Fire resistant foam: material features

Fire represents a great threat to human life. That is why rather strict requirements are imposed on the fire safety of buildings. Non-combustible building materials help to avoid the occurrence and spread of fire. Among such products is to provide a fire-resistant foam mounting.

What it is?

Fire safety is the main task that is set for builders during the construction of structures. Fire-resistant building products everywhere displaces materials that easily melt and release toxic substances in the process of thermal exposure. Fire-fighting polyurethane foam has a specific feature that distinguishes it from conventional products - the composition is resistant to exposure to open fire.

Foam has a certain classification regarding the level of inflammability, which depends on the manufacturer, brand and modification. Refractory foam is a relatively new material presented on the construction market. Products do not flow down when applied to vertical substrates. In addition, the composition of high quality fills the cavity.

Among the features of the material is a good level of adhesion to brick, metal bases, wood, various polymers, glass and cement. Products are essentially a one-component or two-component sealant, as a base for which polyurethane acts. Implemented composition is already completely ready for operation. Immediately after applying the foam, the components of the product are polymerized upon contact with moisture contained in the air.

Among the main components of the assembly foam are substances that give the product unique characteristics relating to heat resistance, as well as impermeability to smoke and gas.

It is necessary to highlight the main technical characteristics of the composition.

- Products are resistant to moisture, as well as the development of fungus and mold on the base.

- The foam is resistant to temperature fluctuations ranging from +1000 C to -60 C. The existing additives give the material the opportunity not to lose its strength and elasticity.

- Based on the type of product, the time interval varies, at which the product retains its resistance to elevated temperature and does not ignite.

- Penet is characterized by self-extinguishing flammability. Upon contact with a source of fire, the substance does not drain from the base, and during the cessation of contact with fire, the material itself fades.

- Products have soundproof qualities - the limit for most compositions is about 41 dB.

The disadvantages of fire-resistant polyurethane foam include its sensitivity to ultraviolet radiation. Therefore, it is necessary to provide the facility with an appropriate level of protection.

Composition

The composition of heat-resistant products include the following components.

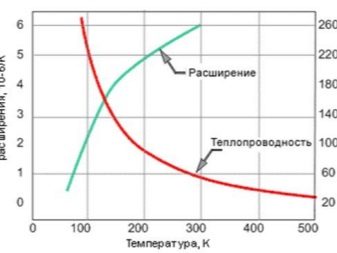

- Catalysts. Due to the presence of such substances, the foam after application can expand and fill the designated area as quickly and efficiently as possible. In addition, they provide the material with low thermal conductivity. It is catalysts that allow the use of foam in the work even at sub-zero temperatures.

- Frothers give the composition a porous structure and give it the opportunity to quickly freeze, taking the form of an opening. Such ingredients are responsible for indicators of adhesion of the material to the working surface, the consumption of the composition and coefficient of expansion directly depend on them.

- Included stabilizers responsible for the uniform distribution of the foam and the tightness of the formed layer of the substance. In order to activate the effect of stabilizers, the balloon with foam must be shaken before use.

- In addition to the above components, the foam contains gaswhich allows her to exit the balloon. The substance is a mixture of gases dissolved in the polymer.

In order to distinguish foam among other mounting tools, manufacturers produce fire retardant products of red or pink color. Similar coloring allows to avoid mistakes and confusion during the acquisition of material and work with it.

Fire Resistance Classes

Fireproof construction products should be used in all premises that will be used by man. Polyurethane foam has several classes of fire resistance.

- IN 1 - composition, which has the highest physical extinguishing characteristics: the substance does not support combustion at all, spontaneously decays after contact with fire ceases, retains its properties for a long period of time when exposed to flame. Products are recommended for use in buildings with a large crowd of people.

- AT 2 - a material that has an average flammability. Foam can release toxins when it melts, but stops burning immediately after the fire is removed from it. It can be used for rooms with an average level of permeability of people.

- IN 3 - composition, which is rarely used for construction works because of its flammability.

Another indicator that is assigned to products is the fire resistance coefficient. This indicator is marked as follows - EI, where the letters are followed by the digital values inherent in one or another of the mounting foam. There is the following products.

- EI 30 - the structure keeping the properties within 30 minutes. It is allowed to be used inside buildings, where possible as quickly as possible evacuation in case of fire.The number of people in the building can be from 15 to 300 people.

- EI 90. Based on the data obtained during the testing of such a material, it follows that the foam, when heated to 1000 C, is stable and does not lose its qualities for about 90 minutes.

- EI 120, 150 - types of polyurethane products that have the highest level of protection during ignition. The use of such a sealant is quite extensive. The group of rooms where the use of foam is recommended includes buildings with a high level of danger associated with fire. With the help of such compounds, cable penetrations are put in place, the products are used for arranging stoves, chimneys, and repairing cracks.

Other characteristics

All mounting foams are divided into two groups, taking into account the resistance of the substance to low temperatures.

- Winter heat-resistant polyurethane foam. Its use is permitted in buildings or in open areas where the air temperature can be -10 C. This material is used as an all-season product.

- There is also a product that can be used when temperature not lower than +5 С.

Based on the number of active components of the foam, There are two types of sealant.

- Single component materials. The process of solidification of substances occurs under the influence of humidity. Professional installers advise to additionally wet the working base to increase the adhesion of the composition to the surface.

- Two-component foam produced according to GOST, its thermally expanding ability manifests itself without participation in the chemical process of external factors. The material hardens due to the inclusion of a special reagent. These products are frost-resistant and therefore used for work in the winter.

Scope of application

Fire-resistant foam must be applied on those areas where fire safety plays an important role. Given the SNiP, similar products are necessary for the following work:

- with the help of fire-resistant polyurethane foam, seal deaf or through gaps in fire barriers;

- the material can be sealed doors and window units for the purchase of fire-resistant and smoke-proof structures;

- foams isolate voids in walls and interfloor ceilings;

- the composition is the sealing chimneys;

- using foam to glue insulating materials;

- similar products are used in the creation of soundproof structures and screens;

- fire-resistant polyurethane foam acts as a thermal insulator in the cooling systems of climatic equipment;

- material is required to use during the installation of heating networks;

- cable penetrations are made using fire-resistant foam.

Manufacturers Overview

Fire-resistant foam must be sold with a certificate confirming its production in accordance with the established GOST. In the current market can be identified as follows companies that sell products.

- Soudal. Polyurethane foam of this manufacturer has a pink color, the material is sold in cylinders with an adapter under the gun. Products have positively proven themselves in the course of work, due to which the products of this company are in demand in the modern construction market.

- Foam "Fire" produced by a Russian manufacturer. The recommended temperature at which it is necessary to work with a substance is +5 C, before use it is recommended to heat the balloon itself to +18 C.This product has a high cost and good performance.

- German products Makroflex On the shelves of supermarkets presented a wide range of mounting foams, including fire-resistant products. It is recommended for use in the process of sealing seams in panel-type houses, when fixing window and door frames, as well as during laying of sewer and heating utilities. All products are tested and fully comply with European quality standards.

- Foam DKC It is recommended for work on the insulation and fastening of window and door structures, when installing electrical equipment. Products can be used only for interior work in rooms with a small flow of people.

In addition, the market presents the products of the companies "Tehnonikol", Hilti, Waller, Penosil. These brands are also in demand by many consumers.

How to calculate the flow?

Thanks to the use of online resources, it is possible to perform calculations related to the consumption of flame retardant mounting foam using online calculators. In addition, the information provided by product manufacturers can also help in resolving this issue.However, the obtained values do not always coincide with the actual consumption figures, therefore, when obtaining results, it is worthwhile to increase them, in order to avoid situations when the cylinder with the material ends earlier than the scheduled date, and there will be unprocessed areas.

In addition, different types of foam may have different flow rates. Therefore, the following points should be taken into account when calculating:

- quality and type of material composition;

- the depth of the voids that need to be filled with the agent, taking into account adjacencies or recesses;

- method of processing foam (using plastic tubing or a special gun);

- master qualification;

- the presence of the dispenser in the cylinder;

- uniformity of the applied layer of the composition;

- foam volume increase rate;

- temperature and humidity levels at which the area will be processed.

In the estimate documentation, the consumption of material is indicated when working under optimal conditions by a professional expert, as well as when using a pistol. Actual conditions of work may be different.

Sealants are of three types:

- weakly expanding;

- medium extension;

- strongly expanding.

Such differences can drastically affect consumption. Therefore, the values obtained will be only approximate.

Useful tips from the pros

To do the job as well as possible, you should stick to basic rules for the operation of fire-resistant mounting foams.

- When using conventional material, the optimum surface temperature should be between + 5 ° C and + 35 ° C.

- The cylinder's working temperature is +10 С - +30 C. It is not worth heating the composition, it is enough to hold the cylinder for some time indoors.

- Store products need to neck down at room temperature.

- Before starting the process of filling the joints with foam, shake the balloon thoroughly and check the level of the composition.

- It is best to work with a wetted surface, but the presence of drops on the basis can not be allowed.

- The seams must be filled with material not more than a third of the entire area.

- After 24 hours, the foam should completely harden, which allows you to close it with plaster or other composition.

When buying, you need to focus on the following points.

- The weight of the cylinder. The cost of production directly depends on the volume.

- The name of the brand. Today you can find products made in China, whose name, at first glance, will be very similar to well-known brands. In this case, you must be vigilant.

- Fire resistance class It is necessary to select based on the requirements for the level of fire safety at a particular facility.

For an overview of Zigger PF flame retardant foam, see below.