Metal fence posts: selection rules and corrosion protection methods

There are many options for building fences, and their differences depend on the functions for which they are intended. In accordance with the functions chosen material of the future fencing.

Functions and material of the fence

The fence is intended for simple and specialized fencing of the territory: privately owned land plots, parking places, recreation areas, construction and specially protected objects, animal pens. Also, fences are often an element of decor in landscape design or make up a single composition with architectural solutions.

Such a variety of functionality makes it possible to use different materials for their construction: the usual wooden or metal picket fence, decorative picket fence in the style of “Ranch”, colored profiled sheets, mesh chain-link, welded, sectional, forged,asbestos cement and concrete spans. Like any construction, the fence involves the creation of some kind of foundation on which the material is mounted. For the fence such a foundation are the pillars.

Pillar material

Regardless of the choice of material of the fence itself, the pillars can be made of:

- wood;

- metal;

- concrete;

- bricks;

- asbestos cement pipes.

Metal advantage

A universal material for the manufacture of pillars for the fence are metal products, because in the vast majority of cases, the installation of the fence using welding.

The special quality of metal pillars is their durability. Whatever way to process a wooden bar, it will rot much faster than the metal will collapse.

The process of metal corrosion on average occurs at 0.15 - 0.2 mm per year. It depends on the weather and weather conditions, the composition of the metal and the quality of its processing. A positive advantage of metal pillars is reliability and durability. Asbestos concrete pipes are not subject to corrosion and do not require additional care for themselves, but they are fragile and do not withstand rough mechanical loads.

The pillars, made of metal, in comparison with reinforced concrete, are easily repaired and installed, dismantled and can be used again.

Corrosion

Metal corrosion is a natural phenomenon that cannot be completely prevented, but this destructive process can be significantly slowed down. The oxidation process takes place with the participation of oxygen and aqueous solutions containing acid, alkali or salt.

In nature, iron is not found in its pure form, but is contained in iron ore. Mankind invented the production of steel and invented ways to save it. The plants use methods for phosphating steel, by immersing it in various solutions, and also by electrochemical processing. This coating has the character of priming and requires further painting. Steel is coated with other metals. From cheaper - aluminum and zinc.

There are silicate coatings - this is a different type of enamel. Enamel is fragile and not quite suitable for the fence. Cement has approximately the same temperature of expansion with steel and serves as an insulator from aggressive media. A good insulation is a polymer film applied in several layers in the factory.

Treatment

The durability of the metal depends on the steel grade.More precisely, there is alloyed steel with different additives. But for a simple fence - it is expensive. Usually use factory metal, or make pillars with their own hands from what you can get. For temporary fences, poles welded from pieces of iron will be suitable or previously used, but still strong pipes from the water supply.

The internal cavity of the pipe is difficult to clean, and the outside is removed by rust with an iron brush, treated with a grinder or grinder. If necessary, degrease and apply a primer for the metal, for example, GF-021. After drying the primer, the pipe is painted in two layers.

To paint the metal, suitable most common oil paint PF-115. For the lazy, there is a three-in-one paint. It neutralizes rust, primes and creates a protective surface.

But in practice it is better not to do without preliminary machining, it is necessary to at least clean the metal with emery paper.

The best solution for the selection of new fence pillars is a combined version of the metal coated with zinc and polymer film. Factory metal produces paint, observing all the technologies. It is best to purchase the posts already ready for installation, since this will significantly save time and labor. However, this option can not be called financially economical.

In practice, most often iron pillars independently ground and painted with oil paint or bituminous varnish.

Special spray paint cans that are convenient to use during welding work are present. Powder coating will be more expensive and technically more difficult. The thinner the coating layer, the more durable the protection. Therefore, make several layers of spray or carefully rubbed with a brush, avoiding air bubbles that provoke an oxide reaction.

Soil is a more aggressive environment than air. Therefore, the part of the metal in the ground is insulated with concrete or bitumen mastic. Rolled insulators for these purposes are not suitable. Dross arising during welding stimulates metal corrosion. It is necessary to remove the grinder.

Forms of metal pillars

The fence posts can have a wide variety of configurations, from simple to designer:

- round;

- square;

- rectangular;

- screw;

- homemade.

Round pipes are the easiest to buy and cheaper. The choice of their diameter depends on the design of the fence, and most often use the size from 57 mm to 108 mm, in exclusive versions the diameter increases to 159 mm. Thickness is selected based on the characteristics of the material filled spans: from 1.5 mm to 4 mm. The thicker, the longer the life.

A good option with drill pipes, whose wall thickness is 5 mm.

The cross logs are attached directly to the pipes by welding, or guides for fasteners are welded to the pipes. Guides can be made in advance by welding them to the clamp, which is put on the pipe and tightened with a bolt. In this case of installation, an insulating gasket made of cotton material or a special plastic lining that fits the diameter of the pipe is placed under the clamp.

Shaped pillars are square or rectangular. This form allows the fastener lag not only by welding, but also with the use of bolts or rivets. It is more convenient to work with them if the guide lags made of wood or the fence is built in the style of "Ranch".

The screw posts are a pipe with a drill welded on its end.This option is used for quick installation of the fence, because there is no need to dig a pre hole for the post.

Self-made pillars are made from used material that is available (unowned), or from that which can be obtained. Suitable, for example, iron corners.

Ground Effect and Installation

The choice of metal pillars also depends on the method of installation, and it, in turn, depends on the condition of the soil. For a light fence, it is enough just to drive a pillar into the ground if it is dense (gray, clay, sand). Two people are involved in the work - one drives in and the other holds the pole, checking it on the level in two vertical planes.

In order not to damage the top of the pillar with blows, they put some improvised iron lid on it.

The most dangerous, wear-resistant area at the pillar is its exit from the ground. Here there are two environments with different temperatures and mechanical loads. For this reason, there are microcracks, contributing to the destruction of the structure. The quality of the isolation of this place needs more attention:

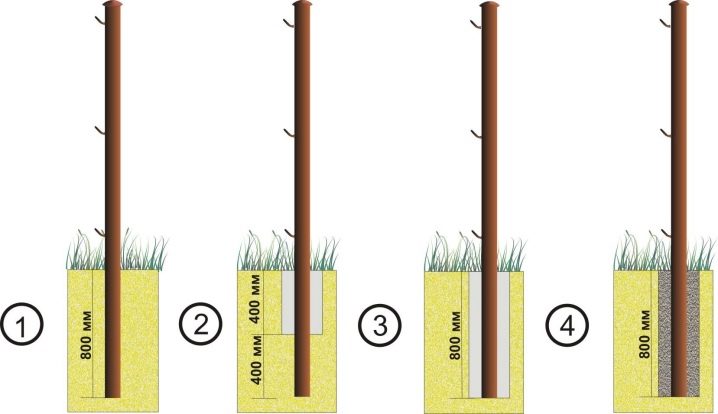

- When heaving the soil using the method of botovaniya.A small sand cushion is poured into the drilled hole with the help of a hand drill and tamped with it. Insert the column vertically and in small portions fill the hole with rubble with sand. Each portion tamped, pouring water. The last 20 cm post is poured with concrete.

- There is also a more stationary method of patching. The posts should have a welded heel, or a through hole 15-20 cm in length is cut into the bottom into which the concrete is poured. It is necessary for better fixation of the post.

- In heaving soil, the heel of the column can be filled with concrete by 30-40 cm, and the remaining distance to the surface can be covered with a plastic pipe used for conducting sewage. A plastic pipe of a large diameter is put on a metal pipe, leaving 5-10 cm above the ground. The cavity between the pipes is poured with cement, and from the outside they fall asleep, ramming the excavated earth.

- If groundwater is located close to the surface, or the land is marshy, do not do without a strip foundation for the fence.

The length of the pillars extending into the ground must be at least one third of the total length of the pillar. The depth of concreting is selected to the depth of soil freezing.

From the video below you will learn how to properly install the fence post.