Cold welding for linoleum

Linoleum is a universal floor covering that can be used in various conditions. This product is produced in the form of rolls of a certain width. The dimensions of the products are limited, which does not allow to select a solid sheet for a specific room.

Solve a similar problem by using several elements that are joined together. Cold welding for linoleum is one of the most popular ways to join sheets. This allows you to create strong and even joints that will withstand significant loads for a long time.

What it is?

Linoleum is an artificial material that is produced on the basis of various chemical compounds. The joining of the sheets forms a small gap, which is not aesthetic and beautiful. To obtain a solid seam using the method of cold welding.

This approach involves using special glue that connects the sheets of linoleum into a coherent whole. When exposed to a substance, a chemical reaction occurs that makes the material liquid. In this short time, the joints have time to grab and form a strong connection. Cold welding is a relatively simple method of joining, which can be performed even without experience and special tools for soldering (soldering iron, etc.).

The properties of the adhesive are such that allow you to work with joints of different widths. The resulting joint also has plasticity and, according to its characteristics, practically does not differ from the properties of linoleum.

Welding linoleum with cold soldering allows you to get an aesthetic surface, which is very important for residential interiors.

Special features

Cold welding of seams is an excellent option for people who make repairs in the house and plan to get a beautiful surface with minimal visibility of the seams. There are several positive aspects of this method:

- Gluing with this method allows to obtain high-quality results in a relatively short time.

- To obtain the connection does not need to use and purchase accessories. Often, manufacturers sell all the necessary tools complete with glue. In addition, you only have to buy a double-sided masking tape that covers all the joints.

- Low cost of work. This is the best alternative for the repair of the old coating, and for laying new sheets of linoleum.

- Invisible joint. The junction visually resembles the usual surface of linoleum. Although, if you take a good look, you can define it.

But cold welding is not the best solution, since this approach has several significant drawbacks:

- Glue consists of toxic components that emit harmful substances into the air to the human body. Therefore, all work should be done only with the use of special protective equipment (masks, respirators, etc.). It is important when purchasing cold welding to check its quality, as well as compliance with all SNIP standards.

- Limited use Only single-layer linoleum can be connected with such glue. If you use a substance for multilayer products, it will increase the seam, which will be very noticeable to the naked eye.Some experts also do not recommend the use of welding, if you have under the linoleum insulation.

The choice depends on the type of linoleum

The modern market represents many types of linoleum, which are obtained from several components. But not all of them are suitable for cold welding. The best option for such a process would be a substance based on polyvinyl chloride. Today, many types of linoleum are made of this substance. But still, there are products from other components. Therefore, before buying it, it is important to clarify what it consists of.

The best option for domestic linoleum compounds is Type C gluewhich can weld relatively large crevices. Commercial multi-layer linoleum is also amenable to soldering using cold welding.

But if its structure consists of several layers (not necessarily polyvinyl chloride), then the quality of the seam will be much lower. This is important to consider when choosing glue.

Types of welding

Welding glue can work with several types of linoleum. But on the market there are several types of such solutions, which differ in composition and method of application. Depending on these parameters, cold welding is divided into the following types:

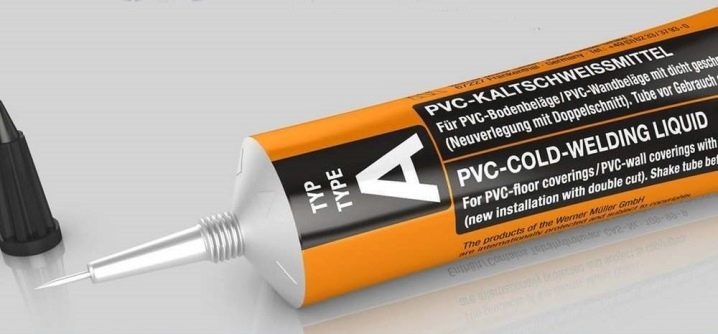

- Type A. The substance has a liquid consistency, as the composition contains a large percentage of solvent. Glue quickly dissolves the edges of linoleum, and also binds them qualitatively. It should be noted that this material is not recommended to be used if there is more than 2 mm between the junction sheets. In another case, the solution simply does not form a strong and plastic compound, it will quickly collapse. Please note that this type of glue forms almost imperceptible seams, which are also very neat. At the same time, the joints remain strong and durable, and also withstand considerable loads.

The best option for using this product is a new linoleum. This product has almost perfectly flat ends that can be joined very tightly.

- Type C. This type of glue is thicker with a minimal amount of solvent. The composition of this product includes a special mastic on waterproof binders, which subsequently forms an elastic connection. This cold welding is suitable for work with joints, between which the gap to 4 mm.Such products are very often used not only for docking, but also for repairing old coatings with minimal damage.

- Type T. Clay of this type in life is very rare. This is due to the fact that it is intended to connect multicomponent linoleum, which is composed of polyester and PVC. Very often it is used for finishing seams on semi-commercial materials.

Composition

Adhesive solutions of this type, although produced by many manufacturers, but their composition remains unchanged:

- Solvent. As this product, tetrahydrofuran is used, which suggests the presence of chlorine. It is this substance that acts on polyvinyl chloride and melts it. At the same time, the mixture practically does not react with other types of linoleum. Some manufacturers replace this substance with special types of polyurethane.

- Filler. It uses the same PVC, which is in a liquid state.

It should be noted that the percentage of these products may differ slightly. This allows you to change the main characteristics of cold welding.

Type A adhesive has more solvent, whereas this component is slightly less in type C solution, which has a high percentage of PVC.

Consumption

Cold welding is a liquid solution that is sold in small tubes. Such products are applied to the joints between adjacent elements of linoleum. The consumption of this substance depends on several main factors:

- Qualification of the performer. If a person often performs cold welding of linoleum, he uses the minimum amount of mortar that is needed to form a seam. This eliminates a large amount of waste. When welding is performed for the first time, then it is not always possible to immediately fill the hand in order to use only the required amount of mortar.

- Linoleum thickness. The higher the rate, the higher the flow rate. But it should be understood that PVC products of considerable thickness are quite rare in everyday life. The main layer of polyvinyl chloride is on top, and the substrate itself does not react to the effect of the solution.

- A kind of solution. Type A glue, which is very often used in everyday life, has a consumption of about 50-60 ml per 25 meters of seam.In turn, a mixture of type C for the same number of cracks will need approximately 70-90 ml.

Please note that some manufacturers indicate consumption not in milliliters, but in grams. Therefore, in order to obtain a qualitative result, before starting work, one should calculate the required volume of the solution, which will be needed to solve a specific problem.

Manufacturers Overview

The market for cold welding for linoleum is very diverse, since it is produced by many manufacturers. This is due to the fact that this glue is universal and suitable for almost all products from polyvinyl chloride. Among the variety of models should be distinguished several major brands of these products:

- WernerMuller. German brand, under which they produce all types of cold welding. The quality of the material meets all international standards. Experts note that the substance forms a high-quality and durable seam. The average consumption of glue is about 44 grams per 20-25 meters.

- Tarkett. Another German brand, which, according to reviews, even slightly exceeds the previously reviewed products. Glue is distinguished by universal characteristics and forms an almost imperceptible seam.

- "Homakol." Domestic glue, which is mainly used for bonding PVC plates and commercial linoleum. The consumption of material is approximately equal to the previously indicated indicators.

- Rico. Glue of this brand does not contain tetrahydrofuran, which is toxic to humans. Instead, there are used special compounds of polyurethane foam or artificial rubber. Spike with the help of these substances is not particularly different from the options where the classic glue is used. At the same time, the cost of production is somewhat lower and there is no strong toxic evaporation.

- "Second" and Sintex. Relatively cheap solutions of Russian and Spanish production. The consumption of this material reaches 45 grams per 50 meters of seam.

How to use?

To glue the joints between the sheets of linoleum using cold welding is quite simple. To do this, you first need to stock up on some tool:

- Long line. It is advisable to use a metal model, as they are more even and can not be deformed.

- Masking tape If not, then you can use the two-way counterpart.

- Knife for cutting.It should be sharp, as the quality of the seam and joining of sheets depends on it.

- Substrate. Often for this they use thick cardboard, which is placed under the seam, so as not to cut across the floor. Also suitable is a sheet of old plywood, old linoleum or chipboard.

- Means of protection. These include gloves and a mask that protects against the inhalation of caustic vapors.

In order to weld linoleum, it is necessary to get a good joint of elements. This will allow the glue to evenly fill the gap and form a strong bond. This process is quite simple and consists of several operations:

- Initially, two sheets need to be superimposed on each other with an overlap of about 5 cm. This factor should be taken into account when purchasing material. Under them should first put a piece of chipboard or old linoleum along the entire length of the joint.

- After that, a mark is put on the top sheet, which will indicate the place of the joint. Please note that it is located approximately in the center of the overlap.

- At this stage, you need to cut off the extra pieces. To do this, use the ruler, which is placed along the future seam. It is important that under it lay two sheets of linoleum. After that, using a sharp knife should be cut along the ruler.You need to cut two sheets at the same time, which will allow to form an even and minimal joint.

Bonding linoleum consists of several consecutive steps:

- First of all, you need to read the instructions for use. Depending on the type of glue, there may be some nuances that are desirable to consider. Manufacturers also indicate under what temperature conditions it is possible to glue the material qualitatively.

- After that, the sheets are joined to each other by those parties that were previously fitted. It is important to make sure that the material does not move when performing such operations, and there are no air bubbles under it. They may subsequently “migrate” to the seam, which will subsequently collapse.

- To avoid glue on the surface of linoleum, masking tape should be glued along the entire length of the joint. After that, a knife is cut through the channel, which corresponds to the direction of the gap between the sheets of linoleum. This should be done carefully so as not to damage the material from the side.

- For welding on a tube of glue, put on a special nozzle in the form of a small needle. After that, start feeding the solution into the gap between the sheets.Initially, you need to fill the joint until a mixture with a diameter of about 3-4 mm protrudes on the surface of the adhesive tape. After that, you can consistently move along the entire length of the seam, giving similar glue inwards.

- When the joints are full, leave them for about 15 minutes. After this time, you can remove the tape. Full bonding will occur in about 3 hours.

If the mixture gets on the clean surface of linoleum, do not try to wipe it immediately. Let it freeze, and then simply cut it off with a stationery knife. Cold welding technology is a simple operation that only requires care and safety.

You will learn more about how to use cold welding for linoleum in the following video.