology depends on the selected material. Sheet lay in a checkerboard pattern, natural materials - at an angle of 45 degrees, and the roll - perpendicular to the future flooring.

Installing laminate in a room is a laborious process, but it can be done even by a non-professional. For the successful installation of flooring special attention should be paid to the preparation and installation of the substrate. And then the new floor will delight more than one year.

On how to lay the substrate under the laminate, see the following video.