Pillars for the fence: the subtleties of choice

Homeowners, equipping plots, enclose them with fences. Fences perform the function of protection against penetration into private territory. In addition, fences complement the design intent.

A dwelling house, outbuildings, a garden, a vegetable garden, a recreation area - all this becomes cozy, separated from the outside world when a clear boundary is drawn. Such a border is the fence. The fence must be reliable. And for this he needs a good foundation - strong durable pillars.

What are we for?

Most fences can be divided by purpose into:

- temporary;

- decorative, increasing the attractiveness of individual zones, gardens or the entire estate;

- protect pets from predators;

- ensuring the safety of individuals, preventing children from leaving the site;

- border, serving to determine the boundaries between neighboring land plots;

- snow protection, reducing the penetration of snow masses on the local area.

Depending on the purpose of the fence and the condition of the soils in the areas, the constituent parts of the structures are selected, including supports.

It is important to initially make the right choice. After all, the fence posts are the same foundation as the foundation for the house.

Significant factors include:

- type of fence material;

- fence height;

- span length;

- the condition of the land on which the fence is being built;

- climatic conditions of the area.

The condition of the pillars depends on the durability of the structure.. With insufficient strength of the supports, the fence may squint or even collapse after the first winter. With excessive strength increases the cost of construction.

Materials production: the pros and cons

Fence posts are made of various materials. The ideal option for all occasions, perhaps, does not exist. In each case, a specific material is used, each option has both advantages and disadvantages.

By the type of material rack fence are:

- wooden;

- metal;

- reinforced concrete;

- asbestos-cement;

- plastic.

Tree

Wooden posts set for wooden fences. Previously, wood was the only material from which fences were erected. Nowadays, wooden pillars are less common.

Dried wood goes to fence wooden poles. Support should not have chips, deep cracks and other damage.

Wooden poles - not a cheap pleasure. The service life of the supports, provided they are thoroughly protected from rotting and insects, reaches 15–20 years.. Durability provide antiseptics and waterproofing.

Pillars, especially the part located in the ground, are impregnated with waste oil or bitumen, wrapped with roofing felt. Every year the pillars need to be treated, to restore the coating damaged by atmospheric precipitation.

The diameter of the support depends on the height of the fence itself. If the height of the blade is more than one and a half meters, a trunk with a diameter of at least 150 mm. The best supports are obtained from solid wood after removing the bark from it.

Despite the fact that it is more convenient to work with a bar, the choice is to stop on the round timber. The fact is that all the faces of the treated timber absorb perfectly moisture.To protect it from rotting is much more difficult than a bare trunk.

The positive characteristics of wooden poles include:

- environmental friendliness;

- esthetics;

- easy installation;

- availability of material.

The disadvantages of wooden parts of the fence are:

- susceptibility to moisture;

- short (compared with other types of supports) service life;

- inability to install any type of fencing.

Metal

Metal (iron) pillars are most often used for organizing fences. The cost of metal is low, and the service life is great. Metal poles require additional processing. Without special coating, ferrous metal starts to rust very quickly..

Steel supports are pipes. In a section, they may have a circle, square or rectangle. The wall thickness of the profile pipe used depends on the applied load. As a rule, it is never thinner than 3 mm.

The length of the supports is selected by the height of the canvas. Installation of pipes is not a big deal. To facilitate excavation at the lower end of the pillars set screw nozzles. Steel posts are ideal for installation of fences of corrugated and mesh fencing.

Among metal supports a special place is occupied by tubing. Tubing gets to the population after their service life on gas and oil pipelines. Even those who have been in use, they are not inferior in strength to the new water and gas pipelines. Thick walls are practically not subject to corrosion, can withstand very large loads. Even heavy wrought iron fence structures can be attached to them.

Metal Advantages:

- ease of installation;

- low cost;

- durability;

- ease of care;

- high strength.

The main disadvantage of steel pillars is their susceptibility to corrosion. In addition, for the stability of the support must be strengthened. Consequently, without additional work (and costs), the pipes will not provide stability to the fence.

Concrete

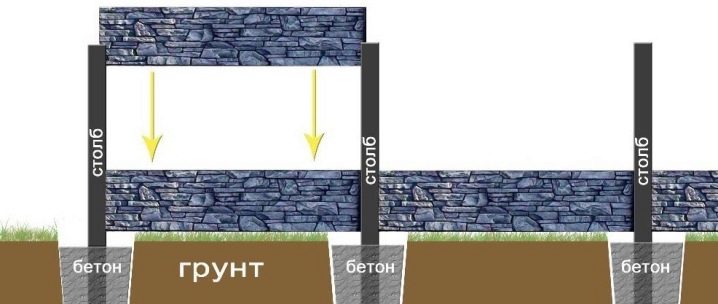

Heavy posts for heavy fences are made of reinforced concrete. Often, concrete products are cast directly on the spot. For supports weld or bind reinforcement, formwork, which is poured concrete. There is another way when using stacked blocks. Block poles should be laid out with a perfect vertical. Any deviations are fraught with distortions and destruction of structures.

The advantages of concrete pillars are:

- high strength;

- long service life. Similar support serve much longer than metal and wooden;

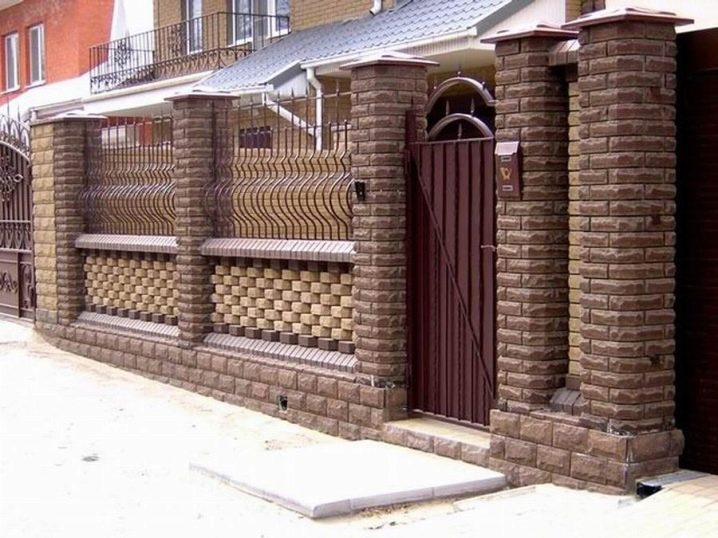

- wide possibilities of decoration. Using the PIX panel, you can "turn" ugly reinforced concrete into neat brick columns;

- ease of processing during installation.

The disadvantages of concrete supports are:

- the need for basement equipment. Sometimes the depth of the foundation reaches one and a half meters, which forces the builders to attract special equipment for trenching, pumping out water and other related work;

- the difficulty of casting supports on site;

- the inability to install ready-made concrete products without mechanized lifting devices.

Asbestos cement

Of asbestos cement pipes, supports for fences are made quite rarely. Such posts are suitable for stretching metal nets and light wooden canvases. As a rule, construction scraps and residues are used. Short tubes can be lengthened. For this, plastic or asbestos-cement couplings are used.

The material has advantages over metal and wood.It does not rot, does not require additional protection, does not corrode. With proper installation, the supports will last for many years.

Material Disadvantages:

- gray color is not too aesthetic;

- high fragility of pipes. If dropped, the pipe may crack;

- low frost resistance. Under the influence of frozen water is the destruction of the product.

Installation Features

For installation of fence posts you will need tools and materials:

- shovel;

- yamobur;

- building level;

- durable twine;

- sand;

- rubble;

- cement.

Depending on the material chosen, other materials, tools and fixtures can be used. First, the markings on the ground. Along the perimeter of the fenced area, it is necessary to hammer in the pegs at the site of installation of future pillars. Markup should be strictly in a straight line.. On the pegs pull the twine.

Special attention is paid to the turning points. In the corner points of the support should be the most durable. They account for the largest load.

The first support is installed at the corner point. Next - in the second corner point opposite the first. The supports should be leveled using hydro level.The strings stretched between the two end marks on the top and bottom will serve as a guide for the installation of intermediate supports. The distance between adjacent pillars should not exceed three meters. For heavy intake structures, the maximum distance between the nearest supports is reduced to 2.5 meters.

If construction is carried out on terrain with a large slope, it is recommended to install a stepped fence. In this case, additional posts may be required. Supports with the greatest strength set for gates and gates.

How to install wooden poles?

Wooden poles set "upside down", that is, the bottom is the upper most thin part of the trunk. So the least absorption of moisture is provided. A round wooden pole must be thoroughly treated with an antiseptic and allowed to dry..

At the planned points, manually or with the help of drill pits to a depth depending on the state of the soil. Usually, when the length of the column does not exceed 1.2 m, the hole is dug 0.5 m. With a greater length, the deepening is performed at 0.9 m. On heaving soils, it is recommended to bury the supports to a depth exceeding the freezing line.It is important that all the pillars are buried to the same depth.

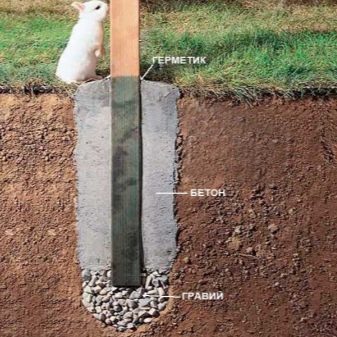

To preserve wood longer, prevent its contact with the ground, therefore sand or crushed stone is poured at the bottom of the pit.. The column is set vertically, and they begin to fill up the free space around it with rubble. Not reaching 0.15 m to the ground surface bookmark stop. Poured rubble, instead of which you can use broken red brick, ram. This periodically checks the verticality.

The remaining 15 cm is poured with cement mortar with rubble. Fill in the form of a cone in order to divert from the post rain and melt water.

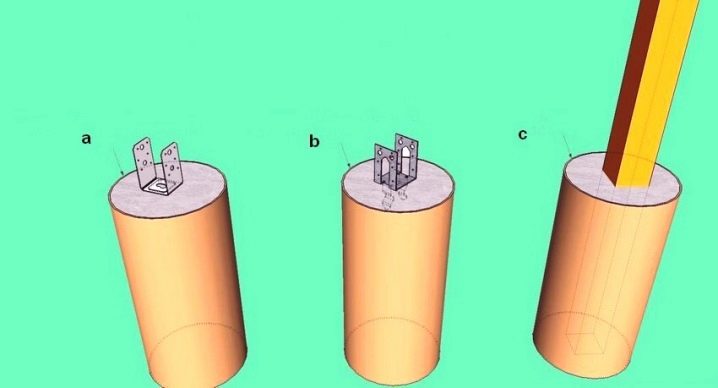

Craftsmen fix a wooden pole with a metal pipe with a wall thickness of at least three millimeters. The diameter of the metal guide choose the dimensions of the support. The pipe is buried in the ground so that the surface is about 15 cm. The barrel is inserted into the pipe. It turns out a reliable design.

Another way to fasten wooden supports is to use metal crutches or concrete spurs. These parts prevent the contact of wood with the ground, which prolongs its service life.

To minimize the penetration of moisture into the trunk in two ways. Either the upper part is cut off at an angle, and the water flows down without stopping on the plane, or a cap is installed above the support. In addition, periodically you need to paint a support or handle special means that prevent rotting.

How to install metal poles?

The steel support must have a fastener for the longitudinal elements of the fence. On self-made supports you need to mark up, welding two plates with holes. It should be noted that the ground will be at least 1.2 m.

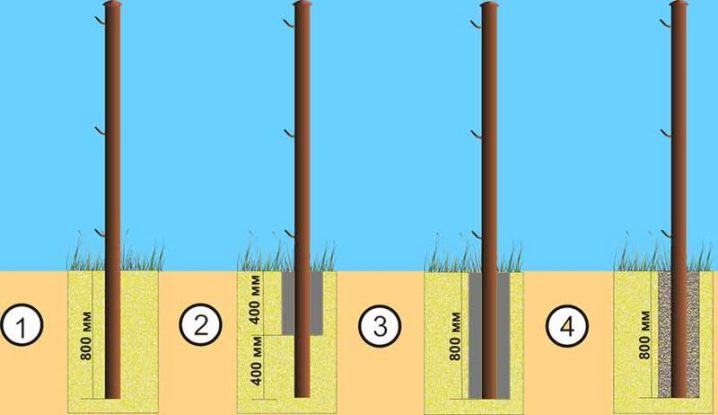

The easiest way to install metal supports is to drive into the ground. In order to hammer the pipe, you need a sledgehammer. Blows directly on the pipe can not be applied. Required laying, for example, of wood. The method can be applied on solid soils.

On loose soils, driving of supports even at 1.5 m may be ineffective. The pipe will not hold.

Zabutovka - Another way to install metal poles. For its implementation requires additional materials: sand, gravel or gravel.

At the marked points of the Buryat holes with a diameter of about 200 mm. Recommended burial size - one and a half meters.. Sand is poured into the well that is formed. The post is installed vertically, buttering is performed with the available material: gravel or rubble. It is allowed to use broken red brick. A seal is formed around the support in several layers. A part of the stones is filled up, compacted, and shed with water. And so, until the fossa is full. A layer of sand is poured on top.

The third method involves partial concreting.. It is not applicable only on heaving soils. Under the supports dig or drill holes at the selected depth. The bottom is covered with sand and gravel. The post is installed vertically and fixed with props so that its position does not change under the influence of heavy concrete mix.

In the concrete mixer prepare a liquid composition of Portland cement and sifted sand in the proportion of 1/3. It is not recommended to fill the pillars in winter. After concreting the supports, a period of 10 to 14 days should pass before the installation of the fence sheets. This time is sufficient for complete solidification of the solution.

How to install concrete pillars?

Concrete pillars are required for massive fence.In wetlands, a columnar foundation is the best method. Concrete poles can be made independently at the construction site or buy finished products. In the first case, it will take much more time and physical effort. Finished products will cost more.

In addition, for their transportation and installation will require special equipment. In any case, concrete pillars should be deepened into the ground by at least 1.2 - 1.5 m.

To fill concrete pillars in place, it will be necessary to build a steel rod frame. The metal structure is placed in recesses at the bottom of which a sand cushion is poured. The form of the pillar is constructed formwork. In the context, it can be either round, square or rectangular.

Concrete is prepared in a concrete mixer, maintaining the proportions of sand, cement, filler and plasticizer. Fill in portions. After the next portion of the solution is in the formwork, it must be pierced with a steel bar.. This operation will allow the mixture to be better distributed throughout the volume. This minimizes the formation of voids and cavities.

The greatest strength is achieved when the pillars are poured together with the foundation, forming a single whole..

Possible installation of precast concrete pillar. Block supports have an aesthetic appearance, do not require additional processing. Installation is easy, as the weight of each element is small. The blocks are equipped with special grooves that provide reliable grip. Stacked supports are installed either on shallow-deeper foundations or on an individual concrete base.

How to install asbestos cement poles?

Asbestos cement poles are standard pipes. Pipe sizes are as follows:

- diameter 120 mm;

- wall thickness 9 mm;

- the length depends on the type of fence.

Under the supports drilled holes with a diameter corresponding to the pipe or slightly larger. At the bottom is laid drainage of sand and gravel. The support is installed strictly vertically. The depth is at least 80 cm.

It is allowed to install pipes directly into the ground, as the asbestos cement in the soil does not collapse for a long time. For greater stability, a metal pin is thrust into the ground, and a pipe is placed on it. Inside the pipe to a height equal to the depth of the concrete mix is poured.After it hardens, sand is poured into the pipe to the top. On top of the support is to install the cover. The cap protects the support from the ingress of water into it, which, when freezing, can damage the support.

Decoration and decor

The type of intake supports depends largely on their location. On the front side of the manor, the pillars are characterized not only by their special strength, but also by their attractive appearance. Where the fence is not visible, usually, decorative supports are not installed.

Finishing fences and pillars speaks of the taste and viability of the owners of buildings. Beautiful supports are made of different materials: wood, metal, natural or artificial stone, concrete, bricks. The shape of the diameter of supports can be a circle, a rectangle, a semicircle, a square, a hexagon. The support may be hollow in the case of a metallic version or solid when manufactured from wood, brick or concrete.

Wood is best treated. The pillars can be given any shape, decorated with carvings or linings, varnished or painted. You can rarely meet interesting wooden poles. The fact is that cheap wood will not last long.And expensive is available only to very wealthy citizens.

The simplest design of metal pipes, which serve as bases for fences, consists in painting, installing decorative caps or hanging lighting devices. Steel pillars will be decorated with original caps made in the form of balls or domes.

Forged fence canvases are often attached to metal supports. However, the best view of the fence becomes not with steel pipes, but with more solid supports. In such cases, imitation of the brickwork around the metal base is performed.

A protective cap can become an adornment of a brick pillar. But more often, decoration is formed during construction. To do this, choose a brick of not one, but several colors. Two is enough to lay out the original columns. And if you make a curly masonry, then the supports will become a real decoration of the entire intake ensemble.

Special treatment required concrete pillars. Without decoration, gray supports make melancholy. Concrete racks are externally converted to stone or brick, if their facing is made of plastic panels.Lightweight plastic imitates natural stone, red brick and other building materials. It is applied to the outer surfaces of the intake supports.

Decorative panels:

- ennoble the type of buildings;

- not afraid of temperature changes;

- successfully withstand precipitation;

- are inexpensive.

Tips for choosing

When choosing supports for the fence should focus on:

- web material;

- mass of the fence;

- combination of materials;

- aesthetic component;

- financial opportunities.

Comparing all of the above, you will certainly make the right choice. Then around your house there will be a beautiful practical fence with reliable original pillars.

How to choose the posts for the fence, see the following video.