Construction of a fence from a professional flooring

Any plot of land, either a cottage or a farm, must be surrounded by a fence. The fence usually performs several functions at once: security, functional and aesthetic. But not every fence can fully comply with these parameters. Often the unreliability of the design lies precisely in the materials from which it is made. Therefore, their choice requires careful study of the issue. This article will consider the features of the construction of the fence of corrugated board.

Advantages and disadvantages

Today, there is a large selection of building materials, which significantly complicates the choice. The most popular are universal materials that can be used under various conditions. These include decking or, in other words, profiled metal sheet.

There are few minuses in the use of the metal profile, and with an objective assessment they are insignificant and completely solvable. To prevent the fence from swaying under the influence of the wind, you need to pick up sheets of a specific marking with a greater thickness. Corrosion can easily be avoided by timely processing the material with a special protective coating. And you can just paint over the scratches.

The advantages of a professional flooring are greater than those of other similar building materials, and for an ordinary person with a modest income living in a middle climatic zone, such fencing material will fit perfectly.

Its main advantages are:

- low cost;

- the ability to install the fence yourself, which will save on wage workers;

- low weight of the material itself;

- long service life;

- durability of texture and color;

- decent appearance;

- ease of care;

- opacity;

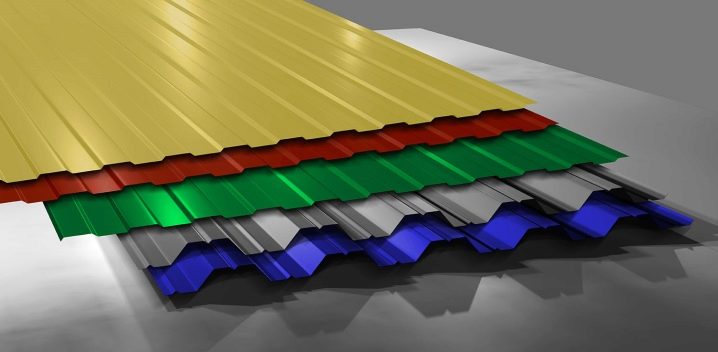

- wide range of colors (about 300 options);

- reflecting qualities of a brilliant coating;

- resistance to ultraviolet radiation;

- flexibility and impact resistance;

- Fire safety;

- long service life - about 50 years.

It should be noted that such an extensive list of advantages has few types of building materials. Profiled floor can be called universal and multifunctional.

But to evaluate these properties will turn out only if used correctly. There is an opinion that the fencing of the metal profile is shaky and short-lived. Perhaps the reason for neglect is the budget price. However, this is a misconception. This building material is clearly underestimated. In addition, such a fence is often cheaper than other species.

Having chosen the metal profile, the site owner will be able to quickly, easily, efficiently and inexpensively build a fence that corresponds to his financial capabilities and taste. Despite the relatively low price, the fencing of metal sheets are not inferior in quality to the fences of more expensive materials.

Types of designs

Profiled metal sheet necessarily has a protective coating, which is:

- Zinc. Covering the material with this metal is the easiest and cheapest form of protection. Galvanized profiled is one of the most popular materials for cladding and construction of fences. It is lightweight, easy to use, easy to transport. In addition, it will not cause inconvenience during installation.However, professionals do not recommend giving him preference. The sheet quickly rusts, and in sunny weather it heats up much more strongly than any other coating.

- Aluminum zinc. When zinc is combined with aluminum, the service life of the material is increased.

- Polymer - the most reliable. Polymers are extracted in the laboratory from the components of paints and varnishes. Sheet metal with this type of coating is produced from galvanized steel by cold rolling in specially designed machines. Also available are extended sheets with different wave parameters that differ in height, width and stiffness of the ribs. They consist of pigments that are responsible for protecting the surface of the fence from external mechanical damage. The polymer is applied to the profiled using a roller. It is first necessary to apply a layer of primer to enhance anti-corrosion properties.

Advantages of polymeric material:

- unusual design;

- ease of care;

- durability and resistance to ultraviolet radiation;

- long period of use.

Among the shortcomings worth highlighting the increase in cost (approximately 15%). The polymer coating provides a durable color and a smooth texture.There are many varieties of polymer coating, each of them has its own characteristics.

Types of polymers:

- Polyester - Wavy polyester (PE) - modern multifunctional component. This sheet is used in both the northern and southern regions. Service life is up to 35 years, layer thickness is 25 microns. The fence will be indifferent to external influences, in particular to corrosion, direct UV rays and precipitation, mechanical and chemical damage. It also has a high temperature resistance and prevents the formation of microcracks, which is the main cause of corrosion. The classic professional sheet is covered with a matte polyester layer that has a matte surface. It gives a more expensive and sophisticated appearance to the fence, so it is the most popular. Also matt polyester gives additional resistance to abrasive loading.

A fence with a coating of this type is ideal for central Europe and Russia.

- Plastisol (PVC). PVC coated flooring provides a high resistance to mechanical stimuli, since its thickness is 200 microns. The texture can be smooth or embossed.This is ideal for harsh climates. However, it should be borne in mind that under the influence of sunlight the paint will eventually burn out, so this coating is more suitable for owners of sites in the northern regions. At the same time, plastisol is much more expensive than polyester. The term of operation is 35 years.

- Polyurethane (PU). The professional sheet treated with polyurethane protects the fence from ultraviolet radiation, because it is recommended to use it where there is a risk of the surface burning out from the sun's rays and its damage. It has high rates of resilience and other external factors. Polyamide and acrylic modified PU sheets are light and easy to use. In places of bends cracks are not formed. Another important advantage is the relatively low cost. The service life is 50 years.

- Pural. The latest development of scientists allows you to apply a 50 micron layer of Pural on a professional sheet. The service life is 50 years, which is achieved due to the wear-resistant resin-based polymer layer. The professional flooring processed by it has the following advantages:

- resistant to sudden changes in temperature (from -60 to + 100-120 C);

- perfectly resists rust;

- UV and chemical resistant.

- PVDF. Such a profiled sheet does not wear out over time and is not exposed to moisture, ultraviolet rays, snow or rain, can be used at temperatures from -50 to +120. PVDF is an environmentally safe component that is applied in a thin layer (27 microns). The high price of the material is compensated for by excellent properties (for example, resistance to even damage that is dangerous for conventional spraying). The period of operation is 50 years.

- Printech - Dongbu Steel's patented technology. The products of the South Korean firm are more expensive than standard profiled sheets by one and a half times, however, they have unsurpassed aesthetic properties. There are about 100 species that mimic natural textures - from granite to cut wood. The term of operation is from 50 years.

- Powder coating. This method of processing is the most environmentally friendly. The fine component undergoes polymerization under the influence of high temperature, due to which it becomes homogeneous and very durable. Application is carried out using electrostatic action. The technology allows to achieve a perfectly smooth coverage.The method is environmentally friendly, since the amount of waste does not exceed 5%. Layer thickness - from 50 to 300 microns.

It is quite difficult for a beginner to choose the right material. However, in order not to be mistaken, it is enough to adhere to the above recommendations of professionals.

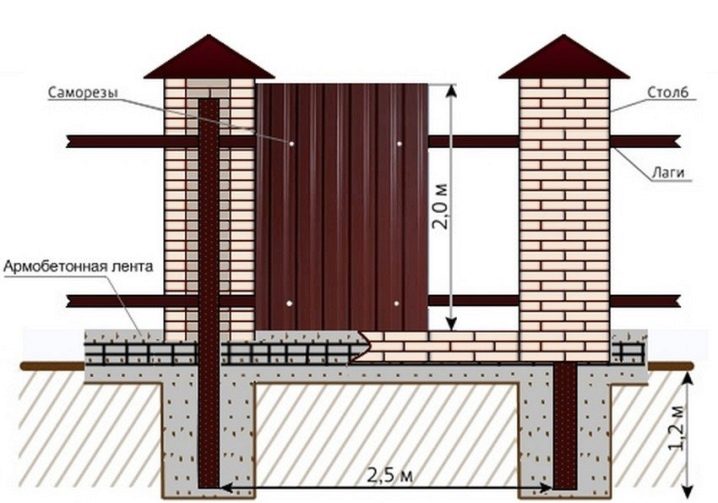

The fence may consist entirely of profiled sheets. But for greater stability, it is recommended to build a fence with a base, that is, with a strong foundation. It is necessary not only to increase stability, but also to drain water, which can accumulate during heavy rain. Cap can be of several types:

- with columnar base;

- with column-base;

- stone.

The option with columns divides the entire sheet of corrugated into sections. A column-ribbon, in addition to sections, also adds a foundation along the entire base from the bottom. In both cases, you can use both cement and brick. The stone type of the base is the most expensive, but at the same time the most reliable. However, the need for such a fence appears only in the case when the fence is built of heavier materials, such as wrought iron.

The calculation of the required construction tools and materials depends largely on the type of fencing and the number of sections.

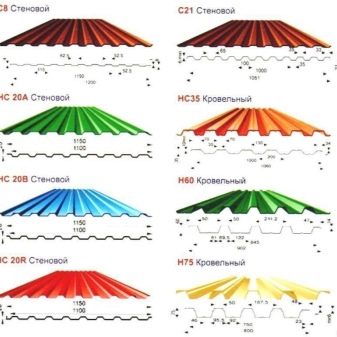

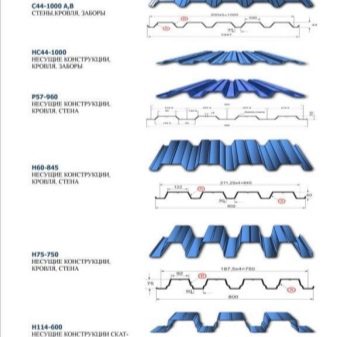

Dimensions

Marking "H" applied to products with a thickness of more than 44 mm. This profile is suitable for bearing walls, as well as for roofing and manufacturing containers. Its thickness is quite large. To use such a view for the fence is impractical and uneconomical.

Professional sheets with marked "NS" 35-43 mm thick is intended for roofing. They are commonly used as fencing material for construction sites. In living conditions, increased resistance of sheets of this thickness is not needed, so do not dwell on this option.

Marking "C" has a thickness of 8 mm and is intended for exterior decoration of buildings. For the construction of fences and fences around private homes, a coating thickness of 21 mm is optimally suited. Despite the ease of profiled sheeting with the “C” marking, it is quite strong and stable, only slightly inferior to the materials with the “H” and “NS” markings.

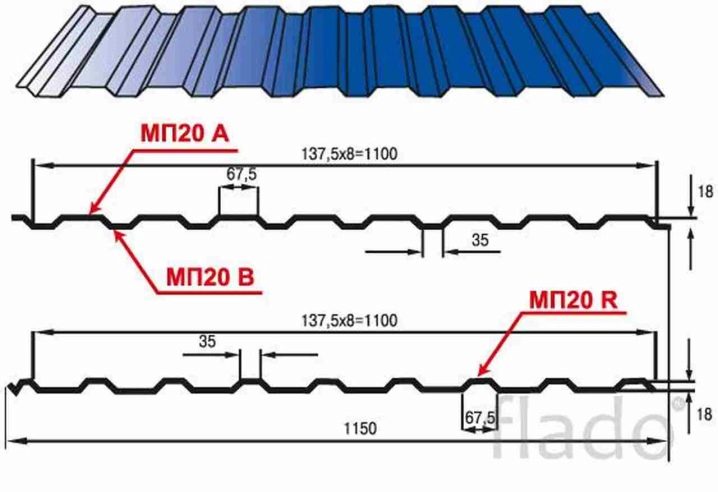

In addition to the above, there is another type of professional sheet. with marking "MP". This type is considered to be universal, it is light and inexpensive, it is used both in roofing works, and in the construction of household buildings, as well as for the installation of fences.However, the professional sheet is best suited for the fence. with marked "C8".

Below are the parameters of the most popular grades in the form of brand / total width, mm / working width, mm / thickness, mm / wave height, mm / distance between the ribs, mm:

- C8 / 1200/1150 / 0.4: 0.8 / 8 / 62.5;

- C10 / 1150/1100 / 0.4: 0.8 / 10/45;

- C18 / 1150/1100 / 0.6: 0.7 / 18 / 91.67;

- C20 / 1150/1100 / 0.45: 0.7 / 20 / 137.5;

- C21 / 1051/1000 / 0.4: 0.7 / 21/65;

- CH35 / 1060/1000 / 0.5: 0.9 / 35/70.

As for the length of the sheets, there are no fundamental restrictions. The seller will cut you material of any length up to twelve meters. It is also possible to get professional sheets over the specified border, but for this, it may be necessary to issue a special order.

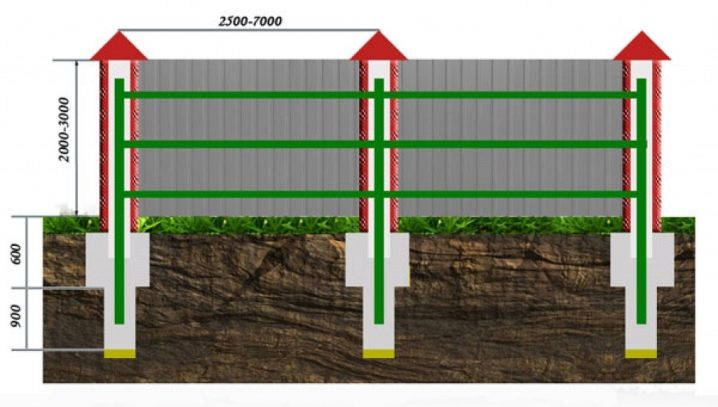

The height of the fence is better to choose at the level of 2-3 meters. With such a height, you can not worry that someone will be able to look inside or climb the fence and get to the site. In addition, from the street will not penetrate loud sounds, the site will be protected from road dust.

Which to choose?

The next step after studying the existing types and forms will be the choice of material for the construction of the fence. When selecting components, those materials that are best suited for low-cost structures and will not create problems when assembling a fence, even by an inexperienced builder, will be considered.

It is quite suitable profiling labeling "C" and "MP". Do not buy sheets without coating, otherwise, the fence will soon need to be replaced or updated. Inexpensive polyester will protect iron from corrosion.

Tools and accessories

The design of the fence is not only metal sheets, but also a number of other components:

- rack supports in the form of metal pipes;

- lintel spacers;

- metal screws or roofing screws.

Before buying building materials, it is important to know how many of them will be required. It is enough to calculate the length of the fence as a whole and each of its sides separately, as well as the height of the structure. To determine the number of sheets, it is necessary to divide the perimeter of the fence by the width of one sheet, then round it up.

The height of the fence is also important because the sheet will be mounted at a short distance from the ground. It is impossible to allow that the professional flooring rested against soil.

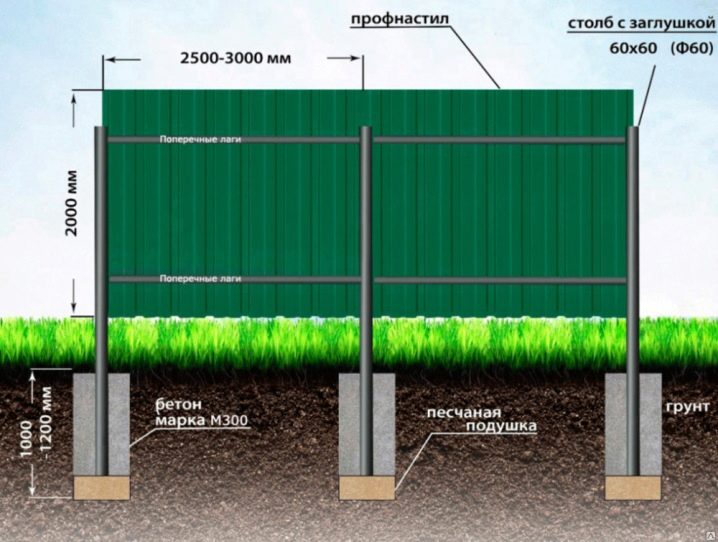

Support stands can be used in both round and square shapes. However, it is better to give preference to square. Their size should be 50x50 mm or 60x60 mm. For round pipes, it is recommended to choose a diameter of 50 mm.The most suitable wall thickness is 3 mm.

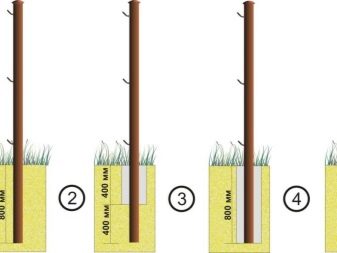

The length of the supports depends on the height of the fence and on how deep it will be necessary to dig them into the ground. The height of the fence itself will also be of great importance. For example, if the depth of the pit under the rack is 1.3 meters, and the height of the structure is 2 meters high, then a pipe of 60x60x3 mm is equal to about 3.3 meters.

Theoretically, it is allowed to use wooden racks as bases. Before installation, they must be treated with antiseptic.

It is also necessary to pay attention to the part of the pillar that will sink into the ground: it must be particularly strong. Preliminary it is recommended to process it with a blowtorch, and then with a bitumen primer.

Usually the distance between the supports is made in 2-3 meters. In areas with strong winds, it is worth reducing this gap. When calculating the number of pillars, it is necessary to take into account that the supports are necessarily placed at the corners of the perimeter and on both sides of the gate or wicket.

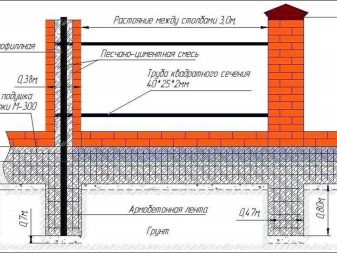

If, nevertheless, there is a desire to erect a sectional fence with pillars, then it will be necessary to make sure that in each section one sheet of corrugated sheet is included entirely. As a jumper lag it is also better to use profiled pipes.To determine the required number of them is simple: to do this, you need to multiply the total number of cross-beams by the perimeter of the fence. Optimal parameters of strength have logs with dimensions of 40x25x2 mm.

To connect the supports with lags will need welding. In the absence of a welding machine or experience with it, as an alternative, you can use bolts or special fasteners - "crabs". Working with them is much easier. In terms of reliability, they are inferior to welding, but they are indispensable in case of need for quick and easy installation.

And the last thing you need to build a fence - roofing screws for metal. Suitable size - 4.8 x 19 mm. Their number depends on the planned size of the fence itself. For example, for sheets of markings "C" or "MP" 20 mm thick, 4 screws are required for each crossmember.

If there are two lags, then you need 8 screws, if three - 12 pieces. However, this calculation will be correct, provided that the screw is correctly screwed into every other wave. In all other cases, the calculation of their number is done individually.

In order to make the fence look aesthetically pleasing, one should match the color of the screw in one tone with the fence.

Manufacturing features

In addition to the main components of the construction of the fence of corrugated board, you will also need:

- auger or shovel to dig holes under the pillars;

- length measuring tape;

- capacity for mixing the solution;

- level to check verticals;

- cord for marking borders;

- a screwdriver or drill to tighten the screws;

- cement marking M200, as well as sand and crushed stone for filling racks;

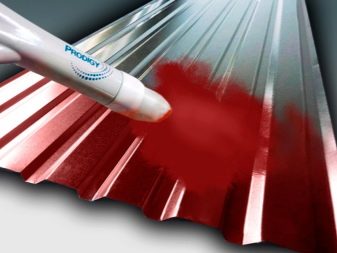

- spray can to mask the scratches when installing the fence.

Installing a fence made of corrugated DIY is easy. There is a universal type of metal profile fence with a simplified device. However, it is important to understand that deciding to build a structure yourself, you must take responsibility for completing additional actions that are no less important than the assembly itself. Before the start of construction work it is important to present the type of fence in the final version. For this you need:

- draw a drawing of the fence, noting the size (height, length in general and individual sections), as well as its exact location on the diagram;

- to assess the territorial features (topography, climate, other objects and plantings, if any, a communications device); with uneven ground surface with a slope the best option is a stepped view of the structure;

- think in advance where the gates, also made of corrugated flooring, will be located for the passage of vehicles;

- clean the surface of the earth from unnecessary objects and debris, level small curvature, if they are in the places where the fence will be installed;

- determine the degree of stability of the soil for the support pillars.

In this case, the construction of a universal fencing without a foundation is being considered. If it is necessary to build a fence on a cement or brick foundation, then for this it is necessary to calculate their number.

In general, the construction of a concrete sheet with a concrete base is more difficult to build. The reason for this is the additional efforts for pouring the strip footing, as well as the cost of fittings and hiring a concrete mixer.

The presence of the mixer machine is optional, but with it the work will end faster. If there is a soft soil on the land plot, it is recommended to use a strip foundation, which provides greater stability of the fencing of the metal profile.

Step-by-step instruction

The construction process itself should be considered in more detail and consistently. So, the main stages of work:

- Installation of pillars and their concreting. First, you need to determine the distance at which the racks will be from each other, and dig holes for each of them. Typically, the distance between the pillars is 2.5-3 m. The recommended depth is 1.3 m or 1/3 - 1/4 of the total length of the pillar. The thickness of the gravel-sand pillow must be at least 100-150 mm. First of all, the supports are placed at the corners of the perimeter, and then on the sides of the gate and the gate. The height around the perimeter must be checked by level.

- After installing the racks should be their concreting. To do this, pour the mortars with the remaining indentations, and then fill the cavity of the pipes. Next, the supports are left for 3 days for the cement to harden.

- Installation lag. This stage can be started only after the cement has completely hardened. Lags should also be treated with a solution of corrosion. Next is the installation log for the support racks. This can be done both by welding and self-tapping screws. There are three ways of fastening:

- butt-front mounting has proven to be the best method;

- mounting the rear of the pole with the help of the bracket is more often used for fencing with sections;

- fixing on the side of the rack allows you to attach both racks and logs to the sheets, which gives stability to the structure, but you have to spend more time and screws.

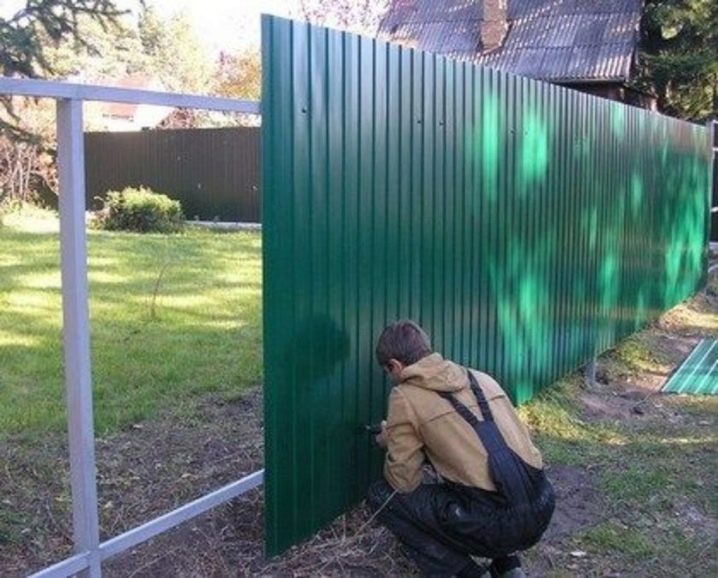

Professionals in this case are advised to use the bracket. It connects the pillar and the lag. This method is considered more costly, but also more reliable.

- Fastening of a professional flooring to a framework basis. Here you can do without welding. Using special screws or rivets, it will be much more convenient to join sheets together. It is important to correctly determine the position of the very first sheet of professional flooring - it should be “overlapped” in such a way that the beginning of the second sheet covers the end of the first sheet, and the third sheet covers the second one. This principle should be used around the perimeter of the fence. One layer covers the other. Sheets are attached at the edges of the transverse lag. Brackets are installed in the center of the sheet.

- The rules for attaching a metal sheet require special attention. If we neglect them and carry out installation at our own discretion, then the wind load can soon lose the fence.The self-tapping screw fastens to a log on the lower bend, but does not connect sheets from above. You can not tighten them all the way: they can come off and damage the outer surface of the profiled sheet. The main thing is to fix the first professional sheet correctly. The appearance of the entire fence depends on it, because each subsequent sheet is attached to the previous one.

If for some reason there are gaps or cracks in some places, then they need to be riveted. It is also useful to purchase paint for coloring scratches formed during the installation of the structure.

- It is possible to install racks with the help of bricks in several stages. The pillars are laid out with bricks, while we should not forget about the intermediate lintels. Brackets are placed on racks at a height of about 30 cm. Then you need to check the level. Horizontal brackets are attached to the brackets. After that, it remains only to fasten the sheets with self-tapping screws.

If you want to fill the foundation of the fence with concrete, then for this you need:

- dig a trench around the perimeter of the site;

- make the formwork;

- fill it with a solution;

- wait until it freezes.

To do this, you need a flat board with a size of 2.5x1.5 cm.The width of the formwork can be chosen at will, a side approximately 20 cm will look neatly. Shields are attached to the sides of the trench, they are joined at the ends with self-tapping screws. This is necessary so that there is no leakage during the outflow of the foundation.

Further, pegs are placed in the corners of the boards for strength. The formwork must be installed approximately 30 centimeters above the intended cementing border. If you plan to do the fence with pillars, then the foundation for it must be monolithic. This ensures the strength and durability of the structure. In this case, do not forget about the valve.

Immediately before pouring it is necessary to check whether the pillars are evenly standing.

If inside pipes the concrete hardens in three days, then the readiness of the foundation will have to wait a few weeks, after which the formwork can be removed. Concrete will harden faster if 10-15 days after pouring it is necessary to lay bricks on top of it. So the density of the foundation will be higher. In the process of "ripening" the foundation should be protected from increased evaporation of moisture. To do this, periodically water the concrete with water from a hose, and then cover it with any film or wood chips.

After the foundation is ready, the installation of the fence can be continued. Pouring the foundation, as well as building a fence is a simple matter, but it is energy-consuming and troublesome, so it’s best to ask for help from a friend or neighbor.

Professional builders recommend closing the top edge of the sheet with a special U-shaped bar.. This will prevent the formation of rust, and the fencing itself will look more beautiful outwardly.

This kind of "nozzle" can be purchased in any size in accordance with the size of the main sheet. However, it is believed that the raw end of the fence is an obstacle to the penetration of thieves, because the edges of the profiled sheet are quite sharp.

In any case, to close the upper end or not - everyone decides on their own. You need to be prepared for the fact that even with the most accurate calculations there will still be waste, and this, respectively, is an extra cost. But these are “production costs”, and they are inevitable.

Useful tips

Nuances in the construction of the fence:

- Experts advise to put plastic plugs on top of the pillars, this will eliminate the appearance of water inside and the formation of rust.

- When purchasing fence strips, you must ensure that their edges are concave inwards. Otherwise, a lot of scratches may appear on the surface of the sheet. Then you have to make repairs to the new fence.

- Decking is considered to be quite sharp material, so when working with it is better to use durable gloves.

- If it is planned to install barriers with posts, then one section should be one whole profiled sheet.

- If at the site there are uneven terrain, then it is necessary to mark these places in the drawing: this will help to avoid mistakes in the installation of support pillars.

- When choosing a professional flooring, it is necessary to take into account that an ordinary galvanized sheet will last 20-30 years, and iron coated with polyester - up to 50 years.

- The bottom of the fence should start at a distance of approximately 100-150 mm from the ground. This will protect the sheet from corrosion.

- In case of an error in calculations or other subsequent deformations of the structure, small gaps are possible. They can be sealed with cement residues.

- Before installing supports, it is recommended to treat them with a corrosion-resistant coating.

Design examples and variants

The fence of corrugated flooring with wooden racks, supports, although used infrequently, but it has a place to be.

The combination of sheeting with forging or forged inserts looks solid and prestigious. Iron products can strike at the family budget, but they stand out with particular strength and reliability.

Even the most primitive fence can be made outwardly attractive. Therefore, if the budget is limited and the fence with a metal ornament cannot be built, you can do the following:

Insert into one or more profiled sheets strips of glass, which can be vertical or horizontal lines, separate “islands” in the form of circles, squares or other geometric shapes. Any glass is suitable: frosted, transparent, embossed, smooth, with or without a pattern.

- Around the perimeter or on one of the front sides of the fence to apply a pattern - it looks unusual and attracts attention.

- Trim the top edge of the sheet. For example, the wavy line will add individuality to the structure and will give a complete look.

Decide on the choice of the fence, arm yourself with all the necessary tools and start work.With the right approach, the assembly of the structure does not take much time.

Tips for the construction of the fence of corrugated you can see in the next video.