Laying linoleum

When planning a repair and deciding which flooring to give preference to, many make a choice in favor of linoleum. People's love for this material is primarily due to its practicality. The simplicity of the appearance should not be misleading: this coating is resistant to mechanical damage and moisture, which is especially important for the kitchen, hallway and utility rooms.

Special features

Linoleum is not only affordable, but also simple to install. The fact that for laying this material does not necessarily have to be a master of extra class, and requires only minimal skills and understanding of flooring technology, is a kind of motivation.This feature is particularly relevant, given the current price tag on the services of professionals. We will study this issue in more detail and find out all the details of the installation.

Modern linoleum strikingly differs from the coverage of the times of the USSR not only by its performance, but also by its decorative qualities. Depending on the material that is used to make the canvas, the final product acquires some useful properties.

Manufacturers use:

- Natural materials. Giving preference to linseed oil, powdered limestone, resin of softwood, wood flour in combination with natural dyes. Buying natural linoleum, which is distinguished by its decorativeness, ecological purity and durability, is not a cheap pleasure.

- PVC (polyvinyl chloride). In this case, the base may be foamed or fabric with heat insulating or sound insulating properties. Coverage is groundless.

- Alkyd / Glyphthalic Modified Resins in combination with organic / inorganic fillers. High heat and sound insulating qualities are characteristic of alkyd (glyptal) linoleum with a fabric base.

- Nitrocellulose. The coloxylic coating does not have a base, it has good elasticity, resistance to a moist environment. The disadvantage of such products is low fire safety.

- Rubber. High properties of elasticity and water resistance Relin coating is obliged to the combined composition: synthetic rubber, recycled rubber and bitumen as a binder component of the lower layers.

Advantages and disadvantages

Consider in detail the arguments in favor of the purchase of linoleum:

- Hygiene. It is immune to dust, is of no interest to pathogenic microorganisms and has a dust-repellent ability.

- A variety of colors and textures. A large assortment expands the possibilities for decorating the premises for any purpose and style orientation.

- Easy installation. Self-laying linoleum - a procedure available to anyone who knows how to handle the simplest household tool.

- Trouble-free service. To maintain the cleanliness of the floor, decorated with linoleum, enough conventional washing with water.

For new models, it is characteristic to have an anti-slip or bacteriostatic coating that brings only benefit.

There are several disadvantages:

- Contact with open fire and chemical substances is contraindicated to this material; exposure to low temperature and direct sunlight is also undesirable.

- High ductility is another negative characteristic of linoleum. Regardless of the type, the flexible material always takes the form of the surface on which it is laid, so the existing base will definitely need high-quality preparation. Otherwise, any unevenness will be noticeable, which will affect the appearance of linoleum and will negate the effort.

How to prepare?

Preparatory work involves three key points.

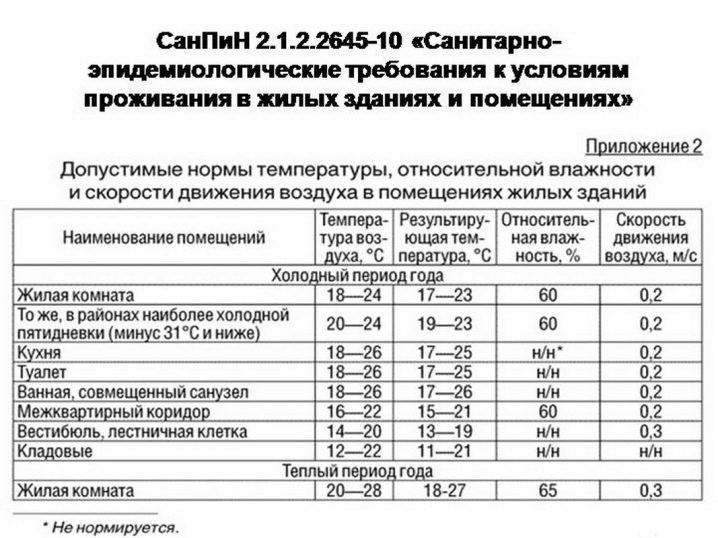

- Creating optimal conditions in the room, which includes the removal of furniture and restoring order. According to SNIP, the value of the optimum temperature in the room where the material will be stored, before laying should be between 15 ° C. You can not ignore the moisture and rough floors. If they are concrete, then the maximum is 5%, if they are wooden or made of chipboard, then - 10%. The rate of humidity of air - from 60%.

- Surface preparation.First, the dismantling of baseboards and fittings - connecting elements, plugs, corners. The floor must be cleaned of debris, crumbs, grease stains. The better prepared the base, the longer the linoleum will last. The smooth surface under it serves as a guarantee that the material will not be stretched, deformed and rubbed. To understand whether it is necessary to dismantle the existing coating or to lay a new linoleum on the old one, you need to evaluate the existing base. Most craftsmen who have been repairing for years are advised not to neglect the removal of the previous layer.

There are several serious arguments for dismantling the previous cover:

- Laying on the base, cleaned from dust, dirt, mold and fungus - the key to creating a healthy microclimate in the apartment.

- The flattened surface contributes to a uniform distribution of the load, which eliminates damage to the inner side of the material.

- A clean base provides better adhesion of linoleum to the floor than in the case of laying on the old floor.

Coating preparation

An important part of preparing linoleum for laying is acclimatization in the room where you plan to lay it. Roll to give a vertical position and leave in this form. If you yourself have to perform laying in the winter, then you will need to place the roll in advance in the room, allowing it to lie down in a folded form for half a day.

Under conditions of low temperature, the brittleness of the material increases. It is important that the linoleum is heated naturally, and the room temperature is suitable for this.

24 hours before the flooring roll is rolled and cut, leaving the cloth to straighten to prevent the formation of waves. When cutting fabrics, leave 10 cm of stock, taking into account the bends on the walls, placement in doorways, niches and under the batteries. After cutting the linoleum should be given time to lie down, even under its own weight. Alignment will proceed much more efficiently if large blades are pressed down by small ones.

How to pick up materials

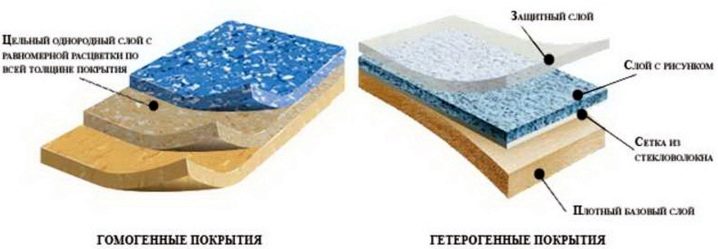

Decide on the type of linoleum. The flooring can be homogeneous (baseless) and heterogeneous, where a special lining is provided - felt or polyethylene.If the surface is flat, the best option is considered the first. When the floors have small irregularities, it is preferable products of the second type. Linoleum with a felt substrate can be used exclusively in a dry room.

The rolled coating is durable, therefore, there are 3 types of material:

- Household type. Scope of models with a low class of wear resistance is limited to living quarters.

- Semi-commercial type. Coatings with a middle class of wear resistance are used in places of medium maneuverability. It may be small office space,

- Commercial type. The high wear resistance class allows it to be used in high-traffic areas.

The choice of the thickness of the sheet material in the case of laying on fiberboard depends on the height of the drops and the number of defects. If the surface is very uneven, then to hide all the flaws, a thicker material is selected.

Choosing a plinth to the linoleum on the material, the design of the coating is crucial:

- For linoleum with imitation of parquet, MDF / PF plinths with wood texture are considered as the best framing;

- For linoleum with other patterns, polyurethane / PVC fillets are most often used as the finishing touch.

When choosing plinths for linoleum in color, the easiest way is to listen to the advice of professional designers who suggest starting from the color solution:

- Floor covering This is a classic. Skirting should be a couple of shades darker.

- Platbands. The main thing is that the framing in thickness and color coincides with the thickness and shade of the platbands.

- Background finish. The dimensions of the room are important here. The baseboards in a small room with a low ceiling are painted to match the walls, as with a contrasting frame it will visually decrease in size.

- Furnishing. The basis is the color of the largest piece of furniture that forms the center of the interior.

- Ram on the windows. This solution looks unusual, especially with non-traditional window frames - gray, beige, black, olive.

- Accent decor. Suitable for those who like non-standard solutions.

Another option is to choose a color arbitrarily, without tying it to anything. But the color palette will then be limited to neutral shades of white and cream.

Instruments

During the installation process, you will need:

- Universal assembly knife for cutting and a set of replaceable edges.

- Construction line-level, short meter line and long from 2 m.

- Connective plinth for a linoleum plant on the wall.

- Spatula with cloves.

- Roller large size.

- Tape measure and pencil.

With special scissors, which include interchangeable blades, it is much easier to cut / trim the material. The markup is made trapezoid blade, and the final pruning - hooked.

From consumables, depending on the chosen method of installation, prepare:

- spackling mixture;

- pressure plates;

- Double-sided tape;

- composition for welding seam joints;

- emulsion glue-mastic;

- trailing edge;

- screws and nails.

How to calculate the material?

Linoleum is sold in rolls of various widths up to 5 m in half-meter increments. When installing, laying the material, you need to retreat from the walls by 1-2 cm. Thanks to the gaps, the coating will not rest against the walls, starting to stray and forming ugly waves. In order not to make a mistake when calculating the material, it is important to carefully measure the room.

Algorithm of actions:

- Measure the width of the room.For accuracy, indicators are taken at the extreme points and in the center. With uneven walls, the greatest accuracy of measurements will ensure the verification of indicators in four or five places.

- Measure the length of the room. The work is performed according to the above scheme. It is important to measure at least three points, which allows you to detect flaws or deviations.

- Rooms with non-standard geometry are measured differently. The baseline data are the length / width of the room at the widest point. Choosing linoleum, on the spot, determine which of the options is more suitable, and how you will place it.

- Accounting for doorways. Often laying means placing the material in the gaps or joining it with the floor covering in the next room. In this case, the margin is 70% of the wall thickness. When planning the installation inside the doorway using thresholds, proceed from the calculation that the door frame will hide the joints.

- Accounting for niches under heating radiators. The depth of the batteries on each side is measured, and then the total width of the coating is added to the resulting value.

- To the obtained indicators of length / width plus 7 cm, which will be a margin, allowing you to perform an exact fit of linoleum under the base.

The presence of a small lapping - your insurance against unpleasant surprises when installing linoleum.

Laying rules for different coatings

Preparation of different surfaces has its own specifics.

Consider the requirements for any foundation under the future coverage:

- It should be dry, even, firm. Use a level to check the flatness of the surface.

- The permissible size of the gaps is 0.3 cm.

- Make sure there are no irregularities, sagging, cracks, blisters, protruding screws, nail heads.

Laying on an uneven rough floor speeds up the wear of the coating, reducing its service life. The initial state of the base determines the scope of preparation work.

If you are going to lay linoleum on a wooden floor, then you need to inspect the floor for dropped fragments, curvature, drops, all sorts of deformations.

Disadvantages are eliminated in several ways:

- You can putty problem areas, and then sand the surface with a grinder or planer.

- To trim the hardboard / particleboard / plywood. Flooring on hardboard is allowed.

- To reanimate the damaged parquet, replacing the missing strips and otkiklevav it.

- To use bulk floors with the leveling ability.

Linoleum is often laid on concrete pavement. In almost every case, such a surface needs to be leveled.

For this fit:

- Cover the hardboard / chipboard.

- Pour self-leveling mixture, if you need to eliminate minor surface drops.

- Make a concrete screed.

New screed dries within a month, and self-leveling mixtures dry for several days, which saves time. Make sure you choose the right linoleum, because not all its varieties can be laid on the concrete floor.

For such bases are suitable such flooring models:

- Materials on the heat and sound insulating basis.

- The main type of alkyd linoleum, having a non-woven / woven substrate.

- Some types of coating, which exclude the possibility of combining directly with the draft version of the concrete base, so you will need to create a dry layer using sheet material.

Consider a few more simple types of bases and the nuances of laying linoleum on them:

- On the carpet. It is necessary to get rid of the obsolete coating in the room, clean the surface and level the problem areas.

- On linoleum. Not everyone wants to do extra work, to spend time and effort on dismantling the old coating, therefore it is limited to laying new linoleum over the existing one. Such a foundation needs only thorough degreasing.

- On the tile. Most often this is done in the kitchen or in the hallway. Loose tiles re-stick. The leveling mass and floating floors Knauf are equally suitable for leveling the surface.

How to lay: a step by step instruction

Linoleum can be laid in 3 ways:

- Free flooring. This method eliminates the fixation of the coating to the base, which is suitable for rooms up to 20 sq m and non-intensive use of the floor.

- By adhesive tape. This option is advisable to use when the area of the room exceeds 20 square meters and possible frequent movement of heavy objects.

- With the help of emulsion glue mastic. This method must be addressed when active coverage is planned in high-traffic areas.

How to cut?

The first stage of the flooring with your own hands involves marking up linoleum and cutting, when the floor was acclimatized in the room, it lay down and smoothed out, getting rid of the specific "new" smell.

There are two options:

- Rolling out the material on the base and cutting the surplus on the ground, which is faster than the second method, but the accuracy of cutting here is questionable if there is no skill.

- Carrying out all measurements with the subsequent transfer to the surface being cut. In this case, damage to the web is possible due to an error in size.

When laying involves the use of a solid canvas, then after 2 days you can begin to install the baseboards, that is, in fact, complete the work.

When you have to put a few canvases, it is important to master the wisdom of docking linoleum:

- When working with monochromatic canvases, place them in the direction of light to achieve a “solid” coating.

- Place the patterned linoleum on the outer wall, making sure that the pattern of the paintings clearly matches.

- The connection of individual fragments implies their docking with each other along the factory edges.

- To make it easier to trim, skirting engineering communications, wait until the material finally acclimatizes and acquires the necessary flexibility. At the cutting points, the coating is alternately bent at the right angles, carefully shaping the contour.

Ready templates should be allowed to rest for several days. The canvases are laid out on the floor, following the cutting pattern, and fixed with massive objects.

Styling process

Fixation methods

First, the floor and the back side of the coating are primed. After a couple of days, when the primed surfaces are dry, proceed to the installation itself.

Work order:

- Apply glue-mastic on that part of the base, which is covered with linoleum and on the canvas itself.

- Transfer it to the treated area, then press it down properly.

- Smooth out the coating with a roller, removing air residue.

When applying mastic, it is important to ensure that the layer is not excessive, as a result of which linoleum can go knolls.

It is also possible to make laying of a covering on dry. Sequencing:

- First you need to glue the perimeter of the base, the joining point and optionally the entire coating with adhesive tape, leaving the protective layer of the tape intact.

- Spread the canvas, cut, give recline.

- Trim place allowances.

- Glue the first panel parallel to the wall.

- Lift the panel to the wall along which it was glued, after which, the attached tapes alternately release from the protective layer, fixing the linoleum on the whole site.

The remaining canvases are glued in the same way, then carefully smoothed, trying not to miss any irregularities, otherwise all the work will go down the drain.

You can produce flooring with glue. Procedure:

- Unscrew the fabric from one edge, evenly distribute the adhesive on the base and leave the cloth on the floor. Roll back the opposite side of the web to the border of the coating area with mastic and distribute the glue along the base of another part.

- A large roller is ideal for quick surface leveling. The tool begins to wield from the middle, gradually moving in the direction of the edges and getting rid of excess air.

- Smooth the canvas next to the walls using a spatula.

- A metal ruler canvas consistently pressed closer to the wall, and then cut off the excess with a knife, pre-tucked into it with a hook blade.

- The second canvas is fixed on the glue in a similar way, and it will need to be glued overlapped onto the surface of the first, going three centimeters.

To make the coating durable, it will take three days. Docking sites can be processed after a day has passed since the installation.

Qualitatively lay natural linoleum using special glue with specific properties. For this reason, increased demands are placed on the base. The surface should be dry, clean and absorbent, and self-leveling mixtures help to achieve these conditions. The roll is acclimatized and must be rewound so that the front side is inside: this will reduce the longitudinal shrinkage due to the action of the water-dispersible adhesive composition.

Work order:

- To make cutting sheets on the arrows on the back side of the canvas.

- Open and mix glue. Distribute it over the prepared base.

- This type of linoleum is glued on the strip, and rolled them using a steel roller, which weighs about 10 kg, which allows you to evenly distribute the adhesive, removing air from the bottom.

- After rolling the joints, the glue is allowed to dry out completely, and then the jointing is performed with a combisher for the welding cord.

- After cleaning the seams with a vacuum cleaner, you can begin soldering, preheating them with a hairdryer to 350 ° C. Finishing trimming is carried out when the seams are completely dry.

How to fix?

Although in the premises of a small footage do not stick the coating, here may require fixing the joints. This is done with double-sided tape. On one canvas, a longitudinal line is drawn, indicating the middle of the adhesive tape. Having pasted it in the right place, the protective layer is removed and two canvases are laid. Linoleum will stick to the tape, and the tape to the floor, and all together will ensure fixation of the coating. It remains to install the plinth and nail or fix on the screws screws that fix the linoleum in places of transitions to other rooms. If the operation does not involve frequent rearrangement of furniture or appliances, then fixing the plinths is enough. For other cases, there is laying on the glue and additional fixing skirting.

Sound insulation in the apartment

If the priority is insulation floors, then to achieve the desired effect should be used simultaneously:

- Three-layer "floating" screed. It is a combination of a hard base, insulating layer and screed. Installation is carried out in a well-dried and heated room. A damping material is used to fill the gaps between the floor and the walls.Plinths are mounted only on one surface - the floor or walls, so as not to form vibro-bridges.

- Sound insulating substrate, the flooring of which is made both separately under linoleum, and as a supplement to the soundproofing “floating” floor. The substrate should be moderately thick and soft. If you plan to lay natural linoleum, then this part should be cork / jute and you should use waterproofing.

- Sound insulation linoleum.

How much should linoleum rest after laying?

It is important to consider three factors:

- linoleum thickness;

- the amount of time the roll has acclimatized;

- room temperature during acclimatization.

To calculate the minimum time (hours), a formula is proposed: a coating thickness (mm) x 3, provided that the temperature is ≥20 ° C or x 4 when the temperature is 10-15 ° C. To align the folds enough days. Of strong excesses, when the foundation is overstrained, of course, there is no talk.

Examples and options

Excellent decorative properties of linoleum confirm numerous design projects. Consider for example the possibilities of this coating in the interior of different rooms.

- For kitchen spaces, the ideal solution is linoleum with imitation of marble, stone, wood or granite. The covering with geometric patterns, imitation of mosaic or ceramics looks impressive.

- 3D linoleum looks fantastically beautiful. This is one of the opportunities to become the owner of a truly exclusive interior.

- A great way to diversify the situation and perform zoning - a combination of linoleum of different colors. This option is especially relevant for open-plan apartments.

- Contrast tandems transform any situation.

- Linoleum under the carpet or artistic parquet can be treated as you like, but not indifferent. In the corresponding interior, it looks amazing. The main thing is to choose the right pattern and color.

- Bright linoleum with a pattern in the form of puzzles is a great solution for a nursery. Small fidgets are attracted by rich colors and everything unusual.

- Natural linoleum can become a highlight in the interior of the premises of various purposes from living rooms to children.

- In the spacious room, you can safely finish the floors with dark linoleum with texture under the laminate or parquet, which will give the interior expressiveness.

How to lay linoleum with your own hands, see the next video.