How to choose a pipe for the fence?

With the help of a fence, you can protect the territory, hide from outside views, define the boundaries of your possessions, protect yourself from illegal entry into the territory. At the heart of any fence are pipes that need to be able to choose the right - that is what we will learn today.

Types of pipes

For the fence can be selected different types of pipes. Not all of them are equally good, but each species has certain differences. First of all, the base for the fence can be made of different materials. This distinctive factor will be used for classification.

Metal props - reliable, durable, easy to work. Their cost may seem high, but such fences will last more than 10 years, and in the case of stainless steel, they will last 50 years. It is not in vain that the profiled metal pipe got the first place in the list - it leads in popularity.

Wood do not have high durability, such supports are mostly chosen for small or temporary fences, for example, for front gardens, flower beds. But the wooden base - light and affordable, natural and beautiful, can be easily combined with other materials.

Choice of asbestos cement supports justified by their durability, resistance to rotting and moisture. The difficulty lies in the installation of fasteners, the further installation of the lag and the installation of the material at the place of spans.

Yet asbestos supports are often chosen for the construction of the fence.

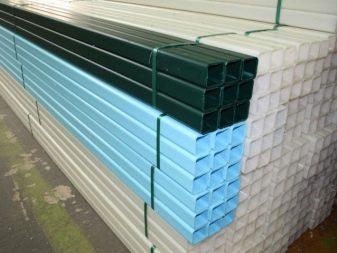

Block posts - This is a new type of support, which is rapidly replacing all the varieties that existed before it. Block poles can be created not only from plastic, but also from concrete. Manufacturers are rapidly expanding the range of such products so that the buyer can choose the desired color, texture, shape and material, which served as an example for the decorative form. Externally, it is extremely difficult to distinguish natural material from imitation, as far as it is plausible blocks convey the characteristics of the original version. Inside the blocks are hollow, which allows you to make communication inside the pillars without any problems.

PVC, or simply plastic - material that has firmly entered the life of modern man. It is found in almost all spheres of life. From polypropylene pipes are water supply systems, drainage, heating. According to some performance characteristics plastic pipes are superior to metal products from the profile. It is logical that plastic poles are also used for the base of the fence. The main disadvantage is the limited choice of material for the fence itself.

It should not be too heavy, otherwise the pipes will not withstand such a load. For example, heavy sectional doors require the installation of stronger pillars.

- Concrete pillars can be eternal, if you strictly comply with the technology and use of hydrophobic additives. This option is expensive and complex, but the most durable of all the existing varieties. The manufacture of such pillars is usually done independently, since the purchase of finished products is impractical because of the high cost.

- Brick supports They look beautiful and expensive, but are difficult to install and have a high weight. Brick necessarily laid out on the foundation.A metal pipe is installed inside the future pillar, around which brickwork is located.

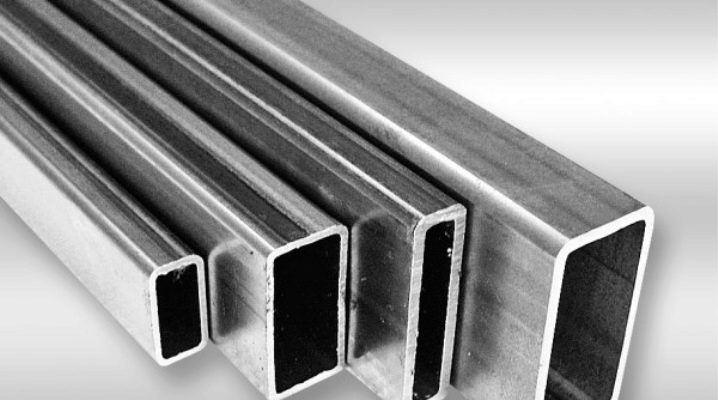

Types of metal pipes

Special attention deserves a metal base for the fence. Such pipes can be of different thickness, shape, diameter, length. Now we are interested in the form, according to this criterion there are two large groups.

- Round tube best suited for mesh designs. Metal hooks are welded to the pipes. They serve as a mount for the material that will fill the span.

- From the profile construction are created square and rectangular options. Rectangular and brick base is chosen for mounting profiled sheet and metal picket fence. Mortgage elements may be present in such fences. In this case, the installation of the intake web will be significantly simplified. Profile pipes with protective elements at the ends are less susceptible to moisture penetration and its destructive effect.

Fencing constructions

Whatever the choice of pipes for the fence, there are not so many types of fencing designs. The choice of the basis for the fence is largely determined by the type of future construction.

Fences from a professional flooring - affordable, lightweight and durable, have a good appearance, blend perfectly with other materials and easily fit into many landscapes. Perfect performance in a unique combination. The basis for this design will be shaped tubes.

Wooden fences - light and strong, but short-lived. But they are inexpensive, and installed easily. In addition, wood is a natural material that does not harm the environment and man. For such a fence, you can install any support - natural material will look harmoniously with concrete, iron, brick, and even asbestos or plastic.

- Rabitz With equal ease attached to any support. Its low weight allows you not to choose the pillars with a large margin of safety. Such material is produced from plastic and steel. From the first option, you can only create temporary fences, since the plastic mesh does not differ in particular strength. The main disadvantages of this design is the visibility of the territory and easy access for unauthorized persons.

These drawbacks are removed by using an opaque material with the mesh.

Forged construction - This is an expensive fence, which is rare in which it is cost-effective. But it looks beautiful and rich, especially in combination with brick or metal. Forged fence does not close the area from prying eyes. Often you can see the combination of forged elements with opaque polycarbonate sheets.

Criterias of choice

To select the right material for the base of the fence, you must follow some instructions and rules. First of all, you need to decide on the dimensions. As an example, metal structures are considered, moreover, it is precisely with their choice that the issue with dimensions is the most relevant.

- Wall thickness determines the reliability and durability of pipes. Thickness starts from 1 mm and reaches 12 mm. Materials with a thickness of 2 to 5 mm are suitable for the fence.

- Diameter of section responsible for the sustainability indicator. This does not mean that you need to choose the thickest pipe. With the increase in diameter, the weight also increases, therefore, there is a probability of a skew of the structure under its weight, and the installation becomes much more complicated.For most cases, a section of 100x100 mm is the maximum, beyond which it is not worth going out.

It is better to choose round supports with a diameter of about 57 mm, square - 60x60 mm, and rectangular - 40x60 mm.

- Length - This is the third parameter that affects the choice of pillars. Metal pipes are produced in three versions: 1.5, 3 and 6 m. It is easy to make the desired length - the excess is trimmed, the missing is welded. Any pipe will be recessed into the ground at least 0.5 meters. This figure can be 0.7 meters, reach a meter and even rise even higher. So do not rush to cut the pipe - first you need to decide on the depth of penetration.

- steel grade significantly affects the durability of the structure, frequency and complexity of pipe care. An expensive option are galvanized pipes. They do not form rust, and the life is measured in decades. Galvanized base for the fence does not require special care and treatment during operation, but for such benefits will have to pay a lot. A more affordable option is black steel, but it requires annual processing to protect against corrosion.

Quantity calculation

You can not buy the material without a preliminary calculation of the number of pipes and material to fill the spans. A simple calculation will save money, because no extra material will be bought, and you will not have to travel a second time to buy the missing items.

- First you need to calculate the distance at which the columns will be located from each other. The average is a mark of 3 meters. With such a distance, the rigidity and compliance indicators of the wind load are at the optimum level. If it is planned to hang heavy material on poles, the distance will have to be reduced to 2 meters, or you can build intermediate supports on which a part of the weight of the braces will lie.

- Knowing the perimeter of the fenced area and the distance between the pillars, you can easily calculate the required number of the latter. It is necessary to add 2 or 3 to the received number - these additional supports are necessary for hanging the gate and the gate.

Installation Recommendations

There are many types of fence posts, their installation in each case is performed under different scenarios. Describe each case is not worth it, but you need to tell about the main ones.Any rack, regardless of material, must stand firmly, ensuring the reliability and durability of the structure.

Let's start with brick pillars, which are installed according to the following scheme.

Foundation - a prerequisite for heavy structures. Stone, brick and concrete fences are necessarily located on the foundation, which is poured not only under the supports, but also along the entire length of the fence. What type of foundation to choose is a question that depends on the characteristics of the soil and the groundwater level. Often used concrete tape with a slight deepening. In the locations of the pillars, an iron pipe is laid or a framework made of reinforcement is mounted.

- On the foundation, you can lay the base of a maximum of three rows of bricks. This solution will improve the external characteristics of the fence. It is not necessary to make a plinth, but if the pillars are brick, then the plinth will look harmonious and will give the construction of completeness.

- A brick is laid out around the pipes or reinforcement cage. The necessary communications are laid inside the pole. During the laying it is necessary to immediately install the embedded elements, which will allow in the future to fix the bases, the gate and the wicket to the bases.

- The top of the pillar must be closed with a protective and decorative element, most often it is a cap. Thus, water will not accumulate inside the column, otherwise the lifetime of the structure will be significantly reduced.

If pipes are chosen as a support, the installation will look like this.

- The territory is cleared and marked up. At the place of each support pegs are driven into the ground, which will allow you to visually see the future picture.

- To install the post drilled hole in the ground. This stage applies to all types of pipes. The width of the hole should be 15 cm larger than the diameter of the pipe, and 50 cm longer than the depth by 50 cm. Rubble is laid on the bottom of the hole, a pipe is installed on top. Free space is filled with stones. Indentations are best done with a drill, but you can also get along with ordinary shovels in case of emergency.

- In the holes are placed poles, first extreme on one side. Between the posts, a rope is stretched, along which the height of the intermediate pipes is adjusted.

- In order for the concrete to fill all the space as much as possible and no voids left, the pipe needs to be shaken.We expose the pillar to the level, propped up with bars for fixing and leave until the concrete completely solidifies.

- Three days after pouring the concrete, you can install horizontal lintels.

You can do without drilling holes and pouring concrete, if you choose screw piles as a support for the fence. This option is well rescued when working on heaving soil. Construction assembly time is reduced, quality and reliability are not reduced, sophisticated technology is not required

To learn how to make concrete pillars for the fence with your own hands, see below.