Makroflex: Pros and Cons

The list of construction works often includes the need to connect elements made of different materials, eliminate gaps and holes, and fasten panels to various surfaces. It is for this purpose that a mounting foam is used, designed to ensure quick fixation of construction elements and allowing a considerable reduction in the costs of certain construction operations. A special place among the various types of this product takes a foam from the brand Makroflex, which has excellent technical characteristics and high quality.

Special features

It was from the beginning of the production of Makroflex foam that the history of the eponymous manufacturing company, which is now a part of the Henkel group (the country of origin - Estonia), was popular in many countries of the world. Today, the company is known for an extensive range of various sealants, adhesives, cleaning fluids and tools.Such a variety of products, and most importantly, its quality, makes the Makroflex brand high-ranking in its segment of the world market.

Foam for mounting Makroflex or polyurethane sealant is available in tubes with different volumes. The substance consisting of a prepolymer and an ejecting gas hardens on contact with air, which ensures high-quality filling of cavities. For this product in accordance with its main purpose, the following features are characteristic, which led to its widespread use in construction work:

- a high degree of adhesion (adhesion) to most building materials (wood, concrete, stone, metal and other building elements, etc.);

- high heat-insulating and sound-proof qualities;

- preservation of strength for a long time;

- high filling qualities;

- hardened material is non-toxic and non-flammable;

- dosage accuracy (when using a gun) allows you to save on material consumption when using it;

- possibility of organizing breaks in work.

Specifications

The official manufacturer declares the following technical parameters of products from Makroflex, which in most cases corresponds to reality:

- The final hardening time of the used substance is exactly one day. Under conditions of temperature above + 20 ° С, the solidification time decreases to 1.5-2 hours.

- Temperature resistance of the product is from -50 ° С to + 100 ° С.

- The density of the solidified substance is 25-35 kg / m3.

- The ignition temperature of the foam is about 400 ° C.

- The degree of fire resistance of the hardened product is from B1 (fire resistant) to B3 (combustible).

- Foam output - from 25 to 50 liters, depending on the volume of packaging. With such characteristics, Makroflex products provide a substance output of about 10% higher than that of counterparts from other brands.

- Reliable level of strength - up to 3 N / cm² in compression and tension.

- The storage time of the product in the package is up to 15 months (it is better to keep the tube vertically to maintain tightness). Storage temperature is not lower than + 5 ° С. Storing the product directly under solar radiation is strictly prohibited.

- The performance of the foam application is limited by the ambient temperature. The product displays its best qualities at a temperature not lower than + 5 ° С. Developed and sold a special composition and to work in the winter. Nevertheless, it is important to know that at low temperatures the foam hardens longer, respectively, and its filling properties are reduced.

Kinds

The range of products from Makroflex contains an extensive list of substances of various quality and applicability.

- Makroflex Shaketec (Winter) - all-season foam used in dry and cool conditions (-10 ° С - + 25 ° С). Provides reliable noise insulation, is able to completely fill the voids when repairing roofs, installing doors and window openings.

- Makroflex Premium on the basis of polyurethane refers to the type of professional installation tools. When applied, it increases its volume by about 2 times. Applied to the surface to be treated with a pistol. The high degree of adhesion of a substance allows its use in working with wet structures. It is sold in cylinders with a capacity of 750 ml.

- Makroflex Premium Mega - professional level winter remedy. Used at a temperature of -15 ° C, it provides a reliable degree of adhesion with various building materials.

- Makroflex Pro applied with the use of special tools, the practical yield of the material reaches 65 liters. The composition does not contain chlorine, fluoride or carbon inclusions, is used when insulating windows and doors, filling various voids. As a sealant used for insulation of premises.

- Makroflex Whiteteq - an innovative product. White is a polymeric substance made by the Whiteteq method, based on a process of perfect cleaning of the constituent mixture of inclusions. This procedure leads to the formation of a crystal-white shade of the material, microporous Quattro structure and, as a result, an increase in the level of protection from exposure to ultraviolet radiation.

The tube contains a special ball that provides a high degree of homogeneity of the substrate during mixing. There is also a safety valve that helps preserve the quality of the material. It is used in the process of isolation and removal of voids, with the fastening of various elements.

- Makroflex "Penocement" completely replaces weighty coolies with cement, additional tools and water, is able to glue various elements and blocks easily and quickly. It is used for installation of panels, equipment of stair steps and window sills. The scope of the composition is somewhat limited - it is not recommended to apply it on foam concrete surfaces.

Makroflex sealants constitute an independent product category:

- Makroflex TA145 - super heat-resistant material used in conditions of high temperatures or sudden temperature changes (wind containers, ceramic panels of cookers).Hardening substance TA-145 contributes to a moist environment. In the composition there are no solvents, the tool has no odor and dries within 1-2 days.

Comparative studies indicate that Makroflex sealant has several advantages over conventional sealing compounds. In case of fire, the material burns, without forming cracks, where the products of combustion can penetrate. The finished coating can withstand from -65 ° C to + 315 ° C.

- Makroflex AX104 - on top of a universal sealing substance, including silicone, used for self-sealing of building elements during the production of works in closed conditions and in the open air. Possesses excellent adhesion to materials from glass, ceramics and aluminum. The product contains anti-fungal components.

The substrate is resistant to UV light. Favorable temperature for installation - + 5 ° С - + 40 ° С in the absence of moisture. Stored up to 18 months.

- Makroflex NX108. It is characterized by high adhesion with wood, glass, metal, ceramic, plastic, concrete surfaces. The product is resistant to rust and ultraviolet radiation.The advantage of the substrate is the possibility of its use in conditions of high humidity (for example, in the bathroom).

- Makroflex FA131 - effective frost-resistant polyacrylic product. Used in the processing of suture elements and structural defects, internal and external works. The material is resistant to extreme temperatures. Do not recommend its use in conditions of high humidity. The main functionality is the treatment of suture elements and defects in concrete, brick, wood and other types of coatings.

- Makroflex SX101. Performs sanitary functions, because it contains antifungal fungicides. Used in conditions of high humidity. Substance is white or without color.

It should not be used to treat aquariums, because the substrate contains antiseptics. In contact with the stone, stains may appear. Application is limited by temperature conditions - + 5 ° С - + 40 ° С.

- Makroflex MFf190 - powerful extra strong white gluing substrate, which is based on the aqueous dispersion of polymers. Used in the process of gluing products from plastic and wood for internal and external works. Acts quickly and efficiently.

There is a certain classification, dividing foam into household and professional products. When sealing small gaps, installing small products, it is irrational to acquire professional foam. In addition, household foam more increases in volume than professional. It is important to know that the shrinkage of professional foam is not large (within 0–3%); for household appliances, this parameter is up to 5%. Shrinkage should not exceed 5%, since this excess leads to the deformation of the substance, and sometimes to unwanted ruptures.

On this basis, Makroflex 750 ml professional foam is used in more demanding cases, for example:

- thermal insulation of heat networks, roofs;

- filling various voids;

- construction of insulating bulkheads;

- erection of fire-resistant structures (fire-resistant Makroflex FR77).

Scope of application

Consider the main areas of application of foam from Makroflex:

- For installation of windows and doors. It is important to remember that the use of the material does not preclude the use of the necessary mechanical fasteners, and especially does not replace them. To avoid the formation of defects, it is necessary to install spacers.

- In the process of sealing joints, cavities, joints and suture elements.

- For sealing docking lines for roofing.

- During the sealing of pipes in buildings.

- For self-sealing of cracks and holes.

- Filling of emptiness in building materials.

- In order to thermal and sound insulation of structures of the premises.

The advantages of Makroflex foam are:

- no need for special preparatory manipulations;

- versatility and breadth of use;

- ease of use;

- affordable prices;

- reliability;

- fast hardening compared with cement composition;

- the ability to work with wood, stone, metal, PVC and chipboard coatings, concrete products and foam concrete;

- wide temperature range of application;

- eliminating the formation of dust and pollution in the production process.

The disadvantages include the following points:

- The loss of performance of the material with prolonged exposure to ultraviolet radiation. To protect it using coloring water-based formulations.

- The need to use in the work with the substance of the spec. remedies, because foam adversely affects the respiratory organs, skin, irritates the mucous membrane of the eyes.

- Decent consumption of material.

How long does it dry?

The rate of drying of a substance depends on a number of factors: humidity and temperature of the medium, temperature of the substance itself, its volume and type. At a temperature of + 20 ° C, the substance dries in 2-3 hours, but its final solidification occurs only after half a day. At lower temperatures, the substance dries within 24 hours. During the period of primary hardening (2-3 hours), the substance can be cut, puttied and painted. Hardening time is reduced by moistening surfaces, which also contributes to an increase in adhesion to various processed materials.

Consumption

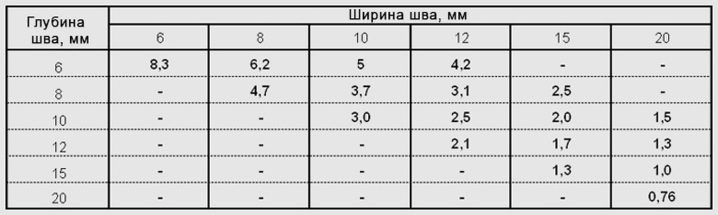

The factors that determine material consumption are the size and shape of the seam applied to the surface. With a rectangular cross-sectional shape, an approximate calculation of the flow rate per 1 m of the seam can be made using a simplified formula: G x B, where G is the depth of the seam (mm), B is the width of the seam (mm). For example, if the width and depth of the seam is 6 mm, then the flow will be 6 x 6 = 36 ml per 1 m of the seam. With a triangular seam, the flow formula will look like: ½ B x G. That is, at equal width and depth, for example, 12 mm, the flow will be: 6 x 12 = 72 ml per 1 meter of seam.

In the case of the composition "Penocement", according to experts, when performing 10 m2 of laying in 1 brick, about one standard tube of 850 ml volume is consumed.Approximately the same amount goes when gluing gypsum panels of 12 m2.

The manufacturer, as a rule, indicates on the package the maximum possible foam output. It is important to understand that such a volume is achieved by strictly following the rules of the instruction and under favorable environmental conditions. When calculating the volume, it should be taken into account that expansion of the foam occurs in two stages - primary and secondary. The first stage follows immediately at the moment when the material leaves the tube. The second - at the end of the polymerization cycle of the substance.

The high-quality foam at the second stage expands by 25-30%, which should be taken into account when filling various gaps and cavities. That is, when filling 1/3 of the space, it must remain hollow in order for the swollen foam not to go far beyond the cavity. In this context, highly expanding household sealants, for example, Titan, and products with a medium and low expansion index, which are used for more delicate works, for example, Makroflex, are distinguished.

Tips and tricks

The following tips and tricks will help you to qualitatively, productively and safely apply foam from the Makroflex brand:

- Before using the product, we recommend holding it at room temperature for about 12-14 hours, this will allow the substance to take on the optimum condition for use.

- Before starting, the processed elements are cleaned of dust. Porous surfaces are moistened with water from the sprayer. Work is carried out at humidity more than 60%. If the humidity is low, the surfaces are moistened. It is not recommended to work on surfaces covered with ice or covered with ice. To prevent substance from getting on other surfaces, they should be covered with polyethylene.

- The ready-to-use substance should be of a uniform consistency, therefore it is recommended to shake the tube immediately before use.

- During operation, the cartridge must be held upside down, regardless of the method of applying the material to the coating (manual or using a gun).

- Given that the foam increases significantly in volume, when installing windows or doors, you need to install specials. spacers to avoid deformation of the structural elements.

- If it is necessary to arrange a break for more than 15 minutes before starting again, it is important to clean the pipe from the dried pieces of foam.

- Foam stains that did not have time to harden are easily cleaned with special means, but now the frozen part can only be mechanically cleaned (cut off).

- Makroflex is best used when filling cavities and seams with sizes of 0.5-8 cm, since the substance may not reach the desired depth in narrower places, resulting in voids. More voluminous seams and crevices may not withstand the heavy mass of the product.

- In order to obtain the highest foam output, the cartridge tip must be cut at a 45 degree angle.

- Avoid contact with the finished substance on the skin and organs of vision, it is fraught with severe irritation. In case of contact, it should be quickly washed off the skin, and the eyes should be thoroughly rinsed with warm water.

- It is not recommended to remove a completely unused tuba from a pistol. Replacement is made only if the tube is completely empty.

- Installation work should be performed only in places with effective ventilation, since substances that are harmful to the respiratory system are released during the spraying process. Do not forget about protective equipment!

- It is strictly forbidden to use the material on hot surfaces and old electrical wiring. This may cause an explosion.Next to the sealing solution is not recommended to smoke.

An analysis of the reviews and reviews of the product shows that the vast majority of specialists and those who first applied themselves Makroflex foam, recommend this tool to use, based on its very real advantages:

- practicality and ease of use;

- short curing time;

- quite reasonable price;

- wide selection for specific conditions of use;

- reliability and durability.

As a rule, positive reviews are also based on the elementary adherence to the instructions and the observance of safety precautions when using the product.

Review of Makroflex construction adhesive foam, see the following video.