Moisture resistant drywall: what is it and how to choose?

More recently, drywall was used for leveling walls, building partitions and arches, but in the bathroom or in the kitchen it was not used, because when it came into contact with water and even steam, the material quickly became unusable.

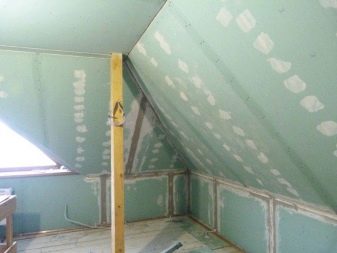

When a moisture-resistant type of material appeared, sheets of drywall, comfortable, lightweight and easy to install, began to be used in rooms with high humidity.

Definitions and varieties

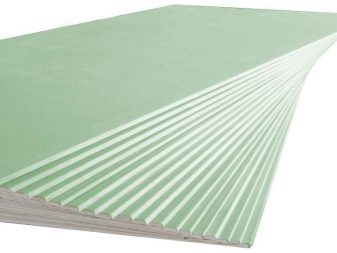

Interpretation of the abbreviation GKLV is a moisture resistant plasterboard. Like a standard plasterboard fabric, this material consists of two layers of durable cardboard and a plaster layer between them, but all layers are treated with special impregnations, making it waterproof.

It is very simple to distinguish moisture-resistant material from non-moisture-resistant visually - sheets GKLV are green, and ordinary drywall is gray.The features will tell and information on the package (labeling). The difference is noticeable in price - moisture-proof materials will cost more than usual.

Also in the building stores we can find drywall labeled "GKLVO" - this is a unique canvas with additional refractory properties.

Of course, even GKLV materials will last you much longer if you protect them from moisture as best you can. It is necessary to ventilate the room with high humidity and finish GKLV and install a ventilation and exhaust system there. Also, wall panels can be covered with moisture-resistant paint, covered with plastic trim or pokleit special moisture-resistant wallpaper.

In addition to the criteria of fire resistance and water resistance, the building materials market offers buyers plasterboard sheets for floor insulation, ceiling finishing, leveling and finishing walls, as well as for the erection of arches, columns and vaults.

The choice of plasterboard or plasterboard for walls depends on the needs and features of repair work. If the walls are simply aligned, both options are perfect. The higher the humidity, the more relevant the use of GKLV. If the main quality is compliance, then you should choose thin drywall for the construction of decorative elements - arches and columns. Such material can be very decorative due to different textures, while its service life is at least 10 years.

GKL-sheets allow you to create unique suspended ceilings, as well as zone the space with different walls and arches. The question of the use of moisture-resistant or ordinary material is determined by the characteristics of the room itself - the degree of humidity, whether it is salted or not, etc.

For the floor it is best to use not drywall, but gypsum fiber - this material is much more durable.

Specifications

Moisture resistant HL have a lot of advantages:

- not afraid of strong humidity and resistant to water vapor;

- differs from the usual higher density;

- stronger than standard drywall;

- You can choose exactly those sizes that are necessary for the decoration of your room;

- even the beginning master will cope with installation works;

- perfectly tolerates wet cleaning.

Almost all manufacturers of moisture-resistant drywall provide it at the same time and fire-fighting qualities.GKLV is not only waterproof, but also fire-resistant material.

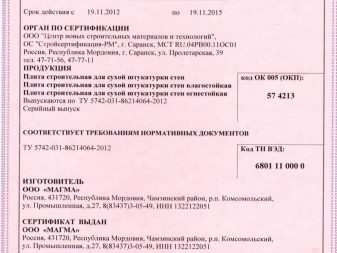

In the manufacture of FCLV, all the requirements of GOST are carefully observed, all materials must be certified. That is why GKLV can be applied in schools, kindergartens, hospitals and clinics. GKLV impregnate with special impregnations against the formation of mold and mildew, and in itself it is a hypoallergenic material.

GKLV are referred to as "breathable" materials. In the rooms decorated with them, the optimum microclimate is always maintained. Due to its light weight and elasticity, unlike gypsum-fiber boards, GKL is ideal for the construction of modern and beautiful suspended ceilings, arches, etc..

Let's talk about the technical characteristics of the material.

The main advantage and difference from standard drywall is moisture resistance. This figure is above the standard by 90%. The fire resistance of the material is also kept at a good level - it slowly ignites (level G1), does not create large quantities of smoke during combustion, and practically does not emit harmful substances.

The composition of the material (modifiers that reduce the absorption capacity, are added to gypsum) allows you to use the material very widely - in kitchens, loggias and balconies, bathrooms, when covering the walls in country houses. In the presence of good waterproofing and ventilation suitable for the bathroom.

According to the requirements of GOST 32614-2012 (adopted in our country in 2015) plasterboard building boards are marked as follows:

- standard sheet "A";

- with density depending on the conditions of use of the "D";

- fireproof "F";

- moisture resistant "H";

- with increased hardness "I";

- facade - vapor permeability and water absorption "E";

- under plastering works or subsequent laying of “P” tile;

- especially strong on a bend of "R".

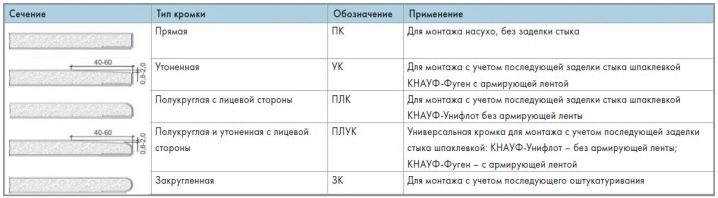

The longitudinal edge of the drywall sheet can be different, for example, of smaller thickness than the main fabric, which will allow to putty the joints in high quality. The beveled or tapered edge is suitable for finishing, and when installing several layers of gypsum plaster it is better to choose a standard straight edge. The type of edge is indicated on the package.

Gypsum, which is part of the GKLV, is in itself non-flammable. Because of this, drywall can withstand fire for some time.

Indicators of compliance with GOST are as follows:

- flammability group G1 (slightly flammable);

- ability to ignite - B2 (flame-resistant materials);

- ability to smoke - D1 (low smoke-forming ability);

- toxicity - T1 (low hazard materials).

In order to choose exactly the material that you need, carefully study the sheet marking and quality certificates, where all its technical data should be: type, group, edge type, parameters, GOST standards.

Dimensions

A standard drywall sheet is a rectangle consisting of two sheets of thick cardboard and a layer of plaster. Adhesives, blowing agents and impregnations can be added to this “sandwich”.

The size of the drywall sheet can vary greatly. The length can vary from 2.5 to 4.7 meters, and width - from 1.2 to 2 meters. 1.2 m - the standard width of a drywall sheet, but if necessary, most hardware stores will accept your order for a material of smaller width. The thickness is also very different - from 5 mm to 24, it depends on where and how the material will be used. Most often in the building stores there are sheets 5,6,8,9,10,14 and 16 mm thick.

The most common (and most popular in use) leaf is 3 square meters in area. m with a thickness of 12 mm, that is 2500h1200h12 mm. This GKL best suited for wall decoration. For the ceiling, materials are taken thinner - 9-9.5 mm thick, and the thickness of the arched drywall is quite small - 5-5.6 mm. Due to its small thickness, it can be used to create various curved openings and arches of unusual shapes.

All calculations of the required material must be made in advance, because for finishing it is much more convenient to use a whole GVL-sheet, rather than a composite one.

The weight of a gypsum plasterboard depends on its thickness and depends on the type and characteristics of drywall. Sheets of standard and moisture-resistant drywall should not have a mass of more than 1 kilogram for each mm of sheet thickness. The flame resistant sheet can weigh from 0.8 to 1.6 kg per mm of thickness. If the materials weigh more, then most likely they were stored in conditions of high humidity.

1 square meter of drywall with a thickness of 6.5 mm is 5 kg, 9.5 mm will have a weight of about 7.5 kilograms, GLA thickness of 12.5 mm will weigh about ten kilograms.

To estimate how much weight you will have to deal with, the following data will help: a sheet 1200x2000x / 2.4 square.6 mm thick will weigh 12 kilograms, 9.5 cm - already 18 kilograms, and 12.5 mm already 23 kilograms. Drywall Size 1200h2500h / 3kv. m 6 mm thick weighs 15 kilograms, 9.5 mm - 22 kg., and 12.5 kg - 29 kg. Sheet 1200x3000x / 3.6 square. 6 mm thick will weigh 18 kg, 9.5 mm - 27 kg, 12.5 - already 35 kilograms.

The weight of the gypsum board will help us calculate the load that the structure can withstand, calculate the weight of the structure itself and select the most suitable fasteners and other elements. This can be done independently using the calculation methods, including online calculations, or contact the specialists.

Manufacturers Overview

In construction stores are presented GKLV-materials of both Russian and foreign manufacturers.

One of the most famous manufacturers of drywall of all kinds - firm knaufwhich has production in 30 countries, including Russia (10 plants). Customer reviews of Knauf drywall sheets are almost always positive. Customers appreciate it as a high-quality material, easy to work, perfectly cut and sawing, allowing to realize the wildest dreams of interior designers.

The high quality of the material produced is also provided by the French Compagnie de Saint-Gobain SA. Approximately 10% of all types of drywall, sold in our stores, is made by this company.

Its plants in our country have Polish company Lafarge Group and Scandinavian Gyproc. Scandinavians offer excellent thin drywall for the construction of zoning walls of non-standard forms. The reviews on Polish drywall are mostly positive, but some craftsmen have noted a large amount of dust formation when cutting.

Russian-made drywall accounts for only 20% of the Russian market. it GKL production of JSC "Gypsum", JSC "Sverdlovsk plant of gypsum products", LLC "Arakchinsky gypsum".

Mark of building and finishing materials "Volma" is known, perhaps, to all masters working with gypsum plasterboard. Volma is produced at various enterprises, including JSC Gips, in Volgograd. According to reviews of buyers and craftsmen, Volma products are of good quality and are only slightly inferior to German drywall. In addition, Volma GKLV has a very attractive price.

Sverdlovsk Plant of Gypsum Products manufactures Gifas drywall with modern high-tech equipment.The quality of “Gifas” is quite high and can easily compete with German and Scandinavian manufacturers.

Production of "Arakchinsky gypsum" is located in Kazan and produces various types of gypsum cardboard under the brand name "Abdullingips". According to customers, the price of this material is the lowest among all Russian manufacturers.

The plant for the production of plasterboard "Golden Gypsum" produces the same material. The company is located in the city of Tolyatti. Differs in worthy quality and low cost, and specializes on release of GKLV.

In Russia there are many small-scale production of gypsum plasterboard, for example, the production of "Gipsolimer" in Perm or "Utah Gyps" in Bashkiria. Most often, the materials are produced on imported equipment and have a decent quality.

Nevertheless, I would like to remind you that all GKL materials must be manufactured taking into account the requirements of GOST, and when you buy GKLV sheets, you must necessarily require quality certificates. This is especially true of products sold at low prices.

How to choose?

Choose drywall is necessary depending on where you will apply it.So, multi-level ceilings with bends and roundings are best done from 6.5 mm thick gypsum plasterboards - it is plastic and light. For flat ceilings and arches with a small angle of curvature suitable GCR 9.5 mm. This drywall is called - “ceiling. It can be used to create zoning partitions, but not to create load-bearing walls.

For the walls of the living room, bathroom or bathroom apply GKL 12.5 mm. This material is quite suitable for filing a single-level ceiling, but for a multi-level it is better not to use it - the design will be too heavy.

HL material for interior partitions must be strong, withstand severe loads, provide noise absorption, and therefore be from 14 to 24 mm thick.

The correct choice of drywall involves mandatory preliminary calculations - measurements of the premises and the calculation of the required amount of material. It should be borne in mind that the seams on the surface to be trimmed should be as small as possible., which means you need to choose the optimal sheet size. Both in Russian and in foreign manufacturers, the width of the sheet is about the same - up to 1.2 m, while the length can be very different and reach 4.8 m.

When buying drywall should decide on the type of edge that is best suited for your finishes. If it is difficult to choose - be sure to consult with a consultant in the store or a master conducting your repair.

Moisture-resistant drywall is best suited for tile in the bathroom.. Despite the fact that the humidity of such material is not terrible, all the seams need to be very well repaired. In order for a plasterboard wall with a laid tile to serve you for a long time, you need to follow simple rules: do not use tiles with chips and cracks - water will penetrate into them and sooner or later the wall will begin to collapse; choose a quality tile that has a marking, a uniform color and a clear pattern (when buying a tile, you can lightly tap on something solid — the sound should be clear, ringing).

Lay tile only on high quality glue suitable for this type of work.. You should not hurry and lay all the tiles in one day (no more than 5 rows per day), so the lower rows will not “crawl” under the load of the upper ones.

Instructions for use

To work with moisture-resistant plasterboard did not cause problems, we recommend that you use some instructions:

- If the room is small, then plasterboard walls should be sheathed only when necessary, because the plasterboards will inevitably "eat up" some of the space.

- Drywall can be mounted on glue. If some sheets protrude, then after the glue dries out, they need to be “tapped” with a rubber hammer.

- Drywall during installation should not rest against the floor. There should be a gap of at least 1 mm between the floor and plasterboard sheets.

- Ceiling thin sheets for the installation of partitions can not be used - they will bulge and crack.

- Do not save on mineral wool in the preparation of the frame. Drywall, although it has sound-absorbing properties, but not so much as to abandon the laying of additional materials.

- When fixing the drywall on the frame, use a screwdriver with the ability to set the depth of drilling.

- Do not sheathe the walls with drywall. It is necessary to leave small gaps that allow the surface to breathe.

- To transfer large sheets, use the construction pickup - so the sheet will not break and crack.

- If you scratch a drywall sheet, then putty the scratch and close it with reinforcing tape - this will help preserve the integrity of the sheet.

- To fold the canvas, apply the marking with a special needle roller and wet this place - after a while the sheet can be bent.

Which side to mount?

It is very important to observe the correct placement of sheets GKLV - the front side of the drywall should "look" inside the room. It is easier to distinguish it - it is lighter than the purl; in addition, the correct side will be indicated by folding - the narrowed edge of the GKLV-web (the front side is beveled, slightly pressed).

If you fix the drywall side with the inside out, then the GOST marking and other inscriptions may appear on the finishing wall decoration.

Can I use in the bathroom?

Moisture-resistant drywall can be used in any room with a wet microclimate - in the bathroom, in the kitchen or toilet. GKLV-list is treated with special impregnations - hydrophobic and anti-fungal. but this material should not come into contact with water! Impregnation can protect from moisture, but not from constant contact with water. Remember that in the middle of a drywall sandwich is a gypsum, albeit treated with special compounds, which will gradually lose its shape from the interaction with water.

The coating to be installed on drywall - plastic panels, tiles, etc., must be waterproof. This means that you need to take care of the primer GKLV special "penetrating" primer, choose high-quality tile adhesive, use silicone sealants and liquid nails.

Silicone grout has proven itself well, preventing water from penetrating into joints and crevices.

The role of finishing can be performed by waterproofing paint. This is a special paint based on acrylic latex, not permeable to water, suitable for both wall painting and ceiling. During further use of the premises, the walls can be cleaned with various detergents, as waterproofing paints are resistant to household chemicals. True, experienced craftsmen recommend still prefer tile.

There is another option for plastering walls in the bathroom or kitchen - vinyl or glass cloth wallpaper. This dense material is not afraid of water vapor.

Remember that all wet rooms, finished GKVL, must be equipped with high-quality ventilation - it will ensure the safety and long life of the finishing materials from plasterboard.

Can I glue wallpaper?

Of course, you can glue wallpaper on the GKLV.The ideally even and smooth surface of the GCLV seems to be specially designed for pasting wallpaper. However, the GKLV needs preparatory work. Directly on the GKLV-sheets wallpaper should not be glued, because the inscriptions, designations GOST and seams can tread through the wallpaper. In addition, moisture-resistant and fire-resistant drywall has a green or red color, and if you glue the wallpaper directly on the sheet GKLV, the shade can tread even on very dense wallpaper.

If the sheets of drywall are not processed, then it will be almost impossible to remove them later from the GKLV, because along with them the layer of cardboard covering the gypsum will be removed. In such cases, you have to change drywall or glue new ones on top of old ones.

To achieve an optimal result, you must perform the following steps:

- We make preliminary priming of walls. This is done both for the prevention of fungus, and for better adhesion of the surface of the FCMC with putty. The primer can be applied with a roller or brush.

- We process seams. Apply the putty on the joint and level with a spatula, put a reinforcing mesh over it. After drying, you need to put another layer of putty, level it and rub it.

- We cover the wall with putty in two layers. The first is leveling, and the second is finishing (no more than 5 mm).

- Gently, without undue pressure, level the wall with sandpaper.

- If the wallpaper is very dense, then for a good adhesion of materials you can apply another layer of primer.

- Paste wallpaper. Putting drywall allows you to stick on it wallpaper of any kind.

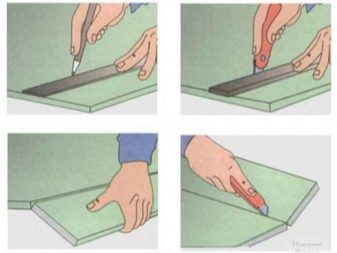

What to cut?

At home, you can cut drywall with a regular sharp knife, a hacksaw or a jig saw is also suitable. The main condition for neat and even cutting is proper placement of the material and marking. You can mark up using a regular long ruler and a simple pencil, for large sheets you will need a tape measure.

Moisture-resistant drywall is cut as well as normal, perfectly sawed and bends. All necessary holes, for example, holes for sockets, are much easier to cut before installation.

To cut a sheet of GKLV carefully, you need to follow these guidelines:

- Place the sheet on a flat surface and mark up with a pencil.

- Attach a metal ruler to the marking line and hold it with a knife several times, deepening the cut. If drywall is thin, then even a stationery knife will do.

- Quick movement to break off the sheet, with the need to break in the direction of the cut, and not vice versa.

Remember that when cutting GKLV dust and chips are formed, therefore the respiratory organs and eyesight must be protected.

Is the material harmful to health?

Drywall is a building material that is harmless to humans. Gypsum and cellulose are environmentally friendly materials, and the manufacturing technology of them GKLV and GKLV-canvas complies with the requirements of GOST and various international characteristics.

Unfortunately, counterfeit products can occur in the materials materials market, the quality of which does not meet the norms and standards. Buy drywall only proven and well-known manufacturers, always with the purchase you need certificates of conformity.

There is another nuance - if in a room with a GKLV finish, humidity is more than 80% or the material is in direct contact with water, then after some time, even on the material treated with special impregnations, mold will start to form, which can harm human health.

On the use of moisture-resistant drywall, see the following video.