Winter polyurethane foam: differences from summer, technical characteristics

Polyurethane foam - a material widely used in construction or repair. Manufacturers produce many types of such compounds. One of the most common is “winter” sealant. It can be used in the cold with low humidity.

Thanks to such materials there is no need to stop construction work in conditions of negative temperatures. Before using frost-resistant foam, its properties, technical characteristics and application features should be studied.

What is different from the summer?

Summer and winter mounting foams are implemented in an aerosol container. Their main component is a liquid polymer. In the process of applying the composition when exposed to moisture, it expands significantly.Over time, the substance polymerizes and hardens, forming a strong mass.

In late autumn, in winter and in early spring, summer formulations are not allowed, because when the temperature drops to +5 degrees they become unsuitable. The fact is that in the cold season, the sealant's performance decreases: during frost, the volume of foam can “fall” to a minimum.

The use of materials not intended for cold weather often leads to certain problems:

- the composition does not reach the desired consistency;

- the necessary hermetic base cannot be formed;

- the resulting foam mass is colored immediately when it freezes.

Visually on the difference between the winter and summer foam, see the following video.

Using cold-resistant compounds can avoid these problems. Winter sealants, unlike summer ones, are allowed to be used at negative temperatures.. This is possible due to the unique chemical composition of the substances. They contain specialized additives that allow the substance to polymerize in a frost in conditions of low air humidity.

And in the summer, winter foams retain their effectiveness.

Specifications

There are many varieties of winter sealants on the market that differ in cost, quality, and application conditions. Most formulations are designed for use at temperatures from -10 to +35 degrees. Some manufacturers produce materials with which you can work up to minus 30 degrees.

Consider other technical characteristics of the winter foam:

- Foam volumemeasured in liters. From a 300 ml bottle it is possible to obtain up to 30 liters of sealing mass. This indicator is always indicated by the manufacturer on the package. However, it should be borne in mind that with decreasing temperature the volume of the material will be reduced.

- Primary expansion. This characteristic is responsible for the percentage increase in the volume of the substance. This indicator for different sealants ranges from 30 to 50%.

- Porosity. The quality of the sealing mass porosity can reach 88%.

- Adhesion. The ability of the foam to "mate" with the base. As a rule, all winter compounds have good adhesion. They adhere to concrete, wood, brick, metal and other materials (except Teflon, silicone, polypropylene).

- Viscosity. The consistency of the mass depends on this indicator.The higher the viscosity, the better the sealant will “cling” to the surface and drain less from the base.

- Drying time. For winter foams, the drying time is 4 to 10 hours. This period is enough to form a crust on the surface of the foamed mass. During the day it is not recommended to touch the layer until it is completely dry. Otherwise, there are great risks to the integrity of the shell.

- Shrinkage. For quality materials, this figure should not exceed 4%.

With greater shrinkage, there is a possibility of breaking of the stiffened foam and its deformation, which leads to poor sealing.

On the packaging of some compositions are additional technical parameters. They indicate how the sealant will work in certain conditions (for example, when exposed to high temperatures or power loads).

Kinds

Polyurethane foam is classified according to several criteria. She is professional and household. For the first one, it is necessary to use a special dispensing pistol, while household sealants are stacked using a special plastic tube that comes with the material.The main difference between the two compositions is the secondary expansion. In professional sealer, this indicator is much lower than that of domestic.

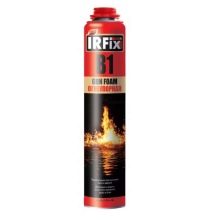

Foam is also classified according to the class of flammability:

- fireproof B 1;

- self-extinguishing B2;

- combustible in 3.

Fireproof - Special Purpose Foam. It is often used in the installation of fire doors, for sealing joints in the construction of fireplaces, stoves and other equipment for space heating. The refractory composition is able to withstand the onslaught of fire for 6 hours. All this time, the foam will not burn or melt.

The main visual difference between flame retardant and ordinary sealant is Colour. In flammable masses, it is white or yellow, in non-flammable pink color predominates..

Scope of application

Due to the high expansion rate and good adhesion to almost any material, frost-resistant foam can be used for both internal and external works. Due to its ease of use and reliability, it is often used not only by amateur masters, but also by professional builders.

Mounting sealant may be required when installing doors and windows, to insulate pipelines or cable ducts. Material also can be used as a sealant when repairing gaps, cracks, joints, dents or voids inside or outside the room.

Sometimes foam is used as insulation to increase the insulation of heated or unheated objects.

Mounting sealant can be used as a fastener for fixing wall panels or sheets of insulation. Thanks to the use of the material, it is also possible to mount wall soundproofing products.

How to use?

Before using a sealant bottle it must be kept in a warm room for at least 12 hours. Before using the composition, it is necessary to prepare the surface: clean it from dirt, dust, snow or ice. It is acceptable to wet the base with water using a spray bottle.

When sealing joints or seams the balloon must be kept upside down. In this case, it is recommended to fill approximately 1/3 of their gaps.. Before use, you must not forget to shake the can vigorously for 20 seconds.Such manipulation will contribute to the rapid mixing of components and increase the yield of the sealing mass.

If necessary, the foam can be applied in several layers. However, the subsequent one can be laid only when the previous one is set (for this, at least one day must pass). The applied mass must be protected from snow or sunlight.

Neglecting this recommendation may lead to a decrease in the protective properties of the insulating seam.

Storage rules

It is necessary to store the container with mounting foam upside down at the temperature specified by the manufacturer (permissible temperature range is from +5 to +30 degrees). If these conditions are not followed, the sealant may lose the performance properties declared by the manufacturer.

If the cylinder has been in the cold for a long time, it should be kept warm for a day. But it is also allowed to warm the container with hot water (the temperature should not exceed 50 degrees).

Manufacturers

Domestic and foreign companies are engaged in the manufacture of winter assembly foam.

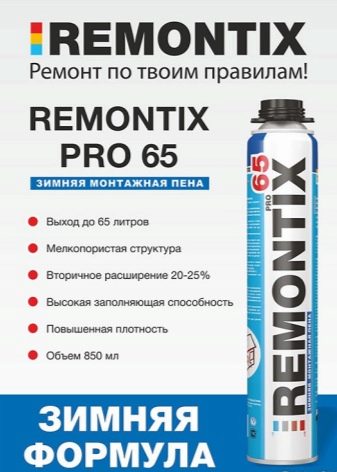

The leading sales positions are occupied by products of several brands:

- Soudal.One of the largest manufacturers of aerosol sealants. Delivers various types of mounting foams for over 20 years. Soudal compounds are distinguished by excellent technical and operational characteristics, uniform consistency, high degree of thermal insulation.

- Penosil. The materials of this brand have good adhesion with most materials, low secondary expansion, high mass yield.

- TechnoNIKOL. Products of domestic production. Single-component materials are easy to use, have good technical parameters, but they are inexpensive.

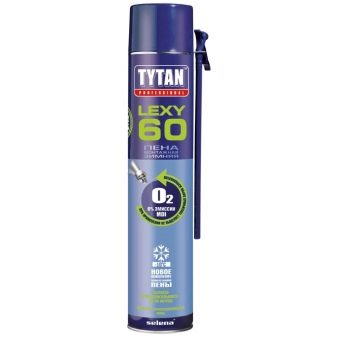

- Tytan professional. Household winter sealants designed for use at ambient temperatures up to -20 degrees. Eco-friendly materials with absolute safety for health even at the time of application.

Before you buy foam, you should study its technical characteristics and operating conditions. If necessary, you can contact the seller for informational support. It will help to understand the extensive choice of construction products based on the requirements and financial capabilities.the buyer.

For information on how the foam behaves in the cold, see the video below.