Metal fences: types and features of installation

The fence is an important detail in the design of the local area. These designs protect the site from prying eyes and uninvited guests. Do not underestimate the decorative properties of modern fences made from various materials. Today we will take a closer look at reliable and durable metal products, and also consider in detail their features and varieties.

Features of the device

Metal is not in vain is a popular and sought after material. It is used in many industries, because, as a rule, it is characterized by wear resistance and long service life. Fences made from such raw materials serve their masters faithfully for many years without causing any special troubles and problems.

In addition, their installation is not difficult, so the house master can easily cope with it without the help of specialists.

Metal is fairly light in processing. With it, you can build attractive and durable fences of any shapes and configurations. Distinctive characteristics of the device of such structures are:

- Durability and Reliability. High-quality metal fence is able to serve its owners for many years. Of course, correct material handling and proper installation of the entire structure play an important role here.

- Democratic value. Metal is not too expensive material. For example, it will be much more expensive to put a concrete fence than a metal one.

- Fireproof. The fence, made of metal, is non-flammable. Also, it does not support burning.

- Practicality. Such structures are not branded and prone to the appearance of pollution. If those still appear on the surface of the fence, then get rid of them is not difficult.

- Large assortment of colors. Today in the shops of building and finishing materials you can find many types of paints intended for finishing metal. Thanks to such a rich assortment, it will be possible to repaint the structure inany color you like.

- Wear resistance. Metal is not afraid of dampness, moisture and aggressive sunlight. These qualities can not boast of popular designs of wood.

- Ease of installation. Simplicity of installation is one more distinctive characteristic of similar devices. To cope with concrete or brick options will be much more difficult.

Metal fences differ from each other by the type of material from which they are produced. For example, the construction of a chain-link mesh is recognized as the most simple and inexpensive. Their height can be different, but most often there are options with an indicator of 1.5 m. With such structures, you can conveniently divide the site into several functional zones, as well as protect it from prying eyes.

Kinds

There are several varieties of metal fences. They have different properties and performance characteristics, which should be reviewed before proceeding to the selection and installation of a particular design.

Out of chain-link

As mentioned above, such prefabricated structures are considered among the most accessible and uncomplicated. They enjoy an enviable popularity in the arrangement of garden farms and large gardens.

The similar grid from a special steel wire is made.The manufacturing process can be both manual and automatic (on machines).

So that the net does not become rusty, it is pre-coated with zinc, high-quality coloring mixture or special polymer compounds.

Sometimes the mesh netting is made of stainless steel. The strength of this design depends on the size of the cells. The smaller the mesh in the iron fence, the more reliable the fence. This component is produced in rolls and has a height of 1.5 m. As for the length, it is usually 10 m. Many companies offer a custom-made mesh service.

The grid the chain-link differs in ease and unobtrusive design. It is suitable for neat and well-groomed areas that are not ashamed to put on display. Also worth noting is the durability of such structures and their simple installation.

Many owners use a chain-link not only for fencing of the local area, but also for reliable support of climbing plants.

From welded mesh

Such fences are also in great demand and are most often found in the design of garden and suburban areas. These sectional designs are made of steel wire, as are the chain-link models. The edges of these parts are welded directly to a robust tube frame.

Wire in such structures can be located both at right angles and diagonally. These options are inexpensive and are installed very easily. It does not take a lot of time and effort. Also, such structures are not afraid of harsh weather conditions and do not cast a shadow on the garden or garden beds.

The main disadvantage of such lattice structures is that they leave the site completely open, as they are cross-cutting (as well as the chain-link).

Many consumers refuse to buy welded mesh, because it looks too simple and unpresentable, but then, of course, everything is strictly individual and depends on the wishes of the owners.

However, this fence has its drawbacks:

- If you do not want to put your site on public display, then you should abandon the grid, because it is transparent and you can see everything through it.

- The integrity of this steel-grill design can be easily broken with ordinary wire cutters.

- Through such a fence rodents and other parasites can easily get through.

From bar

Bar fences also have a low cost. They look more aesthetic than simple welded options or mesh chain-link.Similar structures consist of rods, which are connected to each other by welding in the form of a lattice. Such variants very often have a sectional structure.

Lattices in bar fences can be made of shaped or ordinary round pipes.

From a professional flooring

Such fences are recognized as one of the most popular and are found very often. They are relatively inexpensive and serve more than one year, maintaining a presentable appearance for a long time.

The sheeting itself has the form of a profiled steel sheet treated with an additional layer of zinc. Due to this material is not susceptible to the formation of corrosion. Besides, galvanized corrugated is not afraid of ultraviolet rays and adverse climatic conditions. Over time, it does not lose brightness and color saturation. These steel sheets are painted with special enamels, which are based on polymer components.

Such fences have many advantages. Here are some of them:

- Fencing of corrugated board is quite easy to install. You do not need to pour additional foundation.

- The professional flooring is not afraid of temperature differences.He will not suffer when the seasons change.

- The fence from a professional flooring differs in esthetic and accurate appearance. Currently, you can find this material of different shapes and colors.

- It should be noted democratic cost of such structures. For example, a model of solid metal will cost the buyer much more than an affordable system of corrugated flooring.

- With the help of such a fence you can protect the territory near the penetration of dust and street dirt. In addition, profiled can boast good sound insulation characteristics.

Forged

The most expensive are forged fences. However, the high cost is justified by the unsurpassed appearance of such structures, as well as their performance characteristics. Serve these options for a very long time, while maintaining the pristine beauty. In addition, they are durable and durable.

You can install a decorative forged fence yourself, but it will take much more time and effort. If you plan to install a large and impressive fencing, then it will require additional installation of sturdy pillars made of stone or brick.

The personal plots in which the forged fence surrounds not only the territory, but also flower beds look very harmonious and harmonious.

Structures with spectacular forging are safer and more reliable than, for example, cheaper options from a chain-link mesh.

Fence blinds

If you want to surround the site with an interesting and attractive fencing, then you should look at modern products in the form of blinds. Such constructions are sections made of shaped pipes, which are connected to each other and supplemented with horizontal panels fixed to them.

The advantages of fence-blinds include:

- Resistance to high temperatures. Due to this characteristic, such constructions do not ignite and do not support the flame, so they can be safely called fireproof.

- Sustainable design. If you make the installation of such a fence correctly, as well as to secure all the necessary supports, then it will serve for many decades. In addition, a similar fence is characterized by increased rigidity.

- Low weight. Fence blinds for many customers seem overweight and heavy.In fact, this design has a relatively small weight, because the thickness of the walls of the composite components in such a system is small.

- Easy installation. To install such a fence, it is not necessary to fill in an additional strip foundation.

- High quality. As a rule, materials with increased strength are used in the production of such fences. So, frames are created from a reliable profile pipe, and lamellae from rolled steel, coated with a polymer coating (on one or both sides).

- Not susceptible to mold and mildew. Fence blinds are not afraid of harmful microorganisms and are not destroyed by their influence. Such systems do not need to be treated with additional protective mixtures.

- Large assortment of colors. Modern manufacturers offer a choice of buyers fences, blinds of various shades. Everyone can choose the perfect option.

Carved

Carved metal fences are a good alternative to forged structures. Decorative metal cutting - a relatively fresh direction in the design of interiors and exteriors.With the help of a unique carved fence, you can emphasize the excellent taste of the owners of the dwelling, as well as give the site a unique look that definitely will not be ignored.

Such constructions are not only transparent, but also deaf. The second option is equipped with an additional sheet of metal, corrugated board or polycarbonate. Some manufacturers complement such beautiful compositions with canvases made of wood with which the carved metal looks simply amazing.

Fence

Another popular design option for the local area today is a painted iron picket fence. Such a fence is quite simple and consists of several metal segments that are parallel to each other and fixed on two lags.

Initially, all the shtaketniki were exclusively wooden, but recently the metal versions are very common. Individual parts in them may have different widths and shapes, ranging from classical to forged design elements.

Especially often metal picket fence is found in landscape gardening facilities.Their small counterparts are great for decorating flowerbeds or front gardens.

Advantages and disadvantages

Metal fences have a number of positive and negative qualities. First, consider the strengths of such structures:

- First of all, it is worth noting the durability of metal fencing. Of course, an important role in this matter is also played by the competent installation of the structure, as well as its anti-corrosion characteristics.

- Such fences are durable and reliable. As a rule, they do not deform with time, and it is not so easy to break them. In addition, the metal is not afraid of adverse weather conditions.

- Metal fencing will provide housing and site additional protection and security. Many consumers chose such options because they consider them impregnable. It is especially difficult to overcome high and massive designs.

- Difficult care such products do not require. They only need to be treated from time to time with special anti-corrosion agents, as well as cleaned from rust stains, if any.

- Metal gates are presented in a large assortment.

- The qualitative design from metal can be found for the low price.

As for the shortcomings of metal fencing, these include:

- Great weight. Of course, not all metal structures are massive, but most of them fit this description. Because of this, it will not be so easy to install and disassemble such a product.

- If over time, the anti-corrosion coating has deteriorated, then rust spots will appear on the surface of the fence and the material will suffer from contact with water or snow.

- Many buyers are repelled by the purchase of a metal fence that you need to pay close attention to the materials. For example, an overly thin profile will be less wear-resistant, so it is better to refuse to buy it and look for something more reliable.

Style and design

Today, a reliable metal fence can be selected for any site and under any facade of the house. So, for buildings in modern style (such as high-tech or minimalism), you can use concise (transparent) horizontal fencing, consisting of metal horizontal stripes, alternating with vertical ones.

Such designs do not close the area and it will remain open to prying eyes, so this decision should be addressed only to those people who agree with this nuance.

For registration of cottages and country wooden houses, a neat, rustic-style fence is ideal. To do this, you can pick up a spectacular and original shtaketnik with the surface of a tree. Such designs look very interesting. In a rustic style, you can use a chain-link, but it is better to find a place for her at the site and divide the space into separate zones with its help.

For luxurious buildings in elaborate stylistic directions, it is recommended to select equally luxurious fences. For this, expensive forged structures with interesting decorative elements and gold-plated parts are suitable. If you prefer the mysterious Gothic style, then you are perfect black metal fence with elements of forging and pointed peaks on the top. Also similar designs can be added with relief drawings and ornaments.

For the classic facade of the building, you can also choose a metal fence.In this case, the best solution would be a design with forged parts, wood surfaces made from metal siding.

As in the artsy ones, in the classical directions one cannot use cheap fences like a chain-link mesh or a welded grid. Such designs are best left for a rustic style.

Installation tools and materials

Installation of a metal fence is a multi-stage work. At all stages will use their tools and materials.

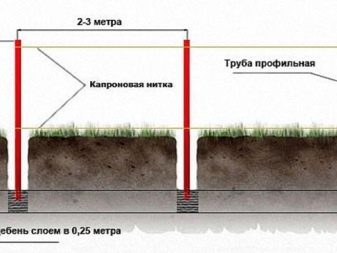

To build a trench and formwork, you need to stock up on the building level, pegs (for fencing), fishing line, special nylon thread, crowbar, shovel, bags under the ground, wheelbarrow for exporting dug earth, screws for woodworking, half-edged boards, electric drill, wooden lintels , knitting wire and bars of reinforcement.

To fill the foundation, you will need rakes, shovels, steel sheets, a separate container in which you can mix mortar, sand, water, cement, crushed stone, liquid soap, trowels, solution buckets and plastic film.

For the manufacture of a reliable frame you need to purchase metal pipes (as a rule,parts with a cross section of 60x60 mm), profile pipes (20x40x2 mm), embedded plates made of metal shield and special glasses for eyes when working with electric welding, electrodes, alkyd enamel, level, Bulgarian are used.

To install fencing of corrugated board, it is necessary to purchase professional sheets, roofing screws, electric drill, cardboard and a dark marker.

How to put the pillars?

Pillars in the manufacture of the fence play the role of supports. They can be made of metal or other materials. It can be brick, concrete and even wood. However, most often people turn to installing metal poles made of pipes with a diameter of about 60 cm.

Universal are steel supports. They can be used to install a variety of fences, from the chain-link mesh to heavy picket fence. Consider the process of mounting the pillars in stages:

- First, the site must be cleaned of any debris and vegetation. After that, it can produce markup. So, with the help of a cord or a nylon thread, it will be more convenient to determine the place of installation of the support pillars. If you calculate everything correctly, then the structure will not sag and deform over time.

- Now you need to calculate the number of required posts.

- The method of mounting the support depends largely on the type of fence, as well as its mass and individual characteristics of the site.

- The simplest and most common method is to fill the pillars with a solution of concrete. However, it is permissible to use this method only if the optimum amount of moisture is present in the soil.

- First you need to dig a hole under the support, install a metal pipe into it and fill the excavated excavation with concrete.

- To simplify the drilling process at the site, water is most often used to soften the soil.

- If the length of the support is not more than 150 cm, then the depth of the hole for its installation should be no more than half a meter. If you mount high poles, then you have to dig a deeper hole in 70-80 cm.

- If the site has low-heaving soil, then you can simply drill a hole with a drill and put a support. However, it should be borne in mind that the hole should be made strictly in the vertical direction.

- Also supports can be driven into the ground.

As a rule, a similar option is used if there is soil with a minimum amount of stones on the plot.To score supports, you must use a special technique or design that needs to be made of steel pipe and weighting agent.

The blow should be applied to the object axis in such a way that the support is level as a result.

Installation of fencing

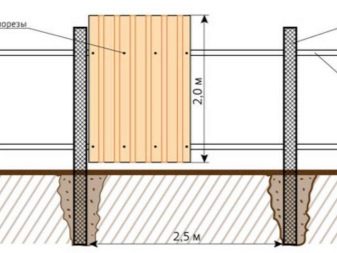

After high-quality installation of supports, you can proceed directly to the installation of the fence itself. Let us consider this process step by step on the example of the construction of a metal profile:

- When the supports are installed, it is necessary to fix the prozhilin. It must be done by welding. This is to give extra strength to the existing structure. Mounts should be made of transverse elements.

- Fastening sheets profiled need to be done with screws. It is desirable to select fasteners for the color of materials.

- It is recommended to overlap by one wave and at the same time make a small indention of 15 cm from the ground. This is necessary so that the materials do not “float in the water” in the spring.

- You do not need to make holes in the steel sheets beforehand, especially if you use special screws for working on metal.

- Now you need to go to the installation of the bar.Ideally, a straight line of the upper part of the fence is very difficult to achieve; therefore, a special fence fence is often established above, which will eliminate any irregularities.

If we are talking about a fence from the fence, then:

- First you need to install the corner posts.

- Then it is necessary to proceed to the manufacture of transverse streaks. Immediately before fixing the bars, it is necessary to bevel the upper edge. Then the cross member must be inserted into the grooves of the supports and secured with screws.

- Next you need to go to the equipment picket. Each element is attached to the bars with four screws (2 - at the top, 2 - at the bottom). To prevent the shtaketniki from cracking during the installation of fasteners, it is necessary to make holes in the necessary places in advance using a drill, the size of which is slightly smaller than the diameter of the screws.

- Having completed the construction of the fence, it must be made more attractive and aesthetic. For this section it is necessary to process special mixtures with light-resistant components.

Care Tips

Metal fences are quite unpretentious. They are not subject to rotting or mold / mildew.To prevent fencing from suffering from the effects of dampness and moisture, it is necessary to cover it once a year with special protective mixtures or to carry out a new painting of the structure each time.

There are also special anti-corrosion and paint coatings that do not need to be applied in a thick layer. Abundantly it is necessary to paint only those areas from which the old finish has hatched. The remaining surfaces are treated solely for prophylaxis.

Before painting, it is better to remove the old coating from the metal fence. But do not do it completely. Clean only the places where the old paint began to peel off.

If there are traces of dirt on the fence, it can be easily cleaned by a hose. It is also permissible to wipe the fence with a soft cloth. Do not be too zealous when rubbing the surface, so as not to mash the material.

If you notice that the fence is squinted, then you need to carry out its repair. To do this, the crooked sheets should be removed from the base. If they are bent, they can be aligned quite simply. Carefully inspect and the area in which there was a crooked detail.All elements that have moved away from their main place must be removed, aligned and put back.

Beautiful examples and options

The deaf panel fence painted in black color will look effectively in a tandem with stone support of a square shape. The upper part of the whole structure can be supplemented with wrought iron parts with pointed elements.

A black metal fence can be installed opposite a private house with a soft pastel facade and gray tiles on the roof. In this case, you should not be afraid of gloomy paints, since they are effectively diluted by the delicate color of the building.

The grid chain-link looks quite simple, however the design of gray color will not bad look opposite to a small country house or a bath from a felling.

A luxurious wrought-iron fence with rounded top details and pointed peaks will look great on a small stone base. This design will be a spectacular addition to a two-story house with a peach facade and a sloping roof with red tiles.

A plain bar fence just seems too simple and uninteresting.In fact, it is often used in the arrangement of the local area with luxurious buildings. For example, it can be a real one-story villa with wide entrance arches and a roof covered with chocolate tiles.

Forged structures consisting of thin rods and sharp details look organic in an ensemble with columns of stone. Such combinations look especially attractive if they are surrounded by well-groomed lawn and small trees.

On how to install a metal fence of corrugated, see the following video.