Lining for linoleum

During repair work in the apartment or private house used a huge amount of various materials. They must not only be used correctly and qualitatively, but also be able to combine with each other, creating a single composition. One of the very popular types of flooring is linoleum, but this does not mean that only it should be used for laying on the floor.

If you combine this material, for example, with floor tiles or laminate, you can create not only a functional, but also a beautifully decorated floor.

In order to make the transition between different floor coverings and individual parts of linoleum imperceptible, special powders for linoleum are used.We will understand what their functions are, what types and sizes they come from, what materials are produced and how to install them correctly so that this element will last a long time.

Functions

The main functions of the nut:

- Protects joints from dirt - if you install this element on the floor, then your floor will be protected from dust, dirt and moisture. Thanks to this docking, the linoleum will be protected from delamination, and there will be no mold under it.

- Prevents linoleum from rupture in the joints and joints.

- Eliminates differences - during the connection of two floor coverings, which differ in height, such a docking bar will maximally smooth out differences in height and will not allow the material to delaminate. This powder can be used to connect, for example, linoleum and laminate.

- Acts as a decorative element - even if you try to dock individual elements as much as possible, the seam or joint area that does not look aesthetically visible will remain visible. To avoid this situation, you need to use the threshold for linoleum.

- Improves the perception of various kinds of coatings.Due to this, different floor coverings look like a single element, without contrasting with each other in color, texture and shade.

- A similar threshold is used as a connecting strip between the rooms.

Thanks to the listed functions of such slats, you will be able to create the perfect design cover, without even resorting to the help of specialists.

Types and sizes

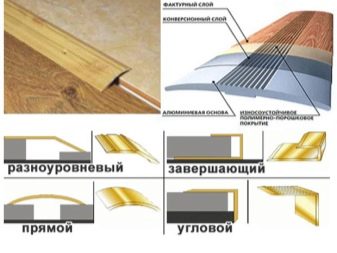

Depending on the functional features, there are several types of powders for linoleum:

- Direct (another name is single-level) - it is used to join one or several variants of different materials. Such floor coverings are located at the same level or have a minimum difference of not more than 1 mm.

- Differential (the second name is split-level) - is used to connect materials that differ in height. Such strips are used to join the linoleum with floor tiles, laminate or parquet. They are able to level even significant differences in the height of floor coverings, the size of such a difference can vary from 0.3 to 1.8 cm.

- Finishing - stacked in the place where the linoleum ended, and docking with another coating is not carried out. Most often, these powders are used in doorways.

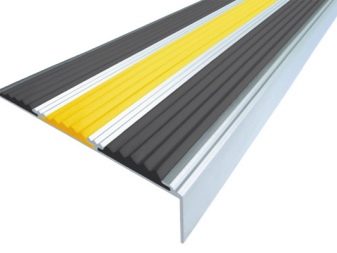

- Corner (also called stair) - this baseboard has a different angular shape and acts as a fastener to join and secure materials on the stairs. These elements are very flexible, as they are made from rubber.

- The final one is used to formalize the approach to the threshold or the podium, which is distinguished by a large difference in height.

Please note that powders for linoleum must be chosen, focusing on the flooring used, the existing differences in height, the requirements for the term of operation. The life of this product will be influenced not only by the correctly selected type of nut, but also by the material from which it is made, as well as by how correctly it was installed.

In terms of size, powders can be both wide and narrow. Most often, the wide powders are used to hide the large gap formed between the various floor coverings.The narrow baseboard is less noticeable in the general background and does not attract much attention.

Materials manufacturing and design

Laminates are made of various materials. The most common options are:

- metal;

- plastic;

- rubber;

- cork.

Metallic

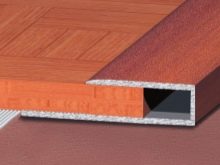

One of the most popular baseboards are metal models, as they are characterized by a long service life and a presentable appearance. Similar products are made either from brass or aluminum. Aluminum thresholds are more common than brass counterparts, as they have a lower cost.

The main advantages of aluminum sills include:

- They are lightweight and durable, so they will last a very long time, retaining the original appearance.

- They are used both in residential and non-residential premises, as they perfectly tolerate temperature fluctuations, stress and high humidity.

- They are made in various sizes: both narrow and wide. If the aluminum threshold fits into the doorway, which is characterized by non-standard dimensions, then such a product is very easy to shorten, just use a hacksaw or grinder.

- The smooth surface helps to make even a significant difference in height less noticeable.

The only disadvantage of this strap is that on it you can easily slip. This feature should be taken into account especially for those families with small children or elderly people. In order to avoid an unforeseen traumatic situation, it is better to opt for an aluminum plinth with a grooved strip in the middle. Such a product can be placed even in the bathroom, where the floor is very often slippery.

During the production of metal thresholds, they can be painted in a variety of colors that copy a bronze, silver or gold color. The use of lamination technology helps produce skirting, the finish of which will resemble the texture of wood, stone or other material.

Plastic

Polyvinyl chloride is used for the production of such strips. The main advantage of plastic sills is extensive color palette, which is obtained due to the fact that the paint is added to the original composition.

Most often, such products are used to combine various types of flooring, for example, linoleum with carpet.

An important advantage of plastic baseboards is also high flexibilitywhich helps to decorate curvilinear joints in floor coverings. It is worth considering when choosing a similar product, that its service life is limited, since it is fragile and may lose its ideal appearance over time. After a certain time, it will have to be replaced, but since the cost of plastic powders is small, you can do it without affecting the family budget.

Rubber

Such thresholds for linoleum are made in two versions:

- completely rubber;

- having an aluminum base.

They are used in the decoration in order to minimize the slip of the floor covering.

Rubber baseboards also perfectly connect curved seams.

Cork

Such strips are used for bonding linoleum, as the cork has excellent cushioning properties. Due to this feature, they are also called compensatory bars. Cork powders can be made in various shapes and sizes.

A wide choice of materials and a variety of colors allows you to finish the flooring on any, even the most fastidious taste.

Installation and mounting methods

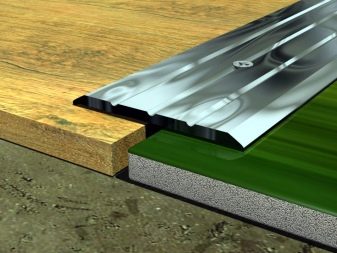

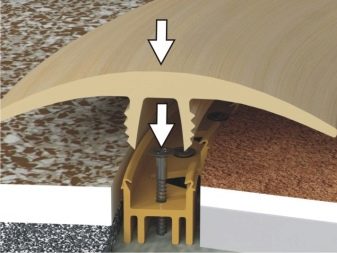

In order to hide the joints between the laminate and linoleum, it is necessary to properly install the threshold. The most popular method of installation is fasteners for dowels. In this case, a decorative plinth with an aluminum strip is used. This mount is called hidden because the dowels are hidden under the cover plate and do not spoil the aesthetic appearance of the floor covering.

In order to secure the straps correctly, carry out the process in stages:

- measure stitches;

- trim the nut, adjusting it to the desired size;

- clean seams from dirt and dust;

- lay the planks, moving from the center to the seam with a marked place for laying;

- mark where the dowels should be located;

- using a drill, make holes into which fasteners will be inserted;

- further, you should fasten the screws and install a decorative strip on top of them.

There are also small tricks on how to fix when laying linoleum, which differs curvilinear or arcuate joints. To fix the strips on such joints in two ways:

- Soft joint - in this case, a flexible plinth is used, which is attached to the floor, and a decorative strip is put on top. Such products are very easy to bend. They are able to hide the joints between the laminate and linoleum by 1 centimeter on each side.

- The aluminum profile is able to hide small joints (several millimeters on each side).

The process of fastening the strap is as follows:

- Drill holes in the floor for dowels.

- Measure the threshold of the appropriate length, insert the dowel in the hole.

- To give the profile the desired shape, it must be dipped in water heated to 70 degrees and left there for 20 minutes. After this time, the threshold will become very flexible and will simply bend.

- Next, you need to fasten the plinth on the screws and insert the cap from the top.

The threshold to the balcony is often attached to the mounting foam:

- It is necessary to clean the base from the threshold of pollution.

- Measure the opening and cut the threshold of the required length.

- Next, you should put an even layer of mounting foam.

- From above, locate the threshold and put the load that will hold the structure in the desired position.

- After the foam dries, the gaps formed at the joints should be sealed with silicone sealant.

- The ends of the nut are closed with special plugs.

Successful examples and options

More and more design solutions include the use of several floor coverings simultaneously. So, for the kitchen a combination of linoleum and ceramic tiles is used, this will allow to zone the space, separating the working area from the dining room.

Floor tiles and linoleum can be connected in the form of curved lines. In this case, it is better to use cork thresholds, since during the laying and twisting of the self-tapping screws it shrinks and almost completely merges with the surface, aligning it.

Not less popular is the combination of linoleum with laminate or parquet. If you use such a combination in the hallway, it will be practical. Applying an insert of linoleum near the threshold, you will save your laminate or parquet from getting wet, which becomes relevant in rainy or snowy weather.

The perfect solution for the kitchen-studio will be a combination of linoleum and carpet. Linoleum is lined at the working area and you can not worry that during cooking the floor will become dirty and it will be difficult to clean it.In the dining area will look great carpet, adding to her comfort and convenience. Use a split nut to combine such materials for flooring.

Cells for linoleum will help complete the design of the flooring and implement a variety of design ideas.

For information on how to install various door sills in the doorway, see the following video.