Features of the choice of Driva dowels

When working with drywall it is important to choose the right additional elements. Otherwise, you can ruin the base. Experts recommend using Driva dowel when working with the above material and other types of bases. The Driva plug-in spike has high technical characteristics, such as practicality, reliable grip, durability and others. Special cutting on the surface of the dowel provides a reliable connection, eliminating the loss of the screw from the socket.

Spheres of use

Depending on the basis, it is necessary to correctly determine the approach and workflow, taking into account its individual characteristics.Drywall sheets are fragile and easily damaged in comparison with wood, concrete, stone and other common materials. To use nails or screws without prior preparation can not be. Professionals fix sheets with dowels and screws.

The Driva key is actively used to work not only with gypsum boards, but also with chipboard. The element is inserted using a screwdriver or a screwdriver without special training. The installation process is not particularly complex. Special tools and high skill professionalism is not required.

While working in the room does not accumulate dust and a large amount of pollution.

Dowels from the above manufacturer are used by both specialists from the repair sector and ordinary buyers who prefer quality. If necessary, the element is easy to dismantle without damaging the base.

Specifications

The Driva brand produces two types of fasteners, namely:

- plastic dowels;

- metal elements.

Nylon, polyethylene and polypropylene are used to make plastic insert studs.. The combination of these elements creates a durable material. The production of metal products involves the use of a special alloy of low carbon steel, zinc and aluminum. Each of the above elements can boast of durability, practicality and durability.

For the products of the brand Driva constant and intensive load is not terrible. Metal shkant easily transfers the weight of 32 kilograms.

Plastic options retain their shape and performance under load up to 25 kilograms.

Features of plastic and metal elements

The plastic used by Driva to make dowels is not deformed during use. The material is able to withstand frosts up to 40 degrees Celsius above zero. Despite the strength and strength, the element is lightweight. Affordable cost has played an important role in the popularity and high demand of the product.

To prevent the metal dowels from deteriorating, they are treated with a special protective solution against corrosion. Moisture resistance over a long service life is guaranteed.

Appearance and size

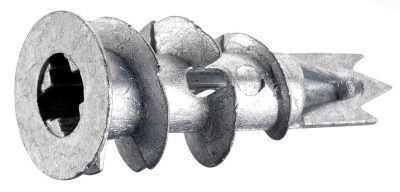

The visually inserted spike is a hollow rod with a screw thread. The head of the element is flat. At the top of the cap there is a special hole designed for a Phillips screwdriver. The sharp tip of the dowel serves as a screw. It is thanks to him that the product is easy to install and fasten on a sheet or surface.

The dimensions of the Driva elements are as follows:

- 15x23 and 12x32 mm (plastic);

- 14x28 and 15x38 mm (metal).

Benefits

Shops specializing in building and finishing materials offer a huge variety of dowels, differing in price, material, size and other features. Among the rich assortment stands out the products of the above brand. Whether it is a “snail” insert thorn or a product with a drill, each element has a number of advantages.

The advantages of choice are as follows:

- affordable cost;

- wear resistance to temperature and external loads;

- durability, practicality and reliability;

- resistance to moisture and corrosion;

- long service life;

- maintaining a large weight;

- lack of preparatory work;

- simple installation and removal;

- fire resistance (metal dowels);

- frost resistance;

- resistance to adverse environmental effects.

disadvantages

Dowels for gypsum and have minuses. Plastic products have taken over the shortcomings of the material from which they were made. Even the densest plastic can deform under excessive load. As a result, not only the spike will deteriorate, but also the plasterboard panel. When choosing metal fasteners, it is necessary to take into account not only their technical characteristics, but also the density of the sheet, because the metal is stronger and more durable than drywall.

Violation during assembly and disassembly will ruin the base.

Types of models for drywall

There are two types of dowels for GCR.

- Passable. Such elements are ideal for placement on the ceiling. The best choice for fixing lighting, sports equipment, spotlights and other things. They are suitable for mounting large-sized chandeliers. The plug-in dowel of the spring type includes a mechanism of the same name, a threaded metal rod and folding locking wings. The tip of the dowel can have a different shape: ring, screw, half ring, rod.The type of product is chosen in accordance with the object that needs to be fixed.

- Unclench. Outwardly, the dowel looks like a plastic or metal cartridge. There are cuts on the element. In the process of passing the screw inside the mount, the cuts begin to unfold. This type of insert spike is considered the simplest.

Mandatory criteria

The key used when working with drywall should fully comply with the following conditions:

- special anti-rust coating;

- high-quality metal alloy;

- the presence of special elements for strong and reliable fixation GKL to the base.

Manufacturer Driva in the manufacture of fasteners for drywall uses harpoon and expansion principle of operation. He is the key to excellent fixation.

Recommendations

- To make the right choice of fasteners, you need to determine exactly what tasks and responsibilities are assigned to them.

- You must first calculate the load and weight of the structure. From this characteristic will depend on the size and length of the screw, and hence the dowel under it.

- Metal dowel is ideal for hanging heavy furniture,for example, a closet on the wall. For additional frame elements are also used metal elements.

- To fix the decorative elements with low weight (paintings, photographs, shelves, lamps), it is recommended to purchase plastic dowels.

Their cost is more favorable in comparison with metal options.

Fastening rules

When working mounting hardware, you must adhere to clear rules. This is the key to excellent results and reliable grip. Listening to the following recommendations, everyone can fix the dowel to drywall without having professional skills.

The order of work consists of the following stages:

- it is necessary to precisely calculate and designate the locations of the elements. When using profile guides, you need to securely fix them, pressing the gypsum board to the profile;

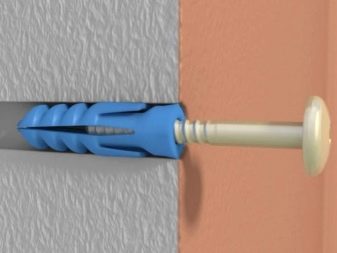

- holes in the sheets are made with a screwdriver. The recommended drill diameter is from 6 to 8 millimeters. For metal dowels, this procedure is optional. Thanks to the sharp tip, they can be immediately inserted into the canvas;

- you need to gently place the insert spike in the hole using a screwdriver or a cross-type screwdriver.The speed of rotation of the screwdriver drill when working with plastic dowels should be lower than when placing metal elements;

- it is necessary to secure the object by screws or self-tapping screws. It is necessary to take into account the maximum weight load when attaching items.

You can learn how to install the drywall yourself by watching the video below.