Drywall Anchors: Views and Features

During repair, the most important is the selection of the right fixtures suitable for the particular situation. Also, before starting work, you should be familiar with the features and installation rules of the fasteners used, which provide aesthetics, durability and reliability of the structures being formed. For example, when choosing anchors for drywall, you should have an idea about their types and nuances of application.

Fasteners are divided into several separate subgroups. The first subgroup - dowels through passage, the second - loosening.

For example, the dowel through passage is used when fixing the structure on the ceiling itself. Also, this type of fasteners are used when installing chandeliers or sports equipment. But the spring fasteners are perfect for fixing any structures to the plasterboard wall or tile.

Dowels must meet certain requirements. First, such products must have a special coating that protects them from corrosion. Secondly, the dowels should be made of high-quality materials, and on the main surface the strut of the fastener itself should create a sufficiently strong fixation to hold heavy structures.

In order not to be mistaken when choosing the right dowels, you need to consider the features and benefits of using each type of fastener.

Dowel molly

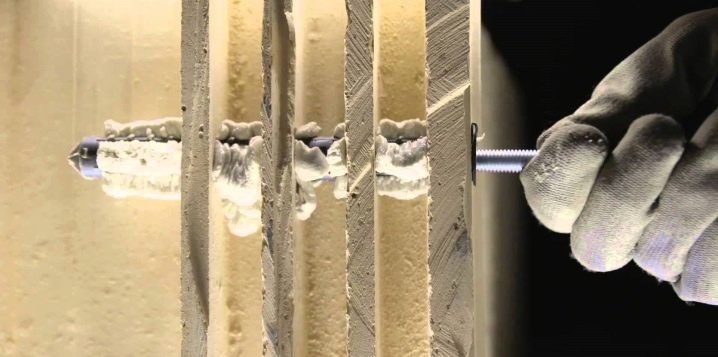

This type of dowel used to mount the gypsum board can be distinguished by type of manufacture. This type of fastener is produced according to the harpoon extension principle in order to obtain a sufficiently strong fastening.

Dowel Molly, to cheap products can not be attributed. Prices for fasteners are very high, but this is due to the excellent quality of products, their reliability and ability to withstand a lot of weight.

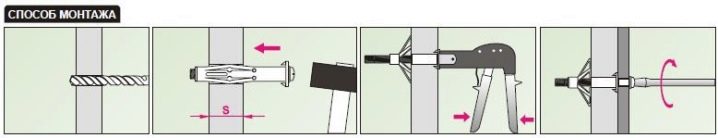

Molly dowels work according to a special principle:

- Under the dowel with a drill drill 8-mm hole.

- The dowel must be inserted into this hole. Then the side of the fastener together with the teeth should be firmly pressed against the drywall coating. This is what avoids turning it.

- Then, using an ordinary screwdriver, fasten a screw to a plasterboard sheet material. Do it by internal thread. Such a screw is attached to the dowel and is sold with it in one set. Screws are usually also supplied complete with dowels.

The advantages of this type of fasteners include its ability to cope with even the highest loads. In addition, if necessary, you can always dismantle it.

Dowel driva

Product Driva (DRV) are among the most popular items designed for fasteners. Driva is produced in only two versions. Such fasteners can be either plastic or made of metal.

Plastic fasteners are considered to be the most relevant and affordable.

This fastener is very easily screwed into the building materials, securely fixed.

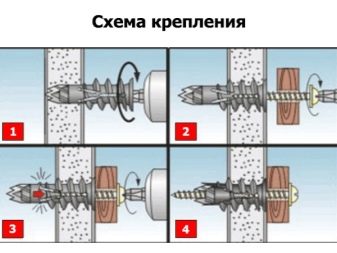

Work is performed in a certain sequence:

- In GCR make a 6-millimeter hole.

- Then the dowel is inserted into the prepared hole. It is necessary to embed the dowel into plasterboard sheet material like a self-tapping screw. For such work it is best to use a screwdriver.

- After that, screw the 3.5-mm or 4.5-mm self-tapping screw or screw into the cross-shaped slit that each Driva dowel has.

Such dowels look aesthetically pleasing with various types of gypsum board material.

This fastener is distinguished by the fact that it does not require free space for plasterboard sheet material. However, when selecting a dowel, its length should be considered. For example, for metal fasteners, it reaches 44 mm, and for plastic products - up to 23 mm.

Dowel fisher

Another type of fastener is the Fisher PD model. The construction of the Fisher PD itself is made of plastic (here it is said about the base of the product, where the screw is subsequently screwed).

During the mounting, the Fisher is pressed against the joint to create a strong grip with the screw. This is what creates protection against possible fallout. Dowels Fisher are very popular, and the cost of products is low.

Dowel nail

Modern models of dowel-nails for plasterboard material are a very common type of fasteners. The extension device is made of pure nylon. The design of the product consists of three separate sections. The through hole is located in the very "tail" of the fastener.This makes screwing easy, creating the desired axial stroke for the screws.

The dowel-nails fasten quite reliably, because the walls of this fastener during installation begin to tear apart in three different directions at once.

With this modern fixture fix:

- window frames;

- plinths;

- door frames;

- cornices;

- reiki.

There are also steel dowels. However apply this type of products when mounting drywall plating is quite rare. This dowel-nail can provide through operational installation. In this case, you can easily hammer the fastener into the hole already prepared with a drill.

Dowel screw

Dowel screws are also used for mounting plasterboard sheet material. Such an element can be made of metal or nylon. This type of fastener applicable when fixing the necessary items to a single-layer or multi-layer drywall. At the same time GKL can be with a decorative or insulated coating.

Such elements are distinguished by size. When choosing a product should pay attention to the length of fasteners.This means that it should not “bulge” from the back of the plasterboard. Such fasteners are considered ideally suited for fastening heavy objects.. This fastener is screwed in very easily. At the same time, it is not necessary to prepare the hole in advance (of course, if drywall is used with a thickness of no more than 15 mm).

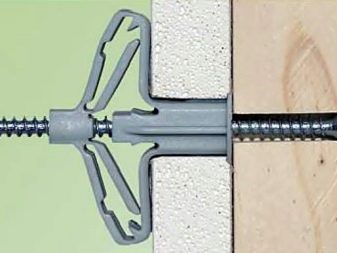

"Butterfly"

Fasteners with the interesting name "butterfly" belong to the universal elements. Used such a dowel for surfaces with voidslocated behind a wall of 5-mm sheets of drywall. This fastener is similar in operation with an ordinary umbrella. The design is moved apart directly behind the sheet in free space. This is precisely the case with a sufficiently reliable support of fasteners.

This type of fixing is suitable for gypsum plasterboard ceilings.

For example, when arranging heavy fixtures, the stops, which begin to open behind the plasterboard sheets, can evenly distribute the load across the quadrature.

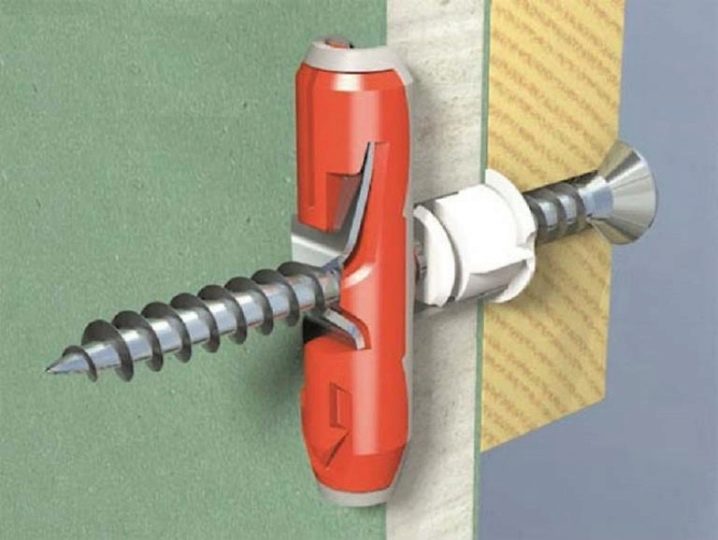

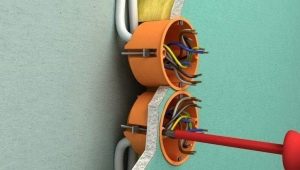

Fastener with drill

Another type of fastener is a dowel with a drill. Such detail can be fixed even on multi-layer walls made of gypsum plasterboard.. Screw fasteners need directly into the material itself.

When mounting it is also necessary to pay attention to the length of the product.

Dowel umbrella

Before mounting the dowel umbrella, it is necessary to drill a hole. This is a self-installing element that opens behind a sheet of KGL. This ensures reliable fixation on the surface. Usually this type of fastener is used for ceiling structures.

Screw varieties

Such products are a set consisting of a dowel and a nail with a special screw thread. The main thing is to screw in the screw plugs. You can't scroll through them, and for this it is necessary to compare the available dimensions and take into account the complexity of the installation.

Metal dowels are mainly made from zinc alloys. By cost, they are almost always more expensive than their plastic counterparts, but are considered more reliable.

Chemical anchors

Chemical anchors used for plasterboard material, in fact, are some kind of cartridges or capsules with a special adhesive mass. In addition to such an anchor, mesh sleeves are sold, creating a very strong mount..

It is quite simple to twist the dowels into the plasterboard material, and a beginner can quite easily cope with such work.

When mounted, chemical anchors are broken, and the composition of the capsule is mixed. Then begins a chemical reaction, which forms a reliable fixation.

Nuances of use

Before working with any fasteners it is recommended to familiarize yourself with some rules:

- Drill a hole designed to mount dowels, umbrellas or other types of fasteners in GLA, you need to carefully, so that during fixing the sheet material is not damaged.

- The hole itself is better to do a little larger in diameter than the fastener. This will also help avoid cracking the gypsum board during installation.

- It is advisable to clean the holes from debris and dust generated during drilling. This can help you ordinary vacuum cleaner.

- When using an electric screwdriver, you should try not to allow the fastening element to turn in place when it reaches the final point. Such improper mounting may adversely affect the density of the part.Accordingly, it is better not to tighten the part until it stops.

- Upon completion of the installation of fasteners in the design, the area around the hole is covered with putty or acrylic.

If you do not have any experience and knowledge in such works, it is better to get advice from a professional before installation. An experienced specialist will help to understand the intricacies of installation and fixing parts, draw your attention to important nuances when working with dowels.

How to choose

On the modern market presents a variety of fasteners. In order not to be mistaken with the choice of parts for fastening, it is necessary to consider a few points. It is necessary to assess the level of load on fasteners, the need for subsequent dismantling and financial possibilities (since the cost of different types of parts may vary).

On the subtleties of the choice of fasteners for drywall, see below.