Ready-made and homemade versions of the lift for drywall

Finishing work, involving work with plasterboard sheets, can be done at high altitude. Finishing the ceiling surface becomes a difficult test for the human body. Due to the considerable weight and size, it’s inconvenient to keep the plasterboard sheet for a long time, even with assistants.

Specialists in this situation use specialized lifting mechanisms. But for those who cope with repairs on their own and do not need constant use of the lift - its acquisition does not seem to be an entirely practical solution. In this case, you can make the lifting mechanism yourself.

Purpose lift

The main task of the lifting mechanism for drywall sheets is to deliver and hold them at the required height during the installation work.This makes it possible to carry out the installation of drywall on their own, without any help, and greatly facilitates the installation process.

Over time, experts have found ways to use the lift, which help to perform other construction tasks:

- When fixing the laser level on the lifting mechanism, you can better mark the necessary elements on the surface and bypass all sorts of inaccuracies. The laser is fixed with special clamps and raised to the desired height. It should be noted that the use of this method produces the most accurate marking of the ceiling surface and the corners in the room.

- It is an indispensable mechanism for the installation of a frame construction for plasterboard sheets in inaccessible areas. The lifting mechanism makes it possible to fix the drywall at the time of its fixture to the ceiling surface.

- In addition to the plasterboard sheets, the lifting mechanism greatly facilitates the installation work with any other massive hanging equipment. For example, air conditioning, chandelier or ventilation system.

Manufacturers today produce a wide range of lifting mechanisms, the cost of which may be unreasonably high.Often they are bought by a construction team that specializes in installation work with plasterboard structures. But they do not neglect the opportunity to build a lifting mechanism with their own hands.

Kinds

According to the field of application, the drywall elevator is divided into:

- wall (the location of the table vertically, which allows installation of gypsum sheets on the wall surface and partition);

- ceiling (table is located vertically to work on the ceiling surface);

- universal.

All of them differ in the placement of the table, which is used for fixing the drywall sheet.

Universal lifting mechanism is the most practical device, because the table for mounting can change the degree of inclination.

Besides, The lift is divided into a device with manual control and electric drive. In the first case, the lifting of building materials is carried out by activating the winch, which is wound on the drum. The second option allows the lift to work without much effort, making it as convenient as possible. The lifting device in this case is controlled by the remote control.

Do not forget about the material that was involved in the manufacture of the lift.

The wooden device is applicable for fixing building materials, its functionality is extremely limited. While the metal device is a multifunctional and more reliable lifting mechanism.

Ready option

In the absence of desire or the need for an independent manufacture of the lifting mechanism, a logical decision would be to acquire it. Brand "Premos" is the most popular in the ratio of cost and quality of the product. According to the principle of operation, such a mechanism does not have distinctive features from rack jacks. Given its democratic cost, the Premos lifting mechanism quickly became a favorite with customers.

This mechanism makes it possible to lift and fix all sorts of building materials, weighing up to one hundred kilograms. And with the help of a telescopic bar, the lift provides a height of up to three and a half meters. And using an additional retractable rod can extend it to four and a half meters.

To work with the lift, whose height exceeds three meters, it is necessary to do the following manipulations:

- Turn the handle; the telescopic bar should be slightly extended.

- Using the rail, support it in sliding supports. Extend the rail to the desired height. For comfortable use around the hole, which is intended to fix the sliding support, the manufacturer indicates the height of the table.

- Fixation occurs with the help of hardware (any metal product), which is inserted into the hole. But experts recommend using steel pins on chains for fasteners.

An overview of the Premos lift see below.

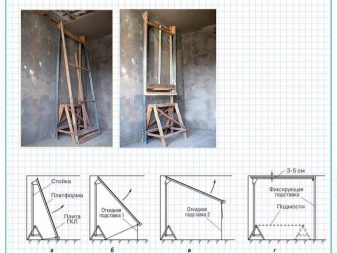

How to build yourself?

The option of purchasing a specialized lifting device for gypsum boards is not suitable for everyone. The approximate cost of such a mechanism is about 15 thousand rubles. In this regard, the manufacture of the lift at home with his own hands seems very tempting to many. Find the finished drawing is not difficult.

On the Internet you can stumble upon a simple version of the lift, and more zamorochenny.

Before you start building, it is worth mentioning the important components. Their presence in the lifting structure should:

- Creating a base in a lift is a chassis or tripod. It is preferable if they are equipped with wheels and locking mechanisms. This will greatly facilitate your further installation on the desired site.

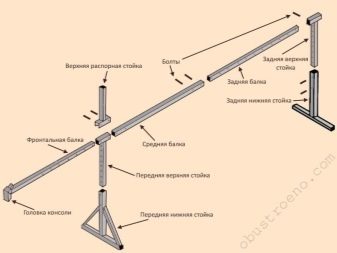

- Telescopic rack can be made from tubes or squares with different sections. Each of them, one after the other is embedded in the system of nesting dolls. And you can push them, with the help of a roller structure and a specialized cable.

- A table that serves to fix plasterboard sheets or other building materials.

- Must have a winch. With it, you can push the telescopic rack. The winch can be manually operated and electrically operated.

The process of building a lift at home begins with the manufacture of a telescopic tripod. This will require three trimming pipes with different sections of forty, eighty and sixty millimeters. All pipes must be drilled through, so that the drilled holes match. Such accuracy is required to further insert the stoppers.

Then three or four metal legs are welded to the telescopic stand.This will give the structure stability. If desired, roller wheels can be attached to the legs and as a supplement a locking mechanism. From above, a frame is welded to the telescopic stand in an H-shaped format. It should be made of light metal in order not to weigh down the structure.

After that, it is necessary to fix the winch with blocks and cables (it is permissible to use strong rope) to the base of the telescopic tripod.

This procedure is done for easy lifting and lowering of the whole structure with plasterboard sheets.

Existing details

Most often, a homemade GCR lift has dimensions of 115 and 290 cm. These are optimal dimensions. This scheme of the internal mechanism has detailed characteristics that you should definitely take into account.

Regardless of whether you will buy a ready-made lifting mechanism or take independent manufacturing It is recommended not to forget about several nuances that will help you purchase or build a quality device:

- Any selected material for the construction of the lifting mechanism, metal and wooden rack will equally experience a significant load.Therefore, it is recommended to equip all support elements of the lift with a “scarf” or any other parts to impart rigidity and strength to the structure.

- Pre-consider a variant of a construction of a folding design of the lifting mechanism. Transportation of such a device will be easier, besides, it will not be necessary to allocate a lot of space for its storage.

- In addition to the locking mechanisms, which are located on the winches and rack gears, it is necessary to additionally purchase parts for fixing. They will reliably fix the table for plasterboard sheets raised at height. Otherwise, there is a high risk of serious injury.

- Avoid models with plastic parts, they are extremely unreliable.

- The height of the lifting mechanism should reach four to five meters, this is quite enough for repair and installation work in a residential house or apartment. The height of the ceiling surface rarely exceeds these parameters.

- The mass of building materials loaded onto the lifting mechanism must withstand from thirty to fifty kilograms.

- The so-called table, which are fixed gypsum board or other building materials,It is recommended to choose in the H-shaped format. A similar base and strut is more stable and durable.

- The multifunctionality of the lift is the ability to work with both horizontal and vertical surfaces.