Subtleties of insulation using foam

Before you start building a building, you must carefully consider the issue of its thermal insulation. At the same time, it is necessary to insulate not only the walls, but also the entire structure.

To date, the construction market is represented by a huge selection of thermal insulation materials, but foam deserves special attention. It allows you to perform high-quality insulation, protecting the building from temperature extremes, and provides a constant indoor climate at any time of the year.

Special features

In construction works, insulation is usually carried out with assembly foam. It is a polyurethane polymer, which in the process of production under high pressure is placed in metal cylinders. The mixture from the cartridge is displaced by gas, expands and, when interacting with air, increases in volume up to 20 times, acquiring a cellular structure.

Foamy insulation is a foamed plastic, which has high strength and ductility. The density and stiffness of the material depend on the components that make up it.

The main difference between foam and other insulating materials is that it acquires its functional properties only after installation. During its application to the surface there is a chemical reaction, as a result of which the mixture hardens and provides excellent adhesion.

Another feature of the material is that it leaves no gaps and seams, which increases its waterproofing characteristics.

Foam is considered a universal remedy, as it can be used for coupling with any kind of surface.

The advantages of foam also include:

- environmental friendliness;

- high heat preservation;

- durability;

- resistance to temperature extremes;

- protection of buildings against the appearance of fungus;

- anti-corrosion properties;

- ease of use.

As for the shortcomings, they are almost nonexistent. The only negative material - the high price. Besides, the applied mixture must be protected from direct sunlight, under the negative impact of which it can collapse.

Kinds

The method of foam insulation is very popular with builders, as this material allows to perform work of high quality, providing reliable heat and waterproofing of buildings. The most popular varieties of such mixtures are: polyurethane foam, polyurethane foam and penoizol.

The polyurethane foam will make a part of assembly foam. This insulation is easy to install, so the work can be done independently, without the help of experts. A mixture of cylinders is applied to the surface by spraying due to the energy of gas compression. After spraying, it hardens and acquires a cellular structure, which is an excellent option for thermal insulation, protecting the surface from moisture absorption and temperature changes.

Polyurethane foam is of several types:

- Facade. It has a high index of frost resistance. This mixture is also used for insulation before laying the roof.

- Ordinary. The material is characterized by versatility and is suitable for finishing both inside and outside buildings.

- With increased strength. Due to the special structure of this mixture has excellent quality and long service life.

- Adhesive foam. It is applied to the work surface under a certain pressure and does not have an air gap.

As for polyurethane foam, with the help of it you can thoroughly insulate any structure. It is made of two components, due to which its structure takes on the appearance of closed cells when it solidifies. Therefore, the polyurethane mixture is resistant to vapor and moisture permeability. This foam is applied in a small layer of 6 cm, usually one barrel is enough for 1 m². Work with the material should be carried out at a temperature not lower than 25 ° C.

Penoizol is not inferior in its qualities. It differs from previous types of foam by its liquid structure and low density. This heater is sold in the form of rigid plates, the granules of which are filled with polynor. Sometimes the mixture is packaged in barrels. Penoizol can be used as a good thermal insulation for buildings constructed from a frame.. Apply it on a dry surface. Penoizol is also often chosen for sealing pipes and other communication systems.

All types of foam have high quality and versatility.The disadvantage of each of the options is considered to be quite high cost.

Therefore, before making a choice in favor of a mixture, it is necessary to make all the calculations and choose the most optimal option.

Scope of application

Foamy insulation is considered a unique material, as for its application in living conditions do not require special equipment. With the help of foam, you can easily make sealing walls, windows and cracks in the roof of the house. The material is suitable for insulation of buildings of the frame type.

Since the foam insulation under the influence of the external environment quickly hardens and turns into plastic with closed pores, It is recommended for certain types of work.

- Installation and connection of various parts of structures. This applies not only to the fastening of the frame elements, but also to the installation of garage doors, door and window blocks.

- Isolation of interstitial space from noise and sounds. This mixture can also isolate the ceiling of the country house or apartment, the installation of hoods, air conditioners.

- High quality thermal insulation. Foam heat-insulated loggias, designs of balconies, garages and hangars. Suitable material for thermal insulation of facades.

- Sealing. Often, the foam mixture is used to repair baths, sealing up the aisles, pipe joints and engineering systems. Technical voids are filled with material, due to which communications last longer.

Scheme

An important point in the construction of buildings is foam wall insulation with the use of special technology, which provides two installation schemes: external and internal.

If you do all the work with your own hands, then first you need to lay the foam polystyrene outside. Then, from the inside, high-quality waterproofing is installed, after which everything is sealed with foam insulation.

When carrying out outdoor insulation, it is necessary to completely eliminate the appearance of an air gap, otherwise condensate will collect on the surface, and later a fungus or mold will appear.

To do this, the foam is fed to the walls sheathed with polystyrene foam from a spray can by spraying. The mixture should be applied to the surface evenly.

Often, external thermal insulation is performed using not only polyurethane foam, but also penoizol, which also has a foam structure and fills cavities well.It is sprayed into the cracks and onto the surface using a special apparatus that creates a certain pressure. Usually, according to this scheme, the cavities between the joints of the brickwork are sealed.. With this technology, complete control of filling voids is performed.

Usually, channels are poured with penoizol in a checkerboard pattern. For this purpose, holes are drilled on the facade and the filling is performed starting from the lower channels. When the foam starts to protrude from the row, it goes higher and continues to fill until the entire surface is insulated.

As for the internal wall insulation, in this case it is worth remembering that the foam should be applied gradually to the prepared surface. The base is pre-cleaned of dust, dirt and moisture, as well as eliminate the remnants of old paint or plaster. After this, the walls are grounded. Then foam is applied.

The thickness of the mixture depends on the degree of freezing of the walls in winter. Therefore, the thinner their base will be, the thicker the insulation should go.

When the foam dries, you can proceed to further finishing the room. If the work is started before the mixture dries out, then the deformation of the front surface of the decorative material and its destruction are possible.

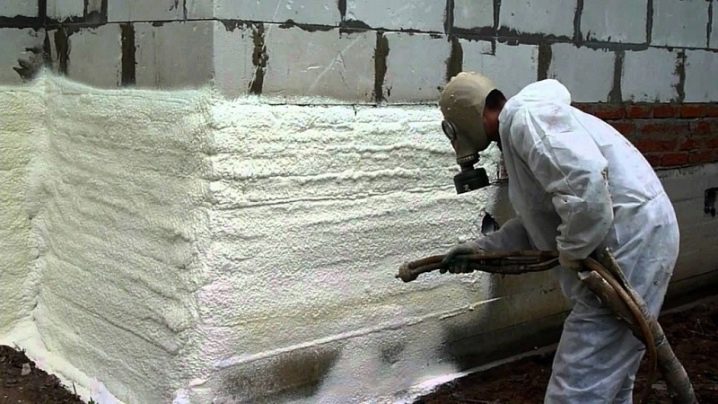

While spraying the foam, it is necessary to adhere to certain security measures: wear protective clothing, a respirator, goggles and gloves.

Reviews

Recently, most builders choose foam as the main insulation. They explain this by the high performance of the material. Judging by the reviews, the foam is easy to install, so it can be used at home, warming balconies or loggias. The material has proven itself not only as a heat insulator, but also as an excellent retainer.. Therefore, the majority of homeowners, in carrying out repairs, choose it for fixing door and window units.

Also satisfied with the installation foam and residents of apartments in multi-storey buildings, where not only heat, but also sound insulation is important. Due to the unique structure, the mixture fits tightly to the surface of the walls and ceiling, reliably protecting them from the penetration of extraneous noise. In addition, many consider the main advantage of foam is its strength and long service life.

Tips and tricks

Before you take up the decorative decoration of the building, you need to worry about its thermal insulation, which will depend not only on the protection of the structure from moisture and temperature changes, but also on the indoor microclimate of the premises.To date, there is an excellent possibility of insulation building foam.

When installing with its help, you need to take into account some recommendations:

- Foam insulation can be started only after a detailed assessment of the surface. The base must be carefully prepared: cleaned of dirt and dust, and dry well.

- If there are cracks on the walls of the building, it is better to choose the type of polyurethane foam. It can also be used as insulation for attic rooms and floors, if the extension of the veranda is open.

If it is planned to make a living room from the attic, then polyurethane foam should be abandoned, especially if the windows face the south side.

Under the influence of sunlight, the material may break down and release harmful evaporation.

- For insulating large areas fit pouring from penoizol. In order to perform installation work, you will need to purchase special equipment for spraying the mixture.

- Insulation inside the building is desirable to carry out assembly foam in cans. It can both seal up the defects of the walls and produce high-quality insulation in small areas.Polyurethane foam is a non-combustible insulation, which is characterized by a dense structure after solidification and consists of environmental components that are harmless to human health.

- External thermal insulation must be performed in a direct way, the technology of which provides for the spraying of foam using a special apparatus or balloon. However, if the surface has significant flaws, then the mixture should be applied in a thick layer, using a special hose that pushes it. To do this, several holes are pre-drilled in the wall.

You can find out how to insulate the attic with polyurethane foam in cylinders by watching the video below.