Substrate for linoleum: features and purpose

In the issue of construction and repair there is a controversial opinion about the substrate under the linoleum. Some believe that this is a completely useless material, while others think that the substrate is necessary for high-quality and even coating.

To decide whether to buy a substrate for PVC coating or not, you need to get acquainted with the material closer, find out what it is, as well as identify its features and purpose.

What it is?

The substrate is an insulating material that is placed under the floor covering. It differs in composition, material production, forms, methods of installation, functions and cost. Basically, the substrate is used for irregularities in the cement pouring, cold coating and baseless single-layer linoleum.

An interesting fact is that moisture is always formed and accumulated on the screed, and the concrete or wooden base has no ventilation openings. That is why the substrate is also a kind of sponge that absorbs condensate. But also linoleum can be laid on an old substrate, if it is in good condition and has no damage. This will greatly facilitate the task and speed up repair work.

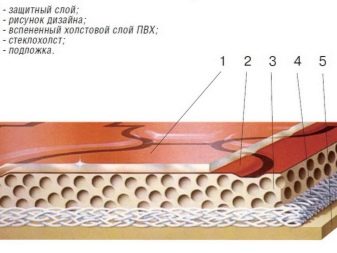

Modern flooring has several layers, so you can buy linoleum with glass fiber, PVC impregnation, some kind of fabric material in the base, polyester or jute and refuse the substrate.

Functions

The reasons for laying the substrate are not many, but they are all crucial and important. Many people are interested in, but is it possible to put it without it and why it is needed at all. In fact, You can easily do without the substrate if the base of the floor is perfectly even, there is no extraneous noise, there are no drafts and unheated rooms from below.

The linoleum substrate has three main functions:

- Leveling the base of the floor. Despite the fact that during repairs on the floor, all cracks, irregularities and other damages are carefully masked, when laying linoleum there is a risk of new defects. Since the flooring is quite soft and ductile, over time, all the gaps become visible, and in some places even tears and abrasions may appear.The substrate easily hides such defects and prolongs the life of the linoleum.

- Warming. Linoleum does not have thermal conductivity, and therefore when laying on cement it will be cold and unpleasant for the feet. Especially it concerns premises on the first floors and private houses. The substrate perfectly copes with this problem, it provides comfort, warmth and comfort.

- Soundproofing. Such a function is necessary in panel high-rise buildings in which there is too much audibility. The substrate under the linoleum perfectly protects against noise emitted from the bottom.

Kinds

In the construction market there are a large number of types of substrate for linoleum. With such an assortment, it is difficult for a beginner to decide and choose the right one. Therefore, it is necessary to get acquainted with each material separately, and only then draw conclusions based on preferences, housing conditions and financial resources.

Corkboard

The cork substrate has a lot of positive properties: high sound insulation, excellent heat retention, moisture resistance, preventing the growth of bacteria, mold and microorganisms, protection from mechanical damage.

The material is made from cork bark, which crumbles and then pressed under pressure and high temperature. Due to this treatment, the cork substrate has an unusual structure consisting of a large number of cells filled with air. This contributes to the uniform distribution of the load on the linoleum. She undoubtedly convenient stylingas produced and produced in roll.

The disadvantages of cork substrate are softness and high cost. Soft material is not suitable for heavy solid furniture, as there is a risk of dents and deformation of linoleum.

Jute

Non-woven material is ideal for the floor, where the concrete is laid directly on the ground or for an apartment on the first floor with a cold basement. Jute perfectly holds and conducts heat, is environmentally safe and has the ability to create a favorable microclimate. It is resistant to burning, rotting and mold, and also perfectly absorbs moisture and is restored after drying.

When choosing a jute substrate, first of all it is necessary to pay attention to its density.It must be extremely large, otherwise over time there is a risk of the formation of dents.

The only minus of jute substrate under linoleum is a rather high price.

Polypropylene

This type of substrate is considered the most impractical and poor quality. Polyethylene foam is very soft and during the operation of linoleum, it quickly loses its original appearance. In most cases, rubbing, cracks and dents appear on it. In addition, PVC flooring is very poorly combined with polyethylene, does not retain heat, is inconvenient when walking, and is rather difficult to put on the base.

To see the minus of the foam isolon, you can spend a small and easy experience with a sheet of paper and a knife. To do this, you must try to pierce the paper with the blade, which lies on a hard surface, and then on a soft one. In the first case there will be an inconspicuous hole, and in the second the knife on the sheet will make a noticeable hole. The same thing happens with linoleum, located on the polypropylene substrate. Of the relative merits can be identified only low cost.

Felt

Such a substrate is made of wool by drying.The material is treated with steam and combined into a complete sheet. In the process of creating a felt substrate, it is processed by high-quality materials that protect against burning and rotting.

Natural substrate has a large number of positive properties: it is environmentally friendly and safe, resistant to damage and abrasion, elastic, soft, anti-bacterial. Felt material perfectly conducts heat and keeps it.

Flaxseed

Natural and environmentally safe material is treated with needles and flame retardants, which prevents the occurrence and reproduction of harmful microorganisms, bacteria and insects. Flax perfectly passes air and creates a favorable microclimate indoors.

Combined

The universal backing consists of flax, jute and wool. This is a completely natural material that has high strength, density and rigidity. The combined substrate perfectly conducts and retains heat, and is also soundproofed.

The material is treated with anti-fungus and mildew agents, as well as flame retardants that reduce the risk of harmful insects.

Foil

Substrate consisting of polystyrene compound, isolon and aluminum foil. This building material is particularly durable, as well as heat-reflecting and moisture-resistant properties.

Foil substrate will be particularly appropriate in cold apartments and in rooms with sharp temperature changes. Lay the material of the foil should be the shiny side up. In this case, the heat will be reflected and enter the room.

Conifer

New in the construction market, which has already won the hearts of consumers. Fiber is made from softwood waste. It has high sound insulation and retains heat perfectly. The only minus of the coniferous substrate is foul odor that evaporates over time.

How to choose: the pros and cons

Linoleum with various bases performs a large number of functions and can easily do without a substrate. It should be noted that the thicker the layers, the warmer and more comfortable it will be on the floor. In addition, a floor covering with a base has a twice longer service life than without it.

The construction market has a wide range of linoleum with variousthe basics. Each of them requires a special approach and careful selection of the substrate. Therefore, before buying the material need to consult with a specialist or the seller and find out which is better to use the substrate under the vending linoleum and under what basis it lies better.

Linoleum on the basis of foam is used as a warming coating. It consists of several layers that protect from damage, noise and cold. Such type of material most often keeps within in a drawing room or a hall. Judging by the reviews of experts, absolutely any substrate will fit under this linoleum.

To date, felt and jute mixed with faux wool and flax fibers are used for the textile base of the floor covering. All these materials are treated with protective agents against moisture and fungal bacteria. Under the warm and soft linoleum with a fabric base you can put cork or jute material to improve thermal insulation and prevent noise.

Modern flooring can be produced on a duplicate basis. This unique double base consisting of foamed vinyl and polyester is considered more resistant to high humidity, stretching, tearing and other mechanical damage.Absolutely any material, except polypropylene, can be put under the soft and elastic linoleum with a duplicated base.

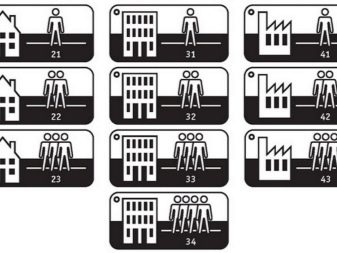

Flooring also varies by class. The most common is household, commercial and semi-commercial. Each of them has its own characteristics and drawbacks, so for a certain class it is necessary to separately select the type of substrate.

For example, commercial linoleum, which is used both in apartments and in office premises, has an increased wear resistance and density. Therefore, under such a material, you can lay a light and thin substrate: foil or flax.

Semi-commercial flooring is a medium strength linoleum. It is used in apartments or industrial premises with moderately high traffic. The substrate for such linoleum should be chosen more dense and resistant to damage. For example, felt or combined.

The household class, judging by the name, can be used only in apartments or private houses. It has low strength and wear resistance. But from the advantages can be identified cost and ease of care.Household linoleum is considered the cheapest material for the apartment.

With an incorrectly chosen substrate, such a floor quickly loses its original appearance. Therefore, the purchase of the base must be approached as responsibly as possible. Jute or cork material is best suited for domestic use.

Linoleum with a calendered base has recently become popular in the construction market. This novelty is made in the process of pressing the material. The main substance of the base for linoleum is a polymer raw material, which has hydro and thermal insulation.

An interesting fact is that although the coating is soft, it is considered fairly durable. And if any mechanical damage happens, the deformation is quickly restored and the linoleum takes on its original appearance. A coniferous, combined or jute substrate is ideal for a calendered base.

Styling rules

If you decide to carry out repair work with your own hands, then before you begin, you should consult with a specialist and clarify how to properly lay the substrate at home, how to glue the joints,which side is best to enclose the material, how to fix the linoleum, and so on.

First you need to carefully examine the cement or wooden base. Installation is always carried out only on a clean and level surface. To the substrate is well strengthened, it is necessary to vacuum the floor, and then get rid of the irregularities with the help of special mixtures.

It is worth noting that Before starting work, it is necessary to check the base for the presence or absence of moisture. To do this, lay polyethylene on the surface and fix it on the sides. After 10-12 hours, you must check the cellophane. If there are no water droplets on it, then you can safely proceed to repair.

Experts recommend two or three days before installation to bring the substrate into the room where the repair is underway. This will contribute to its acclimatization and smooth styling. At the same time, the air temperature should be above 18 degrees, and the humidity is not lower than 60%.

If the repair is on the first floor of an apartment building with an unheated room downstairs or a private house, then you must first take care of waterproofing. To do this, polyethylene is spread on the concrete surface, and the sides are fixed with adhesive tape.

To join the sides of the substrate, you must use construction tape or glue on polyurethane or artificial resins. The substrate can be in the form of a roll, strips, panels or any other forms, therefore, the methods of laying can be different.

It is important to remember that the substrate, despite its density and rigidity, should be laid and moved along it very carefully to avoid mechanical damage from shoes or construction tools.

The wooden base is recommended to sheathe sheets of hardboard as a substrate without a waterproofing layer. But First you need to make sure the strength and cleanliness of the floor. To do this, you need to get rid of all the baseboards, fix the slats and smooth out all uneven boards. And also should be removed from the base of the old paint and thoroughly wash the floor.

Examples and options

Oriented strand board can also be used as a substrate. It is also considered an ideal option for creating a subfloor. But It is worth noting that the OSB must be laid very carefully to avoid further sagging of plates, squeaking and linoleum swelling.

The floor covering is laid only on an ideally flat and clean surface of the oriented strand board. Therefore, at the base it is necessary to putty all the seams and attachment points of the screws with a putty, clean it from crumbs, construction debris and dust. Only then will linoleum serve for a long time and it will be possible not to worry about the appearance of bumps and peeling.

We should also consider the option of laying linoleum on a wooden floor. If the base consists of old squeaky floorboards, cracked uneven boards and other defects, then a leveling substrate is simply necessary. In this case, moisture-resistant plywood is considered the best material, but you can also purchase a jute base.

If possible, it is worth buying a substrate made only from natural materials that serve for many years and are safe for health.

How to choose linoleum, glue and substrate, see the following video.