Corrugated fences: selection criteria

Recently, people are increasingly moving to live outside the city. Someone spends on cottages and garden plots only a certain period of time. But all the owners, as a rule, want comfort, privacy and protection from unwanted guests, so they enclose their grounds with fences.

Among the materials for fences, a profiled sheet is of particular popularity, due to its remarkable performance characteristics.

Special features

Features of a design from a metal profile:

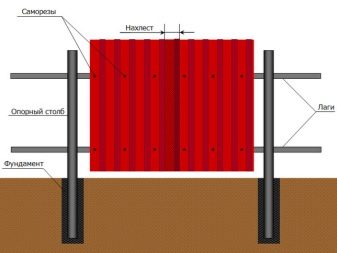

- The presence of support pillars.

- Mandatory tube frame.

- Foundation: concreting each support or tape.

- Frames for gates and gates.

- Other fixing, decorative materials and accessories.

The professional flooring is made of a galvanized steel sheet. On top of it is covered with a protective layer of such means as plastisol, polyester or Pural. Exterior protection also performs decorative functions.

The profiled plates resemble wavy slate. Corrugation is of different heights and different shapes, for example, in the form of a trapezoid or a rectangle. The most common is a sinusoidal profile.

The professional flooring is easy in storage, installation and is convenient when transporting, therefore it is widely used in various spheres.

Where do they meet?

Most often, the metal profiles are used for the construction of fences in suburban areas, industrial and construction areas.

In addition, sheets of corrugated board used in the construction for the manufacture of door canopies, awnings, wall cladding, construction of frame structures.

Universal material is in demand because it has a low cost, unpretentious in the care and installation.

Advantages and disadvantages

The professional leaf among the advantages has the following properties and characteristics:

- Long service life - from 15 to 30 years.

- Stiffness of the whole structure.

- Practical, easy care.

- Fireproof.The design can be used as a fire barrier against the spread of fire.

- The average degree of noise insulation.

- All-weather resistance of the external polymer layer, which protects against the loss of brightness of color, scratches, and corrosion.

- The universality allowing to use metalprofile for construction of any constructions.

- Low cost due to uncomplicated production technology.

- Decorative, the ability to choose colors and shapes. Recently, manufacturers offer options with imitation of the structure of wood, stone, brick.

- Ease of installation. The metal profile makes it possible to install the fence at any time of the year.

Installation time is insignificant.

- Variability. The fence from a professional leaf can be put with use of different types of support: concrete, brick, rubble, metal.

Among the shortcomings can be identified:

- Windage Therefore, experts do not recommend making the gaps between the supports too large.

- Low moisture resistance and unpresentable look at the material of low class.

- The thickness of the steel sheet is small, so it is easily cut.

- The self-tapping screws used for fasteners are easily twisted.Therefore, it is better to take care of additional fastening of the structure with rivets.

Kinds

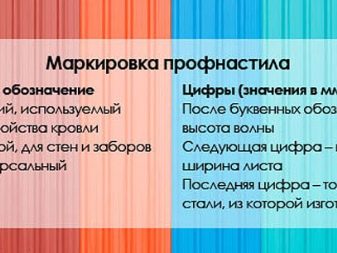

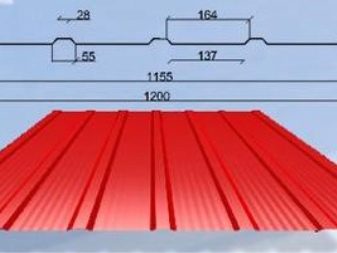

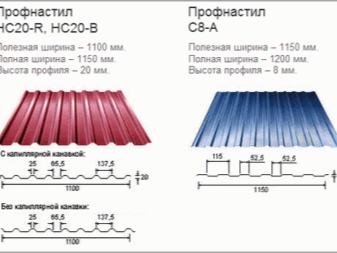

For the construction of professional sheet fences, not all of them are used, but only some. As a rule, the choice is to focus on the brand. For its designation, the following codes are entered: H - carrier, C - wall, NA - universal. The numbers following the letter indicate the height of the corrugated part and the width of the metal profile. Since the fence does not experience maximum loads, for its construction, you can use the material with the letter "C". As for the height of the corrugations, then 20 mm is enough for fencing.

For example, the following marks are appropriate for fences:

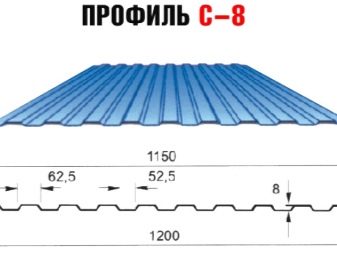

- C8 is a profile sheet designed for wall cladding. The number 8 in the code indicates that the profile has a symmetrical wave with an amplitude of 8 mm. The material is lightweight, inexpensive, but does not have sufficient strength. Experts do not recommend to use it for high fences, and also to make too long spans. Ideal for temporary fences.

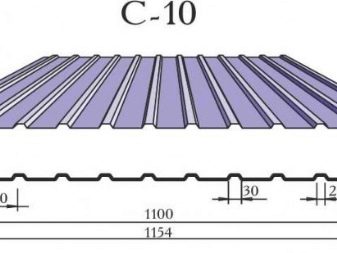

- C10 - wall panel has a height of corrugations of 10 mm, which improves strength compared to C8.The material is slightly more expensive than the previous one, but in terms of its protective qualities and durability it is much better.

- C14 has the shape of corrugations in the form of a trapezoid with a height of 14 mm. Convenient for frame fences in areas of strong winds. Sometimes used for covering garage or production gates.

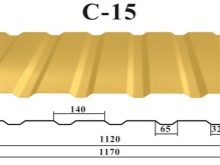

- C15 is a universal type of profiled sheet with a wide edge of the wave. It is rarely used for fences, mainly as roofing, facades and fences.

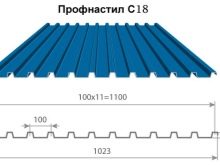

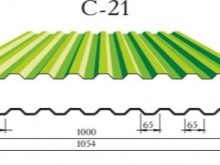

- C18, C20, C21 are the strongest brands in the line of wall sheets. Suitable for the construction of any fences and roofs in harsh climates, as well as, if necessary, to get a fence above 2.5 meters.

When choosing materials for the construction of fences, it is necessary to take into account the peculiarities of the landscape, the climate of the area and the technical characteristics of the structure.

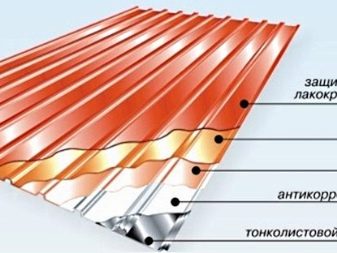

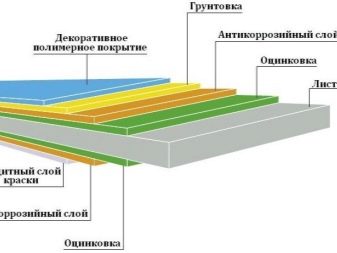

The profiled sheet is a complex structure consisting of several layers. Each of them performs its function. And only with the high quality of each level, you can get the most effective material for the fence.

Metal profile, which is used for the construction of the fence for many years, should consist of the following elements:

- The basis of low-alloy steel sheet.

- Galvanization caused on both sides in a cold or hot way.

- Anti-corrosion protective layer.

- Primer.

- Color polymer.

Depending on the type of coating, there are several types of sheeting:

- Galvanized. The sheet has a characteristic steel color. The thickness of the protective layer and the method of its application cause the anticorrosive properties of the material. The presence of zinc on the surface is almost imperceptible, since up to 300 grams per 1 square meter of the profile. The minimum limit for the fence is 150 grams of zinc per 1 square. flooring meter Two types of galvanized steel sheets are produced: double-sided and one-sided. Manufacturers guarantee a ten-year service life of the material. Galvanization prevents corrosion on the metal surface. A positive argument for buying is low cost. Sometimes the zinc layer can be applied unevenly, which requires sending such goods to substandard. Most often, galvanized sheets are used as temporary fencing in the construction of buildings, fences of industrial sites or warehouses.For decorative purposes it is not used due to its unpresentable appearance.

- Aluzinc The outer layer is a chemical compound consisting of 45 percent zinc and 55 percent aluminum. By analogy with the first used for industrial purposes. The fence from aluzinc can be painted with any paint, but in this case it will become more expensive than polymer, which is unprofitable.

- Polymeric. A layer of polymer is applied on a galvanized profiled sheet. This combined option increases the protective function, improves moisture resistance and corrosion resistance. Service life increases to 50 years. Since polymers are able to acquire any color, their use causes a variety of colors and textures.

Metal profiles are classified according to the type of protective layer.

- Polyester. Chemically inert agent resistant to weather disasters, solvents and various contaminants. It has a glossy surface that is easy to clean even with rain. Experts recommend sheets with polyester protection for the construction of fences around private cottages.

- Plastoisol has a textured surface.It contains polyvinyl chloride and various plasticizers, which increases the resistance of the material to mechanical and chemical influences.

- Pural - polyurethane-polyamide dye, which gives the surface a haze and silkiness. A more expensive type of coating that has increased resistance to any kind of impact. Due to its high cost, it is more often used for the construction of elite structures. Advantages: an increase in the service life of corrugated sheets up to 50 years, a large temperature range, and an increase in the durability of galvanized sheet

- Acrylic - ultraviolet and chemical protection.

Given all the above information, fences are classified into several types.

Types of fences:

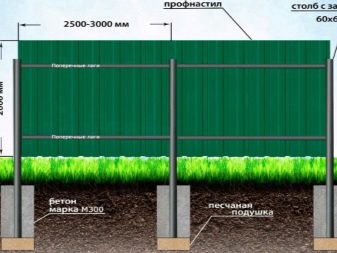

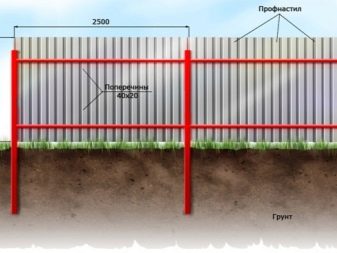

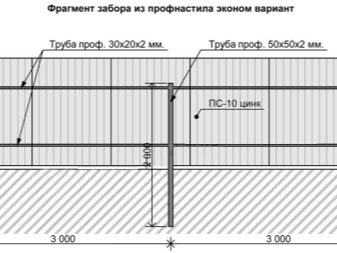

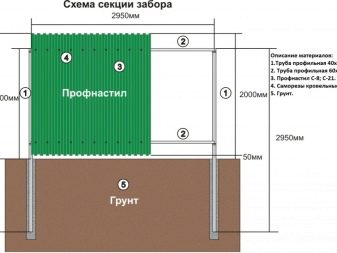

- Continuous light fence. As a rule, they are installed on a metal frame of profiled pipes. For temporary use, the foundation is not made, the columns are driven in or driven in. In areas with a windy climate, structures are not used, because they are inefficient. For other climatic zones, the foundation is concrete, pre-reinforcing the base. Support is recommended to dig in to a depth of 50 to 150 cm.For the framework, pipes of 40x40 mm are used, for frames of wickets or gates - 80x100 mm. As sections - profiled sheet with a thickness of 0.5 to 0.7 mm.

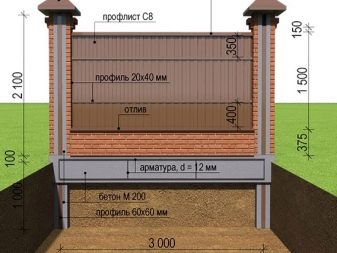

- With brick supports. Fencing can be performed on two types of the foundation: tape and columnar. In any case, the main load falls on the supporting pillars, and the rest of the concrete plays the role of protection, preventing the impact of raw earth with corrugated flooring, the penetration of small animals and other uninvited guests. In addition, the strip foundation does not allow weeds to spread because of the fence.

Brick columns are more solid than metal, have a presentable appearance and are well combined with metal profiles.

- On the tape foundation. Experts consider it the most wind-resistant of the proposed options. At cost, it is more expensive than others, but the end justifies the means. The base can be made by pouring concrete using reinforcement and formwork or from reinforced concrete blocks. The supporting pillars can be different, but they must be installed before concreting and pour the base with the solution. After the foundation and supports are veneered with decorative materials: natural stone, brick, ceramic granite.

The height of the fences are:

- Standard up to 3 meters.The most common type of fencing.

- High fences up to 6 meters prevent vandals from entering and protect the site from the view. As a rule, used for industrial purposes.

- Over 6 meters. Fences of this height are mounted along the autobahns as sound insulation. The internal multi-layer space of the panels consists of penoizol or mineral wool.

Constructions

The design of any fence implies the presence of supports. When building a profile fence, metal pipes are most often used, but sometimes other options are also used.

Depending on the location of the sheets, the fence may be vertical or horizontal. In the first case, the corrugated waves are arranged along the fence, parallel to the pillars, in the second case - the profile is perpendicular to the supports.

An important part of the fence is the foundation, which determines the stability and reliability of the whole structure.

Depending on the arrangement, the fences are classified into the following types:

- Without foundation. The most economical option because it has low time and cost. Piles are concreted, a frame made of a pipe is welded to them, to which, in turn, professional flooring is fastened with self-tapping screws.

Metal profiles can be mounted in two ways:

- The supports are closed from the outside, and from the front side the fence looks solid.

- Sheets are installed between the uprights and can be seen.

- On screw piles. Installation will cost more than conventional supports, but installation is easier and faster. The method is appropriate for unstable soil. The maximum height of the pile reaches 5 meters. Its cross section depends on the size of the spans. For example, if the length of the gaps is planned to be about 2-3 m, then the diameter will be 76 mm. The support must be screwed below the ground freezing level. To install enough three people, each of whom performs his work. The first must support the pole in a strictly vertical position. Two others with the help of levers twist the pile into the ground.

The advantage of such support pillars is the ability to use them repeatedly.

- With a foundation. Compared with the first option more reliable and stable. The fence constructed by this method will last longer in soft marshy soils, and will also be appropriate if there are significant relief drops on the site.

- With foundation, brick supports and basement. The most expensive of these, but the costs justify a long service life and reliability.In this case, first prepare the foundation, then put the base on it. In the construction of support piles use brick. For strength, pipes made of steel are laid inside the columns, as well as fasteners for the profiled sheet. Only after the completion of the preparatory work attached metal profiles.

Profiled flooring options:

- Traditional. Sheet galvanized on both sides. Protective polymer coating can be only from the front. If a pattern is applied to the profiled sheeting, then a transparent layer is applied on top of it for fixing. The top edge of the sheet is smooth.

- With imitation. The traditional professional flooring can be given a different color, for example, under the eurolining or cylindrical logs. Also in demand metal profile with a surface that mimics a brick wall or masonry.

- Figured. Difference from a usual flooring consists in an unusual form of the top edge. Cutouts can be rectangular, peaked shape or in the form of other shapes. The fence looks more decorative and elegant.

- Modular construction The fence is a fence, assembled from ready-made sections, so sometimes it is called "sectional".Conveniently, the assembly of such a fence takes a little time. As a rule, the module is sold partially assembled, i.e. the flooring is already attached to the posts.

Colors

Color profiled sheets universal: brown or green. However, it can be changed at the request of the customer, even to make multi-color.

Coloring sheeting gives the polymer, which is coated with galvanized sheet. This dye does not fade in the sun and additionally protects the fence from mechanical impact. The palette is determined according to the German standard and is divided into several zones, each of which has its own four-digit cipher. This classification greatly facilitates the selection.

As a rule, manufacturers paint a sheet with one hand, but there are always two-sided versions available.

Some tricks

The dark color of the fence distracts attention from him, as if “hiding” from the eyes. Light visually expands the area, but is more branded.

The dark green version is a win-win classic. Such a fence is in harmony with lawns, trees and shrubs.

White fence is easy to repaint or apply drawing in the future.

Fashionable modern colors corrugated wood or stone are widely used in suburban areas.

Dimensions

Before the construction of the fence, you first need to know the dimensions of the material, which will allow you to correctly calculate the quantity and optimize costs.

Since sheet metal is used for the production of metal profiles, the length can be any.

Her choice is due to the following criteria:

- Customer requirements.

- The height of the fence.

- The size of the visors or walls of frame structures.

The width of the flooring varies from 980 to 1850 mm and depends on the equipment on which it is produced. Any profile is obtained from a steel sheet 125 cm wide, which is rolled in a cold way. The size of the sheet decreases due to the corrugated wave - the higher it is, the more profiled it comes out.

Due to the fact that during the installation of professional sheets are attached overlap, experts use the concept of "useful width". As a rule, it is less than real by 4-8 centimeters.

Thickness is static. The standard version is 0.5-0.8 mm, but there are also 1 mm and more. When choosing focus on the climate and destination facilities. When choosing a profiled sheet for the fence, it should be understood that the strength of the structure will depend on the thickness of the material without taking into account the polymer coating.If the fence is to be operated in areas with a large wind load, then with a small thickness the professional sheet can be deformed or torn in places of fastenings.

The profiled sheet is also characterized by the height of the corrugated part, which depends on the shape and usually varies from 15 to 130 mm. For the construction of the fence should not use corrugated flooring with a height of corrugations more than 21 mm.

Knowledge of the dimensions of the material used and the perimeter of the enclosed area is necessary for accurate calculations of the structure.

Decor

As a rule, the fence for private houses, children's sites and parks are trying to do in color and decorate with various decorative elements.

Decorating in the form of a polymer coating with imitation of a brick wall or masonry is in demand.

Manufacturers offer a large variety of models under the tree: eurolining, timber, rounded logs.

The combination of professional sheets of different colors or different shapes of the corrugated surface, as well as the installation of supports from different types of materials will allow you to create an individual original image.Various protective visors and plugs can also serve as decorative elements.

Workshops take individual orders corresponding to the architectural ideas of designers. For example, forged ornaments on monotonous gates and wickets, as well as above them in the form of arches and superstructures, will add elegance or add an element of antiquity.

Figured decking with different options for trimming the upper part - the easiest way to decorate your fence. If you have the capabilities and skills of the owners, you can decorate the metal metal profile with bright drawings or ornaments applied by airbrushing or with an ordinary brush.

Garden plots are often decorated with climbing plants: grapes, ivy, climbing roses. In addition, the fence around the perimeter can be decorated with flowerpots with flowers or planted with different types of shrubs.

If during the construction of the fence on a private plot to provide shelves and protrusions on it, in the future it can be decorated with pots with flowers, decorative elements or used for storing small garden tools.

There are more original ways of decorating fences using old utensils or hand-made equipment.For example, hang out old children's buckets with flowers planted in them or stained glass windows from SD disks.

Which is better to choose?

Knowledge of their technical and quality characteristics will help to choose the right material for the fence.

For a private house or cottage

From wood

The fence with the use of profiled sheet and wooden pillars is the oldest method of fencing its territory. This material is affordable, convenient, environmentally friendly and durable enough. From an aesthetic point of view, he also has no flaws. There are many decorative elements from carving and burning, before staining and painting. However, it is worth noting the shortcomings, the main of which is low fire safety. Rapid decay of support posts and boards requires frequent replacement.

There are, of course, rocks that are waterproof and eventually become stronger, but the material of them is expensive and not everyone can afford.

Of brick

Brick fences with a professional sheet look stylish and beautiful. The material allows you to build real works of art by the hands of masters. The fence is more functional wooden, stronger, more reliable, more monumental. The design is not afraid of strong winds, fireproof.Among the shortcomings should be noted the fear of dampness, the presence of poor-quality raw materials, poor color gamut, an increase in costs due to the need to pay for the services of masters in laying.

Stone

Ideal for a country house in the Scandinavian, Finnish style, in the form of a chalet or alpine classics. Typically, such fences are low and are decorative. Designers recommend using certain types of stones for building fences. Sandstone is a warm, cozy material, simple in processing and tactilely pleasant, but everything spoils its ability to collapse under the action of moisture. Basalt, granite or quartzite - very durable, but visually colder, so experts advise to combine them with wooden elements. Natural stone is an expensive building material, so it is better to use artificial, which is not inferior in decoration, but gains in operational properties.

Concrete

Concrete blocks for the fence of corrugated board are in demand for fencing large suburban areas, because they are quickly mounted and have a low cost.Modern manufacturers offer material of different textures and shapes, which increases its popularity.

PVC

Experts do not recommend plastic fencing as a protection for private property. The best application is the decoration of front gardens and flower beds.

Polycarbonate

If the owner plans to install a fence at intervals, for example, with forged sections, but the visual vulnerability does not suit, you should turn your eyes to such material as polycarbonate. As an independent fence, it is not suitable, but for solving visibility problems in combination with other elements it will allow to decorate the fence and make it elegant.

Professionals warn that polycarbonate will not be able to withstand strong winds and hail storms.

From shtaketnika

The metal shtaketnik represents the professional flooring cut on separate levels. Therefore, the composition and production of shtaketin is similar to a profiled sheet. The height of the strips varies from 1.5 to 1.8 m. The installation method is standard: using support piles and transverse lags. In the presence of a tape foundation strength and reliability will increase significantly.Profile shtaketin is in the form of letters P and M or semi-circular. The second option has a predominant stiffness due to the large number of ribs. When installing the strap can be positioned both vertically and horizontally. The distance between them depends on the desires of the owner.

When buying, experts recommend paying attention to the following factors:

- Shketinov should be from the same party.

- It is better to inspect the product live, because in the same batch there may be strips of different thickness and quality.

- The edges must be rolled. Rolling increases stiffness of the picket fence and eliminates the possibility of injury to the edges during installation.

- The number of protective layers. The more of them, the better the material, but, accordingly, more expensive.

- The number of ribs. With their increase, the resistance of the fence to bending increases.

- Coloring method. It happens one-sided and two-way. In the first case only the front side is painted.

- Staining method. Regular painting using the spray gun is available to any owner. The polymer coating is applied at the factory as specialized equipment is required.It is more reliable and besides decorative functions, it protects from mechanical effects. Powder spraying is a complex technology associated with baking metal coated with a layer of dry dye in special ovens.

With forging elements

Forged items will decorate any fence. They give brutality and prestige. Spans made of similar material are durable and safe. Cons: the fence does not protect against noise, dust and external views, has a high cost.

As a rule, forged elements are combined with other materials: brick, stone, porcelain stoneware.

The fence of corrugated board in combination with other materials in recent times the most popular. Before installing it is important to familiarize yourself with the technical characteristics of the corrugated board, which determine its strength and resistance to various influences. For example, the rigidity of the sheet depends on the height of the corrugations and is an important criterion of choice in strong winds. Profile height is determined by the profiled sheeting. Metal is a durable material, but it has the ability to rust. Therefore, the elements for the fence should be made of galvanized sheet, coated with polymer for protection.

To install support pillars, it is better to use concrete for pouring or to build a foundation. Morki with a professional sheet less than with a tree or brick. It has a different color scheme, can be painted, easy to maintain and install. Metal fence performs the function of noise isolation.

To choose a professional sheet for the fence, it is best to use the advice of experts and take into account the reviews of the owners:

- First of all, you should pay attention to the appearance. Non-standard can be seen with the naked eye.

- The front surface, covered with paint or polymer, should not have defects in the form of blisters, cracks, scratches. Otherwise, the material during the operation will quickly become unusable due to corrosion.

- The cut should be smooth, without chipping.

- Corrugation sheets of the same brand necessarily the same. When fixing overlapping profiled waves should fit each other perfectly. Otherwise, it will be necessary to install additional support columns or cross-pieces, which will affect the cost of the entire project.

- Responsible manufacturers cover the front side of the metal profile with a protective film in order to protect them during transportation and installation.

- The presence of guarantees and additional certificates, the provision of services for calculating the cost and quantity of materials is an additional plus to the manufacturer.

For public buildings

For the fence of playgrounds, school facilities, hospitals and other socially significant places use different options. If the deaf fence is necessary, then most often choose iron from a professional flooring. He is able to decorate and protect.

If you have additional cash, you can improve the appearance of the fence by using a picket fence.

It does not look so monumental, but at the same time performs protective functions.

How to calculate?

An important task at the initial stage is to determine the size of the fence itself, the calculation of its length and height. The builder must decide on the type of material used for fencing, the number of pillars and crossbars. All conclusions must comply with the design, design and capabilities of the landscape. Before starting the installation of the fence, it is necessary to calculate the amount of materials, components and decorative parts, for which you may need a calculator.

The following factors affect the total cost:

- The cost of the metal profile. The price level depends on the brand, hardness and quality of the metal.

- Type of coverage.

- The length of the fence.

- The method of installation of supporting pillars, since it is directly related to the cost of purchasing materials, renting a drill or paying for the work of hired workers.

- The number and type of support and intermediate pillars, transverse beams.

- The number of connecting parts, screws, hinges, castle designs.

- The number of decorative caps.

- The number of input structures in the form of gates and wickets. Difficulty factor at their installation depending on design and the mechanism of closing.

- The cost of delivery of concrete, sand, rubble and other necessary materials.

Some manufacturers offer as a bonus to their customers the calculation of the optimal amount of materials and accessories, as well as the cost of the entire project.

Example of calculating the number of sections and their sizes:

- Suppose you need to protect a rectangular area, having dimensions of 20x15 meters. Let the width of the gate for entry be 250 centimeters, and the gate - 150 cm. Then in order to calculate the total length of the fence (DL) it is necessary to subtract the width of the input structures (B and K) from the size of the perimeter of the section (P). DL = P - (B + K), where P = (20 m + 15 m) * 2 = 70 m, B = 2.5 m, K = 1.5 m.So DL = 70 - (2.5 + 1.5) = 66 m.

- As a rule, the length of the profiled sheeting is about 12 meters, which can cause inconvenience during transportation and installation. Therefore, the sheets are cut into smaller pieces. In this case, the number of segments included in one module is determined in advance.

- Assume that the gate and the gate will be located side by side on the side equal to 20 m. Then the length of the fence in this interval will be 20 - (2.5 + 1.5) = 16 m.

It means that there are enough three sections: two five-meter and one in 6 meters.

- The opposite side of the site, respectively, is divided into 4 sections of 5 meters.

- On the other two sides of the rectangular section, the number of modules is calculated similarly to 15 m: 5 m = 3 sections.

- Thus, the total number of sections will be 2 + 4 + 3 +3 = 12 five-meter sections and one six-meter.

An example of the calculation of supporting piles:

- The number of supports is always 1 more than the sections. Formula: K = N + B. In our example, the number of modules is N = 13, which means we need 14 support pillars.

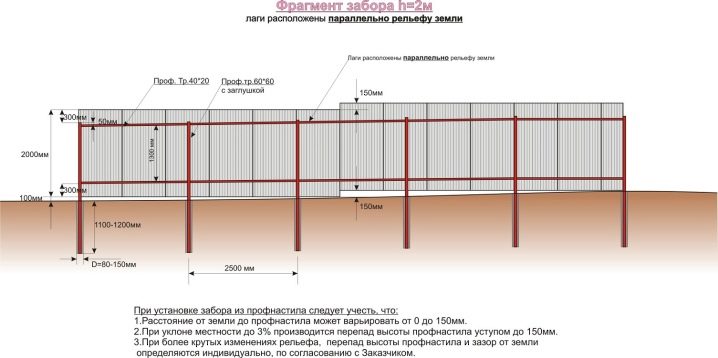

- The length of the supports is also a calculated value. The upper part should be 5-7 centimeters above the professional sheet, the bottom of the pile is, as a rule, longer by 10 cm plus another 80-120 cm for deepening into the ground. In the presence of strip footing 40-50 cm is enough.For example, the height of the fence is planned 2 meters. Then, under all conditions, the length of the column (DS) will be as follows:

When dropping into the ground DS = 200 + 15 + 120 = 335 cm.

When the tape foundation DS = 200 + 15 + 50 = 265 cm.

An example of calculating the number of profiled sheets:

- The height of the fence depends on the length of the profile. In the above example, it is equal to 2 meters, which means that the sheet of a standard size of 12 meters must be divided into 6 parts.

- Suppose that for the construction we chose the C21 brand with a width of 1 m. Then, five professional sheets will be required for the five-meter section, and six meters, respectively, for the six-meter section.

The total number of two-meter segments (KO) can be calculated by the formula:

KO = n1 * 5 + n2 * 6, where n1 is the number of sections with a length of 5 m, n2 is the number of six-meter modules.

Thus, KO = 5 * 5 + 1 * 6 = 66 sections.

As the lag, metal pipes are used, which in length correspond to the dimensions of the modules of the fence. For a two-meter fence should be installed transverse attachment in two tiers. In this regard, the number of lags is easy to calculate, you need to double the number of fencing modules. In the given example there are 13 sections, it means that we need crossbars 26.

For fencing the site, having dimensions of 20x15 m, the following is necessary:

- 14 supporting piles.

- 26 transverse mounts (log).

- 66 sheets of metal profiles 2 meters each.

Training

Preparatory work includes the inspection of the fenced area, its marking.

At this stage, it is important to take into account sanitary standards:

- The distance to residential buildings should be at least three meters.

- The gap to commercial buildings - from 1 m.

- To places of keeping livestock and poultry - not less than 4 meters.

- The distance to the trees, depending on the height of 2-4 m, shrubs - 1 m.

The distance is measured from the wall or base of the house.

Experts note that other elements of buildings, such as a porch, shed or bay window, projecting beyond the plane of the walls for a span of less than half a meter, are not a reference point.

If necessary, at the border of the installation of the fence they clean up and eliminate large interferences.

All around the perimeter of the fenced area, pegs are driven in with the twine stretched on them as an “outline” for intermediate supports.

Support corner posts are also installed during the preparation phase. On them, as a rule, mark the height of the soil.

At the same time, it is recommended to note the location of the gate and gate.

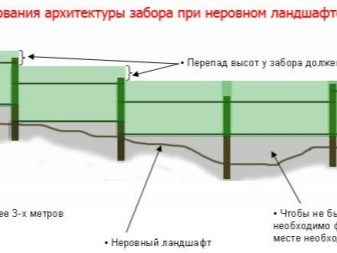

Experts recommend in the presence of large relief differences up to 50 centimeters to align such areas or to provide a stepped structure of the fence.

The next stage is the preparation of recesses for the supports. The pits should have the same depth in order for the metal profile fence to be even. Their width depends on the cross section of the supporting piles, as a rule, their size is small. It’s not very convenient to dig grooves with a spade, it is better to use a drill for this purpose. With its help, pits are made in the ground for supports, the depth of which depends on the planned height of the fence and is not less than 30% of it, according to the recommendations of technical specialists.

Installation

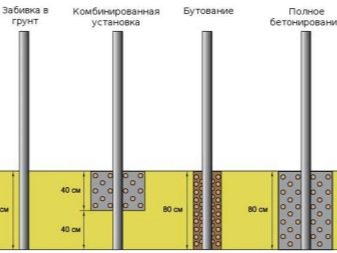

Installation of support pillars can be done in several ways, which are labor-intensive and reliable. The choice of method is sometimes determined by the type of soil or landscape features.

The method of installation without foundation is appropriate in the case of temporary use of the fence or good landscape conditions and soil properties.

Depending on the characteristics of the land on the site and the depth of groundwater, there are several methods for the installation of supports:

- Instilling or hammering with a sledgehammer is the easiest and oldest method. It is used in the case of version with metal pillars of circular cross section. In this case, their diameter should exceed 50 mm, and the size of the recess should be not less than 125 cm. The method is expedient only in the presence of solid land layers.

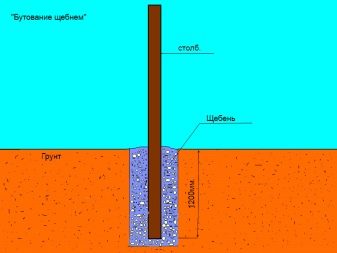

- Zabutovka pillars. Similarly, the first is used for dense soils, but it is more labor intensive. Experts note the reliability and durability of the hammered supports.

The installation process consists in pouring a “cushion” of sand to the bottom of the pit and then falling asleep a column with a mixture of gravel and small stones, as well as their consistent tamping.

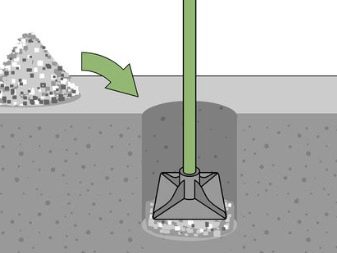

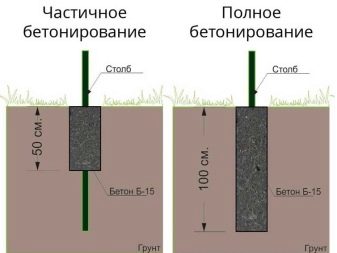

- Partial or complete concreting is one of the most reliable ways to strengthen supporting structures, independent of the characteristics of the soil. Its disadvantage compared with the above methods is a higher cost. Additional rods or plates as reinforcement are welded to the base of the metal pillar. Deepening should be at least 125 centimeters, the gravel-sand layer up to 10 cm is first poured into it.It will protect the supports from freezing. On the "pillow" of gravel set the pillar, after which the pit is filled with concrete. Construction can be continued only after the mortar has completely set.

The algorithm of actions for any method is the same:

- If metal pipes are used as supports, then plugs are welded to their ends first. They provide protection and do not allow moisture and earth to get inside.

- The first install pillars in the corners of the fenced area and near the gate with a wicket. It is important to track their verticality.

- Intermediate supports are mounted in a similar way along the previously designated fence line.

If the fence is planned to be used for a long time or the characteristics of the ground do not allow to install the fence as described above, the fence is mounted on a strip foundation. This method is typical for swampy areas or with soft, flowing soils and allows you to make the fence more stable and durable.

The construction of corrugated board is usually light, therefore, to install it, a depth of 50 cm is sufficient. To do this, a trench with a depth of 60 to 80 centimeters and a width of 20-50 cm is dug along the designated line. mixture.Professionals advise to pour it with water and well rammed, then subsequently the soil will not take moisture from the concrete. Throughout the trench lay out the retaining formwork and waterproofing material. The armature with a section of 10 mm is located inside the trench throughout the volume. It is fastened together by welding. The supports are installed in prepared recesses and welded with reinforcement. The entire foundation is poured with concrete. The formwork must be removed only after complete solidification.

In some cases, the posts are additionally secured with screws using plates.

Profile pipes are used as crossbars. The scheme of their anchorages is horizontal. The optimum diameter is from 20 to 40 mm. Lags are welded to intermediate and supporting structures.

There are three ways of welding:

- Crossbars are butt welded.

- On the sides of the supporting piles.

- Lags are fixed with a U-shaped holder, which is welded to the support in advance.

For fixing, you can use not only welding, but also “crabs” - fastenings in the form of bolted joints.

All metal surfaces of the fence, which were subjected to welding, must be coated with a primer as a corrosion protection.At the same stage it is better to paint the frame, because then it will be more difficult to do it.

It is possible to install metal sheets without welding using self-tapping screws. To do this, drill holes for fasteners in transverse logs; the distance between them should correspond to the profile pitch. Experts advise to attach the profile to the cross beams overlap through the wave. It is important to remember that you need to fix the flooring in the center of the lower wave.

Installation of the gate and the gate begins with the manufacture of a special frame. To eliminate sagging and deformation of the valves, an oblique strip is welded to each one, which connects the upper and lower frames to opposite edges. After fixing the structure on the loops, it is sheathed with a professional flooring. Sometimes with a wicket or with a gate for stiffening they connect the supports with an additional lag.

If the installation work is completed, the fence is decorated with decor. For this purpose, forged or wooden elements are used, plastic caps for screws or other joints, and carved edges on the top of the fence.

At the same stage, painting or drawing a pattern on the surface of a professional sheet is carried out.

The supports must be strictly vertical, which is checked with a building plumb during installation. Otherwise, the whole structure may change its geometric parameters.

If the site has a slope, then when installing the fence on the foundation, it is recommended to provide a multi-level option. It must be borne in mind that the height difference should be the same.

Algorithm of actions:

- A trench is being dug 50 centimeters deep and the length equal to the first level.

- At the end of the first level, it is deepened to the desired depth.

- Each subsequent level is lowered to the middle of the previous one.

When calculating the number of transverse lags, you must consider the height of the fence.

Experts recommend that the first and last beams be positioned 20-30 centimeters from the edge. For example, for a two-meter fence, two crossbars are enough.

When using wooden pillars, it is better to treat them with an antiseptic. In the case of using other materials to strengthen the fence: bricks, tiles, concrete, chain-link mesh, it should also be possible to increase their operational life.

The distance between the supports should not exceed 3 meters to eliminate the effect of "sail". Support piles for the gate choose a larger diameter than for the fence.

The term of operation of the fence from profiled sheets is quite large, but this does not exclude periodic prevention and elimination of defects.

The main reasons for their appearance are the following:

- The appearance of rust in places not covered with anti-corrosion agents or in case of violation of the protective layer. To eliminate the defect, the damaged area is cleaned with emery paper, degreased with alcohol and coated with several layers of primer, and then painted. In the worst case, it may be necessary to replace the entire sheet.

- Destruction of support or intermediate pillars. The elimination depends on the nature of the defect and the type of material from which the supports are made. In the presence of serious damage, it is better to replace the posts.

- Defects of transverse lags. When identifying areas prone to corrosion, they must be treated properly. If the connecting elements are broken, they need to be changed.

- If the fence was built with violation of technology, then the results will not take long to wait. We'll have to fix them as they are revealed.

- After natural disasters may happen soil erosion under the fence.As a temporary measure, it is sufficient to reinforce the fence with temporary supports, but in the future it is recommended to carry out a major overhaul.

- Two times a year, in spring and autumn, the decking on the fence should be washed with soapy water from the accumulated dirt.

- Household chemicals can be used for cleaning, but aggressive solvents, such as acetone, are not recommended.

Design options

To protect the supporting and intermediate pillars from moisture and corrosive phenomena, special bushings are attached to them from above. At the same time they can perform decorative functions. Manufacturers offer a wide variety of types of such decors.

They are beautiful, made of modern materials and perfectly cope with their protective function.

Designers use forged or wooden elements that give airiness to a massive structure. The carved sides on the top of the fence will create an original image.

The combination of different materials and textures also allow you to bring notes of individuality and exclusivity in the appearance of the site.

A fence made of picket fence is a good option for durability and strength. By installing narrow plates, designers create stylish options.

You can make an original fence, using sheets of corrugated sheet and tin left over from other construction, so you will get a kind of metal patchwork.

Professional sheet fences can be decorated with wrought iron elements.

Sections of metal profiles can be located both vertically and horizontally, which is also a design element.

In addition to the game with the shape and arrangement of sections, you can consider options with different types of support pillars: metal, brick, stone, concrete.

Manufacturers offer a variety of models of flooring with imitation of various kinds of material, which allows at low cost to decorate the fence, for example, with masonry or wood.

To learn how to make a fence from the flooring with your own hands, see the next video.