Homogeneous and heterogeneous linoleum: the differences and features

The emergence of the popular flooring is rooted in the distant past. For more than two centuries, the production technology has acquired new and improved features and qualities. With the development of the chemical industry and the emergence of artificial materials, a change in the structure of the previously patented oil-based canvas - linoleum.

Linoleum and to this day remains one of the most popular floor coverings. Such popularity of the product is due to the fact that linoleum is considered to be quite durable and highly functional material.

The universality of linoleum in that allows you to make a choice from a wide range in favor of a solution that is suitable for solving.

The main differences of products

Linoleum is a material with general consumer availability. Modern flooring is quite popular. This is facilitated by a wide range of existing coatings that have the following characteristics:

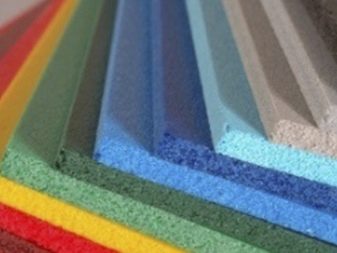

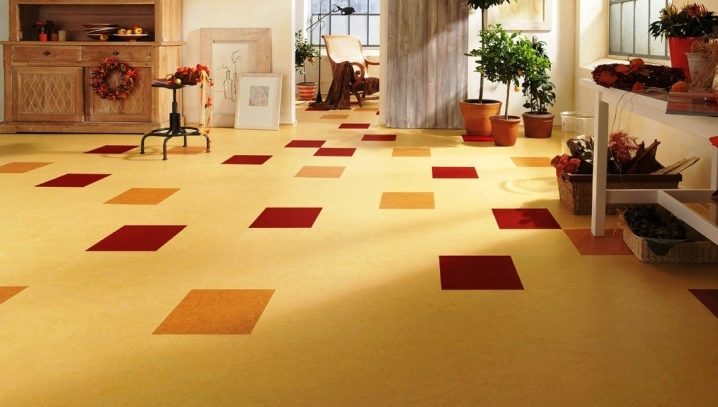

- Color solutions. The variety of shades and patterns of the material allows you to make a choice, focusing on the taste and style of the selected option for various kinds of premises. As part of the drawings, this material can imitate any natural materials: stone, wood, or simply have an original ornament.

- Strength. Unlike natural flooring, such as wood or ceramic tiles, linoleum does not crack over time.

- Softness. The structure has a springy base, and this is due to a pleasant and comfortable tactile feature.

- Price. Along with the budget options, linoleum is presented and premium class options.

- Easy installation. The technique of laying the floor covering is simple in design. To date, lay this material under the power of both professional craftsmen and a simple man in the street.

In modern production should be allocated commercial linoleum, which is divided into two groups:

- Homogeneous linoleum.

- Heterogeneous linoleum.

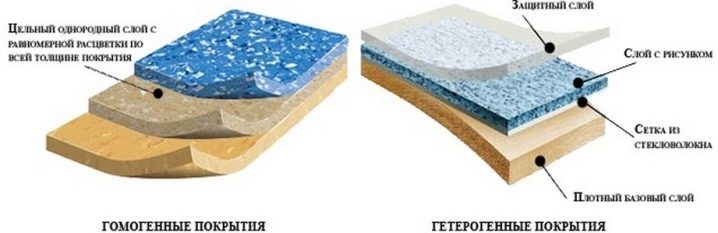

Homogeneous and heterogeneous linoleum differ in composition and technological characteristics:

- Homogeneous linoleum, in fact, is a coating consisting of one layer. The structure of this linoleum is uniform throughout its thickness. Also, the material has a special strength and elasticity. Basically, the texture of a homogeneous coating is a simple marble pattern. This material is used as a flooring in areas with high traffic and industrial load: marketplaces, large halls, railway and bus stations, airports.

Consider the composition of the elements of homogeneous linoleum:

- PVC The polyvinyl chloride used protects the coating from mechanical damage. The disadvantage may be a small smell, which eventually disappears.

- A piece of chalk.

- Quartz sand.

- Lime industrial.

- Tint pigment.

The components are mixed in a multistage way, and then the mixture is processed in special devices.The mixture is then passed through shafts, which give the material the desired width and thickness of the future flooring. The wear resistance of homogeneous linoleum is influenced by the thickness of the coating. The greater the thickness of the product, the stronger and more stable the floor will be.

Over time, the coating, exposed to huge production loads, may be damaged, but this issue is resolved positively. Restore linoleum is not difficult, it is polished, thereby removing the top damaged layer, and put a special protective mastic.

Heterogeneous linoleum is a coating consisting of several layers (heterogeneous means heterogeneous in composition). Modern heterogeneous floor covering allows you to lay it on any type of surface. The method of its manufacture is much more complicated than the production of homogeneous linoleum.

Heterogeneous linoleum is divided into the following types:

- commercial;

- semi-commercial;

- domestic.

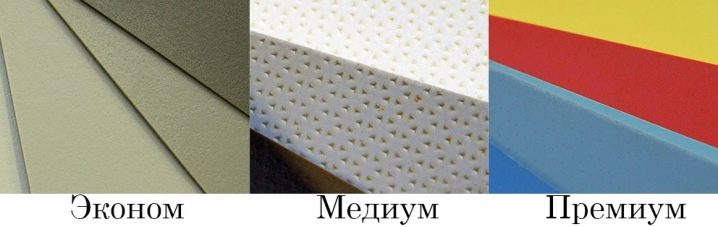

The types of heterogeneous coating differ only in the thickness of the protective layer, which significantly affects the price of the product.

The composition of heterogeneous linoleum includes the following components:

- The base consists of polyvinyl chloride.

- The next layer of fiberglass, it allows you to save the desired dimension of the surface.

- Next comes the embossed pattern. A thin layer of PVC is not limited to colors and decorative elements.

- The outer layer of PVC layer is protective. Thanks to the upper film, the coating is protected from external damage and wear.

The number of applying layers for each manufacturer is different. It usually ranges from 2 to 6.

Coatings of heterogeneous type are suitable absolutely for any kind of premises. Linoleum has proven itself in rooms with large crowds of people, it can withstand any mechanical effects. The positive characteristics were also affected by the fact that the material is resistant to fire, and this is an important fact, since the coating is widely used in children's institutions.

The operational period exceeds more than ten years.

The difference in technical characteristics

Preferring such a flooring as linoleum, should thoroughly examine all the features and specifications of this product. Of the widely used species, each of the coatings presented deserves special attention.

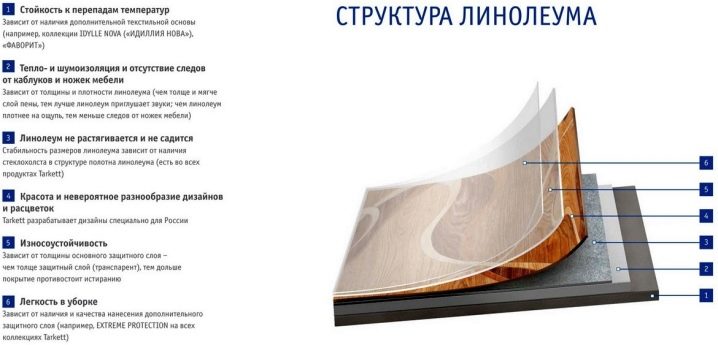

Homogeneous single-layer coating, in fact, is the most wear-resistant, since the drawing is almost not erased.

Components of the characteristic properties include the following indicators:

- The big operational period of service, exceeds twenty five years.

- PVC is relatively safe for health.

- No toxic substances.

- Protected against fire.

The advantages of homogeneous linoleum include, first of all, its high strength, durability of dyeing dense and evenly distributed throughout the layer. Since there is industrial lime in the composition of the product, it is not recommended to allow excessive contamination, this is fraught with deep contamination of the web. Remove dirt from the surface is obtained only with the help of a grinding machine and then applying a special mastic.

Heterogeneous linoleum on functional and technical characteristics is in great demand among consumers. Getting this type of linoleum, carefully study all alphabetic designations and a classification scale. The correct choice of the purchased canvas depends on these parameters.

For example, if the packaging is marked 21-23 class, then the product is used only in home premises. If the class is 31-34, then the installation is done only in places of public type. Class 41-43 is used in industrial-type premises, in chemical laboratories, since these species are resistant to chemical reactions. The lifetime of the PVC coating is significantly less than that of a homogeneous material, it is only 10 years.

Household linoleum, probably the easiest to classify characteristics of all PVC coatings. It is used only in domestic premises, as it is not designed for serious loads and high traffic. The coating of the protective PVC layer varies from 0.15 mm to 0.35 mm.

When giving preference to household flooring, please note that the life will be low. However, a huge selection of colors and budgetary cost of the material will appeal to all.

What is different laying linoleum?

As mentioned above, the interest in linoleum continues to this day. Gone are the days of the Soviet Union, where the floor did not differ in the intricate design solutions.This coating brings sadness and dullness. In the modern world, shopping malls have replenished with a variety of materials that satisfy every consumer whim.

Since the flooring of this type is quite flexible, laying it will not be difficult, even for beginners. First of all, it is necessary to stock up with all construction equipment: a knife for cutting linoleum, a substrate (if necessary), an iron ruler, a plinth, glue, a roller for rolling the surface, a hammer.

Following the exact dimensions of the room, it is necessary to cut the floor covering correctly.

It should highlight the main types of laying linoleum:

- Dry method of laying.

- With glue.

- Easy styling.

Dry method of laying is to lay the material without the help of glue or mastic. It is necessary to take into account the fact that the canvas shrinks. In expanded form, the coating must lie for several days in order for it to “acclimatize”. Be sure to leave allowances at the edges.

If the canvas has a pattern, the parts are adjusted accordingly to the elements of the canvas. For bonding need double sided tape.

Laying on glue more reliable of all ways.The method is also quite simple to use. When applying glue to the inside of the canvas, note that a draft will interfere with the laying process. Putting the canvas to the surface, walk the roller for rolling. Next, you need to completely dry the surface.

How to care for them?

Indicators of quality and structure of the material, as well as methods of care are significantly different. Polyvinyl chloride has a unique property of protection against premature coating defects. The top layer prevents the ingress of dirt into the structure of linoleum, thereby simplifying maintenance. Cleaning is carried out, depending on the operation in a particular room. The material is unpretentious and does not require professional detergents and cleaning products, cleaning is carried out with the help of water and a soft cloth.

Compared with homogeneous linoleum, the use of special mastic this type of coating is not required.

According to its characteristics, homogeneous linoleum has a porous structure, which is why it becomes easily dirty with long-term operation. To do this, you must carefully monitor the condition of the surface. If, however, heavy pollution cannot be avoided,then cleaning with a sander and cleaning agent will come to the rescue. She carefully peel off the top, contaminated surface layer. Further, a layer of mastic is applied, which will save further from contamination and increase the period of use of the coating.

How to choose the right product?

Taking care of comfortable living conditions, people carefully consider the choice of any building material that not only saves the budget, but also does not harm health.

For this it is necessary to base on the characteristics of the products offered:

- The presence of an unpleasant odor. If there is the presence of irritating odors, which indicates harmful chemical components, it is better to abandon this material.

- Weight. Famous manufacturers do not violate the technological process of products. Therefore, high-quality coating has a heavy weight, because all layers are observed and correctly applied.

- Acquire products should be only in specialized stores. After all, only there you can get reliable information about the availability of certificates.

- The surface pattern must be clear and evenly applied.

- The thickness of the linoleum should be within the limits of GOST.For a homogeneous coating, it is 1.5-2 mm, for a heterogeneous floor covering varies from 0.4 mm to 0.6 mm.

In any case, each type of flooring has its pros and cons. Having carefully studied all the components, feel free to make a decision about purchasing the material you like.

For more information on this issue, you can find out from the video below.